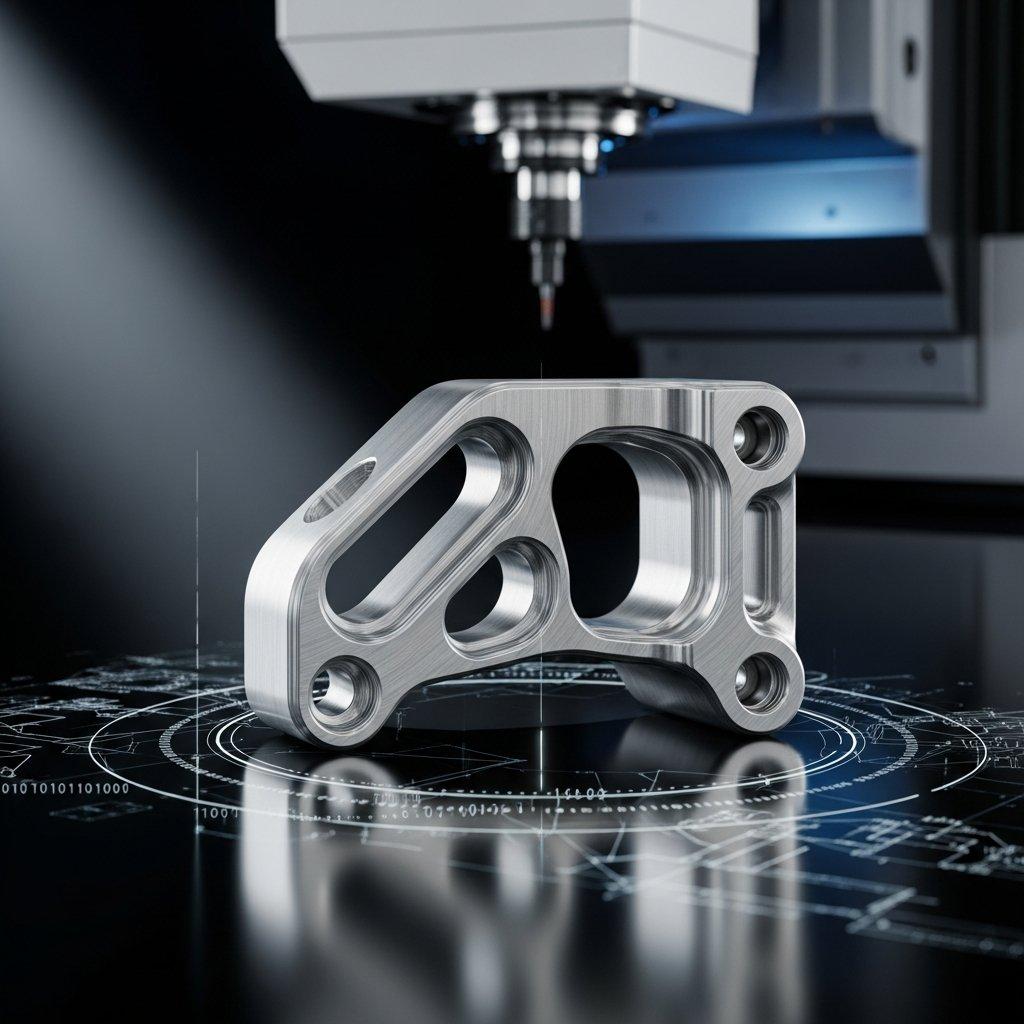

CNC machining delivers unmatched high-repeatability, making it the preferred method for consistent, precise production. This eliminates variations, reduces waste, and ensures identical parts every time.

Are inconsistencies in your high-volume production costing you time, money, and critical customer trust? Fluctuations in part quality can ripple through your entire supply chain, compromising product integrity and delaying market entry.

The challenge of achieving perfect part-to-part consistency is a formidable one in modern manufacturing, where precision is paramount. Businesses require manufacturing methods that reliably deliver identical components, batch after batch, without fail.

Discover the definitive solution: why CNC machining is the undisputed champion for delivering perfect parts, consistently, batch after batch. We will explore the inherent advantages and technical underpinnings that make computer numerical control services the benchmark for high-repeatability production.

Why CNC Machining Excels in Repeatability

In our experience, manufacturers often struggle with maintaining consistent output quality, especially when scaling production. This is where the core benefits of CNC machining truly shine, offering a level of predictability that traditional methods simply cannot match. The inherent design of CNC systems addresses this critical need head-on.

The Fundamental Advantages of CNC Machining

CNC machining, or computer numerical control, automates the manufacturing process from design to finished part. This automation reduces human error and variability, which are common issues in manual or semi-automated production.

The precise control over tool movements and speeds ensures that each operation is executed identically every time. This foundational advantage is crucial for high-repeatability production.

Digital Precision: A Core Benefit of CNC

At the heart of CNC’s superior performance is its digital nature. Designs are translated into G-code, a specific set of instructions that guides the machine’s every action with micron-level accuracy.

This digital blueprint ensures that if the code remains unchanged, the machine will execute the same sequence of operations consistently. This is a core benefit of CNC that eliminates the subjectivity found in manual processes.

Consistent Performance: Why Choose CNC?

When assessing why choose CNC machining, consistent performance stands out as a primary driver. The robust construction of CNC machines, combined with their advanced control systems, provides a stable and predictable operating environment.

This stability translates directly into uniform part quality and reliable production schedules. It’s a significant factor in why CNC manufacturing is chosen for critical applications.

Technical Pillars of High-Repeatability CNC

The ability of CNC machines to produce parts with exceptional repeatability is not accidental. It is engineered through a combination of sophisticated technologies that work in concert. Understanding these technical pillars is key to appreciating the robust advantages of CNC machining.

Programmed Accuracy: Why CNC Machining is Key

CNC machines operate based on highly detailed, pre-programmed instructions. Every cut, every speed, and every tool change is precisely defined by the G-code, which leaves no room for operator interpretation or deviation.

This programmed accuracy is why CNC machining is key to achieving consistent geometric features and surface finishes. It guarantees that the machine performs the exact same movements on every workpiece.

Closed-Loop Feedback: Benefits of CNC Precision

A critical aspect contributing to the benefits of CNC precision is its closed-loop feedback system. Sensors continuously monitor the actual position and performance of the machine’s axes and tools.

Any deviation from the programmed path is immediately detected, and the control system makes real-time adjustments. This continuous self-correction ensures the highest level of accuracy and repeatability, even in dynamic machining environments.

Tool Path Optimization in CNC Machining

Advanced CAM software is utilized for tool path optimization in CNC machining, creating the most efficient and precise routes for cutting tools. This optimization minimizes tool wear, reduces machining time, and maintains consistent cutting conditions.

By optimizing tool paths, we reduce thermal stresses and vibrations that could otherwise introduce variations in part geometry. This contributes significantly to part-to-part consistency.

Material Handling & Stability: A CNC Advantage

Proper material handling and workpiece fixturing are critical to the stability and repeatability of any CNC operation. CNC machines are often equipped with robust clamping systems and automation.

This ensures that each raw material blank is held securely and identically for every cycle. This consistent setup is a significant CNC advantage that prevents movement and maintains dimensional accuracy throughout the machining process.

Realizing the Advantages of CNC Production

The technical capabilities of CNC directly translate into tangible benefits for production. In our operations at ly-machining, we leverage these advantages to consistently exceed client expectations for quality and efficiency. Realizing the advantages of CNC production means achieving operational excellence.

Unmatched Part-to-Part Consistency with CNC

The ultimate goal of high-repeatability production is unmatched part-to-part consistency with CNC. This means that whether you need ten parts or ten thousand, each will be dimensionally identical within specified tolerances.

This level of uniformity is indispensable for complex assemblies and interchangeable components, drastically reducing assembly errors and ensuring product reliability. It is a cornerstone benefit of CNC manufacturing.

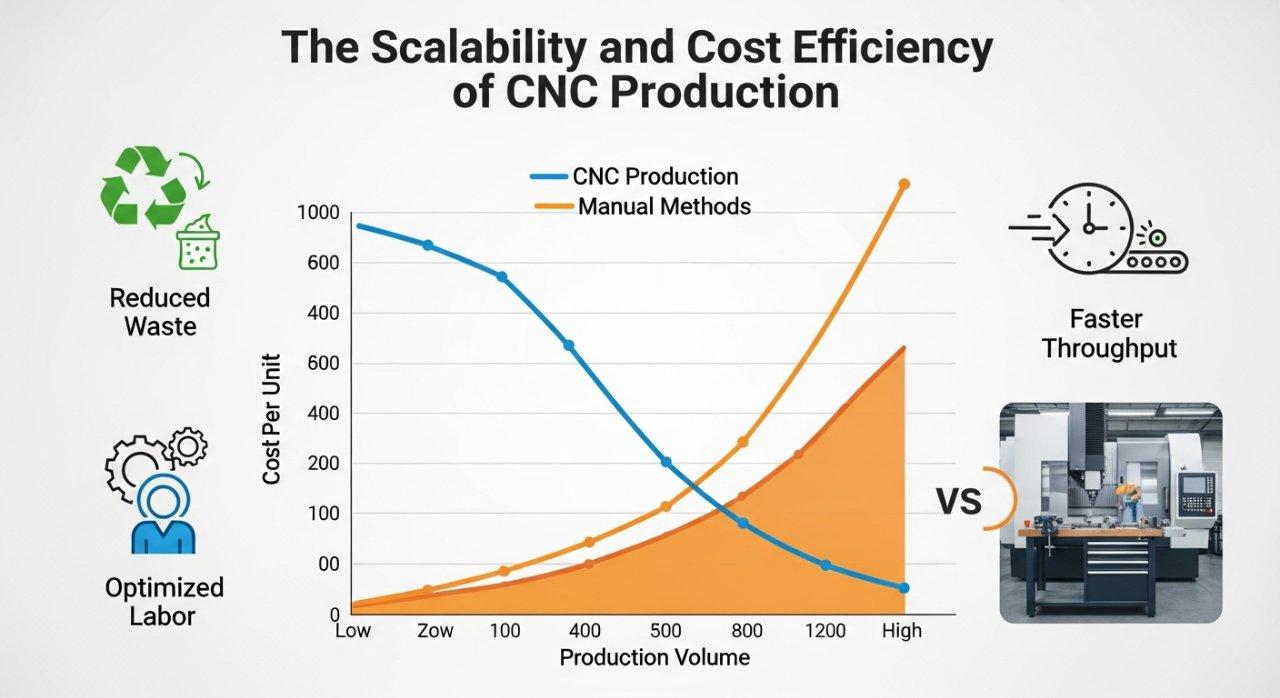

Scalability & Cost Efficiency: Benefits of CNC

The digital nature of CNC allows for seamless scalability. Once a program is proven, it can be run repeatedly on multiple machines or for extended periods, producing consistent parts efficiently.

This scalability, coupled with reduced scrap rates and minimal rework, leads to significant cost efficiency benefits of CNC. Automated operation also means less direct labor per part, lowering overall production costs over time.

Handling Complexity: Why Choose CNC Machining?

Modern product designs frequently involve intricate geometries and tight tolerances that are difficult, if not impossible, to achieve with traditional methods. Why choose CNC machining becomes clear when facing such complexity.

CNC machines, with their multi-axis capabilities, can navigate complex contours and internal features with precision. This allows for the production of advanced parts that meet stringent performance requirements.

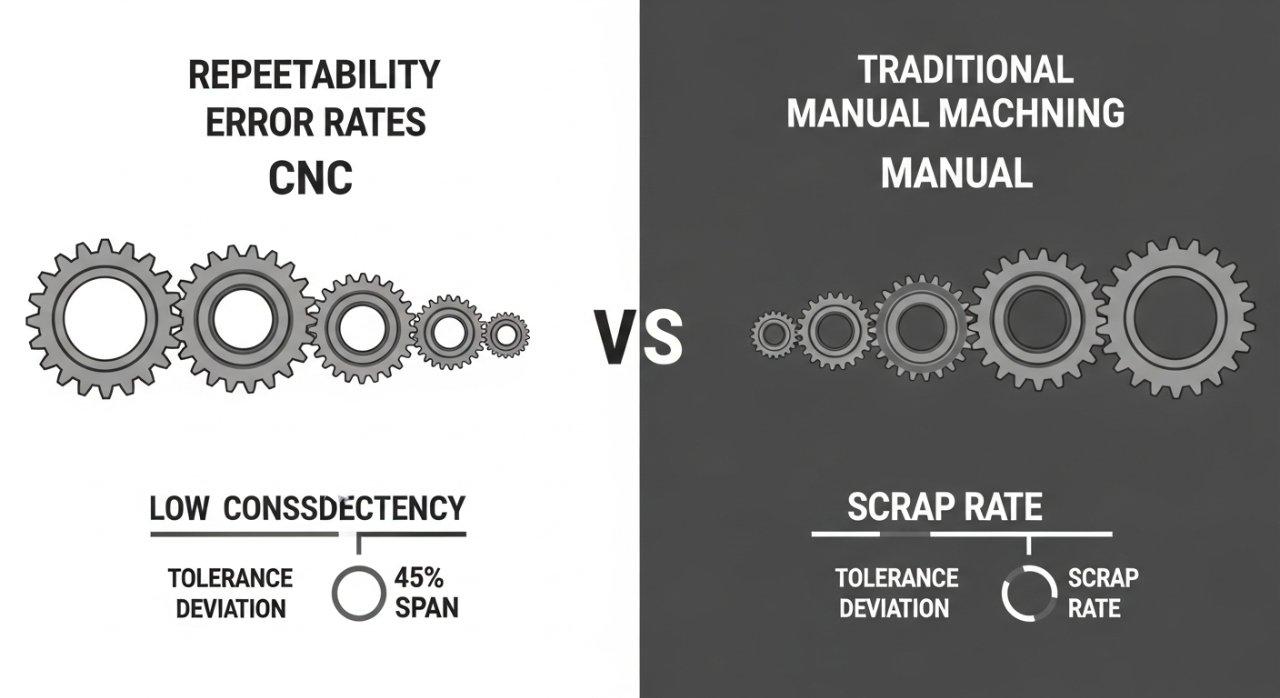

Reducing Waste and Rework: A CNC Benefit

A common issue we see with less precise manufacturing methods is high scrap rates and the need for costly rework. Reducing waste and rework is a significant CNC benefit. The inherent accuracy and repeatability of CNC minimize material wastage.

By producing parts correctly the first time, CNC machining dramatically lowers production costs and improves lead times. This efficiency directly impacts your bottom line and sustainability goals.

Our Expertise in High-Repeatability CNC Parts

At ly-machining, we pride ourselves on our deep technical expertise and commitment to precision. As a dedicated source manufacturer, our entire operation is geared towards delivering high-repeatability CNC parts that meet the most demanding specifications.

As a Source Manufacturer: Trust in CNC Machining

As a source manufacturer, we manage the entire production process from start to finish. This comprehensive control allows us to implement rigorous quality checks at every stage, building trust in CNC machining for our clients.

Our direct oversight ensures strict adherence to industry standards, guaranteeing the consistent quality and performance of every component we produce. This direct involvement is a key differentiator.

Delivering High-Quality Components: Benefits of CNC

Our commitment goes beyond just operating machines; it’s about delivering high-quality components. We invest in the latest metrology equipment and employ skilled technicians to verify every dimension.

The benefits of CNC are fully realized through our robust quality assurance protocols. Each part undergoes thorough inspection to confirm it meets the exact specifications and aesthetic requirements.

Transparent Pricing & Technical Depth: Why CNC?

We believe in fostering strong, long-term partnerships through transparent pricing and unparalleled technical depth. When considering why CNC is the superior choice, understanding the true value is essential.

Our engineering team works closely with clients, offering expert consultation to optimize designs for manufacturability and cost-efficiency. This collaborative approach ensures clarity and confidence in every project.

Success Stories in Precision CNC Machining

In our journey, we have partnered with numerous clients to overcome significant manufacturing challenges. These success stories in precision CNC machining underscore the power of our capabilities.

A leading aerospace client once struggled with inconsistent blade geometries from another supplier, leading to costly rejections. Our application of advanced 5-axis CNC machining, coupled with stringent in-process controls, resolved their issue. We delivered a batch of hundreds of perfectly identical blades, drastically reducing their assembly time and improving overall engine performance. This demonstrates the tangible impact of high-repeatability CNC.

Why Choose CNC for Your Manufacturing Future

The decision to choose CNC machining for your production needs is a strategic one, offering long-term advantages that extend far beyond initial production. It’s about securing your future manufacturing success.

Overcoming Traditional Production Limitations

Traditional manufacturing methods are often limited by human factors, tooling wear, and slower production speeds. These limitations can hinder innovation and create bottlenecks.

By adopting CNC, businesses can effectively overcome these traditional production limitations, opening doors to more complex designs, tighter tolerances, and faster product development cycles. It’s a leap forward in capability.

Securing Your Supply Chain with Reliable CNC

A reliable supply chain is critical for sustained business operations and growth. Securing your supply chain with reliable CNC manufacturing partners like ly-machining provides peace of mind.

Our commitment to consistent quality and on-time delivery minimizes disruptions, ensuring that your production lines remain operational and efficient. This predictability is a key advantage in today’s dynamic market.

Making the Smart Investment: Why Choose CNC?

For any enterprise focused on quality, efficiency, and future growth, making the smart investment in a CNC machining partner is a clear choice. Why choose CNC? It’s an investment in consistency.

The long-term benefits of reduced waste, faster time-to-market, and unparalleled product reliability far outweigh the initial considerations. It ensures your products consistently meet the highest standards.

The Undeniable Power of CNC Machining

The undeniable power of CNC machining lies in its ability to transform complex digital designs into physical reality with incredible precision and consistency. It sets the benchmark for modern manufacturing.

Ready for Flawless Parts? Contact Our CNC Experts

Are you ready to elevate your production to unparalleled levels of precision and reliability? We invite you to contact our CNC experts today.

Our team is prepared to provide a transparent quote and a personalized technical consultation tailored to your specific high-repeatability project needs.

FAQ Section

What makes CNC machining so repeatable?

CNC machining’s repeatability stems from its digital control and programmed accuracy. G-code precisely dictates every machine movement, eliminating human variability.

Closed-loop feedback systems continuously monitor and correct tool positions, ensuring operations are executed identically, batch after batch, for consistent output.

How does CNC benefit complex part production?

CNC machining excels with complex geometries and tight tolerances due to multi-axis capabilities. It precisely executes intricate designs that manual methods cannot replicate.

This allows for consistent production of advanced components, ensuring each part meets stringent design specifications and performance requirements.

Can CNC reduce production costs long-term?

Yes, CNC machining significantly reduces long-term production costs. Its high repeatability minimizes scrap rates and rework, saving material and labor.

Automated processes lead to greater efficiency, faster production cycles, and scalability, ultimately lowering the cost per unit over high-volume runs.