Struggling to select the ideal method for your prototype? Choosing between CNC machining and 3D printing can be confusing, and the wrong decision can lead to costly delays, flawed designs, and inaccurate performance testing. Your project’s success hinges on picking the technology that aligns perfectly with your specific material, budget, and functional requirements.

For rapid prototyping, 3D printing excels at creating complex, conceptual models quickly. However, for functional prototypes requiring high precision and superior material strength, CNC machining is often the more reliable choice. The best method depends on your prototype’s specific application, required tolerances, and desired material properties.

Understanding the core differences between these manufacturing giants is crucial for your project’s success. Therefore, we will delve into a detailed comparison to illuminate the distinct advantages of each. This guide will subsequently explore the critical factors you must consider, ensuring you can confidently choose between CNC machining and 3D printing for your next prototype.

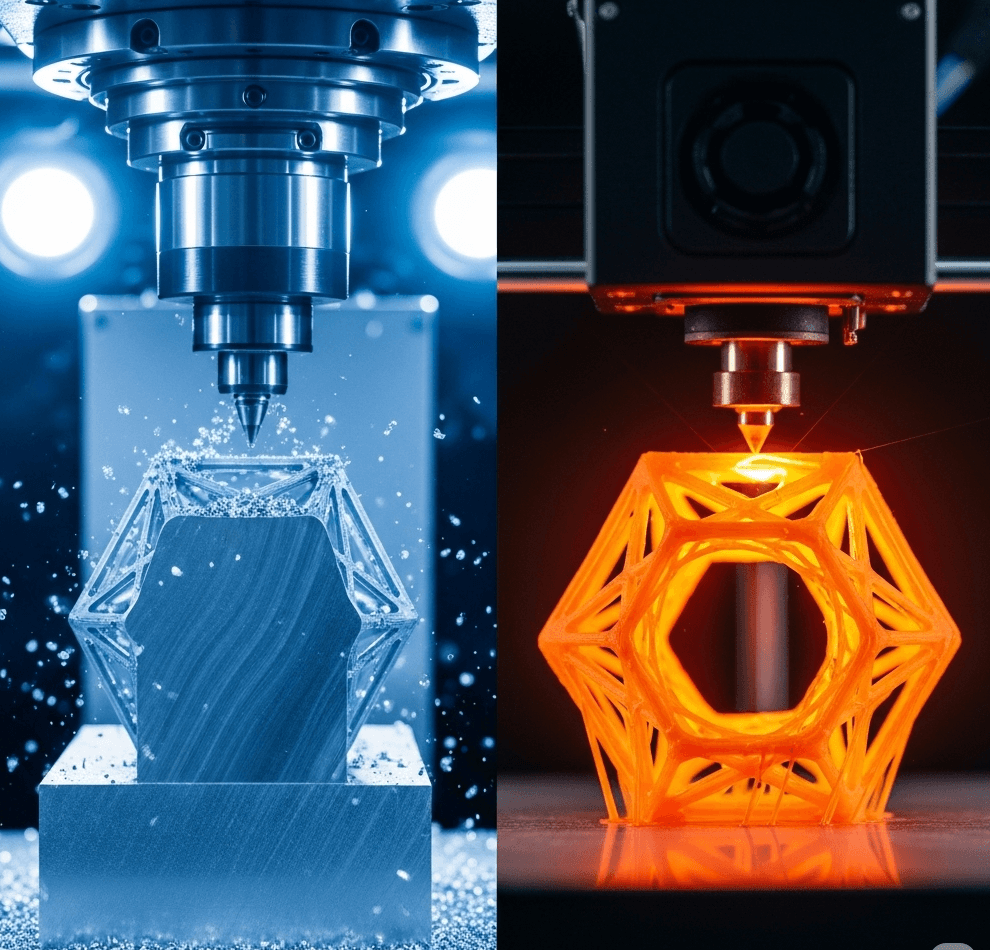

Core Technology: Subtractive vs. Additive

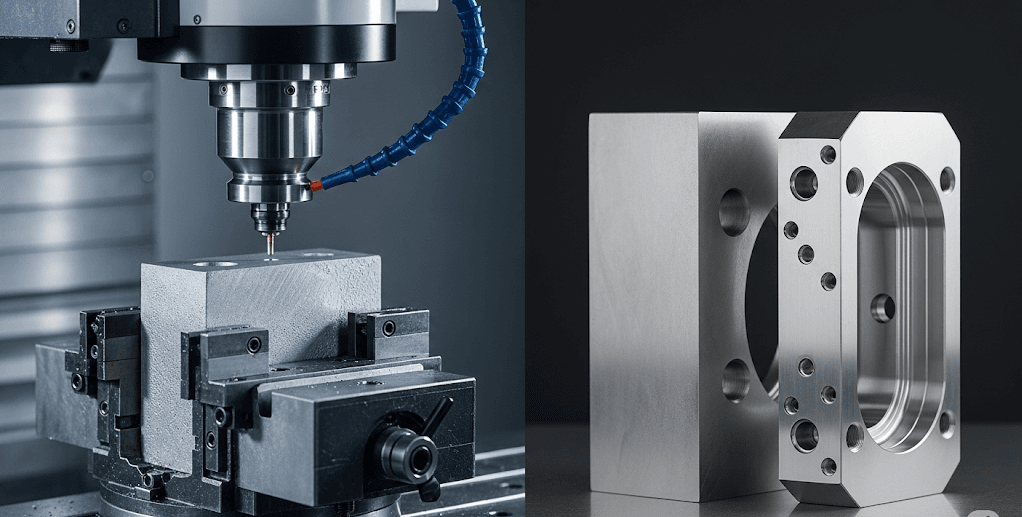

CNC machining is a subtractive process. It starts with a solid block of material (a blank) and uses computer-controlled cutting tools, like drills and end mills, to carve away material and reveal the final part. Think of it as a sculptor chiseling a statue from stone. This method is renowned for its precision and ability to work with production-grade materials.

In contrast, 3D printing is an additive process. It builds a part layer by layer from a digital file. A nozzle deposits molten plastic or a laser sinters powdered material, gradually constructing the object from the ground up. This approach allows for incredibly complex geometries and internal structures that are impossible to create with traditional methods.

Material Selection: Strength vs. Versatility

The choice of material is a critical factor in any prototype project. Your decision here will significantly impact the functionality, durability, and appearance of your final part. CNC machining and 3D printing offer very different material catalogs.

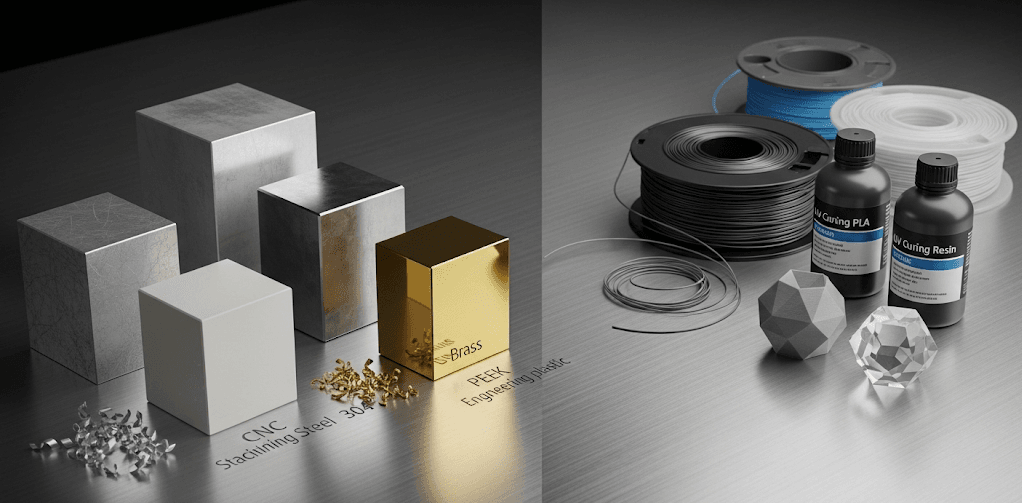

CNC machining provides a vast library of robust materials suitable for rigorous functional testing. You can use the exact same metals, alloys, and production plastics that your final part will be made from. This includes:

- Metals: Aluminum alloys (e.g., 6061, 7075), Stainless Steel, Brass, Copper, Titanium.

- Plastics: ABS, Polycarbonate (PC), Nylon, PEEK, Delrin (POM).

Using production-grade materials in the prototyping stage gives you the most accurate data on how your part will perform in real-world applications. For reliable CNC milling and turning, ly-machining offers a wide selection of certified materials to meet your specific engineering needs.

3D printing, while versatile, primarily uses a range of polymers. While high-performance and metal 3D printing options exist, they are often more expensive. Common 3D printing materials include:

- Plastics: PLA (for conceptual models), ABS (for functional parts), PETG (durable and food-safe), Nylon (tough and flexible).

- Resins: Used in SLA/DLP printers for high-detail, smooth surface finish prototypes.

Material Comparison Table

| Feature | CNC Machining | 3D Printing |

| Primary Materials | Metals, Production Plastics | Thermoplastics, Resins |

| Strength | High, suitable for functional testing | Variable, often lower than CNC |

| Material Cost | Can be higher, especially for metals | Generally lower for standard plastics |

| Prototyping Focus | Functional Prototypes | Form/Fit & Conceptual Prototypes |

Precision and Tolerance: The Engineering Standard

When your prototype needs to fit perfectly with other components, precision is non-negotiable. This is an area where CNC machining holds a distinct advantage.

CNC milling and turning processes can achieve exceptionally tight tolerances, often within ±0.005 inches (±0.127 mm) or even tighter. The computer-controlled nature of the process ensures that every cut is exact, resulting in highly repeatable and accurate parts. This level of precision is essential for functional prototypes used in mechanical assemblies, jigs, and fixtures.

3D printing tolerances are typically looser, often in the range of ±0.010 inches (±0.254 mm), though this can vary by technology. The layer-by-layer construction can lead to slight inaccuracies and a “stair-stepping” effect on curved surfaces. While sufficient for many conceptual models, it may not be adequate for high-performance applications where fit and function are critical. When precision is paramount for your prototype, CNC machining remains the superior choice.

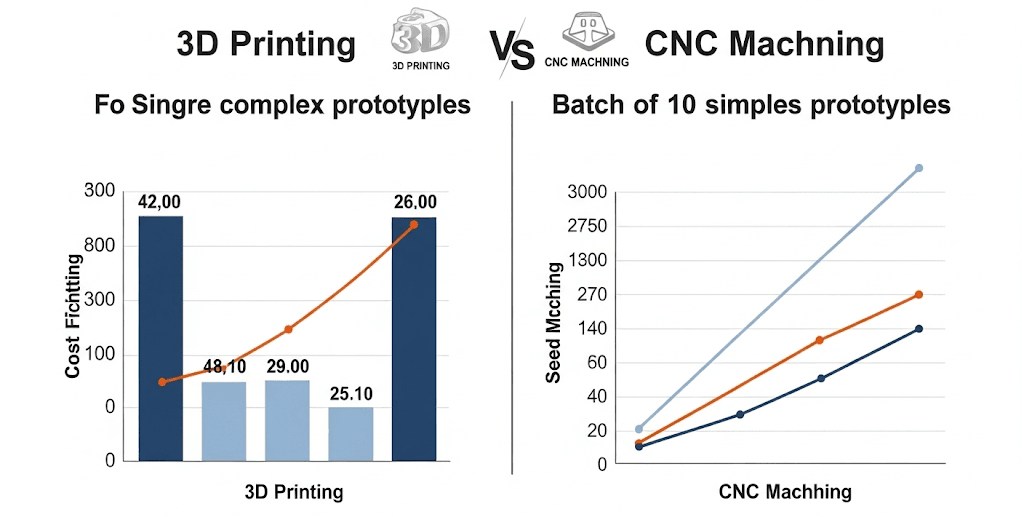

Speed and Cost: A Balancing Act

Choosing between CNC machining and 3D printing often comes down to balancing project timelines and budget.

3D printing is generally faster and more cost-effective for one-off parts with complex geometries. There is minimal setup required; you can often start printing within minutes of finalizing a design. This speed makes it ideal for rapid design iteration, allowing engineers to quickly produce a physical model, test it, and make adjustments. For a single, complex prototype, the automated nature of 3D printing usually results in lower labor costs.

CNC machining involves more setup time. A skilled technician must program the machine, prepare the material blank, and select the appropriate tooling. This initial setup can make CNC more expensive for a single part. However, once the setup is complete, the process is incredibly fast and efficient for producing multiple identical prototypes. The cost per part decreases significantly with higher quantities. For functional prototypes where material properties are key, the investment in CNC machining often provides more valuable testing data.

Surface Finish and Part Complexity

The final look and feel of your prototype can be just as important as its function. CNC machining typically produces parts with an excellent, smooth surface finish right out of the machine. The finish can be further improved with post-processing techniques like bead blasting, anodizing, and polishing to achieve a production-quality appearance.

3D printed parts, due to their layered construction, often have visible layer lines and a rougher texture. Extensive post-processing, such as sanding, vapor smoothing, or painting, is usually required to achieve a smooth finish.

However, 3D printing shines when it comes to geometric complexity. It can create intricate internal channels, complex lattice structures, and organic shapes that are either impossible or prohibitively expensive to produce with CNC machining. If your prototype has highly complex features, 3D printing is the clear winner. For parts with simpler geometries that demand a fine surface finish, CNC machining is the more direct route.

Frequently Asked Questions (FAQ)

1. Is CNC machining better than 3D printing for a functional prototype? For most functional prototypes, yes. CNC machining uses production-grade metals and plastics, offering superior strength, durability, and dimensional accuracy. This allows you to test the prototype under real-world conditions, providing reliable data on performance before committing to mass production. ly-machining specializes in creating high-fidelity functional prototypes with precise CNC milling.

2. Can 3D printing be used for metal parts? Yes, metal 3D printing technologies like Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) exist. They can create strong, complex metal parts. However, the process is significantly more expensive and slower than CNC machining, and the material selection is more limited. It is typically reserved for highly specialized, low-volume applications.

3. Which process is more affordable for my prototype? It depends on several factors. For a single, geometrically complex part where material strength is not the top priority, 3D printing is usually more affordable. For multiple parts or for a prototype that requires high precision and robust material properties, CNC machining often provides better value despite a potentially higher initial setup cost.