Choosing the right CNC machining materials is critical for part performance and cost-efficiency. A thorough material selection for CNC parts requires evaluating application needs, mechanical properties, environmental resistance, and budget, ensuring optimal manufacturability and longevity.

Choosing the wrong material for a CNC machined part isn’t just a minor mistake; it can escalate costs by 20%, lead to critical part failures, and cripple your project timeline. Are you confident in your material selection process? At ly-machining, we understand these stakes deeply.

This comprehensive CNC material guide will demystify the complexities of material selection, equipping you with the expertise to make informed decisions. We’ll explore crucial factors and common materials, ensuring your parts perform exactly as intended.

Why Material Choice Matters for Your Parts

The foundational decision of material selection for CNC parts reverberates through every stage of product development and its eventual performance. It’s more than just a component; it defines functionality. Our experience shows that overlooking this step leads to significant downstream issues.

Understanding these implications is the first step in choosing CNC materials wisely. It ensures that the investment in your machined parts yields the desired return.

Impact on Performance & Lifespan

The chosen material directly dictates how a part behaves under stress, temperature, and environmental exposure. A material with insufficient tensile strength will fail prematurely under load. Conversely, an overly robust material might unnecessarily inflate costs.

In our experience, matching material properties like hardness, flexibility, and fatigue resistance to specific operational demands is paramount. This strategic alignment ensures optimal functionality and extends the lifespan of your CNC machined components.

Cost Implications & Budgeting

Material selection is a primary cost driver in CNC machining. Raw material prices vary dramatically, and the type of material also influences machining time and tool wear. Harder materials, for instance, often require slower feed rates and more specialized tooling.

This directly translates to higher production costs and longer lead times. Balancing performance requirements with budget constraints is a critical aspect of effective CNC material selection.

Machinability & Production Efficiency

Not all materials machine equally. Some, like specific aluminum alloys, are highly machinable, allowing for rapid stock removal and excellent surface finishes. Others, such as titanium or hardened steels, are notoriously difficult.

Poor machinability can lead to increased cycle times, higher scrap rates, and accelerated tool wear, all impacting production efficiency. Choosing CNC materials with good machinability for your design can significantly streamline your manufacturing process.

Key Factors for Choosing CNC Materials

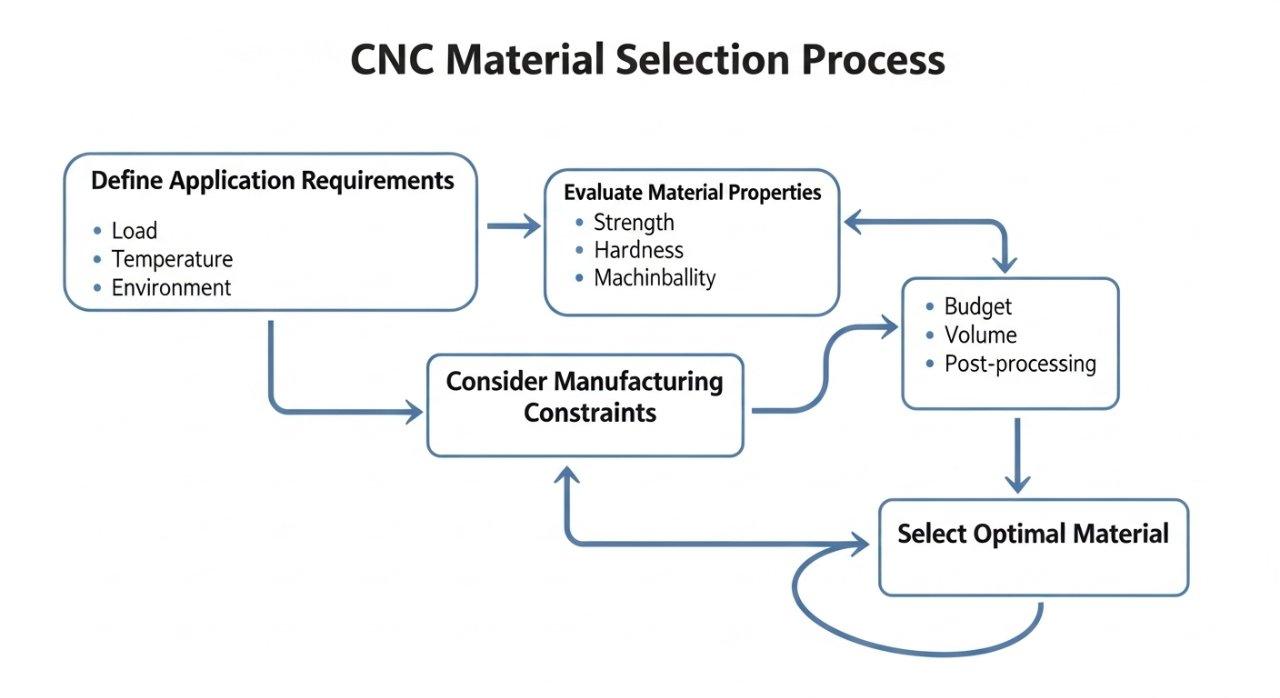

Effective material selection for CNC parts is a multi-faceted process, demanding a holistic understanding of various interdependent factors. At ly-machining, we guide our clients through this decision matrix. Each project presents a unique set of challenges that inform the final choice.

This systematic approach minimizes risks and maximizes the value of your CNC machining materials. It’s how we ensure precision and reliability.

Understanding Part Application Needs

The first and most critical step is a comprehensive understanding of the part’s intended application. Will it be exposed to extreme temperatures, chemicals, or high impact? Is weight a critical factor, such as in aerospace or automotive components?

Defining these operational parameters precisely informs the necessary material characteristics. This foundational insight prevents costly redesigns or premature part failures.

Mechanical & Physical Properties Guide

Once application needs are clear, we delve into the specific mechanical and physical properties of potential CNC machining materials. These include tensile strength, yield strength, hardness, density, elasticity, and thermal conductivity. Each property plays a vital role.

Understanding these characteristics allows us to match the material’s inherent capabilities with the part’s functional requirements. This ensures optimal performance.

Table: Key Mechanical & Physical Properties

| Property | Definition | Relevance for CNC Parts |

|---|---|---|

| Tensile Strength | Max stress a material can withstand before breaking | Resists pulling forces; crucial for load-bearing parts. |

| Yield Strength | Stress causing permanent deformation | Predicts onset of plastic deformation under load. |

| Hardness | Resistance to indentation/scratching | Influences wear resistance and surface finish. |

| Density | Mass per unit volume | Determines part weight; critical for aerospace/lightweighting. |

| Modulus of Elasticity | Stiffness; resistance to elastic deformation | How much a part will deform under stress without permanent change. |

Environmental Resistance Criteria

The operating environment dictates specific resistance requirements. For example, parts exposed to moisture or corrosive chemicals demand materials with excellent corrosion resistance. UV stability is crucial for outdoor applications.

Temperature extremes necessitate materials that maintain their integrity without deforming or degrading. Environmental resistance is a non-negotiable factor in robust CNC material selection.

Budget & Production Volume Trade-offs

The economics of material selection extend beyond raw material cost. Higher production volumes can justify investments in more expensive, specialized tooling for difficult materials. Conversely, prototypes often prioritize readily available, cost-effective options.

It’s a delicate balance between performance, manufacturing complexity, and total project budget. Our engineers are adept at navigating these trade-offs to find optimal solutions.

Post-Processing & Finish Considerations

Many CNC machined parts require post-processing like anodizing, plating, heat treatment, or polishing. The chosen material must be compatible with these processes to achieve the desired surface finish or enhanced properties. Some materials react differently to various finishes.

In our experience, planning for post-processing during initial material selection prevents downstream complications and ensures the final part meets all aesthetic and functional requirements.

Common CNC Machining Materials Guide

A deep understanding of common CNC machining materials is essential for making informed decisions. Each material category – metals, plastics, and advanced alloys – offers a unique suite of properties. This section serves as a practical CNC material guide.

Our team at ly-machining routinely works with a vast array of materials, leveraging our expertise to optimize performance and cost for every client project.

Aluminum Alloys for CNC Parts

Aluminum alloys are among the most popular CNC machining materials due to their excellent strength-to-weight ratio, corrosion resistance, and good machinability. They are extensively used across aerospace, automotive, and consumer electronics industries.

They offer a fantastic balance of properties and cost-effectiveness for a wide range of applications.

Aluminum 6061 vs. 7075

Two common aluminum alloys are 6061 and 7075. Aluminum 6061 is a versatile, heat-treatable alloy known for its good mechanical properties and weldability, making it ideal for general-purpose applications, structural components, and prototypes.

Aluminum 7075, on the other hand, is significantly stronger, comparable to some steels, making it preferred for high-strength applications like aircraft fittings or critical structural parts. It has lower corrosion resistance and machinability than 6061.

Table: Aluminum Alloy Comparison

| Property | Aluminum 6061 | Aluminum 7075 |

|---|---|---|

| Primary Alloying | Magnesium, Silicon | Zinc |

| Tensile Strength | Good (310 MPa) | Excellent (572 MPa) |

| Yield Strength | Good (276 MPa) | Excellent (503 MPa) |

| Machinability | Excellent | Good to Fair |

| Corrosion Resist. | Very Good | Good (can be susceptible to exfoliation corrosion) |

| Weldability | Excellent | Poor |

| Typical Use | General purpose, structural, bike frames, jigs | Aerospace, high-stress components, molds |

Advantages & Limitations

The main advantages of aluminum alloys include their light weight, high thermal conductivity, and ease of machining. This makes them cost-effective for high-volume production. Anodizing also provides excellent surface finishes and added corrosion resistance.

Limitations include lower wear resistance compared to steels and a higher coefficient of thermal expansion. Careful material selection for CNC parts requires considering these trade-offs.

Stainless Steel for Demanding Parts

Stainless steels are selected for applications requiring superior strength, hardness, and corrosion resistance. They are widely used in medical devices, food processing equipment, and marine components. Their durability makes them a cornerstone of many demanding industries.

While more challenging to machine than aluminum, their performance benefits often outweigh the increased manufacturing effort.

Grades 303, 304, 316 Comparison

Stainless steel comes in many grades, each with distinct properties.

303 stainless steel is known for its excellent machinability due to added sulfur, but this slightly reduces its corrosion resistance and weldability. It’s often chosen for parts requiring extensive machining.

304 stainless steel is the most common grade, offering a good balance of corrosion resistance, strength, and formability. It’s used in kitchen equipment, architectural components, and chemical containers.

316 stainless steel provides superior corrosion resistance, especially against chlorides, due to the addition of molybdenum. This makes it ideal for marine environments, medical implants, and pharmaceutical equipment.

Table: Stainless Steel Grade Comparison

| Property | Stainless Steel 303 | Stainless Steel 304 | Stainless Steel 316 |

|---|---|---|---|

| Primary Alloying | Chromium, Nickel, Sulfur | Chromium, Nickel | Chromium, Nickel, Molybdenum |

| Machinability | Excellent (best of the 300 series) | Good | Good |

| Corrosion Resist. | Good (lower than 304/316 due to sulfur) | Very Good (general purpose) | Excellent (superior in chloride environments) |

| Weldability | Fair (sulfur can cause hot cracking) | Excellent | Excellent |

| Typical Use | Fasteners, shafts, fittings (machined parts) | Kitchen sinks, chemical equipment, architecture | Marine, medical, pharmaceutical, harsh environments |

Corrosion & Strength Balance

The key to choosing CNC materials in stainless steel lies in balancing corrosion resistance with required mechanical strength. Higher grades often mean better corrosion resistance but can sometimes impact machinability.

We help clients select the precise grade that meets environmental demands without over-specifying, which can drive up costs. This expert guidance is vital for critical applications.

Engineering Plastics in CNC Machining

Engineering plastics offer unique advantages, including light weight, electrical insulation, chemical resistance, and specific aesthetic qualities. They are increasingly used in components where metal is too heavy or conductive.

Examples include medical housings, electrical insulators, and consumer product components. Their versatility makes them crucial CNC machining materials.

ABS, Delrin, Nylon Properties

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic known for its impact resistance and toughness, often used for housings and prototypes. It’s relatively easy to machine and has good dimensional stability.

Delrin (Acetal Homopolymer, POM) offers excellent stiffness, low friction, and outstanding wear resistance. It’s ideal for gears, bearings, and sliding components due to its self-lubricating properties.

Nylon (Polyamide) is recognized for its high strength, toughness, and fatigue resistance. It’s often reinforced with glass fibers for even greater performance in applications like automotive parts and industrial components.

Table: Engineering Plastic Properties

| Property | ABS (Acrylonitrile Butadiene Styrene) | Delrin (POM) | Nylon (Polyamide) |

|---|---|---|---|

| Key Characteristic | Impact Resistance, Toughness | Stiffness, Low Friction, Wear Resistance | High Strength, Toughness, Fatigue Resistance |

| Machinability | Good | Excellent | Good |

| Moisture Absorp. | Low | Low | High (affects dimensional stability) |

| Chemical Resist. | Good (to acids, alkalis, oils) | Excellent (to many solvents, fuels) | Good (to oils, solvents) |

| Typical Use | Housings, prototypes, electronic enclosures | Gears, bearings, sliding parts, medical components | Automotive parts, industrial components, fasteners |

Best Uses for Plastic Parts

Plastic CNC parts are best suited for applications where weight reduction, electrical insulation, or specific chemical resistance are paramount. They can often replace metal parts in non-load-bearing or lightly loaded situations, reducing overall assembly weight.

Their aesthetic versatility also allows for integration of color and texture directly into the part. Proper material selection for CNC parts here hinges on environmental and load factors.

Other Advanced Materials for CNC

Beyond the most common options, ly-machining also works with a range of advanced CNC machining materials to meet highly specialized requirements. These materials offer unique properties for niche applications where standard options fall short.

Our expertise extends to these challenging materials, ensuring precision even with exotic alloys.

Titanium, Brass, Copper Overview

Titanium, particularly Grade 5 (Ti-6Al-4V), is revered for its exceptional strength-to-weight ratio, outstanding corrosion resistance, and biocompatibility. It is indispensable in aerospace, medical implants, and high-performance automotive parts, despite its high cost and difficult machinability.

Brass is an alloy of copper and zinc, prized for its excellent machinability, good strength, and attractive aesthetic. It’s widely used for electrical connectors, plumbing fittings, and decorative components.

Copper offers superb electrical and thermal conductivity, making it ideal for heat sinks, electrical contacts, and specialized conductors. Its softness, however, requires careful machining.

Table: Advanced Material Overview

| Material | Key Properties | Typical Applications |

|---|---|---|

| Titanium (Gr 5) | High Strength-to-Weight, Corrosion Resistant, Biocompatible | Aerospace, Medical Implants, Motorsports |

| Brass | Excellent Machinability, Good Conductivity, Aesthetics | Plumbing fittings, Electrical connectors, Decorative items |

| Copper | Exceptional Electrical & Thermal Conductivity | Heat sinks, Electrical contacts, Busbars |

Our Expert Process for Choosing Materials

At ly-machining, our approach to CNC material selection is rooted in a collaborative and data-driven methodology. We don’t just machine parts; we partner with you to engineer the optimal solution. Our process ensures that the CNC material guide for your project is tailored precisely.

This structured expertise is what sets us apart, delivering both confidence and tangible results.

Consulting Your Design & Specs

Our process begins with an in-depth consultation, reviewing your part design, functional specifications, and any environmental constraints. We ask probing questions to fully grasp the application. Understanding the critical features and required tolerances is paramount here.

This initial phase is where our engineering team leverages its experience to identify potential material suitability and any initial red flags.

Analyzing Cost vs. Performance

With a clear understanding of your needs, we analyze various CNC machining materials, meticulously balancing performance requirements against cost implications. This involves considering raw material costs, machining complexity, and post-processing needs.

We aim to optimize for both functionality and budget, ensuring you get the best value without compromising quality.

Ensuring Quality with Right Materials

Selecting the right materials is fundamental to achieving high-quality parts. We utilize our deep knowledge of material science and machining capabilities to recommend materials that will reliably meet your design’s demands. This ensures the parts perform consistently.

In our experience, investing time in this early stage saves significant rework and performance issues later on. It’s a core tenet of our CNC material guide.

Transparent Pricing for Material Options

Transparency is a cornerstone of our service. We provide detailed breakdowns of material costs, machining costs, and any associated post-processing expenses for each recommended option. This allows for informed decision-making.

You’ll receive a clear view of how different material choices impact your overall project budget, fostering trust and clarity.

Avoid Common Material Selection Mistakes

Even experienced engineers can fall into common traps during material selection for CNC parts. Our role at ly-machining is to help you navigate these pitfalls. Proactive identification and avoidance of these errors are key to project success.

This section highlights critical areas often overlooked, serving as a practical CNC material guide for preventing common missteps.

Overlooking Machinability Factors

One frequent mistake is choosing a material based solely on its mechanical properties, without adequate consideration for its machinability. A super-strong alloy might seem ideal, but if it’s extremely difficult to machine, it can dramatically increase production time and cost.

This often leads to higher tool wear, slower feeds and speeds, and increased potential for part distortion. We always factor in machining characteristics during our material selection.

Underestimating Environmental Stress

Another common oversight is underestimating the actual environmental conditions a part will face. Forgetting to account for minor chemical exposure, fluctuating temperatures, or continuous UV radiation can lead to premature material degradation.

For example, selecting a standard aluminum alloy for a marine application without proper anodizing can lead to rapid corrosion. Our engineers scrutinize these details to ensure long-term durability.

Balancing Cost and Part Quality

While budget is always a consideration, prioritizing the lowest-cost material without thoroughly assessing its impact on part quality and performance is a critical error. A cheaper material might save money upfront but can lead to frequent failures and costly replacements.

In our experience, a slightly higher initial material investment often translates into significant long-term savings through enhanced durability and reliability. Striking the right balance is paramount.

Ready to Choose Your CNC Part Material?

Making the right material selection for CNC parts can feel overwhelming, given the vast array of options and complex technical considerations. However, with expert guidance, this critical decision becomes a strategic advantage.

At ly-machining, we combine our deep technical expertise with a transparent, client-focused approach to simplify this process. We’re here to be your ultimate CNC material guide.

Get a Free Material Consultation

Don’t leave your CNC part performance to chance. Leverage our deep technical expertise and transparent pricing. Contact our engineering team today for a complimentary material consultation and a no-obligation quote tailored to your specific project needs.

We’ll help you navigate the complexities of CNC machining materials. Ensure your project starts with the strongest foundation.

Request a Transparent Project Quote

Receive a detailed and transparent quote that clearly outlines material costs, machining expenses, and all associated services. There are no hidden fees. We believe in clear communication and predictable budgeting.

Let us provide the clarity and confidence you need. Make informed decisions for your next project.

Case Study: Enhancing Medical Device Performance with Optimized Material Selection

**Problem:** A client approached us with a challenge for their new medical device component – a small, intricate part that required exceptional strength, biocompatibility, and high-precision machining. Their initial prototype, machined from a common stainless steel, exhibited unforeseen wear in specific areas after sterilization cycles and lacked the required longevity. The client was facing potential regulatory hurdles and costly redesigns.

**Our Solution:** Our engineering team conducted an in-depth review of the part’s application and environmental exposure (repeated sterilization, fluid contact, mechanical stress). We identified that the chosen stainless steel, while generally suitable, wasn’t performing optimally under the specific cyclical stresses and chemical exposure of sterilization. Based on our comprehensive CNC material guide knowledge, we recommended transitioning to Titanium Grade 5 (Ti-6Al-4V). This material offered superior strength-to-weight, exceptional corrosion resistance, and proven biocompatibility, all critical for this medical application. We then developed an optimized machining strategy to handle Titanium’s challenging machinability.

**Result:** The switch to Titanium Grade 5 significantly improved the part’s wear resistance and longevity, flawlessly passing all client and regulatory validation tests. The client achieved enhanced product reliability, extended device lifespan, and successfully brought their innovative medical device to market on schedule, avoiding expensive delays and redesigns. Our precise material selection for CNC parts proved pivotal.

What impacts material cost?

Material cost is influenced by raw material price, supply chain availability, and market demand. Exotic or high-performance CNC machining materials typically command higher prices. Machinability also plays a role.

Difficult-to-machine materials increase production time and tooling wear, adding to overall cost. This is why careful planning is essential.

How does material affect lead time?

Material choice significantly impacts lead time. Readily available common CNC machining materials allow for quick procurement. Specialized or custom-ordered materials can introduce significant delays.

Furthermore, materials with poor machinability require longer machining cycles. This extends the overall production schedule.

Can you help with material spec?

Yes, absolutely. Our experienced engineers specialize in material selection for CNC parts. We work closely with you to understand your application, performance requirements, and budget.

We then provide expert recommendations from our comprehensive CNC material guide. This ensures optimal material specification for your project.