The journey from a mere concept to a perfectly realized metal knob—a tactile component of undeniable quality—often proves an exasperating gauntlet of design hurdles, material quandaries, and manufacturing inconsistencies.

Many find themselves ensnared by opaque processes, enduring costly reworks, and grappling with suppliers who simply cannot grasp the nuanced demands of true precision. But really, achieving that unassailable standard, that impeccable finish, that unwavering functionality, need not be a constant battle!

It is time to embrace a methodology that solves these perennial problems, a systematic approach guaranteeing fidelity from digital blueprint to finished product.

This exposition frames the entire CNC metal knob manufacturing narrative through the unwavering lens of ‘ly-machining’s unparalleled technical precision and systematic problem-solving methodology. We believe that clarity, rigor, and an engineer’s steadfast dedication to process define success.

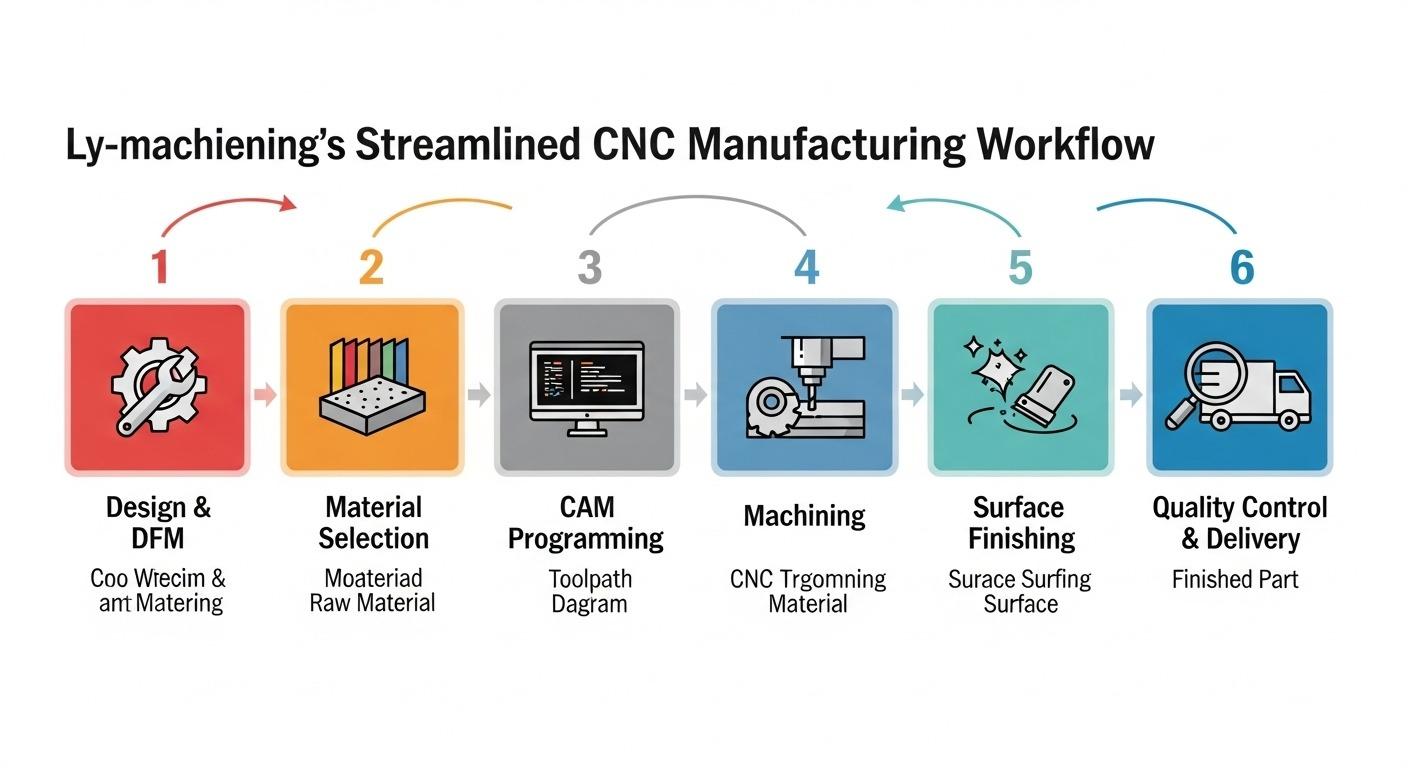

CNC metal knob manufacturing is an intricate, multi-stage process that transforms raw material into highly precise, functional, and aesthetically superior components. From initial design to final inspection, our comprehensive workflow ensures every custom metal knob meets the most stringent specifications, delivering exceptional quality and reliability.

From Blueprint: Designing Your Knob

Initial Concept and Technical Specifications

Any truly successful project begins with an unambiguous vision, does it not? We first meticulously capture the client’s design intent, translating subjective aspirations into objective, quantifiable metrics. This involves a profound dive into the knob’s intended function, the environmental conditions it will face, and its aesthetic role within the larger product.

What forces will it withstand? What rotational torque must it endure? These are not mere suggestions; they are foundational imperatives for our design engineers.

Selecting Optimal Materials for Metal Knobs

The material choice is never a trivial matter; it dictates everything—machinability, strength, finish potential, and ultimately, longevity. One must consider the inherent properties, the cost implications, and, critically, how a particular alloy responds to the precise depredations of our CNC machinery.

But really, some metals offer vastly different performance characteristics! Selecting the correct one is a foundational decision that impacts every subsequent step.

TABLE 1: Common Metal Knob Materials and Properties

| Material | Key Characteristics | Primary Applications |

|---|---|---|

| Aluminum 6061-T6 | Lightweight, high strength-to-weight, good corrosion | Aerospace, consumer electronics, general |

| resistance, excellent machinability. | industrial. | |

| Stainless Steel 303 | Good corrosion resistance, excellent machinability, | Medical devices, marine, heavy-duty |

| moderate strength. | industrial. | |

| Brass C360 | Excellent machinability, good electrical | Musical instruments, plumbing, decorative |

| conductivity, appealing aesthetic. | elements. | |

| Titanium Grade 5 | Exceptional strength-to-weight, biocompatible, | High-performance aerospace, medical |

| superior corrosion resistance. | implants, luxury goods. |

Optimizing Design for CNC Machinability

A design—no matter how brilliant—that ignores the immutable laws of CNC machinability is, frankly, a recipe for disaster. Our engineers engage in rigorous Design for Manufacturability (DFM) analysis, proactively identifying and rectifying potential issues long before a single chip is cut. This is where real value engineering begins.

It’s about simplifying complex geometries without compromising aesthetics, about ensuring tool access, and about minimizing unnecessary material removal—utterly crucial for cost and time efficiency, one would argue.

CAD/CAM for CNC Metal Knob Preparation

Creating the Digital Blueprint and Models

With the design optimized, our expert team, using industry-leading CAD software, translates the conceptualized knob into an impeccably precise 3D digital model. Every dimension, every tolerance, every minute feature is captured with absolute fidelity. This digital twin is the unquestionable master reference for all that follows.

This isn’t merely drawing; it’s digital sculpture, a pre-visualization of physical perfection.

Generating Precision Toolpaths

Then comes the CAM programming—the veritable choreography of the machine tool. Our structural analysts meticulously craft and optimize the toolpaths, defining every single movement of the cutter across the material. Spindle speeds, feed rates, depth of cut, and coolant strategies are calibrated to the minutest degree, always aiming for optimal material removal and unparalleled surface finish.

An unbelievably intricate dance, this is. Each line of G-code must be perfect; even a slight misstep can prove disastrous.

The Core CNC Metal Knob Manufacturing Process

Setting Up for Precise Knob Machining

Choosing the Right CNC Machine and Tooling

The selection of the appropriate CNC machine is paramount—a 3-axis mill for simpler geometries, perhaps, but for the truly intricate, the multi-axis capabilities of a 5-axis machine are indispensable. Each machine has its strengths; understanding these is fundamental. The tooling, too, is critically important.

Different materials demand specific cutter geometries and coatings. We deploy only the finest, high-performance carbide tools, meticulously selected for each distinct operation.

Workholding and Fixturing Techniques

Without rock-solid workholding, precision is an illusion. Our engineers design and implement bespoke fixtures that firmly grip the workpiece, preventing any vibration or movement during the aggressive machining operations. Proper clamping ensures consistent, repeatable accuracy across every single part produced.

We cannot tolerate even the slightest shift. The rigidity of the setup is an absolutely irreplaceable truth.

Executing CNC Machining for Metal Knobs

Roughing, Finishing, and Specialized Operations

The machining journey unfolds in distinct stages. First, roughing operations swiftly remove the bulk of the material, shedding excess with powerful, aggressive cuts. Then, finishing passes follow, employing lighter cuts and higher spindle speeds to achieve the final dimensions and initial surface quality.

But really, for specialized features like knurling, threading, or intricate engraving, dedicated tools and specialized CAM routines are absolutely essential.

Optimizing Parameters for Quality Parts

It’s an unending quest, this optimization. Every machining parameter—feed rate, spindle speed, depth of cut, stepover—is constantly refined, always balancing material removal rates against tool life and surface finish requirements. We leverage years of accumulated empirical data to fine-tune these variables to perfection.

This isn’t guesswork; it’s an empirical science, demanding meticulous data validation.

Achieving Superior Surface Finish on CNC Metal Knobs

Strategies for Polishing and Deburring

Post-machining, even the most precise part will exhibit some tool marks or burrs. Our meticulous deburring processes, often combining manual precision with automated techniques, eradicate any sharp edges or imperfections. Polishing then elevates the surface, preparing it for its final aesthetic and functional treatments.

A truly crucial step, one might say, ensuring both tactile comfort and visual appeal.

Advanced Finishing Techniques and Treatments

The choice of surface finish can profoundly impact a knob’s appearance, durability, and tactile feel. From a purely economic standpoint, one must weigh these options carefully. We offer a comprehensive suite of advanced finishing options, each meticulously controlled for consistent, high-quality results.

TABLE 2: Advanced Surface Finishing Options

| Treatment Type | Description | Benefits | Aesthetic Examples |

|---|---|---|---|

| Anodizing (Type II/III) | Electrochemical process, thickens natural oxide | Enhanced corrosion/wear resistance, diverse | Matte Black, Brushed Blue, Clear Silver |

| layer. | color options. | ||

| Electroless Nickel | Chemical deposition of nickel-phosphorus alloy. | Uniform coating, high hardness, corrosion | Bright Silver, Satin Nickel |

| Plating | protection. | ||

| PVD Coating (TiN, AlTiN) | Physical Vapor Deposition, thin hard ceramic | Extreme hardness, wear resistance, low friction, | Gold (TiN), Gunmetal Grey (AlTiN) |

| layer. | decorative colors. | ||

| Powder Coating | Electrostatically applied polymer powder, baked. | Durable, impact-resistant, wide color palette. | Textured White, Gloss Red, Smooth Green |

| Brushing/Polishing | Mechanical abrasion for directional texture/shine. | Aesthetic finish, removes minor surface flaws. | Hairline Brush, Mirror Polish |

Post-Processing & Quality Assurance

Post-Machining Treatment of Metal Knobs

Cleaning, Surface Preparation, and Degreasing

A freshly machined part, however pristine, carries residues—coolant, tiny metal particles, oils. These must be utterly eradicated before any subsequent surface treatment can commence. Our multi-stage cleaning protocols, often involving ultrasonic baths and specialized degreasers, ensure a microscopically clean surface, primed for optimal adhesion of coatings.

A truly fundamental step; skip it, and you invite disastrous adhesion failures.

Anodizing, Plating, and Coating Options

After cleaning, the chosen surface treatment is applied. Whether it’s the electrochemical transformation of anodizing, the precise deposition of plating, or the high-tech application of PVD coatings, each process is executed with exacting standards. This is where the knob truly acquires its final, distinctive character—its very soul, one might suggest.

Unbelievably precise control is mandatory to ensure uniform thickness and consistent aesthetic.

Rigorous Quality Control for CNC Metal Knobs

Dimensional Inspection and Metrology

This is where the rubber meets the road, wouldn’t you say? Every single critical dimension is scrutinized. We deploy an arsenal of advanced metrology equipment: CMMs (Coordinate Measuring Machines) for complex geometries, optical comparators for profile accuracy, and an array of digital calipers, micrometers, and bore gauges. Deviation from specified tolerances is simply not an option.

Our commitment to quality assurance is absolute; it is an absolutely irreplaceable truth.

Visual, Functional, and Final Verification

Beyond mere dimensions, the visual and functional integrity of each knob undergoes meticulous examination. Surface finishes are checked against specified aesthetic standards—no scratches, no blemishes, no inconsistent textures.

Functional tests ensure smooth operation, correct fitment, and tactile responsiveness. Only upon passing this exhaustive gauntlet of checks does a knob earn its ‘ly-machining’ seal of approval.

Wait, I need to clarify this: “final verification” means *every* specification is met, not just a few. It’s comprehensive.

Optimizing Your Metal Knob Production Workflow

Cost-Efficiency in CNC Knob Manufacturing

Transparent Pricing Models and Value Engineering

Our approach to pricing is refreshingly straightforward: utterly transparent. We break down costs, illuminating where every dollar goes, from material procurement to machining time and finishing processes. Through proactive value engineering, our engineers identify opportunities to optimize design and process, reducing costs without ever sacrificing quality—a true win-win, isn’t it?

We believe in a partnership, not just a transaction. Hidden costs are an anathema to this philosophy.

Batch Optimization and Material Utilization

Efficiency isn’t just a buzzword; it’s an engineering imperative. By meticulously optimizing batch sizes and nesting patterns, we maximize material utilization, minimizing waste and driving down unit costs. Our advanced CAM software performs these calculations with dizzying speed, ensuring every inch of material serves its purpose.

This strategic planning directly translates into tangible savings for our clients.

Partnering with a Specialized Knob Manufacturer

Leveraging Deep Technical Expertise

Why struggle alone when unparalleled expertise is readily available? Partnering with ‘ly-machining’ means tapping into decades of accumulated knowledge in CNC metal knob manufacturing. Our engineers don’t just execute; they anticipate challenges, offer innovative solutions, and guide your project with sagacious foresight. We possess, simply put, an inspirational depth of technical mastery.

Ensuring High-Quality Parts and On-Time Delivery

The most critical metrics, surely? Quality and timeliness. We understand the catastrophic implications of delayed or substandard components on your production schedules and reputation. Our rigorously controlled workflow, combined with an unyielding commitment to excellence, ensures your CNC metal knobs arrive precisely as specified, precisely when promised.

Your supply chain reliability is our solemn promise, an unwavering commitment to operational integrity.

Case Study: Precision for a Medical Device

A client approached ‘ly-machining’ with a truly challenging requirement: an ergonomic metal knob for a new medical diagnostic device. The knob demanded ultra-tight concentricity tolerances—a mere ±0.005mm—along with a specific, sterile-grade satin finish, all under an impossibly tight launch deadline. Previous suppliers had simply declared it unfeasible due to the complex internal geometry.

Our solution involved a multi-axis machining strategy, leveraging our 5-axis CNC machines for simultaneous contouring. We engineered a custom fixture for unparalleled rigidity and developed a bespoke polishing regimen to achieve the precise satin finish without compromising dimensional integrity. Our DFM analysis identified critical areas for minor design tweaks that greatly improved manufacturability without altering aesthetics.

The result? ‘ly-machining’ delivered all 5,000 units ahead of schedule. Each knob met the exacting concentricity specification, and the satin finish passed rigorous sterility and tactile feedback tests. The client praised our “unbelievable technical acumen” and our ability to transform what seemed like an insurmountable engineering hurdle into a resounding success, solidifying a long-term partnership.

Article Summary

The comprehensive guide elucidates the meticulous CNC metal knob manufacturing process, from initial design concepts and material selection through precise CAD/CAM programming and core machining operations. It highlights crucial stages like workholding, advanced surface finishing, and stringent multi-stage quality control.

The article emphasizes ‘ly-machining’s technical expertise, transparent processes, and commitment to delivering high-quality, custom metal knobs efficiently and reliably.

Frequently Asked Questions

What materials are best for metal knobs?

The optimal material depends entirely on the application’s demands. Aluminum offers lightweight durability, stainless steel provides corrosion resistance, and brass is excellent for aesthetics and machinability. Titanium is for extreme performance scenarios.

Our engineers always conduct a thorough application analysis to recommend the perfect material. This ensures optimal functionality and longevity for your specific product.

How do you ensure knob precision?

Precision is paramount. We achieve it through meticulous CAD/CAM programming, utilizing multi-axis CNC machines, and employing custom-designed workholding fixtures. This eliminates vibration and ensures repeatable accuracy across all parts.

Rigorous dimensional inspection with CMMs and optical comparators further guarantees that every knob adheres to the tightest possible tolerances. Our quality control is unrelenting.

What surface finishes are available?

We offer a comprehensive array of finishing options. These include anodizing for durability and color, electroless nickel plating for hardness and corrosion resistance, and advanced PVD coatings for extreme wear.

Mechanical finishes like brushing or polishing also create specific aesthetic and tactile qualities. We match the finish to your functional and visual requirements, every time.