In the fiercely competitive arena of premium electronics and advanced instrumentation, where every nuance defines brand perception, a single truth emerges: compromise is catastrophic. What if, I ask you, a seemingly minor component dictates the entire user experience, the very soul of your product’s tactile interaction? Disastrous indeed, to overlook this! It absolutely does.

Here at ly-machining, Shenzhen, China, we grasp this undeniable reality. Precision-machined CNC metal knobs are not merely functional elements; they are profound statements of durability, superior tactile engagement, and an unyielding commitment to uncompromising quality. They are, unequivocally, the indispensable choice for any truly premium device.

Defining CNC Metal Knobs

CNC metal knobs represent the pinnacle of component manufacturing, a testament to advanced computer numerical control technology. These are not merely cast or molded pieces. Rather, we meticulously sculpt them from solid blocks of raw metal.

This process ensures an unparalleled level of precision, a dimensional veracity simply unobtainable through less refined methods. Every contour, every radius, every minuscule detail is precisely controlled.

Featured Snippet: CNC metal knobs are precision-machined components crafted from solid metal using Computer Numerical Control technology, offering superior durability, tactile feedback, and aesthetic versatility over conventional alternatives. They eliminate wobble and ensure consistent performance, making them essential for high-end equipment requiring impeccable quality and user experience.

Precision Machining for Quality Components

The core advantage lies within the very nature of CNC machining. A digitally programmed machine tool executes intricate cuts with sub-millimeter accuracy. This is not just automation; it is the epitome of controlled manufacturing.

Think of it: the machine meticulously removes material layer by layer, shaping the knob with an exactitude that human hands—even the most skilled—cannot consistently replicate. This translates directly to geometric perfection.

This precision guarantees dimensional stability and consistency across every single unit, batch after batch, an absolute requirement for discerning clients. Its importance, we argue, cannot be understated; it is an absolutely irreplaceable truth.

Key Materials for CNC Metal Knobs

Selecting the correct material is not a trivial decision; it profoundly impacts the knob’s performance, aesthetics, and user interaction. Each metal possesses a distinct set of physical attributes. Our expertise guides this critical choice.

We meticulously analyze application requirements, environmental factors, and desired tactile properties to recommend the optimal alloy. It’s a strategic partnership, truly.

Aluminum, Stainless Steel, Brass Options

| Material | Key Characteristics | Common Applications |

|---|---|---|

| Aluminum (6061/7075) | Lightweight, excellent strength-to-weight ratio, corrosion resistant, highly machinable, diverse anodizing colors. | Audio equipment, aviation panels, laboratory instruments. |

| Stainless Steel (303/304/316) | High strength, exceptional corrosion resistance, durable, robust feel, hygienic, polished or brushed finishes. | Medical devices, marine equipment, industrial controls, high-end kitchen appliances. |

| Brass | Dense, classic aesthetic, good electrical conductivity, excellent machinability, natural antimicrobial properties, smooth tactile feel. | Luxury consumer electronics, vintage audio, decorative fixtures. |

Exotic Alloys for Unique Applications

Sometimes, a project demands more. We—ly-machining, that is—engage with more exotic materials like titanium or specialized aerospace alloys. These provide unique properties—incredible strength or extreme temperature resistance.

Indeed, such materials are challenging to machine, requiring specialized tooling and intricate process control. But the resultant component? Unrivaled performance for truly demanding applications.

Why CNC Knobs Elevate High-End Devices

The perceived value of a high-end product hinges on every interaction point, does it not? A cheap, wobbly knob immediately—and tragically—undermines the entire device’s perceived quality. This is a fundamental engineering tenet.

CNC metal knobs fundamentally rectify this, transforming a potential weakness into a profound strength. It’s an undeniable upgrade.

Unmatched Durability and Longevity

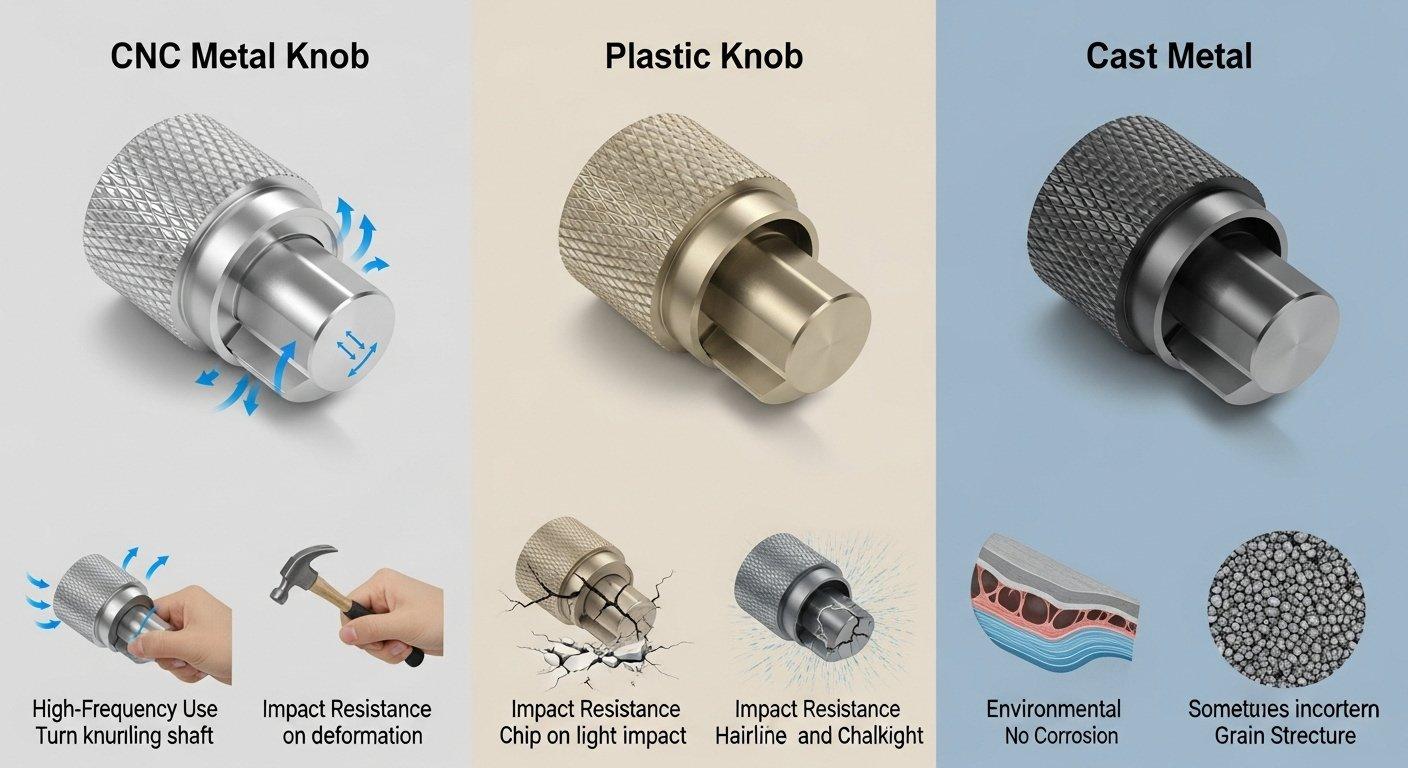

Metal, by its very nature, offers inherently superior mechanical properties compared to plastic or even cast metal alternatives. This isn’t just theory; it’s a verifiable, tangible reality.

A CNC-machined metal knob endures, day in and day out, through countless rotations and actuations. It simply withstands the test of time, an absolute necessity for professional-grade equipment.

Resistance to Wear and Corrosion

The inherent material strength—be it aluminum’s anodized layer or stainless steel’s passive film—provides formidable resistance. Wear, abrasion, and the insidious march of corrosion are profoundly mitigated.

This sustained integrity ensures the knob retains its pristine aesthetic and functional performance even in the harshest operational environments. It’s a remarkable feat of material science married to precision engineering.

Sustained Performance Over Time

An inferior knob degrades. Its action becomes loose; its surface tarnishes. Such degradation is not merely cosmetic; it directly impedes reliable functionality. A truth not often vocalized, but critical.

But a CNC metal knob? It maintains its precisely engineered rotational feel, its firm grip, its visual splendor for the entire lifespan of the device itself. A marvel of lasting quality!

Superior Tactile Feedback and Experience

The connection a user forms with a device is profoundly tactile. The “feel” of a knob transmits an immediate, visceral message about the product’s quality. This is an indisputable aspect of human-machine interface design.

A CNC metal knob delivers a specific, reassuring weight and a consistent, satisfying resistance that communicates robust engineering. It’s a truly inspired design choice.

Engineered for a Premium User Feel

We meticulously design the internal geometry and external surface textures to achieve optimal haptic feedback. This isn’t guesswork; it’s a profound science. The rotational torque, the detent feel—every aspect is engineered.

The user experiences a purposeful, positive engagement—a confidence in control that simply cannot be replicated by lighter, less substantial materials. A truly revelatory experience, for the discerning user.

Distinctive Weight and Gription Qualities

The substantial mass of a metal knob provides a satisfying inertial effect. It spins with a refined momentum, not a flimsy flick. This weighted movement is a hallmark of luxury.

Furthermore, precisely machined knurling or specific surface textures ensure impeccable grip, even with gloved hands or in humid conditions. No slipping. No fumbling.

Aesthetic Excellence and Design Versatility

The visual impact of a CNC metal knob is immediately apparent, a visual anchor of quality. Its crisp lines, smooth transitions, and precise details speak volumes about the device it adorns.

The inherent metallic sheen, whether subtly brushed or brilliantly polished, projects an aura of sophistication. Indeed, it looks magnificent.

Seamless Integration into Product Design

The design possibilities are—let’s be honest—virtually limitless. We can match any aesthetic, from minimalist elegance to rugged industrial. This versatility is a monumental asset for designers.

Complex geometries and intricate branding elements can be directly machined or expertly engraved into the metal surface, creating a cohesive and distinguished product identity. A true blessing for designers.

Customizable Finishes and Textures

| Finish Type | Visual Characteristics | Tactile Properties | Durability Impact |

|---|---|---|---|

| Anodizing (Type II/III) | Vibrant colors, matte or glossy, opaque. | Smooth, slightly textured. | Enhanced corrosion and wear resistance, electrical insulation. |

| Bead Blasting | Uniform matte, non-reflective. | Fine, gritty texture. | Reduces glare, improves paint adhesion. |

| Brushing | Linear, directional grain, satin sheen. | Smooth with subtle directionality. | Hides minor scratches, classic aesthetic. |

| Polishing | High reflectivity, mirror-like. | Very smooth, cool to the touch. | Aesthetic appeal, susceptible to fingerprints. |

| PVD Coating | Wide range of metallic colors, extremely hard. | Ultra-smooth, very durable. | Exceptional hardness, scratch, and chemical resistance. |

Precision Tolerances and Perfect Fit

Precision is not merely a buzzword for us; it is the very bedrock of our engineering philosophy. We mean tolerances measured in microns. This allows for an exacting fit.

Wait, I must emphasize this: a knob that wobbles or has excessive play is not merely annoying; it compromises the functional integrity of the entire device. It undermines everything.

Ensuring Functional Reliability and Accuracy

The precise fit of a CNC metal knob ensures that rotational inputs are translated into accurate electrical or mechanical responses, without deviation. This is fundamental for critical control functions.

This engineering exactitude ensures predictable, repeatable performance, which is non-negotiable for instruments, medical devices, or high-fidelity audio equipment. Accuracy is paramount.

Eliminating Wobble and Unwanted Play

Loose tolerances breed wobble. Wobble begets wear. And wear, inevitably, leads to failure. A truly disastrous chain of events, avoidable with precision.

Our CNC metal knobs, thanks to incredibly tight machining tolerances, eliminate unwanted play, providing a solid, stable, and reassuring connection between user and machine. A magnificent achievement, really.

Choosing a CNC Metal Knobs Manufacturer

Partnering with the right manufacturer is not just a commercial transaction; it is a strategic alliance. Your product’s reputation, its very market viability, hinges upon this critical decision. Indeed.

One must choose wisely. The stakes, I declare, are simply too high for anything less than excellence.

The Importance of a Source Manufacturer

As a source manufacturer, ly-machining directly controls every single aspect of the production process, from material procurement to final inspection. This grants us—and subsequently you—unparalleled control.

There are no intermediaries, no diluted lines of communication, no hidden costs, absolutely none. This translates to superior quality, transparent pricing, and predictable lead times. A truly streamlined approach.

Our Commitment to Quality and Precision

Our commitment to quality isn’t just a corporate slogan. It is an engineering principle embedded within every process, every machine calibration, and every skilled technician’s mindset. We live and breathe precision.

We utilize advanced metrology equipment—because, let’s be honest, you can’t manage what you don’t measure—to validate every dimension. Our quality control protocols are utterly rigorous.

Transparent Pricing and Deep Technical Support

We believe in absolute transparency. Our pricing structure is clear, detailed, and devoid of any unwelcome surprises. We hate those, just like you do.

Furthermore, our team of seasoned engineers provides comprehensive technical support, from initial design consultation (Design for Manufacturability, or DFM, is absolutely critical!) through to post-production assistance. We’re here.

Future of CNC Metal Knobs in Premium Devices

The evolution of user interfaces continues apace, driven by a relentless pursuit of intuitive interaction and aesthetic appeal. Yet, for all the digital screens, the physical control point—the knob—remains profoundly relevant.

Its tactile immediacy, its undeniable tangibility, offers an experience that digital interfaces, for all their dynamism, simply cannot replicate. This is a powerful, enduring truth.

Innovating User Interface Design

Engineers are constantly exploring new ways to integrate CNC metal knobs into haptic feedback systems, making the interaction even more responsive and informative. This is truly inspiring work.

We foresee—indeed, we help shape—a future where CNC metal knobs continue to be a pivotal element in defining the premium user experience, a physical anchor in an increasingly digital world. A truly vital role, it is.

Article Summary:

CNC metal knobs are precision-engineered components, crucial for high-end devices due to their unmatched durability, superior tactile feedback, and aesthetic excellence.

Crafted from materials like aluminum, stainless steel, or brass, they offer exact tolerances, eliminating play and enhancing user experience. As a source manufacturer, ly-machining delivers unparalleled quality, transparent pricing, and comprehensive technical support, making these components a paramount choice for product differentiation.

Case Study: Elevating Medical Device Tactility

Problem: A client, a developer of advanced portable medical diagnostic equipment, faced a perplexing challenge. Their initial prototypes, while functionally robust, incorporated generic plastic control knobs.

The feedback was brutal: users perceived the device as “cheap” and “unreliable,” despite its cutting-edge internal technology. The low-quality knobs were a catastrophic disconnect from the device’s true value, a truly disheartening reality.

Our Solution: We, ly-machining, engaged their engineering team directly. Our structural analysts proposed transitioning to custom CNC-machined 7075 aluminum knobs, hard-anodized for a resilient, matte-black finish. We meticulously designed specific knurling patterns for optimal grip, even with surgical gloves, and engineered internal detent mechanisms for a profoundly satisfying, positive click-action. Precision was paramount here.

Result: The transformation was, quite frankly, astonishing. User perception of the medical device skyrocketed. The substantial, precise feel of the CNC metal knobs immediately communicated reliability, quality, and advanced engineering. Sales figures, it was reported, reflected this shift, underscoring how a seemingly small component can dramatically—even unbelievably—impact market reception and user confidence.

Frequently Asked Questions

What makes CNC knobs superior?

CNC knobs are machined from solid metal, offering unparalleled precision, tighter tolerances, and superior material integrity compared to cast or molded alternatives. This results in exceptional durability and a consistent, high-quality finish.

They eliminate wobble and provide a significantly more refined tactile experience, essential for high-end equipment.

Can these knobs be customized?

Absolutely! Customization is a core strength of CNC machining. We offer extensive options for materials, finishes, knurling patterns, dimensions, and custom engraving.

This ensures seamless integration into your product’s specific aesthetic and functional requirements.

What is the typical lead time?

Lead times vary depending on the complexity of the design, material selection, and order volume. We prioritize clear communication and provide transparent project timelines.

Our efficient manufacturing processes and direct source model aim to optimize delivery, ensuring your project stays on schedule.

Elevate your product’s design and user experience, an imperative truth for any discerning engineer. Partner with our expert team to explore custom CNC metal knob solutions tailored precisely to your high-end device. Request a consultation or, even better, a transparent, detailed quote today.