CNC Mirror Finish Mastery

In high-performance engineering, a mirror finish transcends mere aesthetics; it often represents a critical functional requirement, demanding absolute perfection. Consistently achieving this flawless surface quality in CNC precision machining, however, can present a complex array of variables. This quest for immaculate surfaces frequently leads to significant challenges, impacting both product performance and manufacturing efficiency.

The struggle to attain superior surface roughness, manage high scrap rates, and navigate extended lead times is common. Many engineering teams find themselves in need of specialized expertise to consistently deliver true mirror-finish components for intricate geometries or demanding materials. Without the right approach, critical performance criteria—from friction reduction to light reflection—remain unmet.

What if you could unlock the proven techniques that consistently empower you to achieve true mirror finishes? This article will systematically unveil five core strategies, transforming your mirror finish challenges into a distinct competitive advantage for your most critical components.

The Core Solution for Mirror Finishes

Mastering CNC mirror finish involves a meticulous integration of precision tooling, machine rigidity, optimized parameters, advanced coolant strategies, and refined post-machining techniques.

The Quest for Perfect Mirror Finishes

Why Mirror Finish Matters in Precision CNC

The High Stakes of Surface Perfection

Achieving a true mirror finish is not solely about visual appeal; it is fundamentally linked to the functional integrity and longevity of precision components. Surfaces with exceptionally low roughness values (typically Ra < 0.05 µm) exhibit reduced friction, minimizing wear and energy loss in dynamic assemblies. This is crucial for parts in motion, where smooth contact surfaces prevent premature failure.

Furthermore, in applications such as optical instruments, molds for plastic injection, or medical devices, surface perfection directly influences product performance. A mirror surface ensures precise light reflection, prevents particle adhesion, and enhances resistance to corrosion by reducing potential nucleation sites for chemical reactions. The integrity of these components hinges on the quality of their machined surfaces, making mirror finishes indispensable.

Your Path to Flawless Parts Starts Here

The journey to consistently flawless components requires a deep understanding of machining principles and their synergistic application. It demands not just advanced machinery, but also the specialized knowledge to fine-tune every variable. This often involves overcoming challenges like inconsistent surface quality, which leads to high rejection rates, and a lack of transparency regarding the intricate processes required for specialized finishing techniques.

By systematically addressing each stage of the machining process, from initial material selection to final inspection, a reliable framework for achieving mirror finishes can be established. This structured approach allows for predictable outcomes, higher yield rates, and ultimately, superior product performance. A clear methodology provides the confidence and trust in delivering parts that meet the most stringent specifications.

Roadmap to Mirror Finish Mastery

What You’ll Learn About CNC Mirroring

This guide delves into the essential technical concepts and practical methodologies required to achieve exceptional CNC mirror finish results. You will gain insight into critical factors that influence surface quality, moving beyond conventional machining practices. Understanding these elements is paramount for engineers aiming to elevate their product design and manufacturing capabilities.

The focus will be on the interplay of tooling, machine dynamics, process parameters, and post-machining operations. Each section offers actionable knowledge, grounded in engineering principles, to systematically improve your surface finish outcomes. This comprehensive overview is designed to demystify the complexities of mirror polishing CNC.

Unveiling 5 Key Mirror Finish Techniques

The article will dissect five fundamental concepts and methods that form the bedrock of successful mirror finish achievement. These techniques collectively address the entire manufacturing workflow, ensuring that every stage contributes to the ultimate goal of surface perfection. From initial material removal to the final polishing steps, each method plays a pivotal role.

We will explore how optimizing these techniques can mitigate common defects, reduce scrap, and improve overall component performance. The integration of these strategies is what differentiates standard precision machining from true mirror polishing CNC capabilities. This holistic approach ensures the consistent delivery of high-quality components with unparalleled surface perfection.

Foundational Elements for Mirror Finish

Concept 1: Precision Tooling & Geometry

Understanding Tool Material and Design

The selection of cutting tool material and its geometric design is fundamental to achieving a superior CNC mirror finish. Tools must possess high hardness, wear resistance, and thermal stability to maintain a sharp cutting edge throughout the machining process. Diamond-tipped tools, for instance, are often preferred for their exceptional hardness when working with non-ferrous materials.

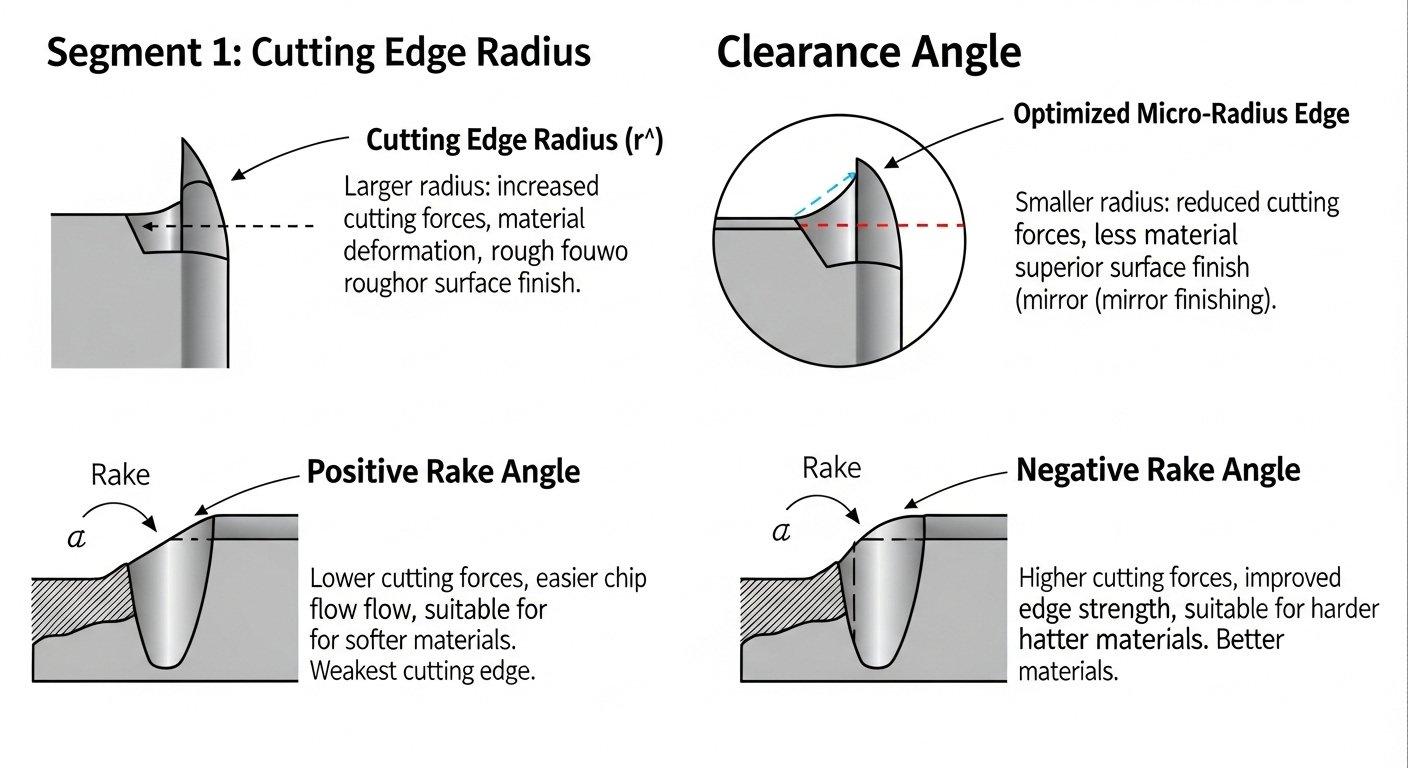

The tool’s coating also significantly impacts performance, reducing friction and preventing material adhesion. Proper design, including rake angles and clearance angles, ensures a smooth shearing action rather than a tearing effect. This minimizes surface imperfections and micro-fractures, which are detrimental to surface quality.

Table: Cutting Tool Properties for Mirror Finishing

| Property | Ideal Characteristic | Benefit for Mirror Finish |

|---|---|---|

| **Material** | Polycrystalline Diamond (PCD), Carbide | Extreme Hardness, Wear Resistance |

| **Coating** | TiAlN, DLC, Uncoated (for PCD) | Reduced Friction, Chip Evacuation |

| **Edge Sharpness** | Sub-micron Radius | Minimal Material Displacement, Clean Cut |

| **Runout Tolerance** | < 2 µm | Prevents Chatter, Consistent Cut Quality |

Optimizing Cutting Edge Radii

The cutting edge radius of a tool profoundly influences the surface finish. A smaller, sharper radius can reduce cutting forces and improve chip evacuation, but it can also be more prone to wear and chipping. Conversely, a larger radius offers greater strength but may lead to more material plowing, increasing surface roughness.

Optimal radii depend on the specific material and desired finish, typically ranging from a few micrometers to tens of micrometers. Precision grinding and honing are critical to achieving the ideal edge condition. This careful balance is key to transitioning from rough cutting to fine mirror polishing CNC.

Concept 2: Machine Rigidity & Stability

Importance of Machine Structure

Machine tool rigidity is a non-negotiable requirement for achieving a consistent CNC mirror finish. Any deflection or vibration within the machine structure, spindle, or fixturing directly translates into irregularities on the workpiece surface. Robust machine construction, often involving heavy cast iron bases and reinforced columns, provides the necessary static and dynamic stiffness.

High-precision spindles with minimal runout and superior bearing systems are also critical. These components ensure that the cutting tool maintains its intended path with micron-level accuracy, preventing chatter and inconsistent material removal. Investing in a stable machine foundation is an initial yet paramount step in the pursuit of impeccable precision machining.

Minimizing Vibrations for Finish Quality

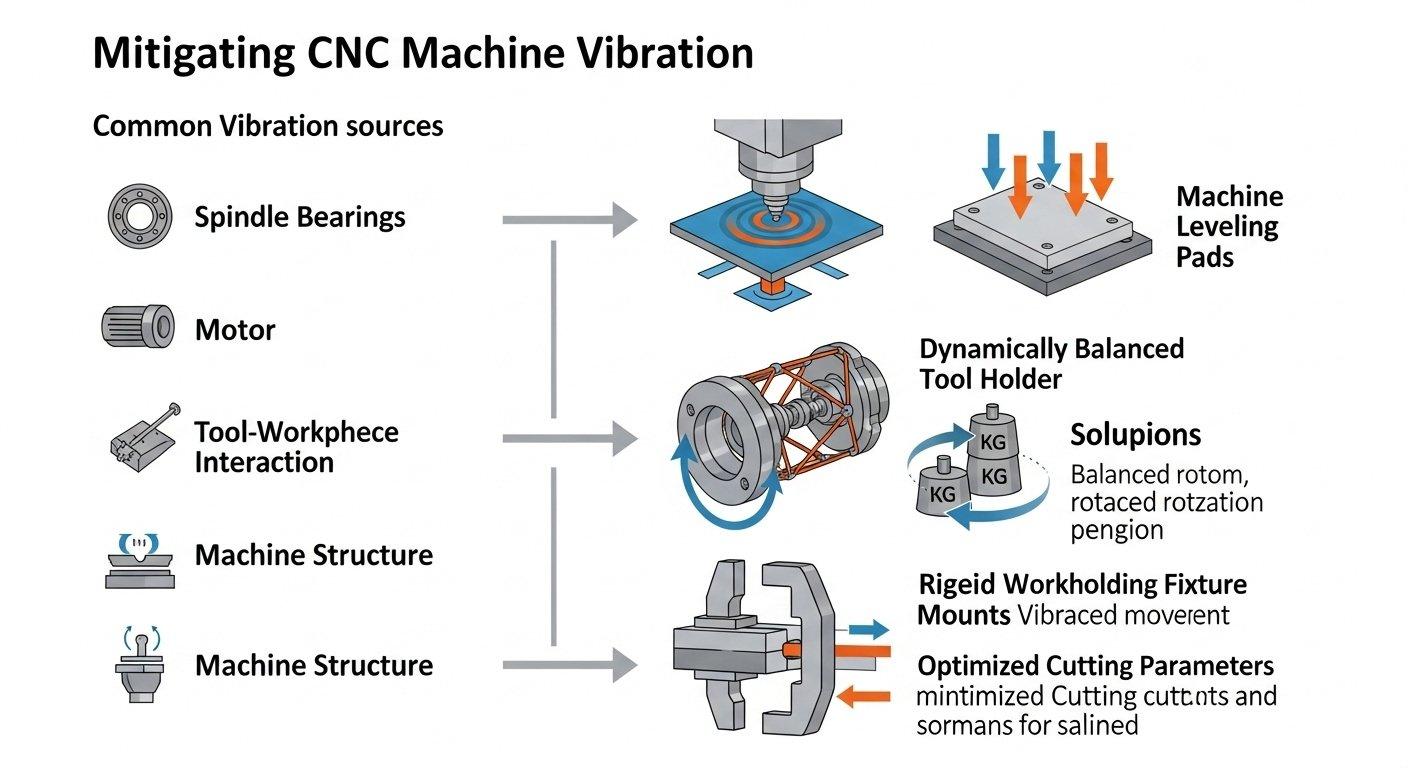

Vibrations are among the most significant impediments to achieving a high-quality surface finish. These unwanted oscillations can arise from various sources, including the machine’s internal components, tool-workpiece interaction, and external environmental factors. Effective vibration dampening techniques are essential to mitigate their detrimental effects.

Strategies include using advanced machine dampening pads, dynamic balancing of tool holders, and optimizing cutting parameters to avoid resonant frequencies. Furthermore, rigid workholding fixtures that provide maximum support to the workpiece are vital. This collective effort ensures that the cutting process remains stable, producing a consistent mirror polishing CNC result.

Advanced Strategies for Achieving Mirror Finishes

Method 1: Optimized CNC Parameters

Fine-Tuning Feed Rates and Spindle Speed

Optimizing CNC parameters like feed rate and spindle speed is crucial for achieving a superior surface finish. A higher spindle speed combined with a reduced feed rate often leads to a smoother surface, as it minimizes the material removal per tooth. However, excessively high speeds can generate heat, potentially leading to material deformation or tool wear.

The optimal combination is highly material-dependent and often requires empirical testing. Precise control over these parameters allows for very fine, controlled cuts, which are essential for mirror polishing CNC. This iterative process aims to find the sweet spot that balances material removal efficiency with surface quality.

Table: CNC Parameter Guidelines for Mirror Finish (General)

| Parameter | General Guideline | Impact on Surface Finish |

|---|---|---|

| **Spindle Speed (RPM)** | High (e.g., >10,000 RPM) | Reduces chip load, finer cutting action |

| **Feed Rate (mm/min)** | Low (e.g., <50 mm/min) | Minimizes tool marks, less material deformation |

| **Axial Depth of Cut** | Very Shallow (e.g., <0.01 mm) | Light “shaving” pass, minimizes subsurface damage |

| **Radial Depth of Cut** | Low (e.g., <10% tool diameter) | Stable cutting, prevents tool deflection |

Strategic Depth of Cut for Polishing

The depth of cut, particularly in the final finishing passes, plays a critical role in achieving a mirror finish. These final passes should involve extremely shallow depths of cut, often in the order of a few micrometers. This “skimming” action removes only the peaks of the surface profile left by previous machining operations.

Such light cuts generate minimal heat and cutting forces, allowing the tool to shear material cleanly without inducing significant subsurface stresses. Multiple, incrementally decreasing depths of cut are often employed to progressively refine the surface. This careful approach to material removal is central to achieving a genuine mirror polishing CNC result.

Method 2: Coolant & Lubrication Techniques

Selecting the Right Fluid for Mirroring

The choice of coolant and lubricant is paramount in CNC precision machining for mirror finishes. The primary functions of these fluids are to manage heat, lubricate the cutting interface, and effectively flush chips away from the cutting zone. For mirror finishes, excellent lubricity and cooling properties are essential to prevent thermal distortion and reduce friction.

Water-soluble coolants, synthetic fluids, or even specialized oils can be selected based on the workpiece material and cutting tool. The right fluid minimizes build-up edge (BUE) formation on the tool, which can otherwise transfer imperfections to the workpiece surface. A meticulous selection ensures the integrity of the surface finish.

Table: Coolant Types and Their Application for Mirror Finish

| Coolant Type | Primary Benefit | Typical Application Area | Key Consideration |

|---|---|---|---|

| **Synthetic Coolants** | Excellent Cooling, Clean | General machining, light-duty finishing | Good for aluminum, non-ferrous |

| **Semi-Synthetic** | Balanced Cooling/Lubricity | Versatile, good for various metals | Good all-rounder, chip evacuation |

| **Neat Oils** | Superior Lubricity | Hard-to-machine metals, very fine cuts | Lower cooling, specific material focus |

| **MQL (Minimum Quantity Lubrication)** | Reduced Fluid Usage, Clean | Specialized applications, high-speed | Precise delivery, environmental benefits |

Effective Delivery for Thermal Control

Beyond the choice of fluid, the method of coolant delivery significantly impacts the mirror finish. High-pressure coolant delivery systems can penetrate the cutting zone more effectively, ensuring optimal chip evacuation and thermal control. Directing the coolant precisely at the tool-workpiece interface is crucial to dissipate heat efficiently.

Suboptimal coolant delivery can lead to localized heating, causing thermal expansion or even re-hardening of the material, which negatively affects surface quality. A well-designed coolant system maintains a stable thermal environment, preventing material softening or excessive tool wear, thereby supporting consistent precision machining.

Refinement, Challenges, and Future Outlook

Tip 5: Post-Machining Polishing for Mirroring

Manual vs. Automated Polishing & Lapping

Even with optimal CNC precision machining, certain applications may demand a level of mirror finish that requires post-machining operations. Both manual and automated polishing and lapping techniques are employed to achieve sub-micron surface roughness values. Manual polishing, though highly skilled-dependent, offers flexibility for complex geometries.

Automated processes, such as vibratory finishing, magnetic abrasive finishing, or robotic polishing, offer consistency and scalability for higher volume production. Lapping, a fine abrasive machining process, can achieve extremely flat and smooth surfaces. The choice between manual and automated methods depends on factors like cost, part geometry, and required surface integrity.

Micro-Scratches, Haze, and Final Inspection

Despite advanced machining and polishing, subtle defects like micro-scratches, haze, or subtle orange peel textures can compromise a mirror finish. Detecting these imperfections requires sophisticated inspection techniques, often utilizing optical profilometry or atomic force microscopy to analyze surface topography at a microscopic level. These tools provide quantitative data on surface roughness (Ra, Rz, Rq).

Rigorous final inspection protocols, sometimes involving specialized lighting or magnification, are crucial to ensure that components meet the stringent surface quality specifications. This meticulous verification guarantees the integrity and performance of the finished parts, reinforcing the value of precise mirror polishing CNC.

Future of CNC Mirror Finish Technology

Innovations in Surface Metrology

The future of CNC mirror finish technology is intrinsically linked to advancements in surface metrology. Non-contact optical measurement systems, such as white light interferometry and confocal microscopy, are becoming increasingly sophisticated. These tools provide rapid, high-resolution 3D surface mapping, enabling precise characterization of surface texture and defects.

Innovations in in-process monitoring and adaptive control systems will allow real-time adjustment of machining parameters. This ensures consistent surface quality throughout a production run, minimizing human intervention and maximizing yield. Such advancements will further streamline the process of achieving perfect surface finish techniques.

Emerging Materials and Processes

The development of new engineering materials, including advanced ceramics, composites, and high-performance alloys, continues to push the boundaries of surface finish requirements. These materials often present unique challenges for traditional machining and mirror polishing CNC. Future processes will likely incorporate ultra-precision machining techniques like ductile mode grinding or energy-beam processing for these difficult-to-machine materials.

Hybrid manufacturing processes, combining subtractive and additive technologies, may also offer novel pathways to achieve complex geometries with integrated mirror-finish surfaces. These innovations promise to expand the range of applications where impeccable surface finish is not just desired, but reliably achievable.

Your Partner in Mirror Finish Excellence

Mastering CNC Mirror Finish: Key Takeaways

Recap of 5 Essential Mirroring Principles

Achieving a superior CNC mirror finish is a multifaceted endeavor, requiring a comprehensive approach. The five core principles highlighted—precision tooling, machine rigidity, optimized parameters, advanced coolant strategies, and refined post-machining—are interdependent and collectively elevate surface quality. Each element contributes critically to minimizing imperfections and maximizing material integrity.

The diligent application of these techniques transforms raw material into components with unparalleled surface perfection. This systematic mastery ensures that even the most demanding specifications for surface finish techniques are consistently met.

Your Blueprint for Flawless Surface Quality

The insights provided serve as a practical blueprint for navigating the complexities of mirror polishing CNC. By understanding and implementing these foundational and advanced strategies, engineers can reliably achieve the highest standards of surface quality. This knowledge empowers a proactive approach to manufacturing, significantly reducing errors and improving product performance.

Our deep technical expertise as a source manufacturer enables us to translate these principles into tangible results, delivering high-quality parts that consistently exceed expectations. We are committed to solving your most challenging surface finish requirements with transparency and precision.

Start Your Next Mirror Finish Project Today

Connect With Our CNC Machining Experts

Navigating the nuances of CNC mirror finish requires specialized knowledge and experience. Our team of expert engineers possesses extensive expertise in precision machining and advanced surface finish techniques. We are equipped to understand your unique project requirements and provide tailored solutions.

We pride ourselves on our problem-solving capabilities, transforming complex challenges into consistently achieved, impeccable mirror finishes. Engage with us to leverage our deep technical insights and optimize your component’s performance.

Request a Transparent Quote for Precision

Ready to elevate your product with uncompromising mirror-finish components? Don’t let surface imperfections compromise your vision or functional requirements. We offer transparent pricing and detailed technical consultations to ensure clarity and confidence in our services.

Contact our expert engineering team today for a comprehensive consultation and a transparent quote. Experience the difference that a true source manufacturer with deep technical expertise can make for your next precision machining project, ensuring unparalleled surface perfection.

Case Study: Optical Component Surface Perfection

Problem

A client specializing in high-precision optical systems faced significant challenges achieving the required mirror finish on a critical aluminum lens mount. Their previous supplier struggled with inconsistent surface roughness (Ra values often > 0.1 µm), leading to unacceptable light scattering and frequent part rejections. The strict requirements for surface finish techniques impacted their final product’s performance.

This inconsistency resulted in costly rework and extended lead times, directly affecting their production schedule and market competitiveness. The client needed a partner capable of delivering sub-0.05 µm Ra consistently across complex geometries for their precision machining.

Our Solution

Our ‘ly-machining’ engineers deployed a multi-faceted approach, starting with a meticulous analysis of the component’s geometry and material properties. We selected a specialized diamond-tipped tool with an optimized cutting edge radius and implemented our advanced CNC mirror finish strategies, including ultra-fine feed rates and high spindle speeds.

We also integrated a high-pressure, oil-based coolant system to maintain thermal stability and enhance lubrication. This comprehensive strategy addressed every aspect from tool path optimization to vibration dampening, ensuring a controlled and precise material removal process for mirror polishing CNC.

Result

By leveraging our deep technical expertise and advanced surface finish techniques, we consistently delivered lens mounts with an Ra value of 0.025 µm, significantly exceeding the client’s original specification. The flawless mirror finish virtually eliminated light scattering, enhancing the optical system’s performance.

This not only resolved the client’s quality control issues but also drastically reduced their scrap rates and production lead times. The success solidified a long-term partnership, demonstrating our capability to deliver high-quality parts for even the most demanding applications in precision machining.

Frequently Asked Questions

What is CNC mirror finish?

CNC mirror finish refers to a highly specialized precision machining process aimed at achieving an exceptionally smooth, reflective surface with minimal roughness, typically below Ra 0.05 µm. This is accomplished through meticulous control of tooling, machine parameters, and processing techniques.

It is a critical requirement for components where surface integrity directly impacts functional performance, such as in optics, medical devices, and high-performance molds. The goal is to eliminate micro-scratches and other imperfections.

What materials can achieve a mirror finish?

Many materials can achieve a CNC mirror finish, though the specific techniques vary significantly. Common examples include aluminum alloys, brass, stainless steel, medical-grade titanium, and various plastics. Harder materials often require diamond tooling.

The machinability and material microstructure play a crucial role in how easily a mirror finish can be achieved. Each material demands a tailored approach to surface finish techniques.

How long does mirror polishing take?

The time required for mirror polishing CNC is highly variable, depending on the material, component complexity, initial surface condition, and the target roughness. It can range from a few additional minutes for a simple, small part to several hours for large, intricate components.

The process often involves multiple, very light passes, which contribute to the overall duration. Achieving true precision machining mirror finishes is an investment in time, reflecting the meticulous attention to detail required.