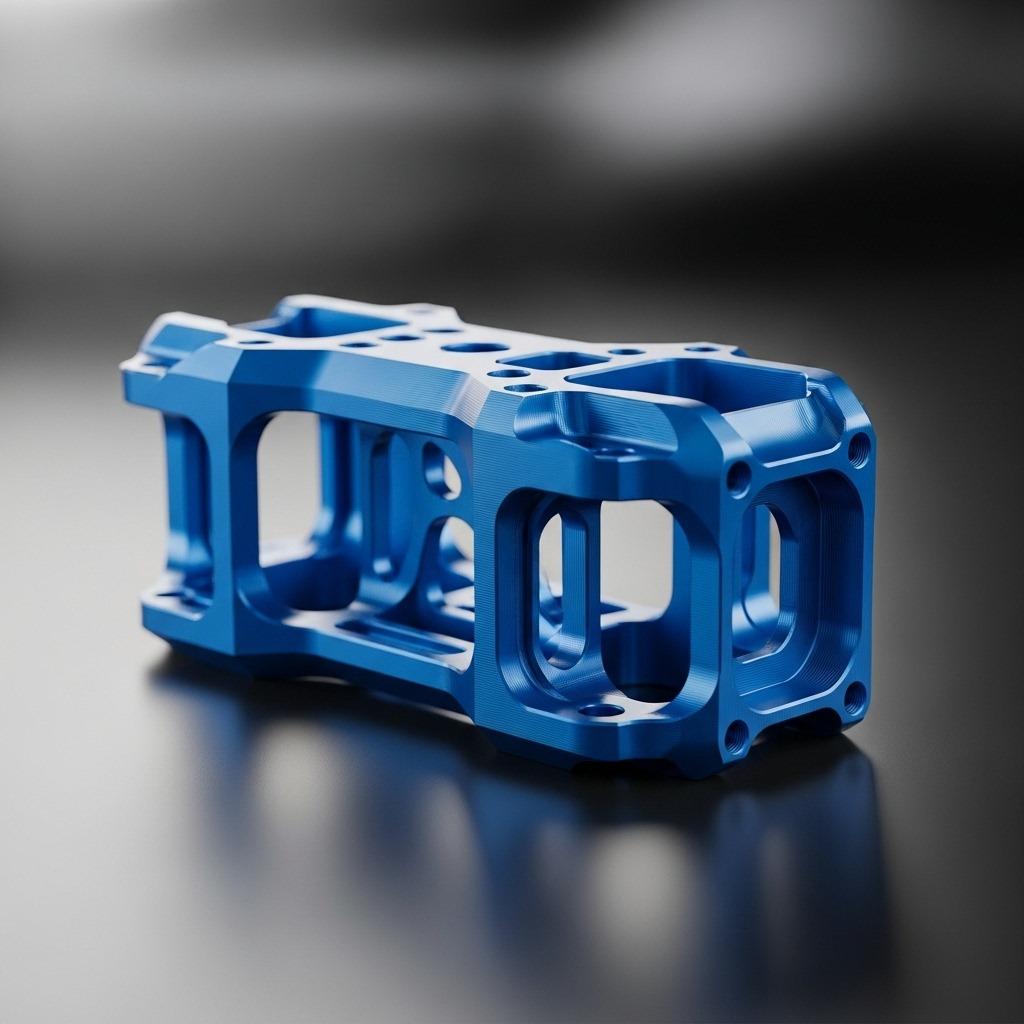

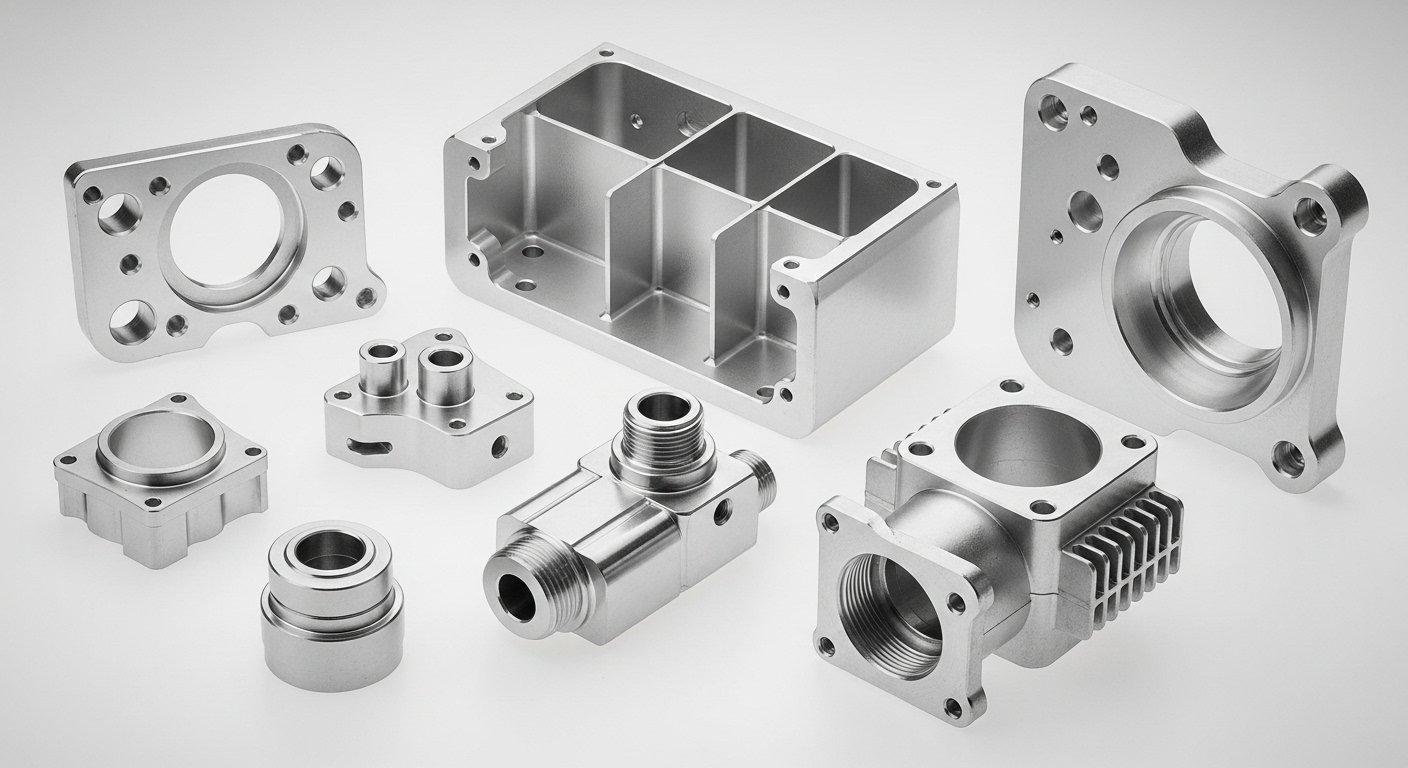

Are you wrestling with the intricate challenges of aluminum CNC machining – from selecting the perfect alloy to achieving a flawless finish under tight deadlines? Discover how deep technical expertise, transparent processes, and a direct manufacturing partnership can guarantee the precision and quality your critical projects demand.

We navigate the complexities of material science, advanced machining techniques, and rigorous quality control to deliver superior aluminum components.

For engineers and procurement professionals, successful aluminum CNC machining requires meticulous attention to material science, advanced processing, and stringent quality control. ly-machining, based in Shenzhen, China, specializes in delivering high-precision aluminum components. We offer expertise from initial alloy selection to final surface treatment, ensuring cost-effective, high-quality parts with transparent processes.

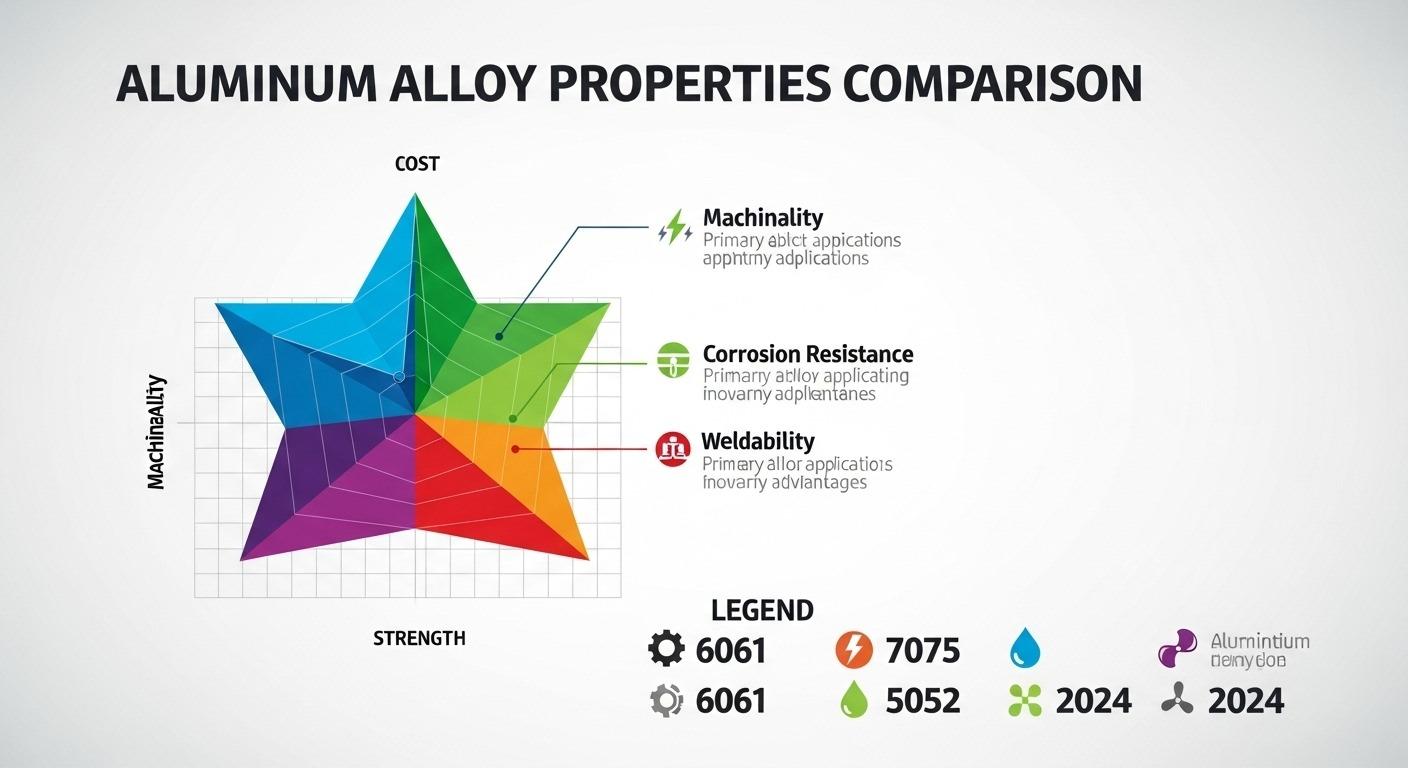

Optimizing Material Selection: How Aluminum Alloys Impact CNC Performance

Choosing the correct aluminum alloy is foundational to the success of any CNC machining project. The properties of the selected alloy directly influence machinability, strength-to-weight ratio, thermal conductivity, corrosion resistance, and the final mechanical performance of the component. An informed decision at this stage can significantly impact production efficiency and part longevity.

Common Aluminum Alloy Grades and Their Characteristics

Each aluminum alloy series offers a distinct set of characteristics tailored for specific applications. Understanding these differences is crucial for matching the material to the design requirements and operational environment of the final part. Our engineers provide expert guidance to ensure optimal alloy selection.

| Alloy Grade | Primary Characteristics | Typical Applications |

|---|---|---|

| 6061 | Good strength-to-weight ratio, excellent weldability, good corrosion resistance, heat treatable | Structural components, bicycle frames, automotive parts, marine fittings |

| 7075 | Highest strength, excellent fatigue resistance, heat treatable, less corrosion resistant than 6061 | Aerospace components, high-stress parts, sporting equipment |

| 5052 | Excellent corrosion resistance (especially salt water), good formability, moderate strength, non-heat treatable | Marine applications, fuel tanks, electronic enclosures |

| 2024 | High strength, good fatigue resistance, poor corrosion resistance (often clad), heat treatable | Aircraft structures, fasteners, military equipment |

Considering Material Cost and Machinability

The choice of aluminum alloy extends beyond performance to practical considerations such as material cost and machinability. Higher strength alloys often come with increased material expense and can sometimes be more challenging to machine, requiring specialized tooling or slower processing speeds. We balance these factors to provide cost-effective solutions.

Machinability ratings are critical for predicting production efficiency and tool wear. Alloys with higher machinability typically allow for faster material removal rates and longer tool life, directly impacting project timelines and overall cost. Our expertise ensures optimal material handling and machining strategies.

| Alloy Grade | Relative Machinability | Relative Material Cost | Notes on Machinability |

|---|---|---|---|

| 6061 | Excellent | Medium | Easily machined, good chip formation |

| 7075 | Good | High | Can be challenging due to hardness, requires sharp tooling |

| 5052 | Good | Medium | Softer, can be gummy; requires sharp tools and good chip evacuation |

| 2024 | Very Good | High | Similar to 7075, good for high-speed machining with proper setup |

Environmental Factors in Alloy Selection

The operational environment significantly influences alloy selection. For parts exposed to harsh conditions, such as saltwater or corrosive chemicals, specific alloys like 5052 offer superior resistance. Temperature extremes also play a role, as certain alloys maintain their mechanical properties better under elevated or cryogenic conditions.

Consideration of environmental factors is crucial for the long-term reliability and performance of aluminum components. Our DFM analysis includes a thorough assessment of the intended operating conditions to recommend the most appropriate and durable alloy.

Precision Machining: In-Depth Look at Aluminum CNC Processes and Challenges

Achieving micron-level precision in aluminum CNC machining requires a deep understanding of machine capabilities, tool dynamics, and material behavior. Aluminum presents unique challenges, including its thermal expansion properties, propensity for galling, and need for effective chip evacuation. Our processes are engineered to overcome these hurdles.

CNC Machining Center Types and Selection

The selection of the appropriate CNC machining center is critical for precision and efficiency. Our factory utilizes a range of advanced multi-axis CNC machines, including 3-axis, 4-axis, and 5-axis centers, chosen based on the part’s geometric complexity, required tolerances, and production volume. This diverse capability ensures optimal machining strategies.

Five-axis machines, for instance, are indispensable for complex geometries and intricate features, allowing for fewer setups and improved accuracy by machining multiple surfaces simultaneously. This reduces cumulative error and speeds up lead times for challenging designs.

Tool Selection and Cutting Parameter Optimization

Optimal tool selection and cutting parameter optimization are paramount for aluminum. Aluminum’s ductility requires tools with sharp edges, high rake angles, and polished flutes to facilitate efficient chip evacuation and prevent material adhesion. Carbide tools are commonly used for their durability and heat resistance.

Precise adjustment of cutting speed, feed rate, and depth of cut is essential to prevent issues such as burr formation, surface finish degradation, and thermal distortion. Our machinists leverage extensive experience and advanced CAM software to fine-tune these parameters for each specific aluminum alloy and part geometry.

| Parameter Type | Impact on Machining Performance | Optimization Strategy for Aluminum |

|---|---|---|

| **Tool Material** | Durability, heat resistance, edge sharpness | Carbide for general purpose, PCD for high-volume, fine finishes |

| **Tool Geometry** | Chip evacuation, surface finish, cutting forces | High rake angles, polished flutes, specific chipbreaker designs |

| **Cutting Speed** | Material removal rate, heat generation, tool life | Generally high, balanced with feed rate to control heat and chip load |

| **Feed Rate** | Chip thickness, surface finish, cutting forces | Adjusted for desired surface finish and chip evacuation |

| **Depth of Cut** | Material removal rate, cutting forces, deflection | Balance between roughing (deeper) and finishing (shallower) passes |

Coolant and Chip Evacuation Strategies

Effective coolant application and chip evacuation are critical in aluminum machining to manage heat, lubricate the cut, and prevent re-cutting of chips. Aluminum chips can be long and stringy, necessitating specialized strategies to prevent entanglement around the tool or workpiece, which can damage the part surface or tool.

Flood coolant, mist coolants, and through-spindle coolant systems are employed to ensure consistent cooling and efficient chip removal from the cutting zone. Proper jig and fixture design also aids in chip flow and prevents accumulation, maintaining a pristine machining environment.

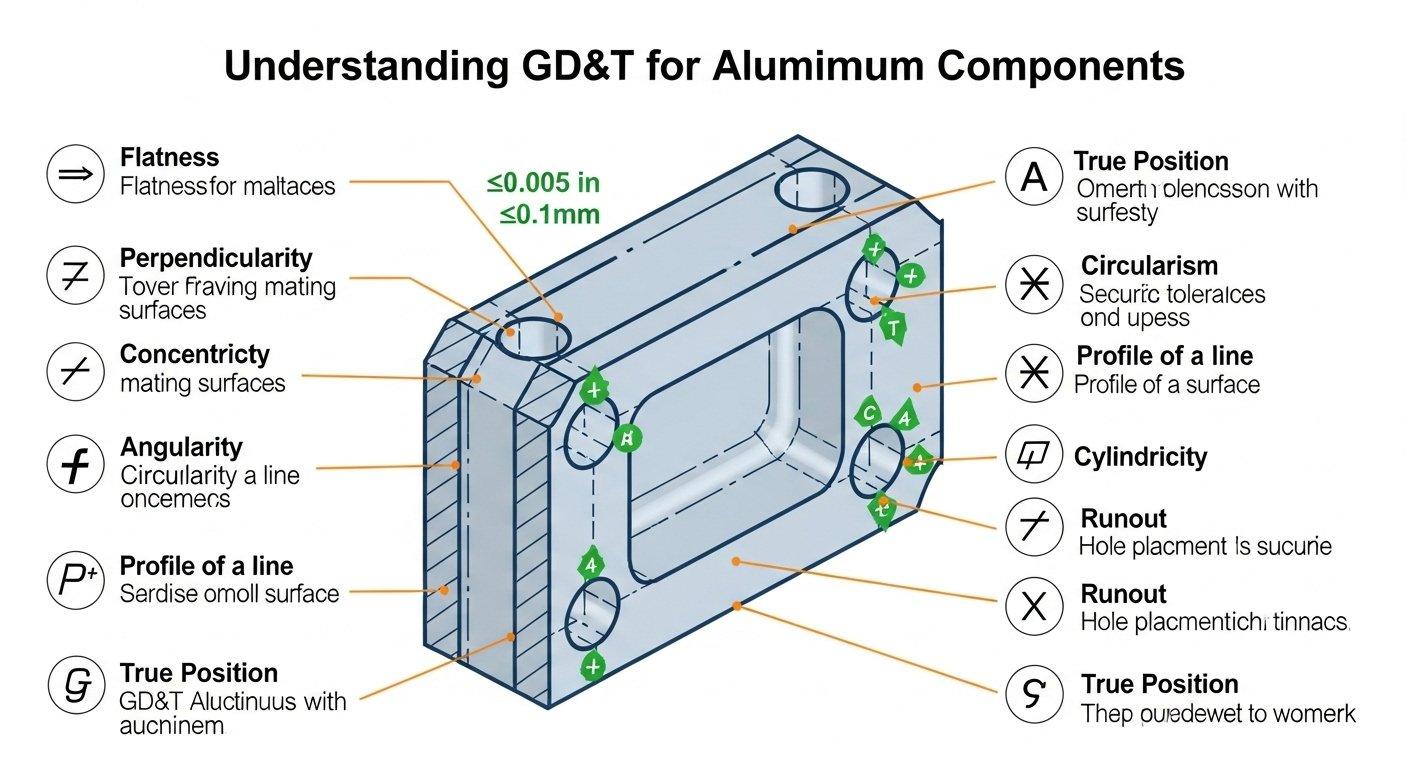

Aluminum Part Tolerances and Precision Control

Achieving and maintaining tight tolerances is a hallmark of high-precision aluminum CNC machining. Aluminum’s thermal expansion must be meticulously accounted for in machining strategies, especially for parts requiring micron-level accuracy. We employ advanced temperature control in our machining environments.

Geometric Dimensioning and Tolerancing (GD&T) principles are strictly adhered to, ensuring that critical features meet exact specifications. Our rigorous process includes frequent in-process measurements and post-machining verification using sophisticated inspection equipment.

Surface Finishing: Enhancing Aluminum CNC Part Aesthetics and Functionality

Beyond dimensional accuracy, the surface finish of aluminum CNC parts plays a crucial role in both aesthetics and functional performance. Proper surface treatment can improve corrosion resistance, hardness, wear resistance, and provide a desired appearance. Our capabilities encompass a wide range of finishing options.

Detailed Overview of Common Surface Treatment Processes

Selecting the right surface treatment is a complex decision, weighing aesthetic requirements against functional demands and cost. Each process imparts distinct properties to the aluminum surface, from decorative finishes to highly durable protective layers. We consult with clients to identify the optimal solution.

Anodizing: Principles and Applications

Anodizing is a widely used electrochemical process that converts the surface of aluminum into a durable, corrosion-resistant, anodic oxide finish. This finish is significantly harder than the base aluminum and offers excellent wear resistance. It can also be dyed in various colors, providing aesthetic appeal.

Type II (sulfuric) anodizing is common for decorative and protective applications, while Type III (hardcoat) anodizing provides a thicker, denser, and even more abrasion-resistant layer, ideal for demanding functional components. This process enhances both the lifespan and appearance of aluminum parts.

Sandblasting, Brushing, and Polishing Effects

For specific aesthetic and tactile requirements, mechanical finishes like sandblasting, brushing, and polishing are employed. Sandblasting (or bead blasting) creates a uniform matte finish, reducing reflectivity and hiding minor imperfections. Brushing produces a unidirectional satin finish, adding texture and visual depth.

Polishing achieves a high-luster, reflective surface, often used for decorative components where a mirror-like appearance is desired. These mechanical processes are often performed before anodizing or other coatings to establish the base surface texture.

Coating and Plating Options

Beyond anodizing, other coatings and platings are available to meet unique functional needs. Chemical conversion coating (e.g., Chromate Conversion Coating or Alodine) provides excellent corrosion resistance and acts as a primer for paint, without significantly altering the part’s dimensions.

Electroless nickel plating offers a uniform, hard, and corrosion-resistant layer. Powder coating provides a durable, colored protective finish, ideal for components exposed to harsh environments or requiring specific color matching. Each option is carefully evaluated for its suitability.

Quality Control: Ensuring Flawless Delivery of Aluminum CNC Components

Rigorous quality control is fundamental to our operations, ensuring every aluminum CNC component meets exact client specifications. Our multi-stage inspection process, from raw material verification to final product validation, guarantees superior quality and reliability. We implement industry-leading standards.

Dimensional Accuracy Inspection Methods

Dimensional accuracy is verified using a comprehensive suite of advanced inspection tools. Coordinate Measuring Machines (CMMs) provide highly precise 3D measurements of complex geometries, ensuring critical tolerances are met. Optical comparators and digital calipers are used for precise 2D measurements and general verification.

In-process gauging and statistical process control (SPC) methods are employed during machining to detect and correct deviations proactively. This proactive approach minimizes scrap rates and ensures consistent part quality throughout production runs.

Surface Defect Identification and Prevention

Surface integrity is critical for both aesthetics and performance. We meticulously inspect aluminum parts for defects such as tool marks, burrs, pitting, scratches, and discoloration. Visual inspection under controlled lighting is supplemented by tactile methods and specialized magnification tools.

Prevention strategies include optimized tooling, precise cutting parameters, effective chip evacuation, and careful post-machining handling. Our skilled technicians are trained to identify even subtle surface imperfections and implement corrective actions.

Application of Non-Destructive Testing Techniques

For critical applications, non-destructive testing (NDT) techniques are employed to assess internal material integrity without damaging the part. These methods include ultrasonic testing to detect subsurface flaws, and liquid penetrant inspection for surface-breaking discontinuities.

Such advanced testing ensures that components meet stringent industry standards for structural integrity and reliability, especially for aerospace or medical applications where failure is unacceptable. Our commitment to NDT provides an added layer of assurance.

Compliance with Industry Standards and Certifications

Our quality management system is fully compliant with international industry standards, including ISO 9001. We maintain detailed documentation for every project, providing full traceability from raw material to the finished component. This commitment to standards reflects our dedication to consistent quality.

Certifications and adherence to specific client-requested standards (e.g., AS9100 for aerospace, ISO 13485 for medical) further underscore our capability as a reliable, quality-focused manufacturing partner. We ensure all parts meet the required specifications and performance criteria.

Cost-Effectiveness: Aluminum CNC Project Planning and Optimization Strategies

Optimizing the cost-effectiveness of aluminum CNC machining projects requires a holistic approach, integrating design considerations, production scale, and transparent supplier collaboration. Our expertise helps clients achieve optimal results without compromising quality.

Design for Manufacturability (DFM) Principles

Implementing Design for Manufacturability (DFM) principles early in the design phase is paramount for reducing costs and improving lead times. Our engineers collaborate with clients to review designs, identify potential manufacturing challenges, and suggest modifications that simplify machining without sacrificing design intent.

DFM considerations include minimizing complex features, standardizing hole sizes, avoiding overly thin walls, and designing parts to be easily fixtured. Proactive DFM guidance ensures designs are optimized for efficient and precise production.

| DFM Principle | Impact on Cost & Manufacturability | Best Practice for Aluminum CNC |

|---|---|---|

| **Feature Complexity** | Affects machining time, tooling, and number of setups | Simplify complex curves, avoid deep pockets with small radii |

| **Wall Thickness** | Risk of distortion, increased machining time | Maintain adequate wall thickness to prevent chatter and warping |

| **Hole Design** | Tooling requirements, drilling stability | Standardize hole sizes, avoid very deep or non-standard holes |

| **Tolerances** | Machining time, inspection time, scrap rate | Specify tight tolerances only where functionally critical |

| **Surface Finish** | Machining passes, post-processing costs | Select finishes appropriate for function, avoid overly fine finishes where unnecessary |

Considerations for Batch Production and Prototyping

Our capabilities support both rapid prototyping and scalable batch production of aluminum components. For prototyping, speed and cost-efficiency are prioritized to validate designs quickly. For batch production, optimization focuses on jigging, automation, and process stability to ensure consistent quality at volume.

Effective project planning includes forecasting production volumes to select the most suitable machining strategies and equipment. We help clients scale from initial prototypes to full production seamlessly.

Supplier Selection and Cooperation Models

Choosing a direct, expert source manufacturer like ly-machining offers significant advantages. Our transparent pricing model ensures you understand all cost components, preventing unexpected expenses. Direct communication with our engineering team streamlines problem-solving and technical consultation.

We offer flexible cooperation models, adapting to client-specific supply chain requirements and project demands. This direct partnership fosters trust and reliability, essential for critical component manufacturing.

Total Life Cycle Cost Analysis

Beyond initial production costs, we encourage clients to consider the total life cycle cost (LCC) of their aluminum components. This includes material costs, manufacturing, quality control, assembly, and potential maintenance or replacement costs. Our focus on quality and durability aims to reduce LCC.

By optimizing material selection and manufacturing processes for long-term performance, we help clients achieve superior value over the entire operational life of their parts. This comprehensive approach ensures genuine cost-effectiveness.

Article Summary:

This guide details the critical aspects of aluminum CNC machining, from strategic material selection and precision processing to advanced surface finishing and stringent quality control. It highlights the importance of DFM principles and transparent supplier partnerships for cost-effectiveness.

By integrating deep technical expertise and comprehensive quality assurance, ly-machining empowers clients to achieve superior precision and reliability for their aluminum components, ensuring designs are transformed into high-quality, functional parts.

Frequently Asked Questions About Aluminum CNC Machining

Q1: What are the primary advantages of partnering with a direct manufacturer for aluminum CNC machining?

Working directly with a source manufacturer like ly-machining offers several key benefits. It ensures transparent pricing, eliminating hidden costs and intermediary markups, which provides better cost control.

Direct communication with our expert engineering team allows for faster problem-solving and tailored DFM guidance, optimizing your design for efficient manufacturing. This direct relationship also provides greater control over quality assurance processes and ensures more reliable lead times, fostering confidence and trust in your supply chain.

Q2: How does ly-machining ensure tight tolerances and high precision for complex aluminum parts?

Achieving tight tolerances for complex aluminum parts relies on a multi-faceted approach. We employ advanced multi-axis CNC machining centers, specialized cutting tools with optimized geometries, and precisely controlled cutting parameters to minimize material stress and thermal distortion.

Our climate-controlled manufacturing environment helps mitigate aluminum’s thermal expansion effects. Furthermore, rigorous in-process and post-machining quality control, utilizing advanced CMMs and optical comparators, verifies every critical dimension against GD&T specifications, ensuring micron-level accuracy.

Q3: What factors should clients consider when selecting a surface finish for their aluminum CNC components?

When selecting a surface finish, clients should consider both functional and aesthetic requirements. Functional factors include the need for enhanced corrosion resistance (e.g., anodizing, chemical conversion coating), increased hardness or wear resistance (e.g., hardcoat anodizing, electroless nickel plating), or improved adhesion for subsequent coatings.

Aesthetic considerations involve desired color, texture (e.g., sandblasting, brushing), and reflectivity (e.g., polishing). Our team provides expert consultation to help balance these factors with cost implications, ensuring the chosen finish optimally supports the part’s intended application and appearance.