The wrong material choice in rapid prototyping isn’t just a delay; it’s a direct pipeline to product failure, budget overruns, and lost market opportunities. Are you confident you’re making the right material decisions, or are costly compromises silently undermining your innovation?

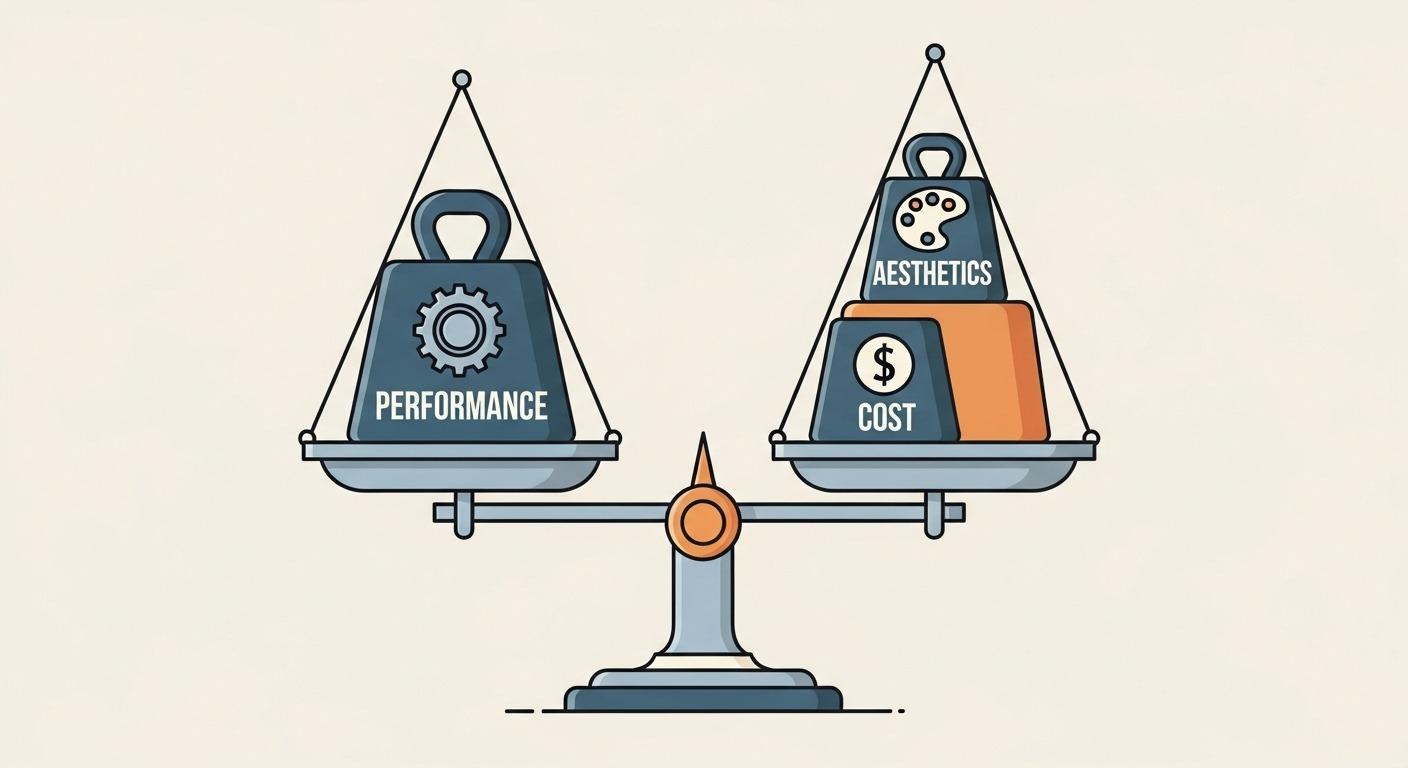

Engineers and designers constantly grapple with the complex interplay of functional performance, aesthetic appeal, and financial constraints. These decisions at the prototyping stage are critical, setting the trajectory for your final product’s success or failure.

This guide will demystify the process, offering a comprehensive framework to strategically select rapid prototyping materials that ensure optimal prototype performance, compelling aesthetics, and cost-effectiveness from the outset.

Optimal rapid prototyping necessitates a strategic material selection guide, meticulously balancing prototype performance, aesthetic requirements, and overall project cost to achieve product success.

Prototypes: Your Material Dilemma

Setting the Scene & Problem

The High Stakes of Wrong Material Choices

An incorrect material choice at the rapid prototyping phase can lead to significant repercussions, extending far beyond simple redesigns. Such errors often manifest as structural failures, functional compromises, and critical safety issues.

These challenges directly translate into increased development cycles, substantial rework costs, and missed market windows. The cumulative prototype performance cost can escalate dramatically, threatening project viability.

Why Prototyping Material Decisions Matter Now

In today’s fast-paced product development landscape, the need for agile and accurate prototyping is paramount. Early and informed material choices directly impact downstream manufacturing and product launch success.

Leveraging the right rapid prototyping materials from the start minimizes risks, validates designs efficiently, and preserves valuable resources. It underpins the reliability and market readiness of your final product.

Core Thesis & Content Preview

Master Material Balance for Prototypes

Achieving a harmonious balance between a prototype’s functional performance, visual aesthetics, and overall cost is the cornerstone of successful product development. This equilibrium ensures your prototype accurately represents the final product’s intent.

This article provides a structured material selection guide, empowering engineers and designers to make informed decisions. It helps navigate the complexities of rapid prototyping materials to deliver optimal outcomes.

Explore Performance, Aesthetics, Cost Strategies

We will delve into detailed strategies for evaluating material properties against specific performance requirements, understanding how material choices influence aesthetics in prototyping, and implementing cost-effective solutions. The goal is to optimize every aspect.

This holistic approach considers both immediate prototyping needs and long-term product lifecycle implications. It guarantees that initial material investments support broader project objectives.

Material Tips

Concept Definition & Basics

Decoding Material Properties for Prototypes

Understanding fundamental material properties is critical for making informed rapid prototyping material selections. Factors such as tensile strength, hardness, and impact resistance dictate a part’s structural integrity and durability.

Thermal stability, chemical resistance, and electrical conductivity are equally vital, depending on the operational environment. Meticulous consideration of these attributes directly influences prototype performance.

Table 1: Common Material Properties for Prototyping

| Property | Description | Relevance to Prototype Performance |

|---|---|---|

| Tensile Strength | Resistance to pulling forces | Structural integrity under load |

| Impact Resistance | Ability to absorb sudden shock | Durability, drop tests |

| Hardness (Shore/Rockwell) | Resistance to indentation or scratching | Wear resistance, surface finish |

| Thermal Stability | Performance at varying temperatures | Environmental application, heat exposure |

| Density | Mass per unit volume | Part weight, buoyancy |

Understanding Rapid Prototyping Processes

The choice of rapid prototyping materials is inextricably linked to the manufacturing process employed. CNC machining excels with a vast array of metals and engineering plastics, offering superior precision and surface finishes.

Additive manufacturing methods like SLA and FDM are ideal for complex geometries and specialized resins or thermoplastics. Each process has specific material compatibilities and limitations, impacting prototype performance.

Table 2: Common Rapid Prototyping Processes and Material Compatibility

| Process | Primary Material Types | Typical Applications |

|---|---|---|

| CNC Machining | Metals (Aluminum, Steel), Engineering Plastics (ABS, PC) | High precision, functional parts, end-use components |

| SLA 3D Printing | UV-curable Resins (clear, flexible, rigid) | Fine detail, smooth finish, visual prototypes |

| FDM 3D Printing | Thermoplastics (ABS, PLA, Nylon) | Economical, larger parts, conceptual models |

| Vacuum Casting | Polyurethanes, Silicones (replica materials) | Low-volume production, aesthetic models |

Relevance & Practical Value

Aligning Material Specs with Your Goals

Effective rapid prototyping begins by clearly defining the prototype’s intended function and environment. A part requiring high structural integrity for a demanding industrial application will necessitate different materials than a visual mock-up for consumer electronics.

Our material selection guide emphasizes matching precise material specifications to your project’s unique functional requirements. This ensures optimal prototype performance without unnecessary costs or compromises.

Practical Steps

Implementation Steps & Framework

A Structured Approach to Material Selection

A methodical framework for material selection minimizes trial-and-error and optimizes your prototype performance cost. Begin by defining all critical functional and aesthetic requirements, prioritizing them by importance.

Next, research suitable rapid prototyping materials based on these criteria, consulting technical datasheets and expert guidance. This comprehensive material selection guide ensures a systematic and informed decision-making process.

Table 3: Decision Framework for Material Selection

| Step | Description | Key Considerations |

|---|---|---|

| 1. Define Requirements | Outline functional, aesthetic, and environmental needs | Durability, temperature range, surface finish, volume |

| 2. Prioritize Criteria | Rank performance, aesthetics, and cost | Criticality of each factor to product success |

| 3. Material Research | Explore material properties and process compatibility | Datasheets, expert consultation, supplier capabilities |

| 4. Prototyping & Testing | Create samples, validate properties, iterate designs | Functional validation, aesthetic review, cost analysis |

| 5. Final Selection | Choose optimal material and process combination | Balance of all factors, long-term viability |

Avoid Common Prototyping Material Mistakes

A frequent error is over-specifying materials, leading to inflated prototype performance costs for capabilities not truly needed. Conversely, under-specifying can result in functional failures and expensive redesigns later in development.

Ignoring manufacturing constraints or neglecting crucial post-processing requirements are also common pitfalls. Our material selection guide proactively addresses these issues, ensuring a smoother prototyping journey.

Case Studies & Comparisons

Real-World Material Choices: Success Stories

Case Study: Optimizing Medical Device Enclosures

Problem: A client required a durable, aesthetically pleasing, and biocompatible enclosure prototype for a new portable medical device. They faced the challenge of high prototype performance cost if the chosen material failed sterilization or impact tests, potentially delaying regulatory approval.

Our Solution: ly-machining’s engineers provided a comprehensive material selection guide. We recommended a specific medical-grade ABS plastic, known for its impact resistance and compatibility with standard sterilization methods. Through a series of CNC-machined prototypes, we validated its mechanical properties and ensured a smooth, refined surface finish.

Result: The selected material successfully passed all functional and biocompatibility tests. The prototypes exhibited exceptional aesthetics in prototyping, which was crucial for user acceptance and regulatory submission. This strategic material choice led to accelerated product validation and significantly reduced overall project costs, impacting time-to-market positively.

Future Trends

Overcoming Obstacles & Solutions

Addressing Your Prototyping Material FAQs

Navigating the vast landscape of rapid prototyping materials can be challenging, with many common questions arising during the selection process. Our expertise ensures that these obstacles are met with clear, actionable solutions.

By preemptively addressing frequent concerns, we aim to streamline your decision-making. This approach minimizes uncertainties and maximizes the effectiveness of your material choices.

Advanced Strategies & Outlook

Emerging Materials and Techniques

The field of rapid prototyping materials is constantly evolving, with new compounds and fabrication techniques continually emerging. Advances in smart materials, sustainable alternatives, and hybrid manufacturing processes are expanding possibilities.

ly-machining remains at the forefront, integrating these innovations into our material selection guide. We ensure our clients benefit from the latest developments, enhancing both prototype performance and sustainability.

Key Actions

Core Takeaways Emphasized

Mastering Your Prototype Material Balance

Mastering the balance between prototype performance, aesthetics in prototyping, and cost is paramount for successful product development. It requires a deep understanding of rapid prototyping materials and their interaction with manufacturing processes.

Our comprehensive material selection guide empowers you to make strategic choices, ensuring your prototypes not only function flawlessly but also present compellingly and remain within budget.

Recapping Core Selection Insights

Remember to prioritize functional requirements, leveraging precise material properties to meet critical demands. Simultaneously, do not underestimate the impact of aesthetics, especially for market-facing products.

Always consider the holistic prototype performance cost, encompassing material expenses, manufacturing complexity, and potential post-processing. A balanced approach drives success.

Call to Action (CTA)

Unlock Your Prototype Material Potential

Stop guessing and start optimizing. Leverage our deep technical expertise as a source manufacturer to ensure your rapid prototyping material choices deliver performance, aesthetics, and cost-effectiveness.

Contact us today for a personalized material consultation and transparent quote for your next project. We are here to guide you through every step.

FAQ

What impacts material choice?

Functional requirements such as mechanical strength, thermal resistance, and chemical compatibility are primary drivers. Environmental factors and expected lifespan also heavily influence the decision.

The manufacturing process itself dictates suitable rapid prototyping materials. Cost and desired aesthetics in prototyping are further crucial considerations for product viability.

How does cost influence selection?

Material cost is a significant factor, but it’s essential to consider the total prototype performance cost, including machining, post-processing, and potential rework. Cheaper materials might lead to higher overall project expenses if they fail during testing.

Balancing upfront material expense with desired part properties and longevity is key. Our material selection guide helps navigate these trade-offs effectively, preventing future budget overruns.

Can aesthetics be prioritized?

Absolutely, especially for consumer-facing products or mock-ups where visual appeal and tactile feel are critical. Materials like polished acrylic, anodized aluminum, or specific resins can achieve superior aesthetics in prototyping.

However, aesthetic choices must still align with functional needs to avoid compromising the product’s integrity. We help identify materials that blend visual quality with necessary performance without compromise.