Precision Aluminum for Marine Sensor Housings

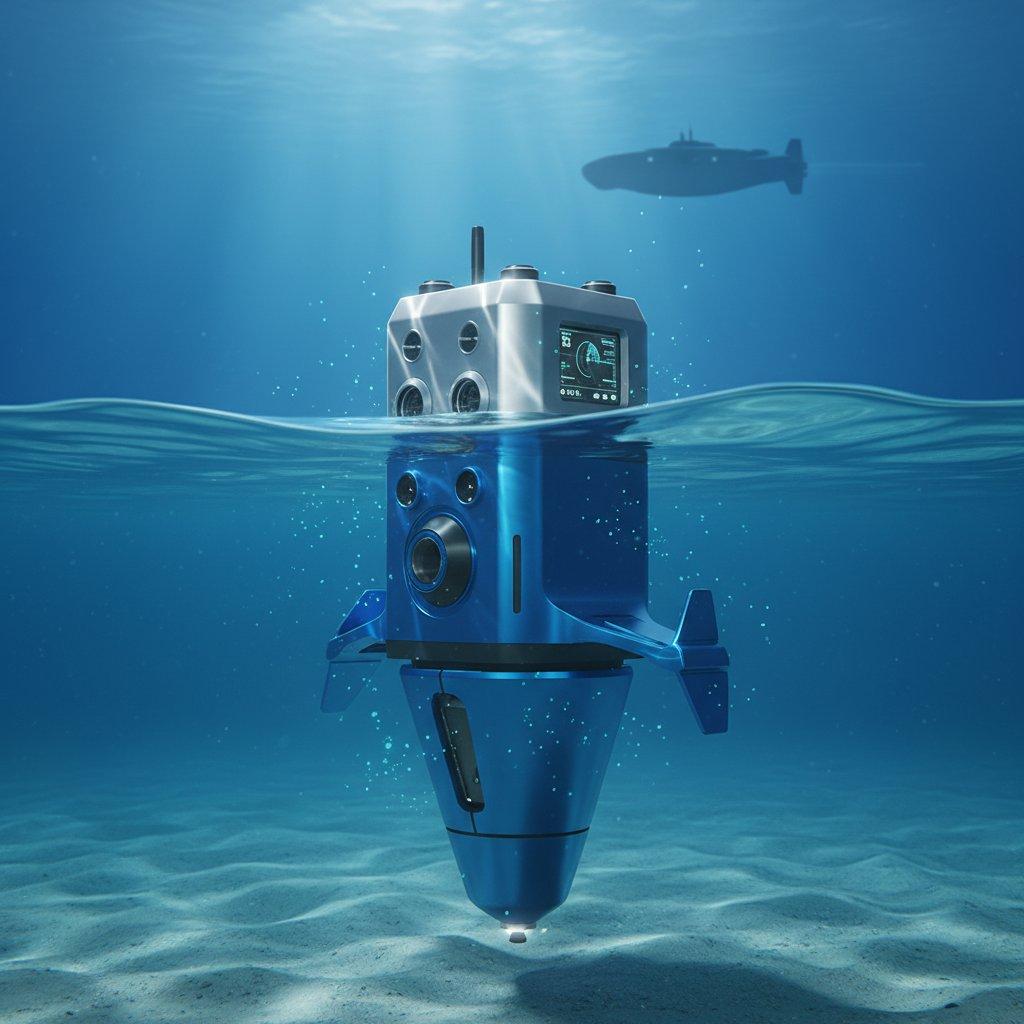

Navigating the depths of marine engineering demands absolute reliability for underwater sensor housings. In ly-machining’s experience, robust protection against extreme pressure and corrosion is paramount. ly-machining, as a leading aluminum CNC machining manufacturer, provides integrated surface anodizing solutions ensuring the longevity of your precision aluminum components for subsea environments.

Imagine the cost of an entire deep-sea mission lost due to a single corroded sensor housing. In marine engineering, the reliability of underwater components isn’t just a feature—it’s the foundation of success. ly-machining understands that failure is not an option when lives, data, and significant investments are at stake.

The challenges of the subsea world, from crushing pressures to aggressive salinity, demand extraordinary materials and manufacturing precision. This article details how ly-machining’s expertise in aluminum CNC machining services, coupled with integrated surface treatments, delivers custom aluminum CNC parts built to thrive beneath the waves. Discover how ly-machining partners with clients to ensure peak performance and unwavering trustworthiness.

Marine Engineering Demands for Sensor Housings

The environment below the ocean’s surface presents some of the most formidable challenges for mechanical components. Underwater sensor housings are not merely containers; they are critical protectors of sensitive electronics, demanding meticulous design and manufacturing. ly-machining focuses on delivering parts that withstand these harsh conditions.

Material Selection for Custom Aluminum CNC Parts

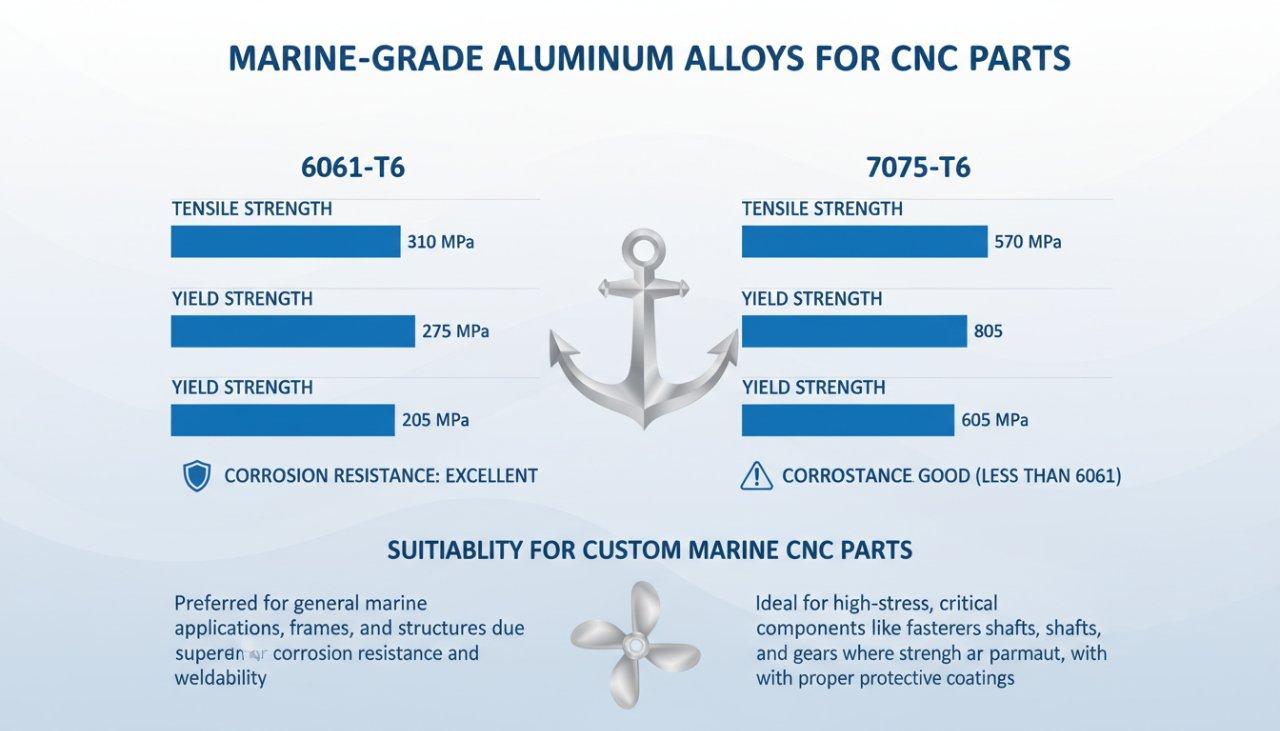

Selecting the right aluminum alloy is fundamental for marine applications. ly-machining critically assesses operational depth, salinity, temperature, and required lifespan to recommend optimal materials for custom aluminum CNC parts. Aluminum alloys like 6061-T6 are favored for their excellent strength-to-weight ratio and inherent corrosion resistance, which is further enhanced by surface treatments.

Other alloys, such as 7075-T6, offer superior strength for extreme pressure applications, though their corrosion resistance requires more advanced post-treatment. ly-machining’s material science experts guide clients through these critical choices, ensuring the chosen material meets all project specifications. This foundational step in precision aluminum machining is non-negotiable for subsea success.

| Aluminum Alloy | Key Properties for Marine Use | Primary Application |

|---|---|---|

| 6061-T6 | Good strength, weldability, corrosion resistance | General purpose, moderate depth |

| 7075-T6 | Very high strength, good fatigue resistance | Deep sea, high-pressure, critical components |

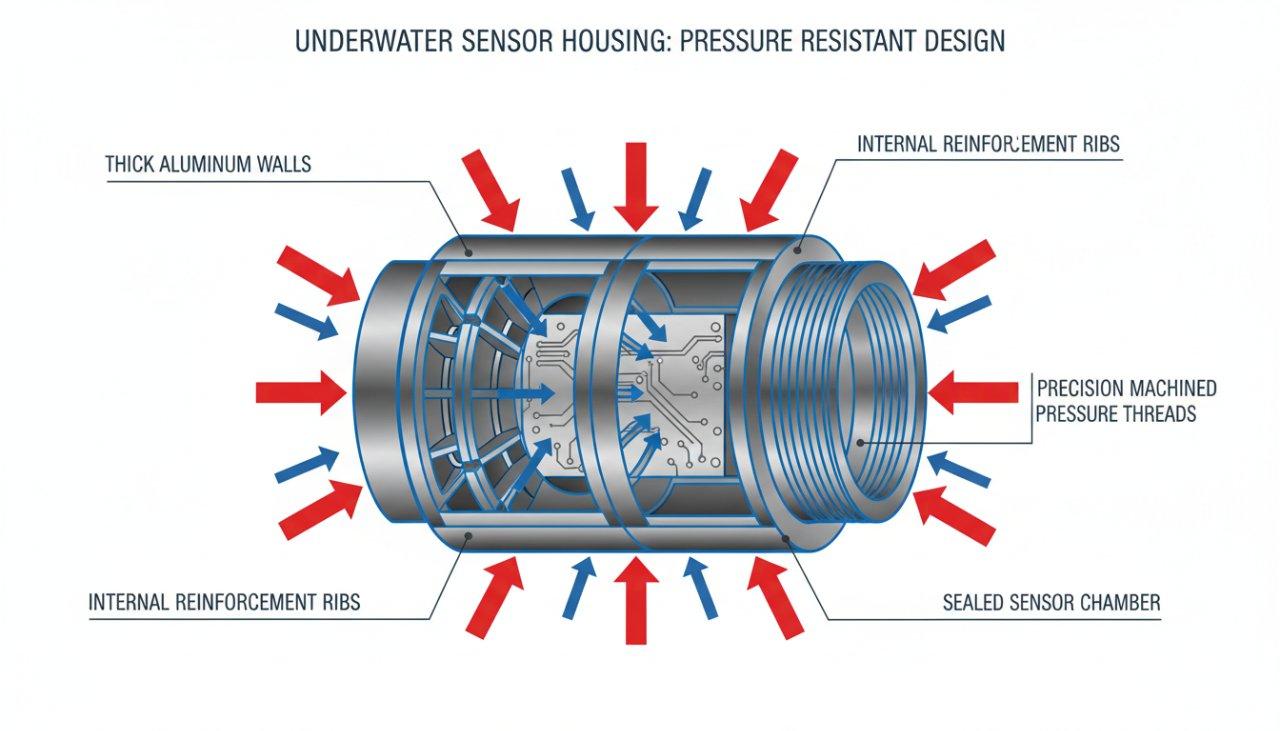

Pressure Resistance in Precision Aluminum Machining

Underwater sensor housings must resist immense hydrostatic pressure, which increases dramatically with depth. This demands exceptional structural integrity and precise dimensional control during precision aluminum machining. ly-machining’s engineering team calculates stress points and designs for maximum pressure resilience.

The design of wall thickness, internal reinforcing ribs, and geometry all contribute to the pressure rating. ly-machining uses advanced simulation software to validate designs against anticipated hydrostatic loads, ensuring watertight integrity and preventing catastrophic collapse. This rigorous approach is a hallmark of ly-machining’s comprehensive CNC machining services.

Mitigating Corrosion with Expert CNC Machining

Corrosion is the single greatest threat to underwater components, especially in saltwater. While aluminum offers some natural resistance, direct exposure leads to galvanic corrosion when dissimilar metals are present, or pitting corrosion over time. Expert CNC machining techniques at ly-machining focus on creating flawless surfaces that minimize potential corrosion sites.

Proper surface preparation is crucial before any protective coating. ly-machining ensures surfaces are free from impurities and micro-crevices, which can harbor corrosive elements. This meticulous approach extends the lifespan of custom aluminum CNC parts, safeguarding sensitive internal electronics from the relentless marine environment.

Designing Robust Underwater Sensor Enclosures

Designing for the deep requires a holistic approach where every detail impacts performance and longevity. At ly-machining, the fusion of engineering insight with manufacturing capability creates truly robust underwater sensor enclosures. ly-machining’s comprehensive CNC machining services cover every aspect from concept to final product.

Critical Design Factors for Custom Aluminum CNC Parts

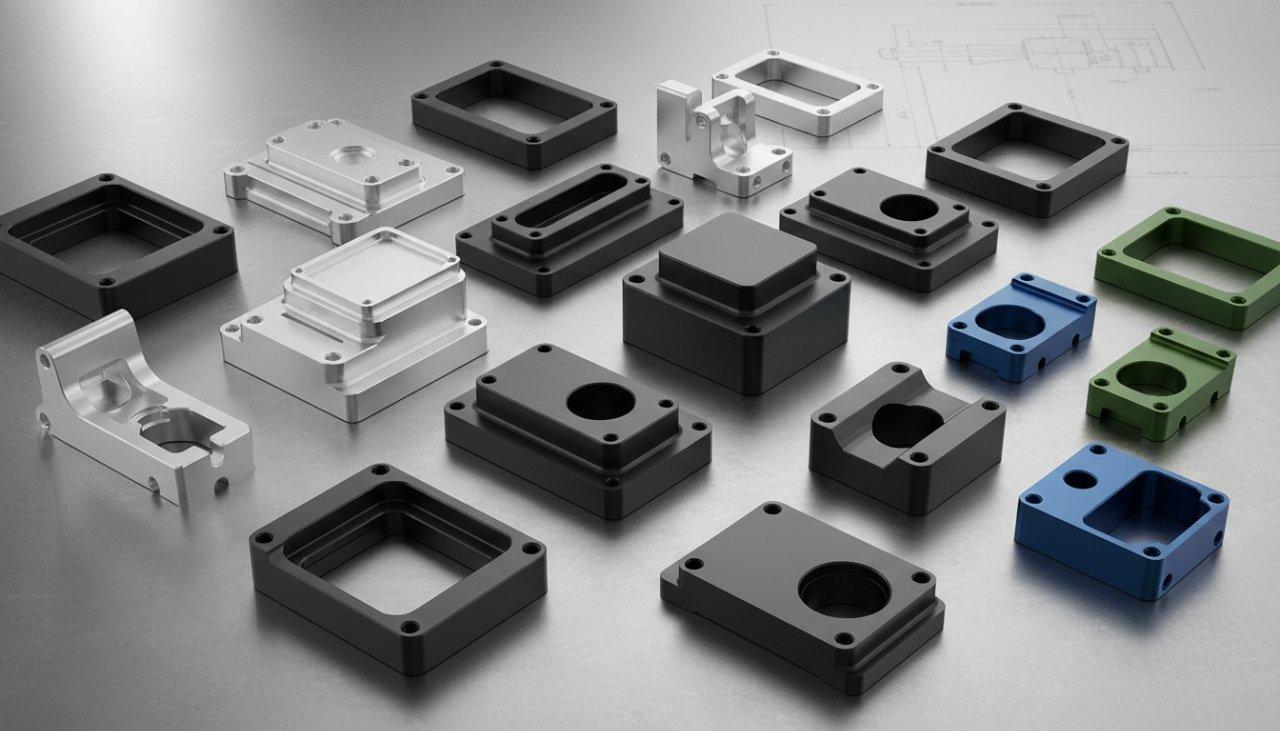

Critical design factors for custom aluminum CNC parts in marine applications include geometric stability, minimal stress concentrations, and ease of assembly/disassembly for maintenance. ly-machining collaborates closely with clients, offering Design for Manufacturability (DFM) insights from the outset. This ensures designs are not only functional but also efficient to produce.

Considerations like thread design for secure closures, optimal locations for O-ring grooves, and overall component balance are meticulously reviewed. ly-machining’s expertise helps refine designs to enhance performance while controlling manufacturing costs through intelligent CNC machining. This proactive approach saves time and resources in the long run.

Achieving Watertight Seals through CNC Machining

The integrity of an underwater sensor housing hinges entirely on its watertight seals. Precision aluminum machining is indispensable for creating the exact dimensions and surface finishes required for effective sealing. ly-machining consistently achieves the tight tolerances necessary for O-ring and gasket grooves, ensuring perfect compression and zero ingress.

Surface finish within seal areas is critically important; rough surfaces can create micro-paths for water. ly-machining’s advanced CNC machining equipment and skilled technicians guarantee surface finishes that meet or exceed industry standards for watertight applications, typically Ra values as low as 0.8 µm or better for sealing surfaces. This prevents water penetration even under high pressure.

Tolerances in Precision Aluminum Machining

Precision in every dimension is non-negotiable for underwater components. ly-machining excels in holding extremely tight tolerances, often down to ±0.005mm or even finer, depending on the part geometry and material. This level of accuracy is vital for mating parts, ensuring proper fit, form, and function, especially for critical sealing surfaces.

Dimensional accuracy directly impacts the performance of sensors and the longevity of the housing. ly-machining’s state-of-the-art CNC machining centers are equipped with advanced metrology tools, including CMMs (Coordinate Measuring Machines), to verify every part against strict specifications. This commitment to precision aluminum machining is what sets ly-machining apart.

| Tolerance Class | Typical Range | Application Example for Marine Parts |

|---|---|---|

| Standard | ±0.1mm | Non-critical mounting features |

| Fine | ±0.025mm | General fit, external dimensions |

| Precision | ±0.005mm | Critical sealing surfaces, sensor mounts |

The Role of Surface Anodizing for Durability

Even the most precisely machined aluminum requires advanced surface protection to survive the marine environment. Anodizing is a crucial post-machining process that significantly enhances the durability and corrosion resistance of aluminum CNC parts. ly-machining integrates this essential step into its comprehensive manufacturing process.

Anodizing Types for Marine Aluminum CNC Parts

Two primary types of anodizing are commonly used for marine aluminum CNC parts: Type II (Sulfuric Acid Anodize) and Type III (Hardcoat Anodize). Type II provides excellent corrosion resistance and can be dyed for aesthetic purposes or part identification. It creates a moderately thick, durable oxide layer.

Type III, or hardcoat anodizing, generates a much thicker, denser, and harder oxide layer. This provides superior abrasion resistance and enhanced corrosion protection, making it ideal for the harshest subsea applications where components face constant wear and extreme conditions. ly-machining helps clients choose the right anodizing type based on their specific application requirements.

| Anodizing Type | Key Characteristics for Marine Use | Thickness (typical) | Hardness (typical) |

|---|---|---|---|

| Type II | Good corrosion, decorative, moderate wear | 2.5-25 µm | 250-400 HV |

| Type III | Superior corrosion, extreme wear, very hard | 25-150 µm | 400-600 HV |

Enhancing Corrosion Resistance in CNC Machining

Anodizing chemically converts the aluminum surface into a hard, porous oxide layer that is then sealed. This creates a barrier much more robust than the aluminum itself. ly-machining ensures precise control over the anodizing process, from pre-treatment cleaning to the sealing phase, to maximize the corrosion resistance of every part.

For marine applications, specialized sealing processes are often employed, such as hot water sealing or dichromate sealing, to close the pores and further enhance protection against saltwater ingress and chemical degradation. This level of detail in ly-machining’s aluminum CNC machining services guarantees long-term performance.

Integrated Finishing: A Key to Precision Aluminum

Integrated finishing means that surface treatments like anodizing are considered from the initial design phase, not as an afterthought. ly-machining’s engineers account for potential dimensional changes due to anodizing layer thickness and how it interacts with critical tolerances. This ensures that the final precision aluminum part, after anodizing, still meets all specifications.

The seamless integration of CNC machining with post-processing capabilities under one roof at ly-machining streamlines the manufacturing process. This reduces lead times, minimizes logistical complexities, and ensures consistent quality. It is a testament to ly-machining’s expertise as an aluminum CNC machining manufacturer.

Choosing Aluminum CNC Machining Manufacturers

Selecting the right partner for your marine engineering projects is critical. Not all aluminum CNC machining manufacturers possess the specialized knowledge and capabilities required for subsea applications. ly-machining encourages thorough due diligence when choosing CNC machining services.

What to Look for in CNC Machining Services

When evaluating CNC machining services, look beyond basic machining capabilities. Prioritize manufacturers with proven experience in marine-grade materials and tight tolerances. Certifications like ISO 9001 and AS9100 demonstrate a commitment to rigorous quality management systems.

Assess their technical support and willingness to engage in DFM discussions. A reliable manufacturer should offer transparent communication, detailed quoting, and a clear understanding of your project’s unique challenges. ly-machining consistently meets and exceeds these benchmarks.

Benefits of Partnering with Source Manufacturers

Partnering directly with source manufacturers like ly-machining offers significant advantages. It eliminates middlemen, often resulting in more competitive pricing and direct access to the manufacturing floor and engineering teams. This direct line of communication streamlines problem-solving and ensures project clarity.

Source manufacturers have complete control over the entire production process, from material procurement to final inspection and finishing. This vertical integration allows for superior quality control and greater flexibility in accommodating custom aluminum CNC parts requirements. ly-machining’s end-to-end capabilities deliver peace of mind.

Quality Assurance in Precision Aluminum Machining

Robust quality assurance protocols are non-negotiable for precision aluminum machining, especially for safety-critical marine components. ly-machining implements multi-stage inspection processes, including in-process checks, first article inspections, and comprehensive final inspections. Using advanced metrology equipment ensures every dimension is within tolerance.

Documentation is equally important; ly-machining provides material certifications, inspection reports, and traceability records for all components. This commitment to quality assurance is vital for industries where failure is not an option, upholding ly-machining’s reputation as a trusted aluminum CNC machining manufacturer.

Our Expertise in Custom Aluminum CNC Parts

ly-machining stands as a premier provider of custom aluminum CNC parts, specifically engineered for the demanding world of marine engineering. ly-machining’s dedicated team combines deep technical knowledge with cutting-edge manufacturing capabilities to solve the most complex challenges. ly-machining delivers unparalleled precision and reliability.

Advanced CNC Machining Capabilities for Complex Parts

ly-machining invests in state-of-the-art multi-axis CNC machining centers, capable of producing highly complex geometries with exceptional accuracy. This allows for intricate internal features, precise sealing grooves, and robust structural elements critical for underwater sensor housings. Our capabilities extend to specialized tools and programming techniques.

ly-machining’s engineers are experts in optimizing tool paths and machining strategies to achieve superior surface finishes and minimize material stress. This ensures that every custom aluminum CNC part is not only dimensionally accurate but also structurally sound, ready for the harshest marine conditions.

Transparent Pricing for Aluminum CNC Machining Services

ly-machining believes in transparency throughout the entire process, including pricing for aluminum CNC machining services. ly-machining provides detailed quotes that break down costs, offering clarity on material, machining time, finishing, and quality control. ly-machining aims to provide maximum value without hidden fees.

ly-machining’s efficiency as a source manufacturer contributes to competitive pricing while upholding the highest quality standards. ly-machining offers cost-effective solutions for both high-volume production and low-volume prototyping, ensuring that clients receive exceptional value for their investment in precision aluminum parts.

Case Study: Reliable Underwater Housings via CNC

A leading oceanographic research firm approached ly-machining with a persistent problem: their existing underwater sensor housings for deep-sea data loggers were failing prematurely due to galvanic corrosion and pressure-induced leaks. This led to significant data loss and costly mission rescheduling, hindering their critical research. The firm required a robust solution for custom aluminum CNC parts.

ly-machining’s solution involved a multi-pronged approach. First, ly-machining collaborated with their engineers on a DFM review, optimizing the housing geometry for pressure distribution. Second, ly-machining selected 7075-T6 aluminum for its superior strength and employed precision CNC machining to create ultra-tight tolerance sealing surfaces. Finally, ly-machining applied a MIL-SPEC Type III hard anodize with a specialized sealing process, ensuring maximum corrosion and abrasion resistance. Post-production, ly-machining conducted rigorous pressure testing and salt spray testing.

The result was a series of custom aluminum CNC parts that consistently exceeded performance expectations. The new housings deployed successfully in depths up to 6,000 meters, delivering flawless data for over three years without a single leak or sign of corrosion. The research firm not only saved significant operational costs but also gained invaluable confidence in their subsea data acquisition, solidifying their trust in ly-machining’s aluminum CNC machining services.

Partner with Us for Your Next Project

When the integrity of your marine engineering project depends on exceptional precision and unwavering durability, choose a partner with proven expertise. ly-machining is dedicated to delivering superior custom aluminum CNC parts designed for the most challenging subsea environments. ly-machining’s comprehensive CNC machining services are your guarantee of success.

Get a Quote for Your Custom Aluminum CNC Parts

Ready to experience the difference that expert aluminum CNC machining manufacturers can make? Contact ly-machining today to get a detailed, transparent quote for your custom aluminum CNC parts. ly-machining’s team is prepared to review your specifications and provide a competitive estimate for precision aluminum components.

Technical Consultation on Precision Aluminum Parts

Do you have complex requirements for precision aluminum parts for your marine application? ly-machining offers technical consultations with its experienced engineering team. ly-machining will discuss material selection, design optimization, and surface treatment options to ensure your project’s success. Let’s solve your marine engineering challenges together.

FAQ Section

Why is anodizing essential for marine aluminum?

Anodizing chemically converts the aluminum surface into a hard, protective oxide layer. This barrier significantly enhances corrosion resistance against saltwater and abrasion, which is critical for the longevity of aluminum CNC machining components in harsh marine environments.

What precision levels can ly-machining achieve?

ly-machining’s advanced CNC machining capabilities allow for extremely tight tolerances, often down to ±0.005mm or finer. This level of precision is vital for creating reliable watertight seals and ensuring the proper fit and function of custom aluminum CNC parts.

How does ly-machining ensure product reliability?

ly-machining ensures reliability through rigorous material selection, advanced precision aluminum machining, integrated surface anodizing, and multi-stage quality assurance checks. This comprehensive approach, including DFM and extensive testing, guarantees durable, high-performing components for marine engineering.