Is your custom CNC machined part failing to meet its full potential because of the *wrong* surface finish? You’re leaving performance, durability, and aesthetics on the table, and potentially risking costly product failures. Discover how choosing the right treatment can transform your components from functional to exceptional.

Understanding the critical role of optimal surface treatment processes is paramount for any high-performance custom CNC machining project. This guide will illuminate the essential choices, empowering you to make informed decisions that elevate your components.

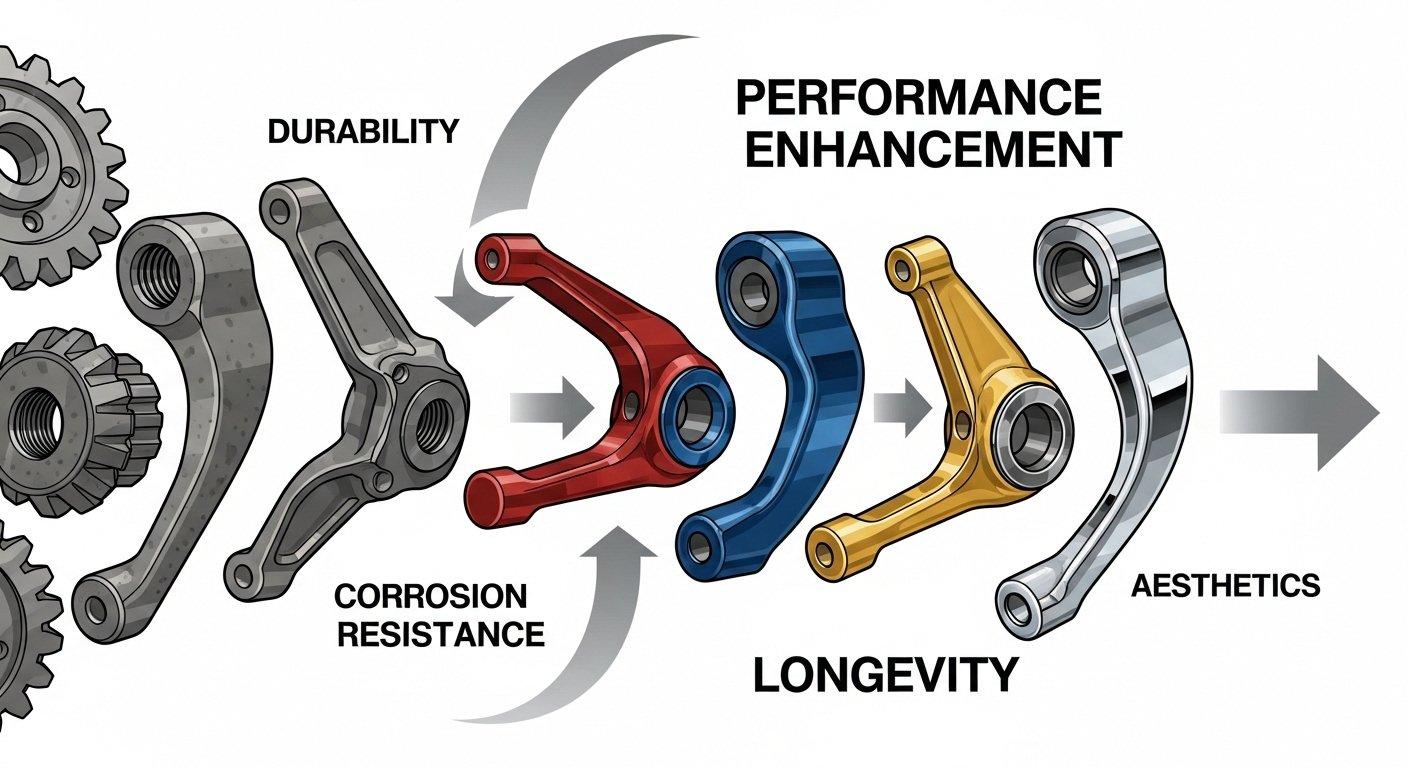

Unlock superior performance, aesthetics, and longevity for your custom CNC machined parts with our factory-direct, high-quality surface treatment solutions.

Unlocking Peak Part Performance

Setting the Stage: Why Finishes Matter

The Hidden Challenge of Perfect Parts

The precision achieved through custom CNC machining is only half the equation for a truly excellent component. Without the correct surface treatment processes, even the most accurately machined part can fall short of its functional and aesthetic requirements. This oversight often leads to unforeseen operational limitations.

Why Surface Finishing Demands Attention

A meticulously chosen machining surface finish can profoundly influence a part’s lifespan, resistance to wear and corrosion, electrical conductivity, and even its tactile feel. It is not merely an aesthetic choice, but a critical engineering decision that impacts performance and reliability.

Your Path to Informed Decisions

What This Guide Will Deliver

This guide serves as a comprehensive resource, demystifying the complexities of CNC surface finishing. We will delve into the technical specifics of six common surface treatment processes, providing insights for engineers and procurement professionals alike.

Inside Your Custom Finish Journey

Our aim is to equip you with the knowledge needed to specify the ideal machining surface finish for your unique custom CNC machining applications. This clarity ensures that every component meets its design intent, from prototype to production.

Finish Fundamentals: Beyond Aesthetics

Decoding Surface Treatment Basics

Understanding Key Finish Concepts

Surface treatment processes involve applying a thin layer of material or altering the surface properties of a custom CNC machined part. This modification can be mechanical, chemical, or electrochemical, each method yielding distinct functional characteristics. The selection dictates the final machining surface finish.

How Finishes Enhance Part Properties

The primary goal of CNC surface finishing is to impart specific properties that the base material alone may lack or to optimize existing ones. This includes increasing hardness, improving lubricity, enhancing electrical insulation or conductivity, and providing a decorative appeal.

Here are key attributes enhanced by various surface finishes:

| Attribute Enhanced | Example Finish Type |

|---|---|

| Corrosion Resistance | Anodizing, Plating |

| Wear Resistance | Hard Anodizing, Nitriding |

| Hardness | Electroless Nickel, Carburizing |

| Aesthetics (Color, Luster) | Polishing, Powder Coating |

| Electrical Conductivity | Gold Plating |

| Insulation | Anodizing |

Real-World Impact on Your Projects

Direct Benefits for Your CNC Components

Implementing the correct CNC surface finishing techniques directly translates to extended product lifecycles and enhanced functional reliability. For industries ranging from medical devices to aerospace, these benefits are critical for operational success and regulatory compliance.

The 6 Essential CNC Surface Finishes

Selecting Optimal Treatment for CNC

Choosing the Right Process

The choice of surface treatment processes for custom CNC machining is multifaceted, considering material compatibility, environmental exposure, functional demands, and cost. Each finish offers a unique set of advantages and limitations that must be carefully evaluated.

Avoiding Common Finishing Errors

Misjudging the application requirements or material properties can lead to suboptimal machining surface finish choices, resulting in premature part failure or unnecessary expenses. Consulting with experienced engineers can mitigate these risks.

Here are six common surface treatment processes:

Anodizing: Enhancing Aluminum Durability

Anodizing is an electrochemical passivation process used to increase the thickness of the natural oxide layer on the surface of aluminum parts. This process significantly improves corrosion and wear resistance, and it allows for a wide range of aesthetic colors.

| Anodizing Type | Primary Benefit | Common Thickness |

|---|---|---|

| Type II (Sulfuric) | Decorative & Protective | 5-25 microns |

| Type III (Hardcoat) | High Wear Resistance | 25-150 microns |

Electroless Nickel Plating: Precision & Corrosion Resistance

Electroless nickel plating (ENP) deposits a uniform layer of nickel-phosphorus alloy without an external electrical current. This process is highly valued for its exceptional corrosion and wear resistance, hardness, and the ability to coat complex geometries evenly.

| ENP Characteristic | Value / Property |

|---|---|

| Coating Uniformity | Excellent, even on complex shapes |

| Hardness | 400-700 Vickers (as plated) |

| Corrosion | Superior, salt spray up to 1000h |

Powder Coating: Aesthetic Versatility and Protection

Powder coating applies a free-flowing, dry powder that is then cured under heat to create a hard finish. It offers excellent durability, impact resistance, and a broad spectrum of colors and textures, making it ideal for both protective and decorative applications on various metals.

| Powder Coating Advantage | Description |

|---|---|

| Durability | Resistant to chipping, scratching, fading |

| Environmental | VOC-free, minimal waste |

| Aesthetic Options | Wide range of colors, textures, and effects |

Bead Blasting: Controlled Surface Texture

Bead blasting is a mechanical surface treatment processes that uses fine glass beads to create a uniform, matte, or satin finish on parts. It effectively removes minor surface imperfections, improves aesthetic appeal, and can reduce glare, making it suitable for cosmetic and functional applications.

| Bead Blasting Effect | Typical Outcome |

|---|---|

| Surface Roughness Control | Achieves specific Ra values |

| Stress Relieving | Can reduce residual stress |

| Aesthetic | Uniform, non-reflective matte finish |

Polishing: Achieving Reflective Smoothness

Polishing is a mechanical finishing process that removes surface irregularities, scratches, and other imperfections to achieve a smooth, often reflective, surface. This process enhances aesthetics, improves hygiene by reducing surface adhesion, and can also increase corrosion resistance.

| Polishing Specification | Common Materials | Applications |

|---|---|---|

| Mirror Finish (Ra < 0.05) | Stainless Steel, Aluminum | Medical, Optical, Decorative |

| Satin Finish (Ra 0.1-0.4) | Various Metals | Consumer Goods, Architectural |

Passivation: Optimizing Stainless Steel Resistance

Passivation is a chemical surface treatment for stainless steel that removes free iron from the surface, enhancing its natural corrosion resistance. This process forms a protective chromium oxide layer, making the machining surface finish more inert and less reactive to corrosive environments.

| Passivation Benefit | Description |

|---|---|

| Corrosion Prevention | Removes surface contaminants, promotes oxide layer |

| Material Integrity | Preserves original part dimensions |

| Industry Standard | Essential for medical and food-grade components |

Success Stories & Expert Insights

Case Studies: Finishes in Action

Observing how the right CNC surface finishing can transform project outcomes underscores the importance of this technical discipline. Successful applications often hinge on a collaborative approach between the client and the custom CNC machining provider.

Overcoming Challenges, Gaining Edge

Troubleshooting & Expert Solutions

Your Surface Finish FAQs Answered

Addressing common queries related to CNC surface finishing and material compatibility is crucial for project success. Our engineers frequently provide guidance on how to select the best surface treatment processes.

Advanced Strategies & Future Trends

Mastering Next-Level Finish Optimization

The landscape of custom CNC machining is continually evolving, with advancements in surface treatment processes offering new possibilities for performance and aesthetic enhancements. Staying abreast of these trends ensures optimal component design.

Elevate Your CNC Machining Today

Key Takeaways for Smart Finishing

Recap: Your Finish Strategy Roadmap

Selecting the optimal machining surface finish is a critical step in custom CNC machining that dictates functionality, durability, and aesthetics. By understanding the six key surface treatment processes, you can significantly enhance your product’s performance and longevity.

Reinforcing Core Finish Learnings

Partnering with a knowledgeable custom CNC machining provider like ly-machining ensures access to deep technical expertise. Our experience in CNC surface finishing empowers you to make informed decisions for your most demanding projects.

Ready for Superior CNC Parts?

Get Your Custom CNC Machining Quote

Proactive engagement with finishing experts ensures that your custom CNC machining parts receive the treatment they deserve. This collaborative approach minimizes risks and maximizes component potential from the outset.

Case Study

Problem: A client in the medical device industry required custom CNC machined components for a new surgical instrument. These parts, made from 316L stainless steel, needed exceptional corrosion resistance and biocompatibility, but initial prototypes exhibited minor surface imperfections that could compromise sterilization and long-term performance.

Our Solution: Our engineers at ly-machining recommended a multi-stage surface treatment process. After precision CNC machining, the parts underwent a meticulous electropolishing process to achieve an ultra-smooth, uniform surface finish, removing micro-burrs and enhancing cleanliness. This was followed by a comprehensive passivation treatment in accordance with ASTM A967 standards.

Result: The combination of electropolishing and passivation effectively eliminated surface imperfections, drastically improved corrosion resistance, and ensured the necessary biocompatibility. The client’s surgical instruments passed stringent regulatory tests, leading to successful product launch and significant market acceptance, directly attributing their success to the optimized machining surface finish.

Call to Action:

Ready to elevate your custom CNC parts with the perfect surface finish? Contact our technical experts today for a free consultation and transparent quote. Let us help you achieve unparalleled performance and aesthetics for your next project.

FAQ: What is CNC surface finishing?

CNC surface finishing encompasses various processes applied to custom CNC machined parts to modify their surface properties. These processes enhance aesthetics, improve durability, or impart specific functional characteristics like corrosion or wear resistance.

The choice of finish is critical for a part’s overall performance and longevity in its intended application. It is an integral part of high-quality custom CNC machining.

Why is machining surface finish important?

The machining surface finish directly impacts a part’s functionality, lifespan, and aesthetic appeal. A proper surface treatment can prevent corrosion, increase hardness, reduce friction, or prepare the surface for subsequent coatings or assembly.

It ensures that custom CNC machined components perform reliably under operational conditions. Neglecting this aspect can lead to premature failure or non-compliance with industry standards.

Which surface treatment is best for my part?

The “best” surface treatment process depends entirely on the part’s material, intended application, environmental exposure, and budget. For aluminum, anodizing is often ideal for protection and color.

For stainless steel, passivation enhances corrosion resistance, while electroless nickel plating offers versatility for many metals requiring hardness and wear resistance. Consulting with our technical team at ly-machining is recommended to determine the optimal solution.