Achieving critical tolerances in high-end CNC machining relies on expert tolerance management, precision machining services, and rigorous quality control for custom CNC parts.

Is your next breakthrough innovation stalled by the seemingly impossible challenge of sub-micron precision? The truth is, delivering truly high-end custom CNC parts isn’t just about advanced machines—it’s about mastering tolerance and precision management at every single

In our experience, manufacturers often struggle to find partners who can consistently meet the stringent demands of modern engineering. Inconsistent quality can lead to costly rework, project delays, and ultimately, product failure.

This guide will demystify the complexities of achieving ultra-high precision in custom CNC machining, detailing the strategies and expertise essential for success. Discover how ‘ly-machining’ transforms your most demanding designs into flawlessly executed components.

Achieving Ultimate CNC Precision

Why Precision Matters in High-End Parts

For industries like aerospace, medical devices, and high-tech electronics, the performance and reliability of a product are directly tied to the precision of its components. Even minuscule deviations can compromise functionality.

High-end CNC machining demands that parts meet exact specifications to ensure seamless assembly, optimal performance, and long-term durability. This is where precision machining services truly differentiate themselves.

Impacts of Poor Tolerance Control

In our experience, inadequate tolerance management can lead to a cascade of costly problems. Parts may not fit together correctly, requiring time-consuming manual adjustments or complete rejection.

This not only increases manufacturing costs but also causes significant delays in product development and market launch. It underscores why effective tolerance management CNC is non-negotiable for custom CNC parts.

Tolerance Management Basics

What Are Engineering Tolerances?

Engineering tolerances define the permissible variations in a part’s dimensions, form, orientation, and location from its nominal design. They are the cornerstone of interchangeable parts manufacturing.

They ensure that components produced within specified limits will assemble and function correctly, even if they are not absolutely identical. This is critical for high-volume, high-precision custom CNC parts.

Dimensional vs. Geometric Tolerances

Dimensional tolerances specify the acceptable size variations of features, typically along linear measurements. They are expressed as a plus/minus deviation from a nominal dimension.

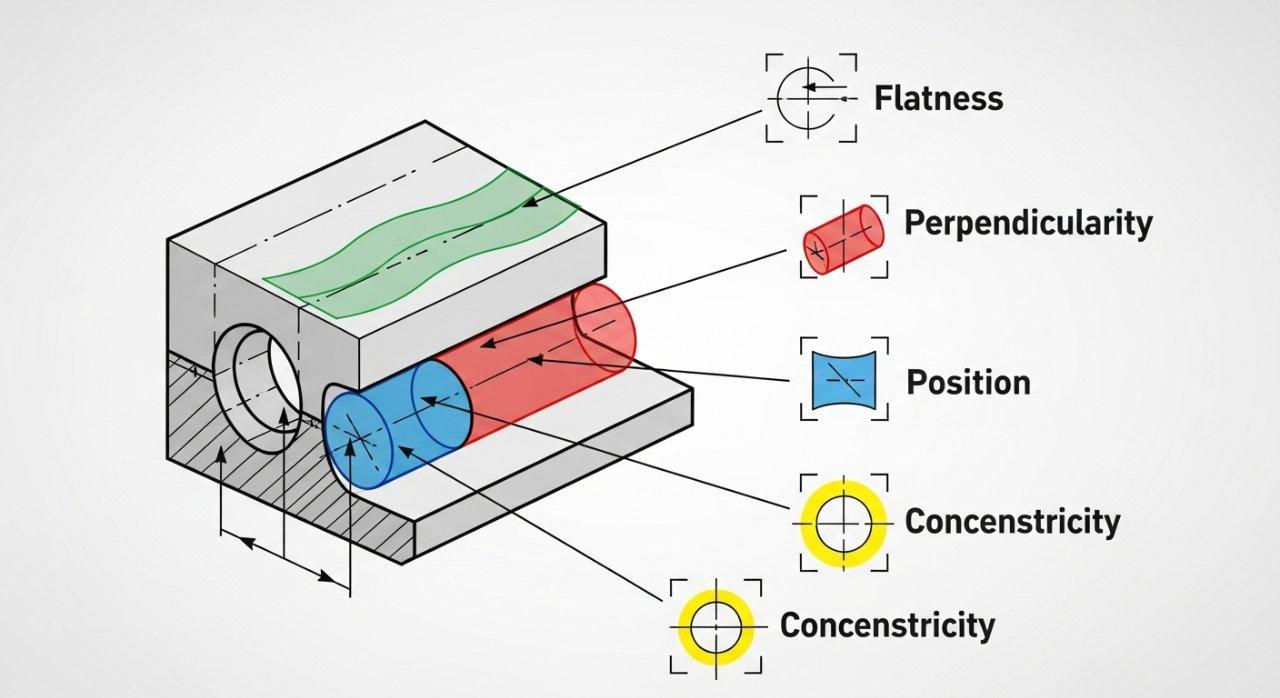

Geometric Dimensioning and Tolerancing (GD&T), on the other hand, controls the form, orientation, location, and runout of features. GD&T ensures critical relationships between features are maintained, which is vital for high-end CNC machining.

ISO and ASME Tolerance Standards

Globally, ISO and ASME define the standards for engineering drawings and tolerances. ISO 2768 is a common general tolerance standard, while ASME Y14.5 is widely used in North America for GD&T.

Adherence to these standards ensures clarity, consistency, and interoperability across different manufacturing partners and regions. We rigorously apply these standards in our precision machining services.

Table: Comparison of GD&T Categories

| Category | Description | Example (Symbol) |

|---|---|---|

| Form Tolerances | Control the shape of a feature. | Flatness (⏏) |

| Orientation | Control the tilt of a feature relative to a datum. | Perpendicularity (⟂) |

| Location | Control the position of a feature relative to a datum. | Position (⌖) |

| Profile Tolerances | Control the shape of a feature’s surface or line. | Profile of a Surface (⌒) |

Understanding CNC Machining Precision

Defining Precision in Machining

In the context of custom CNC parts, precision refers to the degree of exactness with which a machine can produce a feature or dimension repeatedly. It’s about minimal scatter in results.

High precision implies that repeated measurements of a manufactured feature will cluster very closely together, indicating minimal random error. This is crucial for consistent quality in high-end CNC machining.

Factors Influencing CNC Precision

Numerous elements influence the precision achievable in high-end CNC machining. These include the rigidity and accuracy of the machine tool itself, the quality of the cutting tools, and the stability of the machining environment.

Material properties, cutting parameters, and the skill of the machinist also play significant roles. Mastering these factors is central to our precision machining services.

Table: Key Factors Affecting CNC Precision

| Factor | Impact on Precision |

|---|---|

| Machine Rigidity | Reduces vibration, increases dimensional stability |

| Tooling Quality | Sharpness, material, runout directly affect finish |

| Environmental Control | Temperature stability prevents thermal expansion |

| Material Homogeneity | Consistent material properties ensure predictable cuts |

Repeatability vs. Accuracy

Repeatability refers to the ability of a machine or process to consistently produce the same result under the same conditions. It’s about how close successive measurements are to each other.

Accuracy, conversely, describes how close a measured value is to the true or desired value. A highly repeatable process might not be accurate if it consistently produces the wrong dimension. Both are essential for high-end CNC machining.

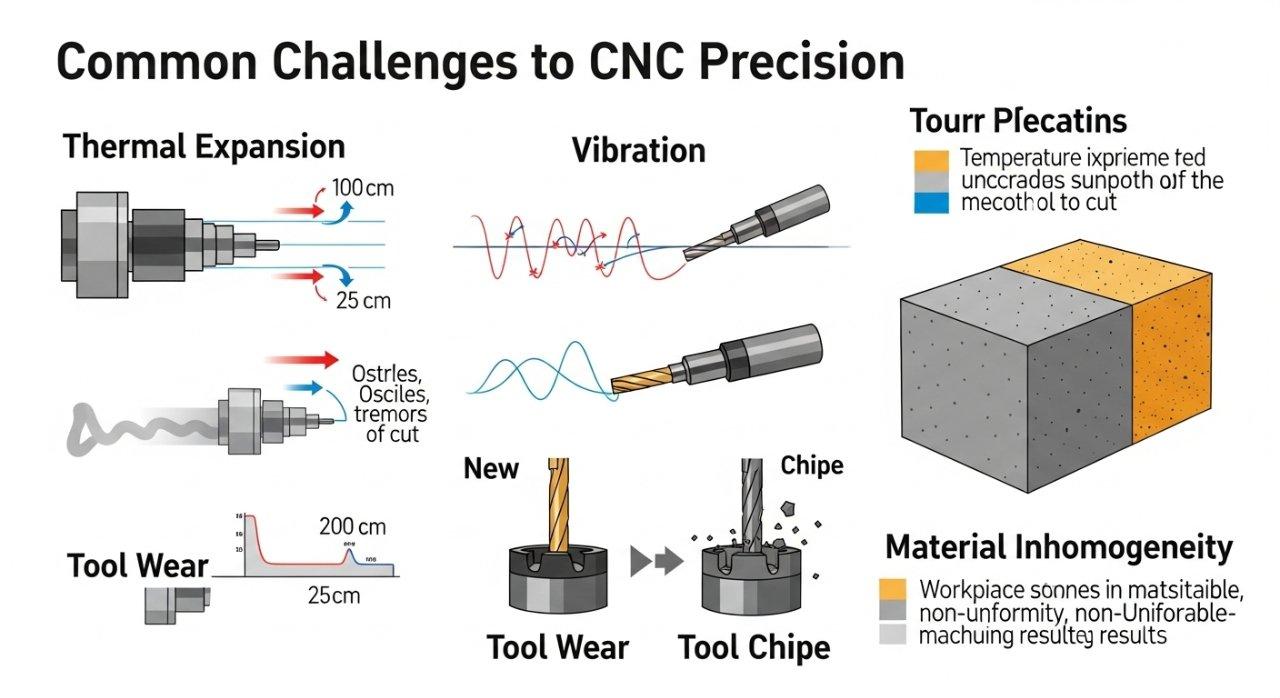

Common Precision Challenges in CNC

Material Property Variations

The consistency of material properties is a significant factor. Differences in hardness, grain structure, or internal stresses within a single batch of material can lead to unpredictable machining outcomes.

In our experience, even subtle material variations can cause unexpected tool wear or part distortion, impacting the final dimensions of custom CNC parts. Rigorous material inspection is key.

Machine Tool Limitations

Even the most advanced CNC machines have inherent limitations, such as backlash in lead screws, thermal expansion of components, and spindle runout. These mechanical factors can subtly reduce overall precision.

Regular calibration, preventative maintenance, and compensation mapping are vital to mitigating these effects. This proactive approach is fundamental to reliable tolerance management CNC.

Environmental Factors & Vibrations

Temperature fluctuations in the workshop can cause thermal expansion or contraction of both the machine and the workpiece, directly affecting dimensional accuracy. Vibrations from nearby machinery or infrastructure can also degrade surface finish and tolerance.

Controlling the shop environment is therefore critical for achieving ultra-tight tolerances in high-end CNC machining. We invest in climate-controlled environments.

Tool Wear and Deflection

As cutting tools are used, they inevitably wear down, altering their effective cutting diameter and edge geometry. This wear directly impacts the dimensions and surface finish of machined parts.

Furthermore, slender tools can deflect under cutting forces, especially when machining tough materials or taking deep cuts. Effective tool management and intelligent programming are essential to counteract this for custom CNC parts.

Advanced Tolerance Management Strategies

Design for Manufacturability (DFM)

Effective DFM is paramount in high-end CNC machining. It involves reviewing designs early in the product lifecycle to identify potential manufacturing challenges related to tolerances, material selection, and part complexity.

Our engineers collaborate closely with clients to optimize designs for precision, reducing costs and lead times. This proactive approach is a core part of our precision machining services.

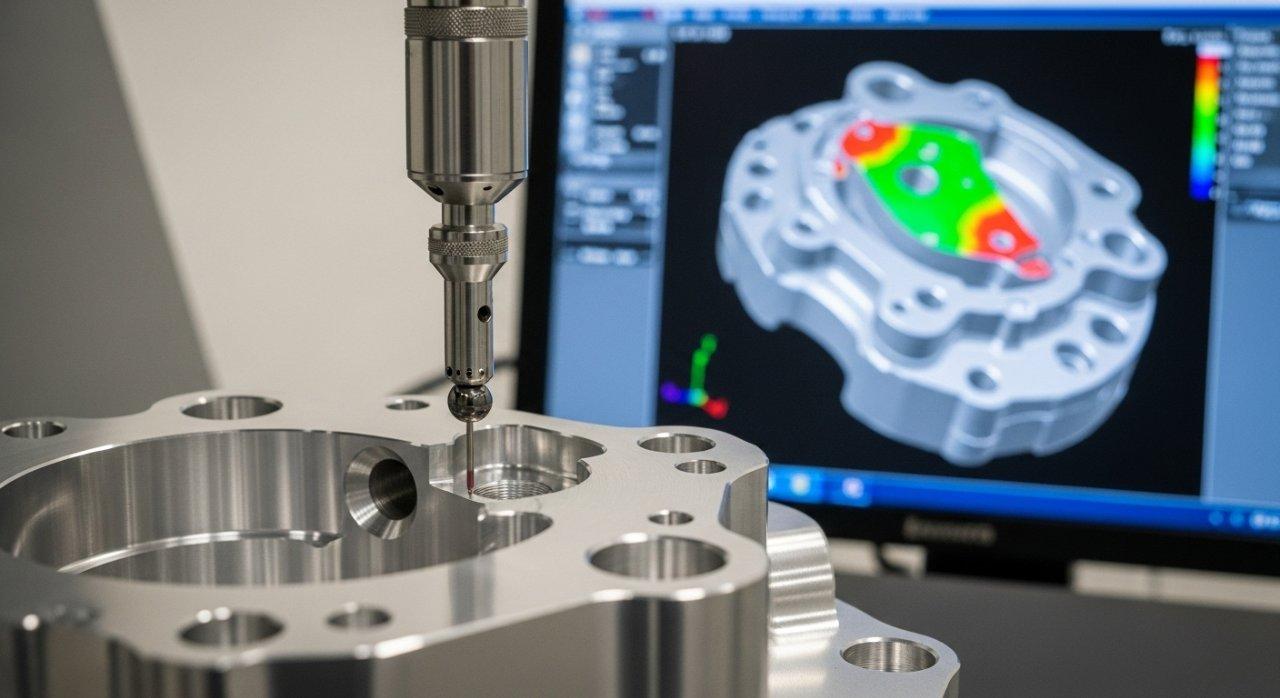

Process Control & Monitoring

Real-time process monitoring, including in-process gauging and adaptive control systems, allows for immediate adjustments during machining. This helps maintain critical tolerances throughout the production run.

Statistical Process Control (SPC) is also employed to analyze data, identify trends, and predict potential deviations before they impact part quality. This is how we ensure consistent tolerance management CNC.

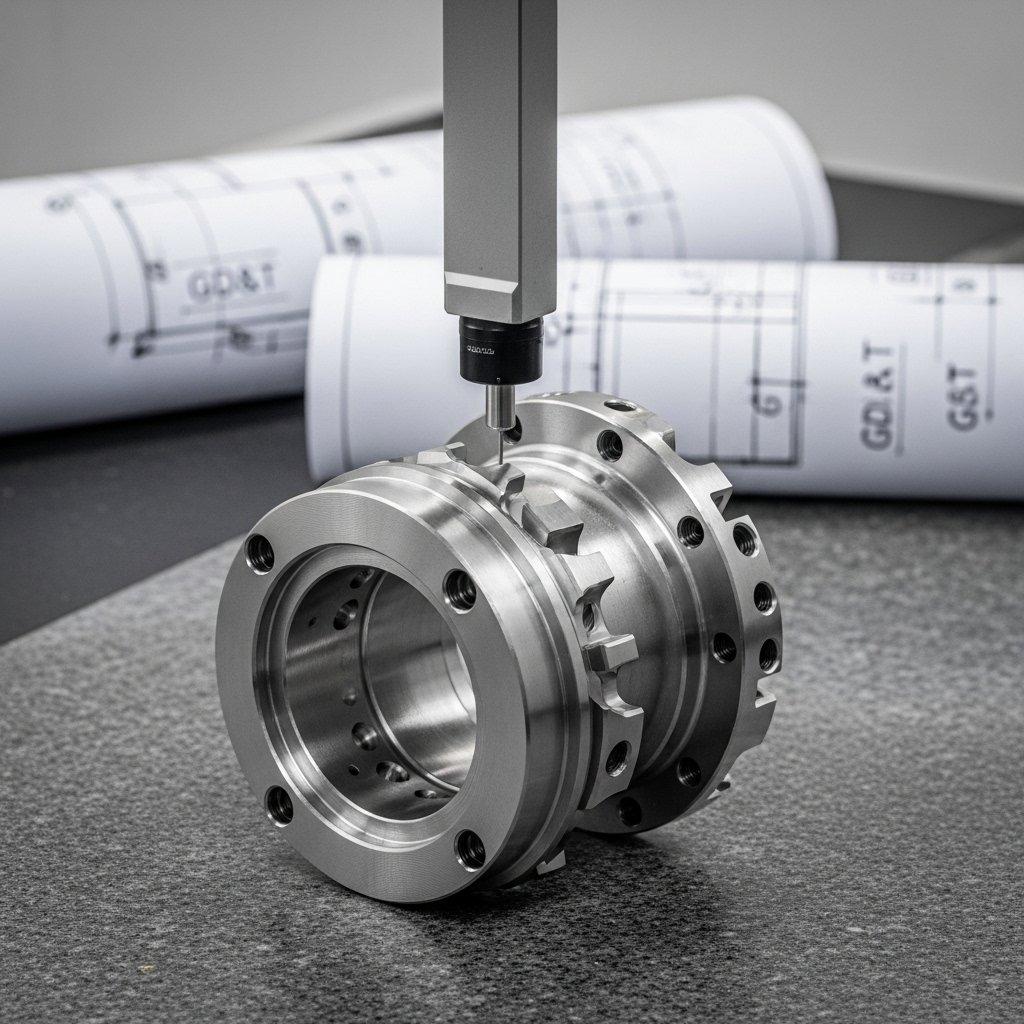

Metrology and Inspection Techniques

Advanced metrology is indispensable for verifying precision. We utilize Coordinate Measuring Machines (CMMs) with sub-micron accuracy, optical comparators, and surface roughness testers to ensure every part meets specification.

In our factory, 100% inspection of critical features is standard practice for high-end custom CNC parts. This commitment ensures trustworthiness and guarantees quality.

Post-Machining Treatments

Sometimes, post-machining treatments are necessary to achieve final specified tolerances or surface finishes. These can include stress relieving, heat treatment, grinding, lapping, or polishing.

Such treatments can remove residual stresses, improve material properties, or refine surface quality, contributing to the overall precision of the final component. This holistic approach supports our precision machining services.

Elevating CNC Machining Precision

State-of-the-Art CNC Equipment

Our commitment to high-end CNC machining is evident in our investment in cutting-edge multi-axis CNC machines. These machines feature high rigidity, advanced thermal compensation, and precise feedback systems.

This technology allows us to achieve incredibly tight tolerances and complex geometries that might be impossible with older equipment. It’s a cornerstone of our ability to deliver superior custom CNC parts.

Advanced Tooling Selection

The choice of cutting tools is paramount. We select specialized tools made from advanced materials, often with custom geometries and coatings, designed for optimal performance and minimal wear.

Our strategy includes using micro-grain carbide, PCD (Polycrystalline Diamond), and CBN (Cubic Boron Nitride) tools for specific applications, ensuring both precision and efficiency in tolerance management CNC.

Optimized Machining Parameters

Achieving high precision requires meticulous optimization of machining parameters—spindle speed, feed rate, depth of cut, and tool path. These parameters are finely tuned for each material and part geometry.

In our experience, minor adjustments can yield significant improvements in surface finish and dimensional accuracy. Our expert machinists employ advanced CAM software and deep knowledge to perfect these settings.

Skilled Machinists & Expertise

Technology is only as good as the hands that guide it. Our team of highly skilled machinists and engineers possesses deep technical expertise in high-end CNC machining and GD&T.

Their experience allows them to anticipate challenges, implement subtle program adjustments, and ensure every custom CNC part meets the most demanding specifications. This human element is irreplaceable in precision manufacturing.

Our High-End Custom CNC Approach

Source Manufacturer Advantage

As a source manufacturer, ‘ly-machining’ maintains complete control over the entire production process, from material procurement to final inspection. This vertical integration ensures consistent quality and unparalleled traceability.

It allows us to implement our stringent tolerance management CNC protocols at every stage, offering our clients peace of mind and reliable precision machining services.

Transparent Pricing for Quality

We believe in clear and transparent pricing that reflects the true value of high-precision custom CNC parts. Our quotes are detailed, breaking down costs without hidden fees for quality control or technical consultations.

We aim to build long-term partnerships based on trust and predictable costs, ensuring you understand the investment behind superior quality.

Deep Technical Expertise in Action

Our engineering team doesn’t just execute designs; we optimize them. We offer DFM consultation, material recommendations, and process optimization suggestions that can enhance part performance and reduce manufacturing costs.

This proactive collaboration is how we leverage our deep technical expertise to solve complex challenges in high-end CNC machining, ensuring your project’s success.

Case Study: Complex Part Success

Problem: A client in the robotics industry faced persistent issues achieving the required concentricity and surface finish for a critical titanium gear housing. Their previous supplier struggled with maintaining sub-micron tolerances, leading to frequent rejections and project delays.

Our Solution: Our engineers conducted a comprehensive DFM review, recommending a specific machining strategy involving specialized five-axis tool paths and custom-ground cutting tools. We utilized real-time thermal compensation on our state-of-the-art CNC machine and employed a multi-stage post-machining lapping process.

Result: ‘ly-machining’ successfully delivered the custom CNC parts with concentricity held within 2 microns and a surface finish of Ra 0.2 µm, significantly exceeding the client’s previous supplier’s capabilities. This enabled the client to launch their robotic system on schedule with enhanced performance.

Partnering for Precision CNC Success

The Value of a Trusted Partner

In the realm of high-end CNC machining, selecting the right partner is as crucial as the design itself. A trusted partner offers not just manufacturing capability but also technical insight, reliability, and consistent quality.

‘ly-machining’ is committed to being that partner, providing unparalleled precision machining services and expertise in tolerance management CNC for your most critical custom CNC parts.

Ready to Discuss Your Project?

When your product’s success hinges on uncompromising precision and reliable execution, our factory is ready. We invite you to experience the difference our expertise makes.

Contact our technical experts today for a personalized consultation on your high-end custom CNC machining project. Receive a transparent, detailed quote tailored to your specific requirements.

FAQ: What are engineering tolerances?

Engineering tolerances define the permissible variations in a part’s dimensions or geometry from its exact design. They are essential to ensure that manufactured components fit and function correctly when assembled.

They account for the practical limits of manufacturing processes, preventing unnecessary costs associated with trying to achieve perfect dimensions. Effective tolerance management is critical for custom CNC parts.

How does ‘ly-machining’ ensure precision?

We ensure precision through a multi-faceted approach. This includes utilizing state-of-the-art multi-axis CNC machines, advanced tooling, rigorous process control, and comprehensive metrology using CMMs.

Our deep technical expertise, especially in DFM and optimized machining parameters, allows us to meet the tightest specifications consistently. We prioritize experience and expertise in high-end CNC machining.

Why is DFM important for tight tolerances?

Design for Manufacturability (DFM) is crucial because it identifies and resolves potential manufacturing challenges early on. It optimizes part design for efficient production while still meeting critical tolerance requirements.

This proactive approach minimizes errors, reduces rework, and ultimately saves time and costs in producing high-precision custom CNC parts. It is integral to effective tolerance management CNC.