Custom CNC manufacturing demands advanced material selection to achieve superior CNC part performance. Our expertise ensures precise material choice for your most demanding applications, enhancing product lifecycle and functionality.

Is your product’s potential limited by your material choices? Discover how strategic advanced material selection in custom CNC can transform your components from standard to industry-leading. This is achievable without compromising cost or quality.

At ly-machining, we understand that material science is the foundation of high-performance components. We guide our clients through the complexities of advanced materials to unlock unparalleled product capabilities. This guide will illuminate the path to selecting the perfect materials for your custom CNC needs.

Why Choose Advanced CNC Materials?

Performance Demands & Innovation

Modern industries constantly push the boundaries of component performance. This requires materials that can withstand extreme conditions, deliver precise functionality, and enable innovative designs. Standard materials often fall short of these rigorous demands.

In our experience, engineers increasingly seek solutions for superior strength-to-weight ratios, enhanced thermal stability, or improved fatigue resistance. Advanced materials are specifically engineered to meet these challenging performance metrics. They are crucial for competitive advantage.

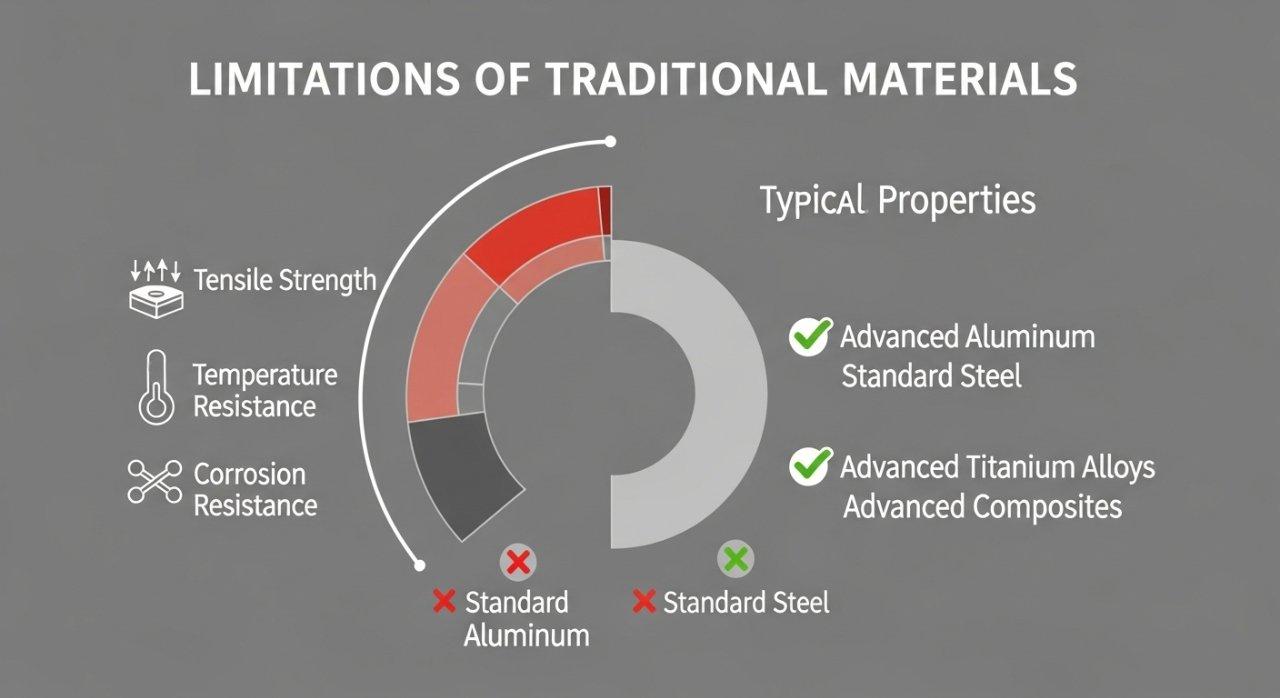

Overcoming Traditional Material Limits

Traditional metals and plastics, while versatile, have inherent limitations in specific environments. High temperatures, corrosive chemicals, or stringent biocompatibility needs often necessitate a switch to specialized alternatives. These limitations drive the need for custom CNC materials.

A common issue we see is component failure due to inadequate material selection for the operating environment. Advanced materials like superalloys or engineering plastics offer properties far exceeding their conventional counterparts, ensuring reliability.

Advanced Material Selection Criteria

Understanding Application Needs

The first step in advanced material selection is a thorough analysis of the application’s specific requirements. This includes understanding the operational environment, load conditions, expected lifespan, and critical performance indicators. Defining these parameters precisely is paramount.

We work closely with R&D engineers to translate their design intentions into measurable material specifications. This collaborative approach ensures that the chosen custom CNC materials align perfectly with the product’s ultimate purpose.

Key Mechanical Properties

Mechanical properties dictate a material’s response to applied forces. Factors such as tensile strength, yield strength, hardness, fatigue limit, and modulus of elasticity are critical. These properties directly impact CNC part performance.

For instance, in aerospace applications, a high strength-to-weight ratio is crucial, often leading to choices like titanium or specific aluminum alloys. For wear resistance, hardened steels or ceramics might be preferred.

Here’s a comparison of common mechanical properties:

| Property | Description | Unit | Importance for CNC Parts |

|---|---|---|---|

| Tensile Strength | Max stress a material can withstand before breaking | MPa (or psi) | Resistance to pulling forces, crucial for structural parts |

| Yield Strength | Stress at which material begins to deform plastically | MPa (or psi) | Prevents permanent deformation under load |

| Hardness | Resistance to localized plastic deformation (indentation) | Rockwell, Vickers | Wear resistance, surface integrity |

| Modulus of Elasticity | Stiffness; resistance to elastic deformation | GPa (or Mpsi) | Predicts component deflection under load |

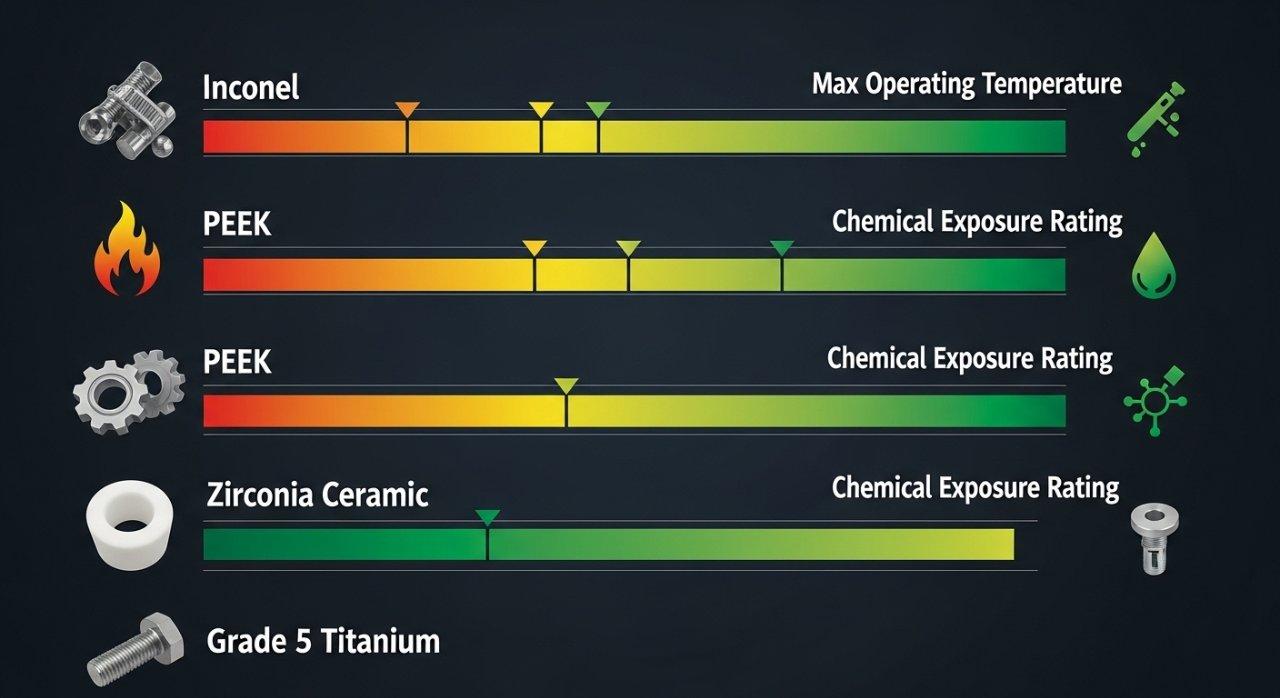

Thermal & Chemical Resistance

For parts exposed to extreme temperatures or corrosive chemicals, thermal stability and chemical inertness are non-negotiable. Materials must maintain their structural integrity and performance under these harsh conditions. We consider these extensively in custom CNC manufacturing.

Superalloys are excellent for high-temperature applications, while certain engineering plastics or specialized ceramics offer superior chemical resistance. Their stability ensures long-term CNC part performance.

Consider these resistance properties:

| Property | Key Characteristic | Typical Application |

|---|---|---|

| Thermal Resistance | Ability to withstand high/low temperatures | Aerospace engine components, industrial heaters |

| Chemical Resistance | Inertness to acids, bases, solvents | Medical devices, chemical processing equipment |

| Oxidation Resistance | Ability to resist degradation from oxygen at high temps | Exhaust systems, furnace parts |

Cost Versus Performance Value

While advanced materials often come with a higher initial cost, their long-term value can be significantly greater. This value stems from extended lifespan, superior performance, reduced maintenance, and enabling innovative product features. We help clients evaluate this total value.

We assist procurement managers in conducting a thorough total cost of ownership (TCO) analysis. This ensures that the investment in advanced custom CNC materials provides a justifiable return through enhanced product differentiation and market success.

Manufacturability Considerations

The chosen material must be amenable to custom CNC manufacturing processes. Factors such as machinability, tool wear, chip formation, and thermal expansion during machining are critical. These directly impact production efficiency and part quality.

Some advanced materials, like titanium alloys or superalloys, are notoriously difficult to machine. This necessitates specialized tooling, machining strategies, and our deep expertise in CNC part performance.

Top Advanced Materials for Custom CNC

High-Strength Alloys & Their Uses

High-strength alloys are fundamental to industries requiring exceptional structural integrity. These include various grades of Titanium, Stainless Steels (e.g., 17-4 PH), Inconel, and other Nickel-based superalloys. They are core custom CNC materials.

Titanium alloys are prized for their unparalleled strength-to-weight ratio and corrosion resistance, ideal for aerospace and medical implants. Stainless steels like 17-4 PH offer a balance of strength and corrosion resistance, suitable for defense and energy sectors.

Inconel, a nickel-chromium-based superalloy, excels in high-temperature and corrosive environments, making it indispensable for turbine components and chemical processing equipment. Selecting the right alloy is crucial for optimal CNC part performance.

Lightweight Composites & Polymers

For applications where weight reduction is paramount, lightweight composites and high-performance polymers offer excellent solutions. These include Carbon Fiber Composites, PEEK, and Ultem (PEI). Our custom CNC manufacturing capabilities extend to these materials.

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic known for its excellent mechanical strength, chemical resistance, and biocompatibility. It is often used in medical, automotive, and aerospace components.

Ultem (PEI – Polyetherimide) offers similar properties to PEEK but with a slightly different balance, often chosen for its high dielectric strength and flame retardancy in electrical applications. CNC part performance with these materials benefits from precise machining.

Specialty Ceramics for Extremes

When confronting extreme heat, wear, or specific electrical properties, specialty ceramics like Zirconia, Alumina, and Silicon Nitride are often the only viable choice. These offer unmatched hardness, chemical inertness, and thermal stability. Our custom CNC manufacturing processes are tailored for them.

Zirconia is known for its fracture toughness and wear resistance, making it suitable for dental implants and industrial knives. Alumina offers high hardness and electrical insulation, used in electronics and seals.

Silicon Nitride boasts exceptional strength and thermal shock resistance, ideal for high-temperature bearings and engine components. Machining these materials to achieve specific CNC part performance requires specialized expertise.

Bio-Compatible Materials Overview

Biocompatible materials are essential for medical devices and implants that interact safely with the human body. Common examples include specific grades of Titanium, PEEK, and certain types of Stainless Steel. We prioritize safety and precision in their custom CNC manufacturing.

Titanium Grade 23 (Ti-6Al-4V ELI) is widely used for surgical implants due to its excellent biocompatibility and mechanical properties. PEEK offers a bone-like modulus, making it suitable for spinal cages and other implantable devices.

Our rigorous quality control processes ensure that custom CNC parts made from these materials meet the stringent regulatory requirements for medical applications, guaranteeing superior CNC part performance and patient safety.

Boosting Custom CNC Part Performance

Design for Manufacturability (DfM)

Optimizing design for manufacturability is crucial for maximizing CNC part performance and minimizing costs. Our engineers collaborate with clients early in the design phase to identify potential manufacturing challenges. This proactive approach smooths custom CNC manufacturing.

This involves simplifying geometries, selecting appropriate tolerances, and ensuring features are accessible for machining operations. A well-executed DfM process reduces iteration cycles and enhances the final part’s integrity.

Precision Machining Techniques

Achieving superior CNC part performance demands advanced precision machining techniques. These include multi-axis machining, micro-machining, and specialized tool path generation. Our state-of-the-art equipment and skilled technicians ensure optimal execution.

For complex geometries and tight tolerances, 5-axis CNC machining is often indispensable. This allows for intricate feature creation in a single setup, improving accuracy and reducing setup times in custom CNC manufacturing.

Surface Finish & Post-Processing

The surface finish significantly impacts CNC part performance, affecting factors like fatigue life, wear resistance, and aesthetics. We offer a range of post-processing techniques tailored to material and application.

Options include polishing, anodizing, heat treatment, and various coatings. For example, electropolishing can enhance the corrosion resistance of stainless steel medical parts, while heat treatment can alter the mechanical properties of alloys.

Quality Control & Validation

Maintaining stringent quality control throughout the custom CNC manufacturing process is non-negotiable. Our robust quality management system adheres to ISO 9001 and AS9100 standards, ensuring consistent and verifiable CNC part performance.

We employ advanced inspection tools like CMMs (Coordinate Measuring Machines) and optical comparators to validate critical dimensions and tolerances. Material certification and traceability are provided for all advanced custom CNC materials.

Partnering for Material & CNC Success

Our Expert Technical Consultation

Leveraging our deep expertise in custom CNC manufacturing, we offer comprehensive technical consultation. Our engineers work collaboratively with your design and procurement teams to select the most appropriate advanced custom CNC materials.

This ensures that every material choice is optimized for performance, cost-effectiveness, and manufacturability. We act as an extension of your R&D team, providing insights that only come from hands-on experience.

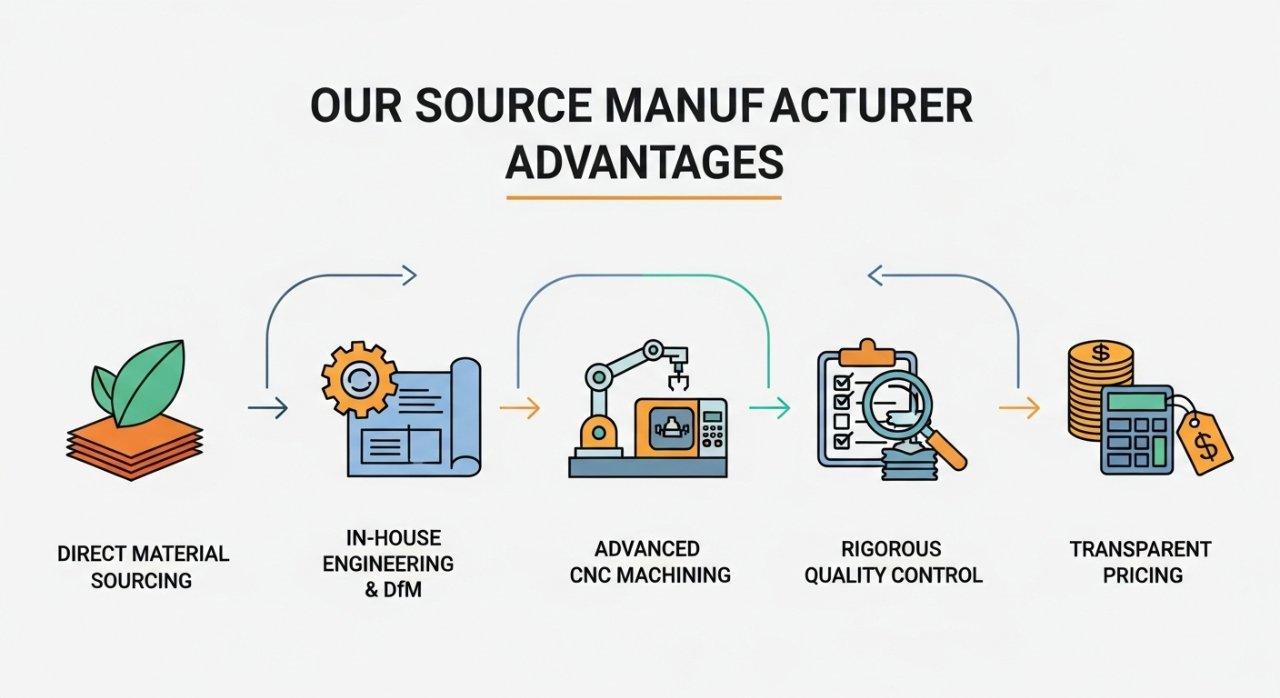

Source Manufacturer Advantages

As a source manufacturer, ly-machining provides distinct advantages. We control the entire custom CNC manufacturing process from material procurement to final inspection, ensuring transparent quality and reliable lead times. This direct relationship eliminates intermediaries.

This means direct communication, greater flexibility, and ultimately, better value for our clients. Our integrated approach ensures consistent CNC part performance and adherence to specifications.

Transparent Pricing & Quality

We are committed to transparent pricing models that reflect the true cost of high-quality custom CNC materials and precision machining. Our clients receive detailed quotes with no hidden fees. Quality is never compromised.

Our robust quality system, backed by material certifications and rigorous in-process inspections, provides verifiable assurance. We ensure that the advanced custom CNC materials meet the highest industry standards.

Case Study: Advanced Material Impact

Problem: A client in the satellite communications sector needed a lightweight, high-strength bracket for a critical antenna assembly. Their existing aluminum alloy solution was too heavy and exhibited unacceptable vibration under specific flight conditions. This impacted overall system stability.

Our Solution: After extensive technical consultation, we recommended switching from standard aerospace aluminum to a specific grade of Titanium alloy, Ti-6Al-4V. Our engineers then optimized the design for this material, leveraging our 5-axis custom CNC manufacturing capabilities. We developed specialized tool paths and machining strategies to achieve tight tolerances and an optimal surface finish.

Result: The new Titanium bracket delivered a 30% weight reduction while increasing rigidity by 25%, significantly mitigating vibration issues. This directly improved the antenna’s pointing accuracy and the overall satellite’s operational lifespan. The superior CNC part performance justified the material investment.

Secure Your Performance Edge Today

Request a Custom Material Review

Are you unsure which advanced custom CNC materials are best for your next project? Our expert engineers are ready to review your design and application. We provide tailored recommendations.

Leverage our deep material science knowledge for optimal CNC part performance. This is your first step towards innovation.

Get Your Free CNC Project Quote

Ready to elevate your product’s performance with the right advanced materials? Contact our expert engineers today for a free consultation. You will receive a customized quote on your custom CNC machining project.

Leverage our source manufacturer advantage for unparalleled quality and value. We are here to bring your vision to life.

Frequently Asked Questions

Why are advanced materials more expensive?

Advanced custom CNC materials often involve more complex refining, processing, and alloying steps. Their unique properties, such as high purity or specific microstructures, require specialized manufacturing. This leads to higher raw material costs.

Additionally, some advanced materials are more difficult to machine, requiring specialized tooling and longer machining times. This increases custom CNC manufacturing costs.

How do you ensure material authenticity?

We maintain stringent supplier qualification processes, sourcing advanced custom CNC materials only from certified vendors. All incoming materials undergo rigorous inspection and chemical analysis. We also provide full material traceability and certifications.

This adherence to ISO and AS9100 standards guarantees the authenticity and quality of every advanced custom CNC material we use. Our commitment prevents material non-conformance.

Can you help with DfM for advanced materials?

Absolutely. Our experienced engineering team specializes in Design for Manufacturability (DfM) for advanced custom CNC materials. We collaborate closely with clients from the conceptual phase. This ensures optimal design for manufacturability.

This collaboration streamlines the custom CNC manufacturing process, enhances CNC part performance, and helps avoid costly redesigns. Our expertise helps translate complex designs into robust, manufacturable components.