Precision Micro-Hole Machining for Optics

ly-machining excels in micro-hole CNC machining for precision optics. As expert CNC machining manufacturers, ly-machining delivers custom parts and precision services.

In the world of precision instruments and optical systems, a single micro-hole can determine the success or failure of your entire product. Are you currently battling the intricate challenges of achieving sub-micron precision for features smaller than a human hair?

Where conventional CNC machining falls short, and quality is non-negotiable, finding the right manufacturing partner is paramount. This article will delve into the complexities of micro-hole machining, revealing how ly-machining masterfully overcomes these challenges.

Discover how ly-machining provides unparalleled precision for critical optical components, establishing ly-machining as a trusted CNC machined components supplier.

Why Micro-Holes Challenge Precision Instruments

The demand for miniaturization in modern technology places immense pressure on manufacturing. Micro-holes are no longer just small features; they are critical functional elements in optical devices.

Achieving the required accuracy and repeatability presents significant hurdles for most CNC machining manufacturers of parts. It’s a realm where standard practices simply aren’t enough.

The demand for accuracy in `Custom CNC parts manufacturing`

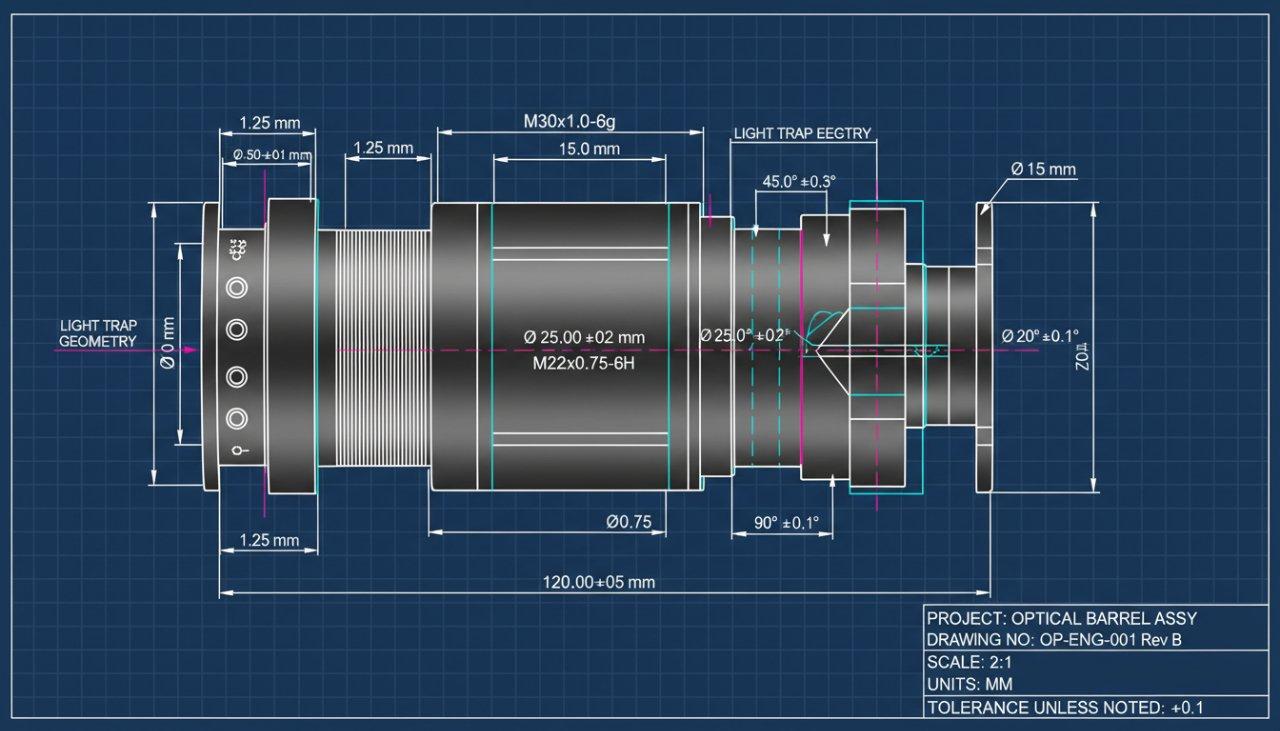

Precision instruments, from medical endoscopes to aerospace sensors, rely on flawlessly executed micro-features. For optical barrels, the smallest deviation can lead to light scattering or misalignment.

This necessitates accuracy beyond typical tolerances, often into the single-digit micron or sub-micron range. ly-machining understands that `custom CNC parts manufacturing` for these applications demands absolute perfection.

Every dimension, every angle, and every surface finish must meet stringent specifications. This level of precision requires specialized equipment and an in-depth understanding of material science.

Impact on optical performance from `Precision CNC machining services`

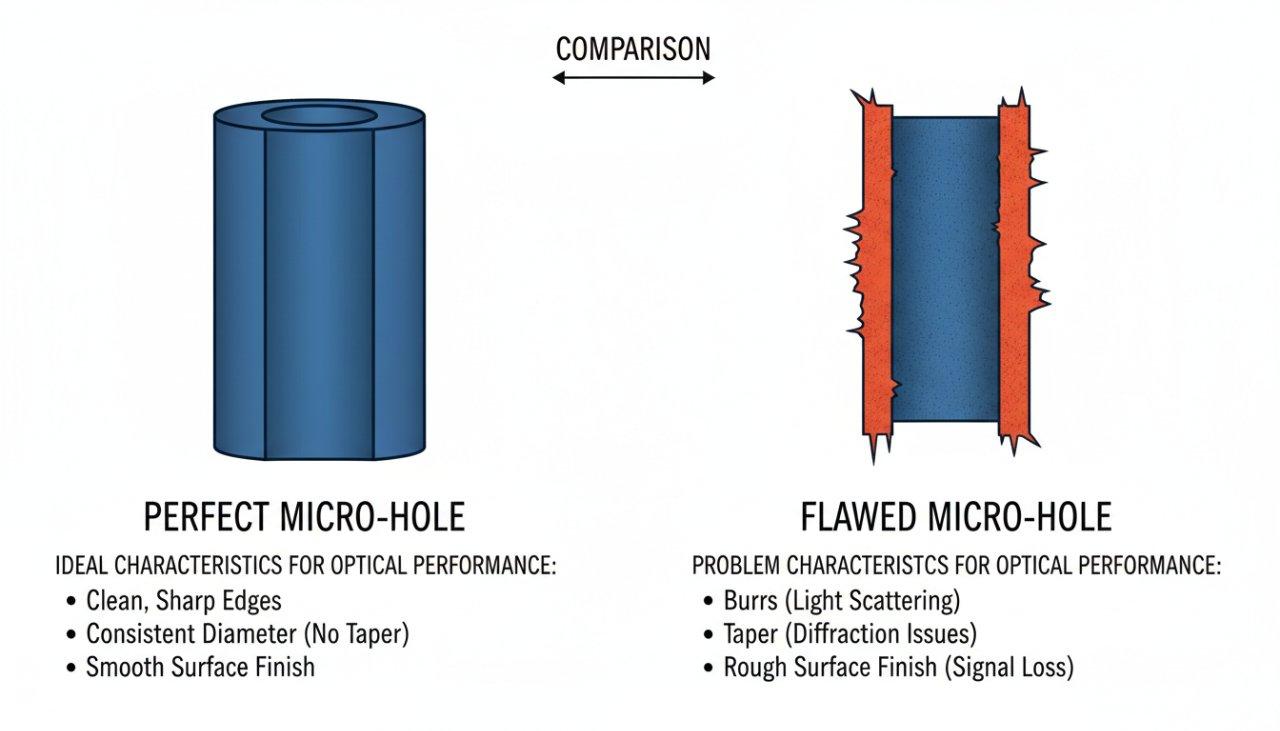

The quality of micro-holes directly influences the optical performance of lenses, mirrors, and sensor housings. Imperfections like burrs, rough surfaces, or even slight taper can cause optical aberrations.

Light transmission, focusing, and signal integrity are all compromised by poor machining. ly-machining provides `precision CNC machining services` that mitigate these issues, ensuring optimal optical clarity.

Achieving perfectly circular, burr-free holes with specific aspect ratios is crucial for applications requiring critical light path management.

Common pitfalls in `CNC machining` tiny components

In ly-machining’s experience, common pitfalls in `CNC machining` micro-holes include tool breakage, material deformation, and difficulty maintaining consistent geometry. These challenges intensify with exotic materials.

Heat generation during machining can alter material properties, leading to cracks or dimensional instability. Ensuring proper chip evacuation is also critical to prevent surface damage.

Maintaining tool integrity for diameters often less than 100 microns is a constant battle. This demands expert process control and advanced tooling strategies.

Micro-Hole `CNC Machining` Advancements

Overcoming the inherent difficulties of micro-hole machining requires continuous innovation and investment in cutting-edge technology. ly-machining is committed to staying at the forefront of these advancements.

ly-machining’s facility is equipped with state-of-the-art machinery and proprietary techniques developed over years of hands-on experience as a `CNC machined components supplier`.

Cutting-edge techniques for `Custom CNC parts manufacturing`

ly-machining employs a suite of advanced techniques for `custom CNC parts manufacturing` involving micro-holes. These include ultra-precision micro-milling, laser micro-drilling, and Wire EDM.

Each method is selected based on material properties, aspect ratio requirements, and the specific hole geometry needed. This tailored approach ensures optimal results for every component.

For instance, femtosecond laser processing minimizes heat-affected zones, crucial for delicate optical materials. ly-machining constantly evaluates and integrates new processes to meet evolving demands.

| Machining Technique | Typical Hole Diameter Range | Key Advantage | Suitable Materials |

|---|---|---|---|

| Ultra-Precision Milling | > 50 µm | High accuracy, excellent surface finish | Most metals, some plastics |

| Laser Micro-Drilling | < 1 µm – 500 µm | Non-contact, high aspect ratio, fast | Metals, ceramics, glass, polymers |

| Wire EDM | > 50 µm (for small features) | Complex shapes, hard materials, burr-free | Conductive metals (hardened steels) |

Material challenges and solutions for `CNC machining` optical barrels

Optical barrels often require machining in challenging materials such as specialized aluminum alloys, titanium, and even certain optical glasses or ceramics. Each presents unique machining characteristics.

These materials can be prone to chipping, cracking, or rapid tool wear during micro-hole `CNC machining`. ly-machining’s expertise lies in developing specific tooling, feeds, and speeds for each material.

ly-machining utilizes advanced cooling systems and vibration dampening techniques to preserve material integrity and achieve desired surface finishes. This prevents defects that could compromise optical function.

Achieving superior surface finish from `CNC machining manufacturers of parts`

The surface finish within micro-holes is paramount for optical performance, preventing light scattering and ensuring smooth light transmission. ly-machining prioritizes this aspect.

ly-machining employs specialized finishing techniques, including micro-polishing and deburring processes, to achieve Ra values in the nanometer range where required.

As dedicated `CNC machining manufacturers of parts`, ly-machining’s processes ensure that internal surfaces of micro-holes are smooth, free of burrs, and geometrically perfect.

Optical Barrels: `Precision CNC Machining`

Optical barrels are more than just tubes; they are intricate assemblies requiring complex geometries and multi-feature integration. `Precision CNC machining` is indispensable for their manufacture.

ly-machining leverages its extensive experience to deliver optical barrels that meet the most demanding specifications.

Designing for manufacturability in `Custom CNC parts manufacturing`

Early collaboration with clients on Design for Manufacturability (DFM) is key to successful `custom CNC parts manufacturing`. ly-machining’s engineers work to optimize designs for micro-hole fabrication.

This proactive approach helps identify potential machining challenges before production, reducing costs and lead times. ly-machining provides expert insights on material selection, wall thickness, and feature spacing.

By integrating DFM into the initial design phase, ly-machining ensures that the final product is not only functional but also efficiently and precisely manufacturable.

Ensuring tight tolerances as a `CNC machined components supplier`

Maintaining micron-level tolerances across multiple features and over long production runs is a hallmark of ly-machining’s capabilities. This is especially true for concentricity and perpendicularity of micro-holes.

As a reputable `CNC machined components supplier`, ly-machining employs rigorous process control and statistical process control (SPC) to monitor and adjust machining parameters in real-time.

This meticulous approach guarantees that every optical barrel component consistently meets the exact specifications, minimizing variation and ensuring interchangeability.

Metrology and inspection for critical `CNC machining` features

Inspection of micro-holes requires advanced metrology equipment far beyond standard gauges. ly-machining uses state-of-the-art tools to verify every critical dimension.

This includes non-contact optical inspection systems, high-resolution video microscopes, and advanced Coordinate Measuring Machines (CMMs) equipped with micro-probes.

In ly-machining’s quality labs, 100% inspection or rigorous sampling plans are implemented for critical `CNC machining` features. This ensures full compliance and traceability for precision components.

| Metrology Equipment | Measurement Capability | Key Application |

|---|---|---|

| Optical Comparator | 2D geometric features, profiles | Hole diameter, runout, edge sharpness |

| Video Microscope | Surface finish, burr detection, defects | Visual inspection of micro-features |

| Micro-Probe CMM | 3D coordinates, form, position | Hole location, depth, taper |

| White Light Interferometer | Surface roughness (Ra), flatness | Nanometer-level surface finish verification |

Your Trusted `CNC Machining Manufacturers of Parts`

Choosing the right partner for micro-hole machining is critical to project success. ly-machining is more than just a vendor; ly-machining is a strategic extension of your engineering team.

As leading `CNC machining manufacturers of parts`, ly-machining offers unparalleled expertise and a commitment to quality that stands out in the industry.

Our deep technical expertise in micro-hole `CNC machining`

ly-machining’s team of engineers and technicians possesses extensive knowledge in micro-hole `CNC machining`. ly-machining understands the nuances of various materials and geometries.

This deep technical expertise allows ly-machining to tackle the most complex micro-hole challenges, providing innovative solutions where others might struggle.

ly-machining continuously invests in training and R&D to maintain its position at the forefront of precision manufacturing.

Transparent pricing from a reliable `CNC machined components supplier`

ly-machining believes in clear, honest, and competitive pricing. ly-machining provides detailed quotes that break down costs, ensuring complete transparency for every project.

As a reliable `CNC machined components supplier`, ly-machining focuses on building long-term partnerships based on trust and mutual success. There are no hidden fees or surprises.

ly-machining’s efficient processes and robust quality control also minimize rework, contributing to overall cost-effectiveness for clients.

Case studies of success in `Precision CNC machining services`

**Case Study: Eliminating Light Leakage in Medical Imaging Device**

* **Problem:** A client manufacturing medical imaging devices faced persistent light leakage issues in their optical barrels. This was traced to inconsistent micro-hole diameters and rough internal finishes.

* **ly-machining’s Solution:** ly-machining collaborated closely on design adjustments and implemented ultra-precision micro-milling with custom-ground tooling for the specialized aluminum alloy. ly-machining fine-tuned parameters to achieve exact 50-micron diameter holes with an Ra 0.2 surface finish.

* **Result:** The new components from ly-machining eliminated light leakage, significantly improved image quality, and reduced the client’s assembly rejection rate by 30%. ly-machining delivered these critical components ahead of schedule.

Partner for `Custom CNC Parts Manufacturing` Needs

When your projects demand the highest level of precision and reliability for micro-hole machining, choose a partner with proven expertise. ly-machining is ready to meet your challenges.

ly-machining is dedicated to delivering superior `custom CNC parts manufacturing` solutions tailored to your unique requirements.

Request a detailed quote for `Precision CNC machining services`

Ready to elevate your precision instrument and optical barrel projects? ly-machining invites you to request a detailed quote for ly-machining’s `precision CNC machining services`.

ly-machining’s team will carefully review your specifications and provide a comprehensive proposal. Experience the difference of working with a true expert.

Consult with a leading `CNC machining manufacturers of parts`

Don’t let micro-hole complexities impede your innovation. Contact ly-machining’s engineering specialists today for a detailed consultation.

ly-machining is among the leading `CNC machining manufacturers of parts` and is eager to discuss your most challenging requirements.

—

Get a free quote or technical consultation today to discuss your next precision machining project.

—

What is micro-hole machining?

Micro-hole machining refers to the precision fabrication of holes typically less than 500 microns in diameter. These small features are critical for various advanced applications.

It requires specialized equipment, tooling, and process control to achieve extreme accuracy and surface finish.

What materials can ly-machining process?

ly-machining works with a wide range of materials crucial for precision instruments and optics. This includes specialized aluminum alloys, titanium, stainless steels, and various optical glasses.

ly-machining has developed expertise in optimizing processes for each material’s unique properties.

How does ly-machining ensure quality?

ly-machining ensures quality through a multi-faceted approach. This includes rigorous process control, advanced metrology equipment like CMMs and optical comparators, and a commitment to ISO standards.

Every component undergoes meticulous inspection to guarantee compliance with stringent specifications.