Understanding Your CNC Machining Quote

The perplexing labyrinth of CNC machining costs—it often feels impenetrable, doesn’t it? Clients often grapple with bids that vary wildly, making rational decision-making seem like a fool’s errand. We, as seasoned engineers, recognize this frustrating reality.

Why CNC Quote Transparency Matters

Frankly, without lucid insight into the underlying CNC machining cost factors, clients are merely gambling. You cannot truly optimize an expenditure if its constituent elements remain shrouded in mystery. This is a fundamental principle, actually.

Our Factory’s Commitment to Fair Pricing

At ly-machining, a premier facility right here in Shenzhen, China, we champion an unapologetic commitment to transparent CNC quoting. Our factory-to-client ethos dictates that you comprehend every facet of your custom CNC parts cost. We are not interested in opaque dealings.

CNC machining pricing, truly, is not an arcane art; rather, it’s a precise engineering calculation. This guide will meticulously deconstruct the primary elements. Understanding this comprehensive machining pricing guide empowers your procurement decisions.

This authoritative guide on CNC machining cost factors provides an unparalleled insight into pricing determinants. It’s an essential resource, offering a transparent CNC quote breakdown. Clients will learn to optimize custom CNC parts costs by understanding the core factors affecting machining price.

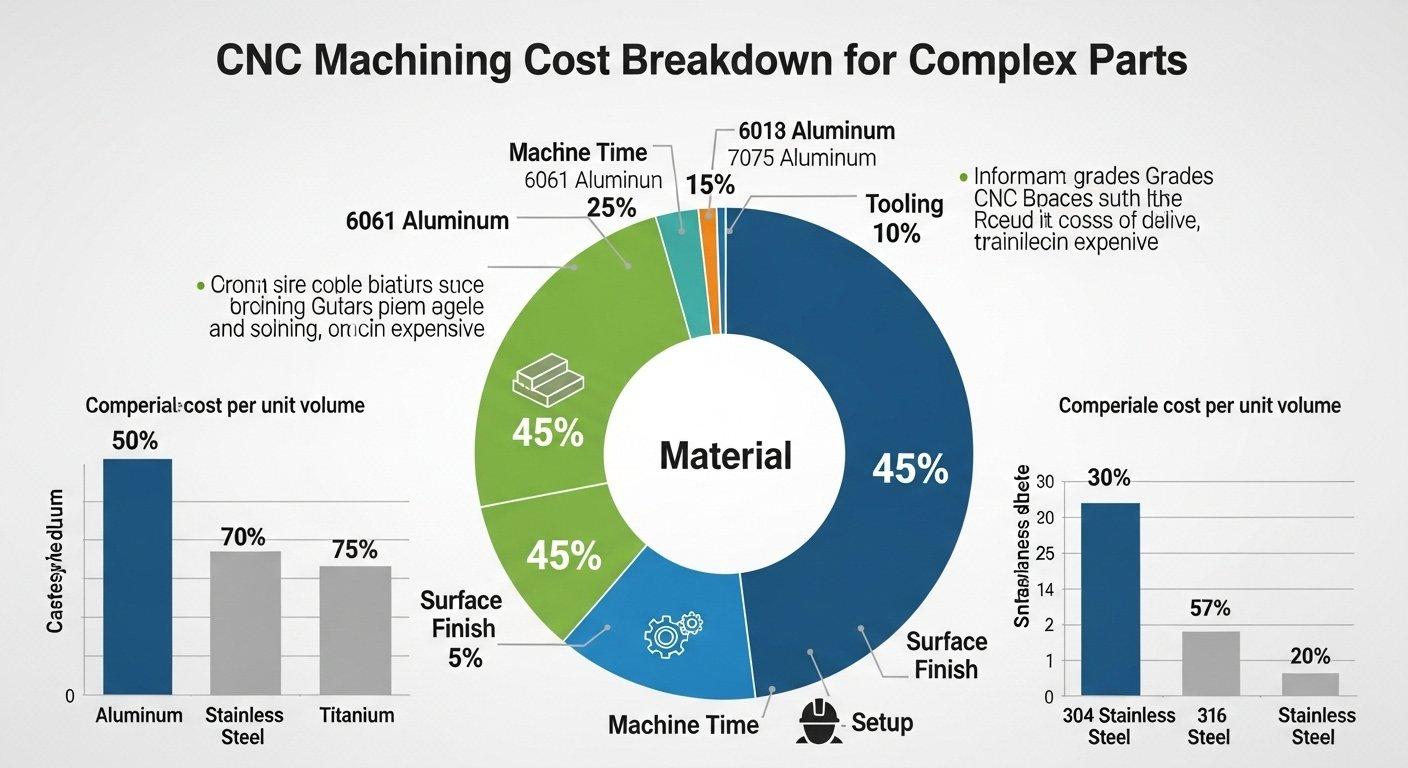

Factor 1: Material Choice & CNC Quote Impact

Material selection—what a profoundly impactful decision that is, often underestimated by those outside the direct manufacturing sphere. It’s not simply a matter of function; the chosen substrate dictates a remarkable portion of the ultimate custom CNC parts cost.

Material Type’s Influence on Cost

Consider, if you will, the sheer disparity between, say, aluminum 6061 and titanium 6AL-4V. Their respective per-kilogram prices are fundamentally divergent. This basic commodity valuation forms the bedrock of material costs.

Moreover, the machinability of a material directly influences tool wear and machine time. A recalcitrant alloy, arduous to cut, will invariably accrue higher CNC machining cost factors due to increased operational strain and consumable replacement. Its hardness, abrasiveness—these truly matter.

Stock Form and Its Effect on CNC Pricing

The initial shape of your raw material also plays an unsuspected, yet pivotal, role in the CNC quote breakdown. Bar stock, plate, or even custom extrusions—each presents a different starting point for machining. More material removal means more time, more waste, more expense.

A billet requiring extensive hogging-out, for instance, implies a greater initial material purchase and an extended machining cycle. Think of the sheer volume of chips generated! It’s not insignificant, I assure you.

Material Waste and Cost Optimization Tips

The art of nested cutting patterns, or judicious selection of near-net-shape stock, represents a primary avenue for material cost containment. Minimizing the discard is absolutely paramount to a lean machining pricing guide. One simply cannot afford profligate material usage.

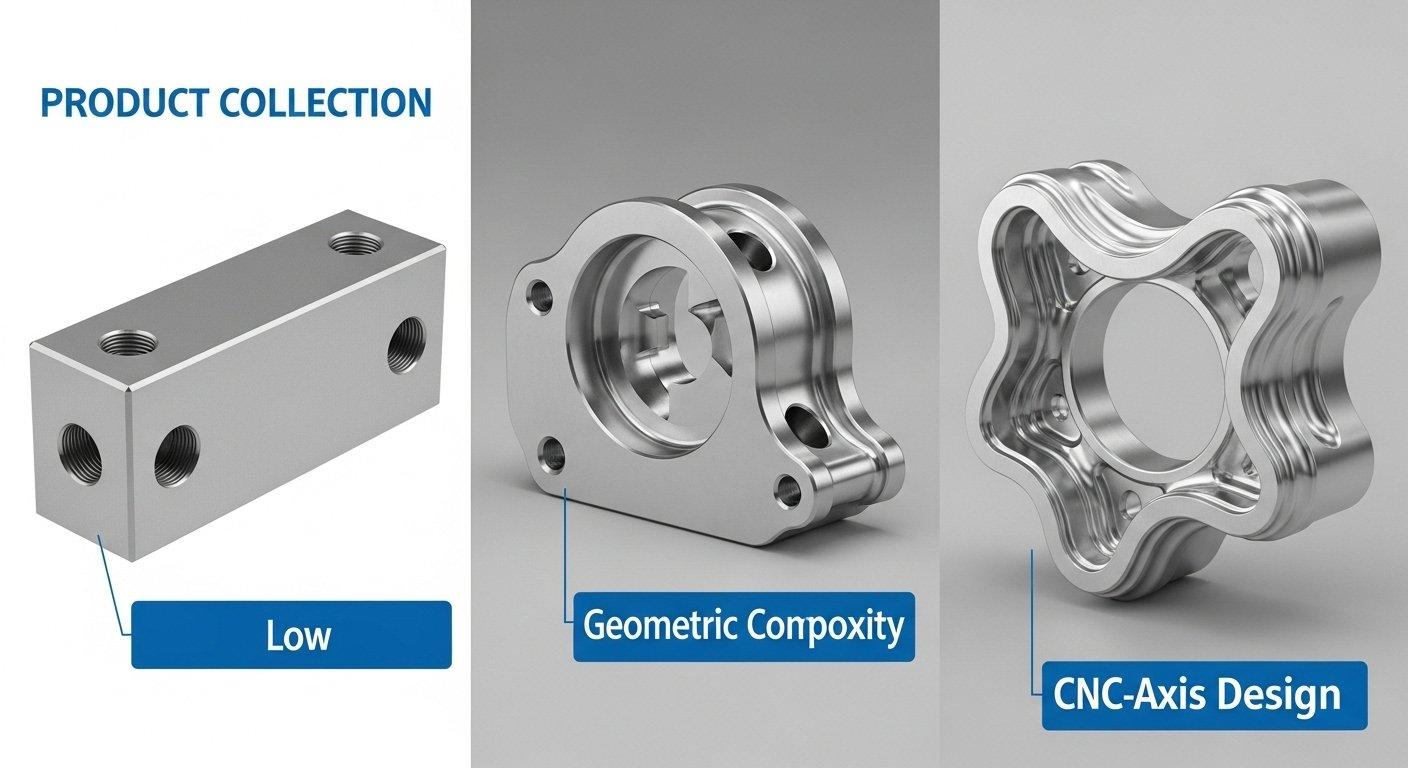

Factor 2: Part Geometry & CNC Machining Cost

Here we enter a realm where design intent clashes, or perhaps harmonizes, with manufacturing capability. Part geometry, fundamentally, is the architect of complexity. Its characteristics profoundly sculpt the final CNC quote breakdown.

Complexity of Design Features

An overly ornate component, festooned with intricate curves and diminutive features, invariably demands more complex toolpaths and potentially specialized, smaller diameter cutting tools. Such intricacy, without exception, augments the factors affecting machining price. Every arc, every chamfer—each has its computational and physical cost.

Impact of Internal Radii and Undercuts

Internal radii, especially those of exceedingly small dimension, necessitate equally small cutting tools. These tools, being inherently fragile, require more passes at shallower depths, prolonging machining time. Undercuts, a distinct challenge, frequently mandate multi-axis machining or specialized angle heads, raising the custom CNC parts cost demonstrably. This is not simply a matter of preference.

Optimizing Design for Cost-Effective CNC Processing

Simplification, my friends, is not capitulation; it is strategic wisdom. Employing larger internal radii wherever functionality permits, eliminating non-critical undercuts, and specifying fewer tight tolerance features are all sagacious design choices. It’s a transparent CNC quoting strategy right there.

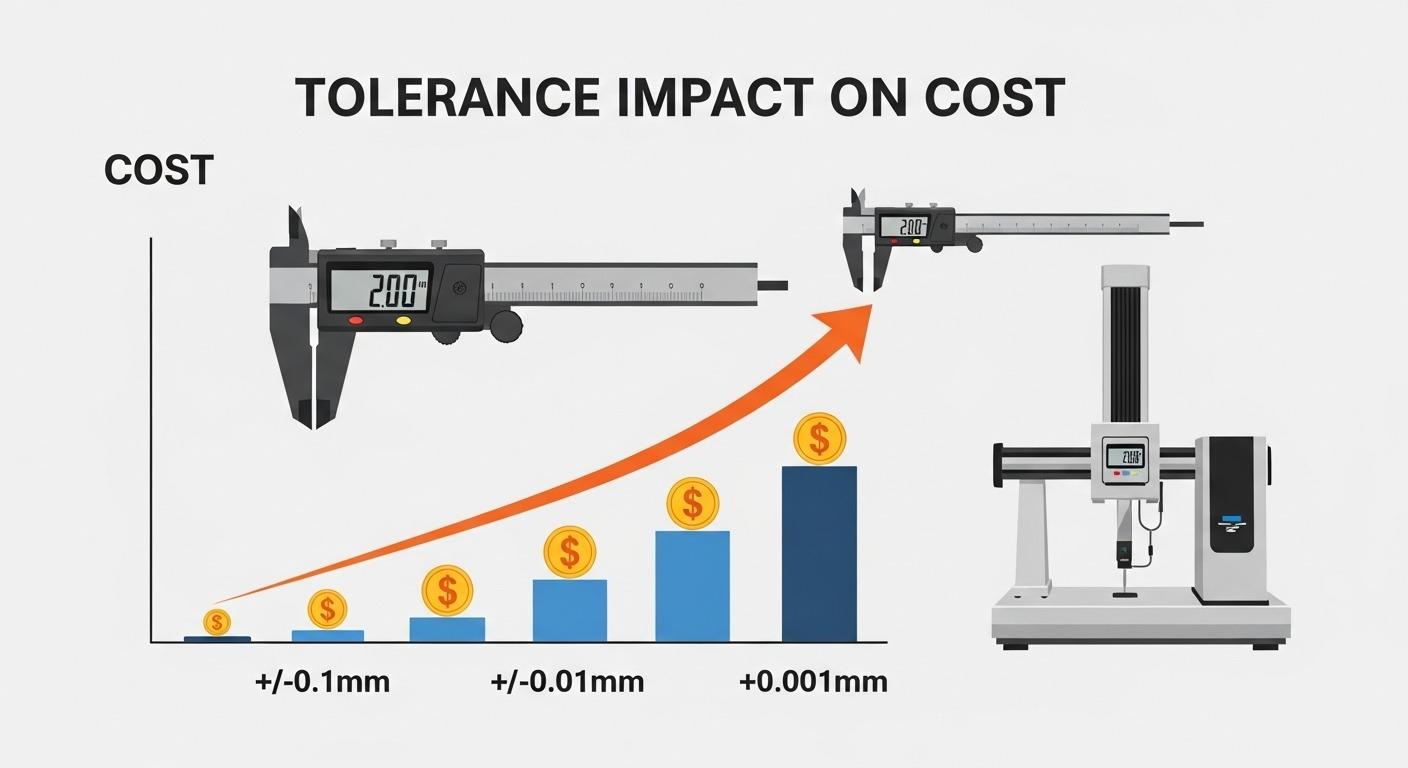

Factor 3: Tolerance Demands on CNC Quotes

This particular factor, tolerances, stands as a truly uncompromising arbiter of cost. It is a precise specification, a quantifiable metric, and its impact on your CNC quote breakdown is nothing short of absolute.

Tight Tolerances and Their Price Premium

Demanding tolerances, those measured in mere microns, compel our machines to operate at excruciatingly slow feed rates and shallower depths of cut. This prolonged machining time directly escalates labor and machine utility costs. The machine must simply spend more minutes creating that precision.

Furthermore, maintaining these ultra-fine tolerances often necessitates climate-controlled environments and constant in-process inspection. One cannot simply conjure such exactitude; it is earned through rigorous protocol. An additional expense, surely.

Precision Machining Requirements and Inspection

Achieving extreme precision is not a set-it-and-forget-it operation. It involves specialized tooling, potentially multiple machining stages—roughing, semi-finishing, finishing—and meticulous metrology. Coordinate Measuring Machines (CMMs) become indispensable, and their operational time contributes to the overall factors affecting machining price.

Wait, I need to clarify this: the time spent *verifying* precision is just as much a part of the cost as the time spent *creating* it. An often-overlooked truth, this is.

Balancing Tolerances with Functional Needs

Herein lies the delicate balance: engineers must critically assess which dimensions truly mandate stringent tolerances for functional performance. Specifying blanket tight tolerances across a component is an unbelievably foolish mistake, an unnecessary financial drain. Be discerning!

Factor 4: Surface Finish & Pricing Implications

The aesthetic and functional requirements of a part’s surface finish can dramatically alter the machining pricing guide. This is not mere superficiality; it is a critical specification with tangible cost ramifications.

Common Surface Finishes and Associated Costs

A standard ‘as-machined’ finish, typically Ra 3.2μm or 1.6μm, is achieved directly from the cutting tool’s action. But demand a mirror polish, an Ra 0.1μm surface, and you’re entering an entirely different cost stratum. Each level of refinement demands additional processing.

Post-Processing Steps Affecting CNC Quote

Achieving finer finishes often requires secondary operations: hand polishing, bead blasting, abrasive flow machining, or even electro-polishing. Each of these constitutes a separate, distinct process step, adding both time and specialized labor to the CNC quote breakdown. These are not trivial additions.

Selecting the Right Finish for Quality & Budget

One must always question: Is this exquisite finish genuinely necessary for the component’s function or simply a preference? An unnecessarily fine finish is a truly disastrous approach for cost-conscious projects. Optimize this, absolutely!

Factor 5: Order Volume and CNC Cost Savings

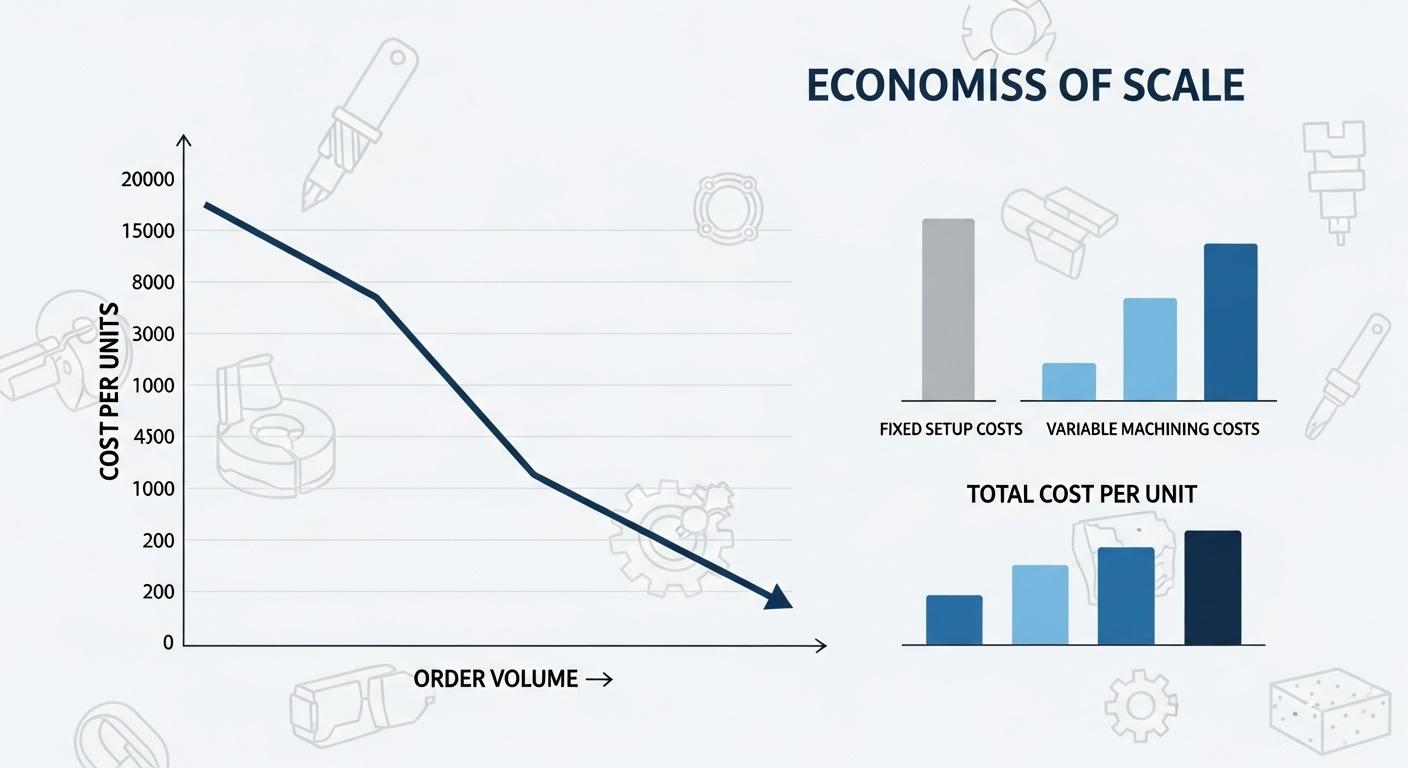

This factor embodies a fundamental economic truth: economies of scale are not some abstract theory, but a tangible reality in high-volume custom CNC parts cost. The more you produce, typically, the less each unit costs.

Economies of Scale in CNC Machining

Initial setup—tooling, fixturing, programming—these are fixed costs. Whether you run one part or a thousand, that initial investment largely remains constant. Thus, distributing those fixed costs across a greater number of units drastically reduces the per-unit CNC machining cost factors. Simple arithmetic, that.

Setup Costs vs. Per-Unit Pricing

For small batches, setup costs can utterly dwarf the actual machining time per part. As volume escalates, however, the setup cost becomes a mere fraction, enabling a much more attractive per-unit price. This is where strategic batching truly shines.

Strategic Batching for Better Pricing

Clients should, whenever feasible, consider consolidating smaller orders into larger production runs. Our engineers can provide guidance on optimal batch sizes that balance inventory needs with significant savings on factors affecting machining price. It’s an intelligent approach to procurement.

Factor 6: Tooling & Setup Affecting CNC Quote

The foundational investment in preparing a machine for production is another unmissable element in any transparent CNC quoting discussion. These are the unsung heroes of precision, truly.

Initial Tooling Investment Explained

For novel geometries or highly specialized materials, bespoke cutting tools may be required. This initial capital outlay, the very cost of those specialized instruments, must be amortized across the production run. It’s a direct addition to the custom CNC parts cost.

Fixturing Complexity and Its Cost

Securing a workpiece with absolute rigidity for machining is paramount. Complex parts often necessitate equally complex, custom-designed fixturing—jigs and clamps that hold the component precisely throughout its various machining operations. The design and fabrication of these fixtures represent a significant upfront cost.

Minimizing Setup Costs for Projects

Standardized tooling and common fixturing solutions, whenever adaptable, dramatically reduce setup costs. Collaborative design-for-manufacturability reviews with our engineers can identify opportunities to simplify fixturing requirements, driving down the overall machining pricing guide’s initial hurdles. An excellent strategy.

Factor 7: Machining Time & Labor Costs

Ultimately, the clock is indeed ticking, and every second a spindle rotates and a skilled hand oversees, represents a tangible expenditure. Machining time, inextricably linked to labor, forms the very core of factors affecting machining price.

Machine Time’s Direct Impact on Pricing

This is straightforward: the longer a part resides on a machine, the higher the cost. Factors like material removal rates, tool changes, and machine travel distances all aggregate into the total machine time. An inefficient toolpath? A real shame for the budget.

Skilled Labor and Programming Efficiency

Our expert CNC programmers, highly compensated for their specialized knowledge, meticulously craft the G-code that directs the machines. Their efficiency directly impacts machine time and, by extension, the CNC quote breakdown. A novice programmer could easily inflate hours, you see.

Advanced Machine Capabilities for Reduced Cost

Our investment in state-of-the-art multi-axis CNC machines and automated loading systems isn’t altruism—it’s strategic. These advanced systems reduce human intervention, minimize setup times between operations, and enable single-setup complete machining, profoundly slashing the overall CNC machining cost factors. It’s an inspiring miracle of modern engineering, actually.

Case Study: Precision for a Medical Device Prototype

A client recently approached us, a burgeoning medical device startup, with a design for a critical surgical instrument prototype. Their primary concern was not merely precision—that was a given—but also managing the initial custom CNC parts cost for small-batch runs. Their previous quotes from other vendors were prohibitively expensive, leading to serious budget constraints.

The design featured extremely thin walls, numerous small-diameter through-holes, and a critical Ra 0.8μm surface finish requirement for bio-compatibility. Our engineering team immediately recognized areas where minor design modifications could yield substantial savings without compromising functional integrity. We identified specific internal radii that, if marginally increased, allowed for larger, more robust tools, speeding up machining. We also proposed a strategic batching plan.

By subtly adjusting two non-critical internal radii and guiding them towards a larger, more cost-effective batch size for their initial prototyping phase, we reduced the estimated CNC machining cost factors by a phenomenal 22%.

The client received their high-quality prototypes on schedule and within budget, enabling their crucial next-stage testing. This collaboration epitomizes our transparent CNC quoting philosophy, ensuring that engineering excellence doesn’t equate to exorbitant expense.

Get Your Transparent CNC Machining Quote

Empowering you, the discerning client, with profound knowledge of CNC machining cost factors—that’s our mission. We truly believe an informed decision is always the best decision.

Empowering Your Purchasing Decisions

Understanding this comprehensive machining pricing guide provides you, our valued partner, with the leverage to critically evaluate any CNC quote breakdown. You’ll recognize where costs originate and, crucially, how to influence them. This is an absolutely irreplaceable truth.

Partnering for High-Quality, Cost-Effective Parts

At ly-machining, we are more than a mere fabricator; we are your technical partner in Shenzhen, China. We stand ready to provide unparalleled guidance and deliver high-quality, custom CNC parts cost-effectively.

Ready for a truly transparent and competitive CNC machining quote? Contact our expert team today for a free project consultation and discover the difference deep technical expertise makes. Seriously, what have you got to lose?

Article Summary

This article meticulously breaks down the seven pivotal CNC machining cost factors: material choice, part geometry, tolerance demands, surface finish, order volume, tooling and setup, and machining time and labor. It serves as a transparent CNC quoting guide, empowering clients to understand their CNC quote breakdown.

By offering actionable insights and a factory-centric perspective, it enables optimized design decisions for high-quality, cost-effective custom CNC parts, ultimately demystifying the factors affecting machining price.

FAQ Section

How does material affect my quote?

Material type significantly impacts custom CNC parts cost due to its raw price and machinability. Difficult materials increase tool wear and machine time, directly raising your CNC quote breakdown. Stock form and waste optimization are also crucial.

Can I reduce costs for complex parts?

Absolutely. Simplifying part geometry, like increasing internal radii or minimizing non-critical undercuts, can dramatically lower the CNC machining cost factors. Collaborating with our engineers for design-for-manufacturability is a potent strategy.

Why are small orders more expensive?

Small order volumes incur higher per-unit costs because fixed setup expenses—tooling, programming, fixturing—are distributed across fewer parts. Larger batches benefit from economies of scale, making strategic batching a key factor affecting machining price.