Camera Housing CNC Machining Process Explained

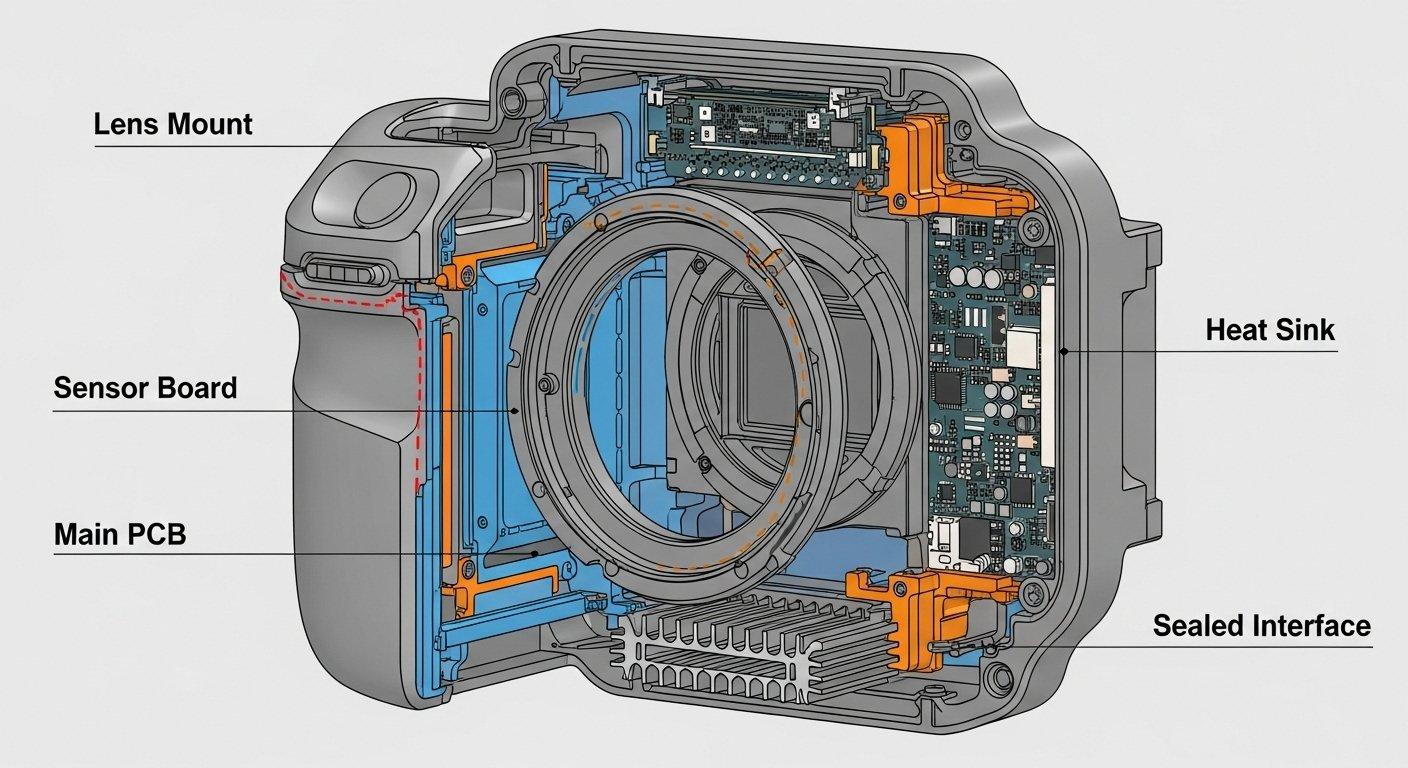

Developing advanced optical and electronic systems often hinges on the integrity and precision of their protective enclosures. Engineers frequently encounter significant challenges in sourcing camera housings that meet stringent specifications for dimensional accuracy, material performance, and surface finish. This can lead to misaligned optical components, compromised thermal management, and a failure to achieve critical environmental sealing requirements.

The repercussions of inadequate camera housing manufacturing are profound, extending beyond mere aesthetics. Subpar machining can result in light leakage affecting sensor performance, structural vulnerabilities that lead to equipment failure in harsh conditions, and costly assembly delays due to parts that do not fit precisely. These issues directly impact product reliability, user satisfaction, and ultimately, market success.

We will explore the definitive CNC machining processes that consistently deliver camera housings capable of robustly protecting sensitive components. This guide offers insights into how meticulous engineering and advanced manufacturing techniques solve these persistent challenges, ensuring superior product outcomes.

Precision CNC machining ensures camera housings provide optimal protection, thermal regulation, and perfect optical alignment through meticulous control over material, tolerance, and finish.

Why CNC Machining is Essential

Precision & Repeatability for Optical Integration

The exact integration of lenses, sensors, and other optical components within a camera housing demands exceptional precision. CNC machining provides the micro-level accuracy required for maintaining optical axes and focal planes. This process guarantees that every housing component is repeatable, critical for mass production.

Material Versatility in Camera Housing Production

CNC machining offers unparalleled flexibility across a wide range of engineering materials. This capability allows manufacturers to select the optimal material for specific environmental, thermal, and mechanical requirements of camera housings. From lightweight aluminum to robust stainless steel, the choice directly impacts performance.

Addressing Complex Geometries in Camera Enclosures

Modern camera designs often feature highly complex internal structures for component mounting and external contours for ergonomics or aesthetic appeal. CNC machining, particularly multi-axis capabilities, is uniquely suited to produce these intricate geometries without compromising structural integrity or design intent.

Key Stages of Camera Housing Machining

Design & CAD/CAM Programming

Preparing 3D Models & Technical Drawings

The journey begins with comprehensive 3D CAD models and technical drawings that fully detail every feature of the camera housing. These models incorporate all critical dimensions, tolerances, material specifications, and surface finish requirements. Accurate digital representation is paramount.

Toolpath Generation & Simulation for Efficiency

Once the design is finalized, CAM software is used to generate precise toolpaths for the CNC machines. This stage involves defining cutting strategies, selecting appropriate tools, and simulating the machining process to optimize efficiency. Simulation identifies potential collisions or inefficiencies before physical production begins.

Material Selection & Preparation for CNC

Common Materials for Camera Housing Machining

Selecting the correct material is fundamental to the performance and durability of the camera housing. Aluminum alloys (e.g., 6061, 7075) are favored for their strength-to-weight ratio and machinability. Magnesium alloys offer even lighter solutions, while certain plastics might be used for specific dielectric properties.

Material Stock Sizing & Fixturing Considerations

Raw material stock is carefully selected and prepared to match the dimensions of the final part, minimizing waste and machining time. Secure fixturing is essential to prevent movement during machining, ensuring accuracy and consistency across all parts. Proper clamping techniques are critical.

| Material Type | Key Attribute | Common Application |

|---|---|---|

| Aluminum 6061 | High strength-to-weight | General-purpose |

| Aluminum 7075 | High strength, aerospace | High-performance |

| Magnesium Alloy | Ultra-lightweight | Portable devices |

| Stainless Steel | Corrosion resistance | Harsh environments |

Core CNC Machining Operations for Housings

Roughing Operations: Material Removal

Roughing is the initial stage where large amounts of material are removed from the raw stock quickly. The goal is to get close to the final part’s geometry, leaving a small margin for subsequent finishing passes. This process prioritizes speed and efficiency.

Finishing Operations: Achieving Tight Tolerances

Finishing operations involve lighter cuts with finer tools to achieve the exact dimensions, tight tolerances, and specified surface finishes. This stage demands high precision and often uses multi-axis machining for complex features. The accuracy here is critical for optical alignment.

Specialized Machining: Threads, Grooves, & Pockets

Camera housings frequently require specific features such as threaded holes for mounting lenses, O-ring grooves for sealing, and precisely sized pockets for electronic components. These are executed with specialized tools and meticulous programming to ensure functional integrity.

Post-Processing & Surface Finishing

Deburring & Cleaning of Machined Components

After machining, parts undergo deburring to remove any sharp edges or burrs that could affect assembly or user safety. Thorough cleaning is then performed to eliminate coolants, chips, and debris, preparing the surface for subsequent treatments. This ensures a clean and precise component.

Anodizing, Plating, & Painting Options for Protection

Surface treatments are vital for protecting the camera housing from environmental factors like corrosion, wear, and abrasion. Anodizing for aluminum offers a durable, protective layer that can also be colored. Plating and painting provide alternative protective and aesthetic finishes.

Surface Texture & Aesthetic Treatments

Beyond protection, surface finishes contribute significantly to the camera housing’s aesthetic and tactile qualities. Options range from smooth, polished surfaces to textured or bead-blasted finishes. These treatments can enhance grip, reduce glare, or meet specific branding requirements.

| Surface Finish Type | Primary Benefit | Example Application |

|---|---|---|

| Anodizing | Corrosion, hardness | Aluminum housings |

| Electroless Nickel | Wear resistance, conductivity | Internal components |

| Powder Coating | Durability, color | Exterior aesthetics |

| Bead Blasting | Matte finish, glare reduction | Ergonomic surfaces |

Quality Control & Inspection

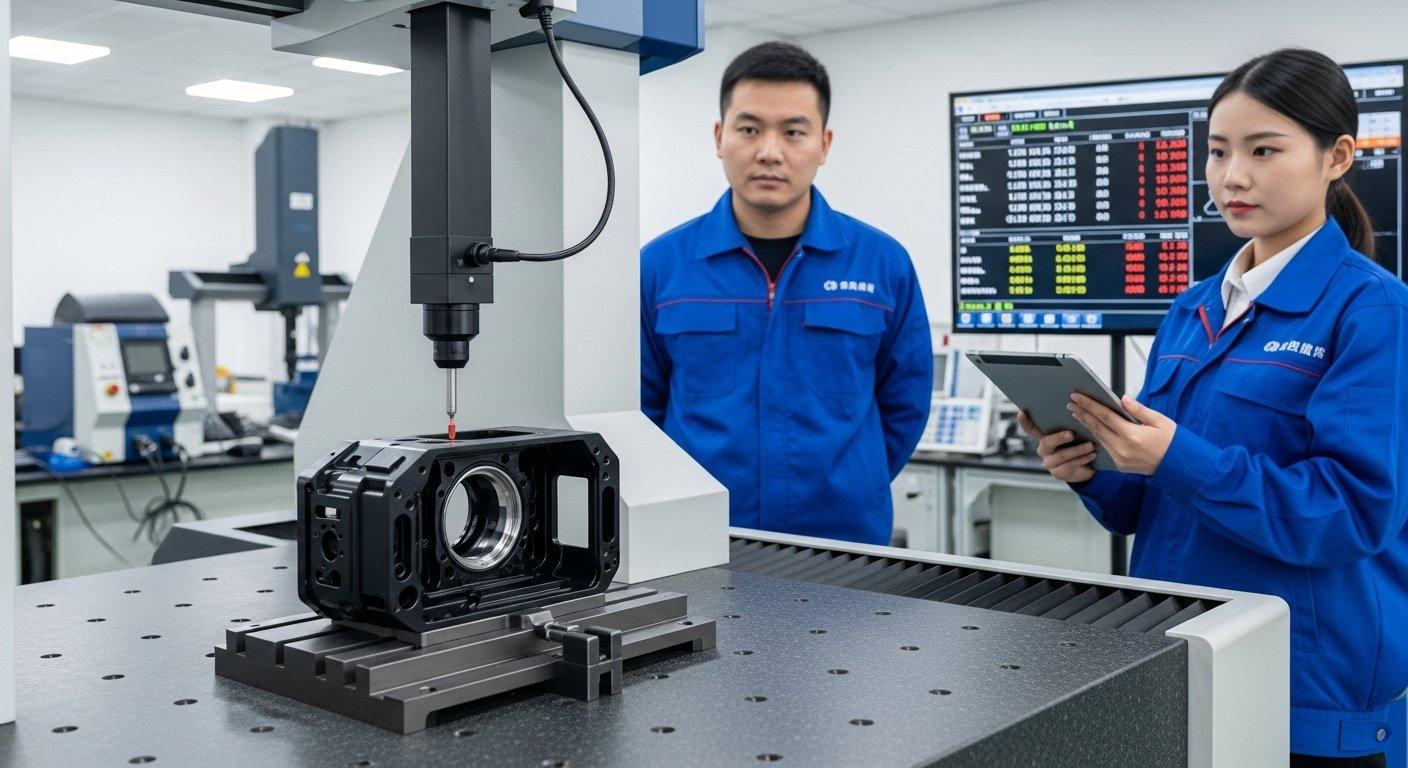

In-Process Checks & Dimensional Verification

Throughout the machining process, in-process checks are conducted using precision measuring tools to verify critical dimensions. This proactive approach ensures consistency and allows for immediate adjustments, preventing costly errors later in the production cycle. Data is collected and analyzed continually.

Final Inspection & Functional Testing

Every completed camera housing undergoes a rigorous final inspection using advanced metrology equipment like CMMs (Coordinate Measuring Machines) and optical comparators. This stage verifies all specified tolerances, surface finishes, and functional features. Functional testing may involve fit checks for optical components or pressure testing for sealed enclosures.

Optimizing Camera Housing Projects

Design for Manufacturability (DFM) for Cost-Effectiveness

Implementing Design for Manufacturability (DFM) principles early in the design phase is crucial for cost-effective production. Our engineers collaborate with clients to review designs, identify potential manufacturing challenges, and suggest modifications. This proactive approach streamlines the process and reduces rework.

Choosing the Right CNC Machining Partner

Source Manufacturer Benefits & Technical Expertise

Partnering with a source manufacturer like ‘ly-machining’ offers distinct advantages, including direct access to engineering expertise, full control over the production process, and transparent communication. Our deep technical knowledge ensures design intent is realized with optimal efficiency and precision.

Transparent Pricing & Project Management

A reliable manufacturing partner provides clear, transparent pricing and robust project management from initial consultation to final delivery. This includes detailed quotations, realistic lead times, and proactive updates. Effective communication minimizes risks and ensures projects stay on track.

Future Trends in Camera Housing Production

Advanced Materials & Hybrid Manufacturing Techniques

The evolution of camera technology drives demand for housings made from advanced composites or high-performance alloys. Hybrid manufacturing, combining additive and subtractive processes, offers new possibilities for intricate internal structures and lightweight designs. This push broadens design possibilities.

Automation & AI Integration in CNC Processes

Increased automation, including robotic loading and unloading, enhances efficiency and consistency in CNC machining. AI-driven systems are beginning to optimize toolpath generation, predict maintenance needs, and improve quality control through real-time data analysis. These advancements contribute to greater precision and reduced human error.

Product Showcase: Precision Machined Components

Our commitment to precision is evident across a diverse range of CNC machined components. From complex optical mounts to high-tolerance electronic enclosures, each part demonstrates superior quality and adherence to strict specifications. We specialize in components where performance and reliability are paramount.

Case Study: High-Performance Drone Camera Housing

Problem: A client approached ‘ly-machining’ with a complex requirement for a drone camera housing. The housing needed to be exceptionally lightweight, highly rigid, and capable of dissipating significant heat generated by internal electronics, all while maintaining IP67 water and dust resistance for extreme operating conditions. Standard aluminum alloys proved too heavy, and traditional sealing methods added bulk.

Our Solution: Our engineering team performed a detailed DFM analysis, recommending a specialized magnesium alloy for its superior strength-to-weight ratio and excellent thermal conductivity. We designed innovative internal fin structures for passive heat dissipation and incorporated precision-machined O-ring grooves. Multi-axis CNC machining enabled us to create thin walls and intricate features without compromising structural integrity.

Result: The client received a drone camera housing that was 30% lighter than their previous aluminum design, while exceeding all rigidity and thermal management requirements. The precision-machined O-ring grooves ensured a perfect IP67 seal, allowing the drone to operate reliably in challenging environments. The project was delivered ahead of schedule, showcasing ‘ly-machining’s technical expertise and commitment to performance.

Invite readers to get a free quote or technical consultation.

What materials are best?

The optimal material for camera housings depends on specific application needs. Aluminum alloys like 6061 and 7075 are popular choices due to their strength-to-weight ratio, machinability, and thermal properties. Magnesium alloys offer even greater weight savings.

Stainless steel provides superior corrosion resistance for harsh environments, while certain engineering plastics can be used for dielectric properties. Our engineers can provide expert guidance on selection.

How are tolerances maintained?

Tolerances are maintained through a combination of precise CAD/CAM programming, advanced multi-axis CNC machines, and rigorous in-process quality control. We utilize high-precision cutting tools and optimize machining strategies.

Our metrology lab, equipped with CMMs and optical comparators, performs continuous dimensional verification. This ensures every critical feature adheres to exact specifications.

What post-processing is available?

We offer a comprehensive range of post-processing and surface finishing options to enhance camera housing performance and aesthetics. These include anodizing, chromate conversion, painting, and powder coating for protection.

Surface textures like bead blasting can be applied for glare reduction or improved tactile feel. We ensure the chosen finish meets both functional and visual requirements.