DFM Essentials for Complex Brass Parts

Quick Solution: Optimizing complex brass parts DFM involves proactive design adjustments, material selection, and machining strategy to minimize costs, enhance quality, and accelerate production through expert **Brass Machinability Design**.

Are you battling manufacturability headaches, escalating costs, or frustrating delays for your intricate brass part designs? Discover the critical DFM strategies that transform complex concepts into flawlessly machined realities, saving you time and money.

Effective Design for Manufacturability (DFM) is paramount for intricate components. Especially when dealing with **CNC Machining Brass**, understanding its unique characteristics is key to success. This guide provides essential **DFM Guidelines Brass** from a manufacturer’s perspective.

Complex Brass DFM: Why It Matters

Reduce Costs and Lead Times

Implementing DFM for **Complex Brass Parts DFM** early in the design cycle significantly cuts overall project costs. It avoids expensive redesigns and tooling modifications that arise from manufacturability issues discovered late.

By optimizing material usage and streamlining machining processes, DFM ensures efficient production. This proactive approach directly translates into shorter lead times, bringing your products to market faster.

Improve Part Quality & Reliability

DFM ensures that designs are inherently manufacturable, leading to parts that consistently meet specified tolerances and surface finishes. This reduces the risk of defects and improves the functional performance of components.

In our experience, proper **Brass Machinability Design** prevents common quality issues such as burrs, chatter marks, and dimensional inaccuracies. It guarantees higher reliability in demanding applications.

Avoid Costly Design Rework

Identifying potential manufacturing challenges during the design phase is crucial. DFM consultation helps pinpoint areas that might cause production bottlenecks or require excessive manual intervention.

Addressing these issues pre-production eliminates the need for costly redesigns and re-tooling after prototyping. This saves significant time and resources, ensuring a smoother transition from design to mass production.

Brass Material & Machining Challenges

Selecting Common Brass Alloys

Brass is an alloy primarily of copper and zinc, with various compositions offering different properties. Selecting the right alloy is a critical step in **Brass Machinability Design**.

Common alloys like C36000 (Free Machining Brass) offer excellent machinability due to lead content. Other options, such as C26000 (Cartridge Brass), provide better ductility but can be more challenging to machine.

| Alloy | Machinability Rating (C36000=100) | Key Properties | Typical Applications |

|---|---|---|---|

| C36000 | 100 | Excellent machinability, good strength | Fittings, fasteners, valve components |

| C26000 | 30 | High ductility, good corrosion resistance | Electrical connectors, ammunition cases |

| C46400 | 30 | Naval brass, good corrosion resistance in seawater | Marine hardware, propeller shafts |

Cutting Characteristics & Consids

Brass typically produces short, brittle chips, which is advantageous for chip evacuation in **CNC Machining Brass**. However, proper tooling and cutting parameters are essential to prevent built-up edge and poor surface finish.

Tool wear is also a consideration, as some brass alloys can be abrasive. Optimizing feed rates, spindle speed, and depth of cut is vital for efficient material removal and tool longevity.

Thermal Expansion & Warp Control

Brass has a relatively high coefficient of thermal expansion compared to other metals like steel. This property requires careful consideration during machining to prevent thermal distortion and warpage.

Effective coolant strategies and rigid workholding fixtures are crucial. They help manage heat generation and maintain dimensional stability, especially for thin-walled or intricate **Complex Brass Parts DFM**.

Core CNC Machining DFM Principles

Simplify Part Geometry

Simplifying part geometry is a fundamental DFM principle. Unnecessary features or overly complex contours can significantly increase machining time and tooling costs.

In our experience, combining features or designing simpler, functional forms reduces setup changes and tool movements. This streamlines the manufacturing process and lowers overall part cost.

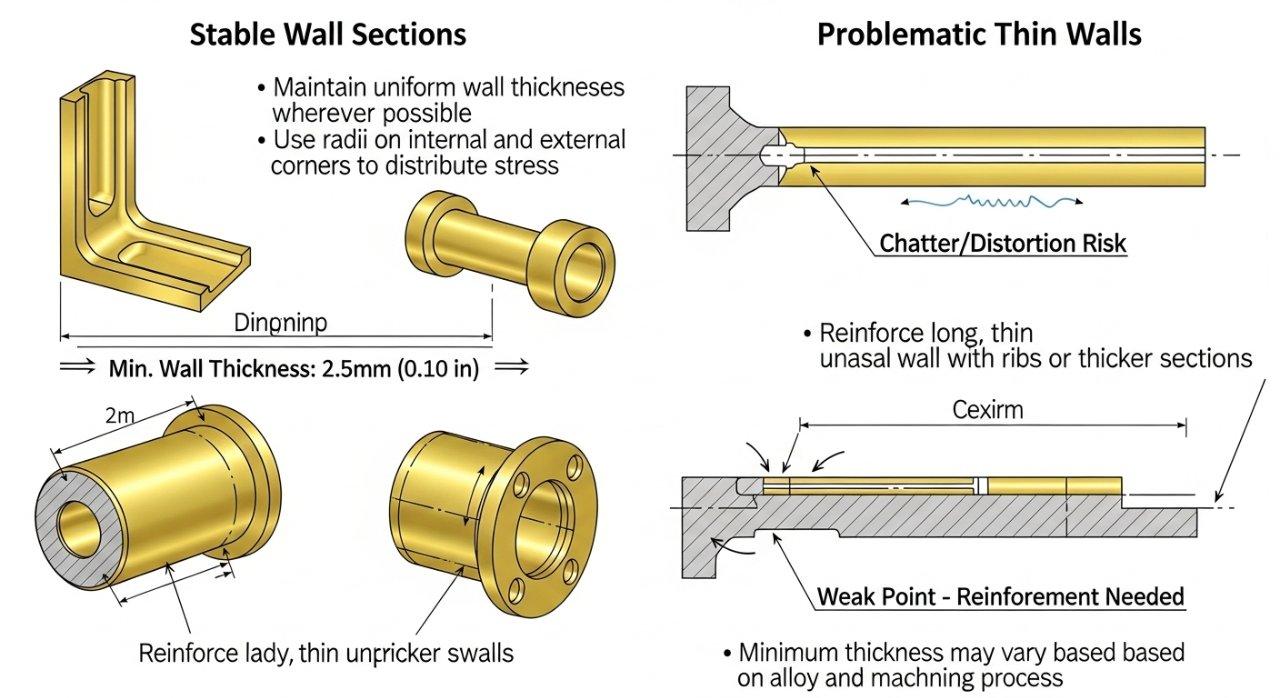

Wall Thickness & Support Structures

Maintaining adequate wall thickness is critical for brass parts. Walls that are too thin are prone to vibration, chatter, and distortion during **CNC Machining Brass**, leading to poor surface finish and dimensional inaccuracies.

Designers should aim for consistent wall thicknesses where possible. Incorporating support structures or fillets can strengthen thin areas, improving manufacturability and part integrity.

| Feature Type | Recommended Minimum Thickness (mm) | Rationale |

|---|---|---|

| General Walls | 0.8 – 1.5 | Prevents chatter, ensures structural integrity |

| Features Requiring High Strength | > 2.0 | Increases rigidity, reduces deflection |

| Bosses/Ribs | 0.5 – 1.0 (relative to wall) | Provides support, aids heat dissipation |

Optimizing Internal Corner Radii

Sharp internal corners are challenging and costly to machine, requiring specialized small tools or EDM processes. They can also create stress concentration points.

Generous internal radii, typically matching standard end mill sizes, are preferred. This improves tool life, reduces machining time, and enhances the structural integrity of the part, aligning with **DFM Guidelines Brass**.

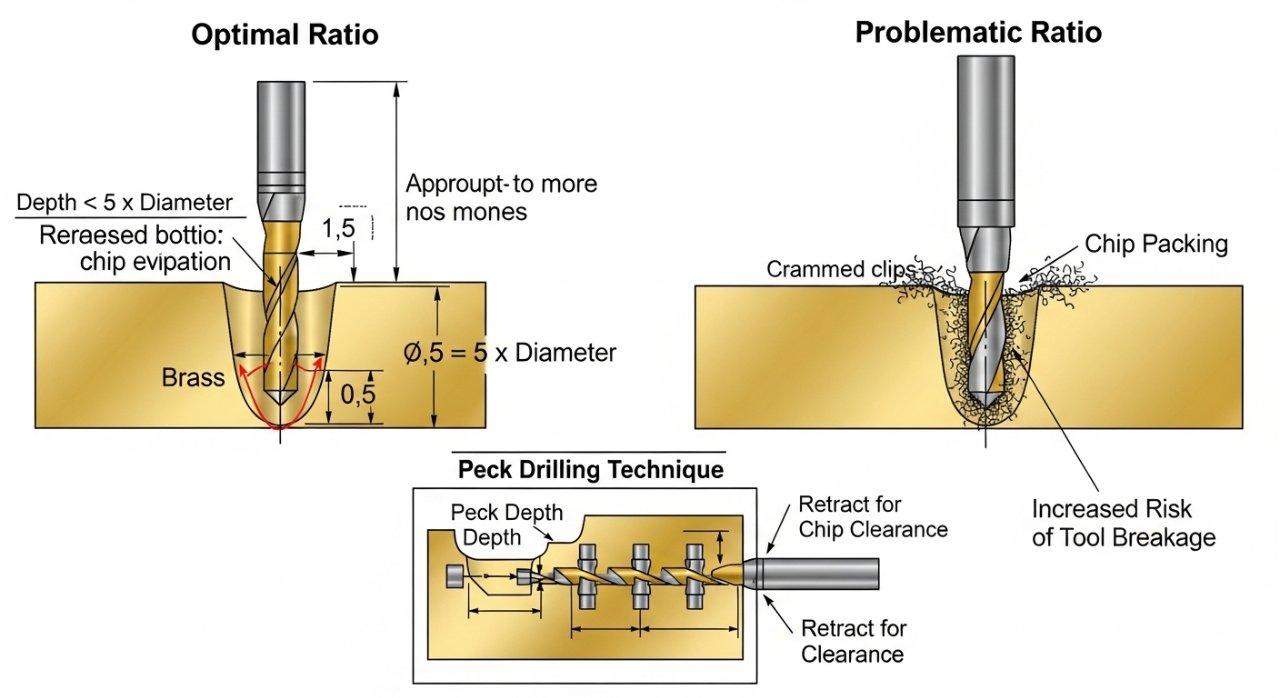

Hole Depth-to-Diameter Ratios

Drilling deep holes in brass can be problematic due to chip evacuation challenges and potential tool deflection. A common issue we see is designers specifying excessive depth-to-diameter ratios.

For optimal **Brass Machinability Design**, aim for depth-to-diameter ratios generally not exceeding 3:1 to 5:1 for standard drilling. Deeper holes may require peck drilling cycles or specialized gun drills, increasing cost.

Thread & Chamfer Design Tips

Specifying standard thread sizes and depths is a key DFM principle. Custom threads or excessively long thread engagements increase machining complexity and potential for tap breakage in brass.

Chamfers are often preferred over sharp edges for ease of handling, assembly, and deburring. They also reduce the risk of burr formation during subsequent machining operations, contributing to better part quality.

Minimize Tight Tolerance Zones

While **CNC Machining Brass** can achieve high precision, specifying overly tight tolerances unnecessarily increases manufacturing costs and time. Each tight tolerance requires more precise machining, specialized inspection, and potentially multiple operations.

Focus on applying tight tolerances only to critical features that genuinely impact part function or assembly. Our DFM experts can help identify and optimize these zones, ensuring cost-effective production.

Surface Finish & Tolerance Strategies

Defining Surface Roughness Needs

Surface finish requirements, often expressed in Ra (Roughness average) values, directly impact machining time and cost. A smoother finish requires finer tools, slower feed rates, and often additional polishing or finishing steps.

In our experience, clearly defining the functional need for surface roughness helps avoid over-specification. Matching the finish to the application’s true requirements is a cornerstone of efficient **Brass Machinability Design**.

Tolerance Impact on Cost

The relationship between tolerance and cost is exponential; tighter tolerances demand more sophisticated machines, specialized tooling, and extensive quality control. This significantly drives up unit cost for **Complex Brass Parts DFM**.

Partnering with ‘ly-machining’ allows our engineers to review your design and suggest achievable tolerances. We ensure your parts meet functional requirements without incurring unnecessary manufacturing expenses.

| Dimension Type | Standard Tolerance (mm) | Precision Tolerance (mm) | Cost Impact |

|---|---|---|---|

| Linear Dimensions | ±0.05 – ±0.1 | ±0.01 – ±0.03 | Medium to High |

| Diameters (Non-Critical) | ±0.05 – ±0.1 | ±0.01 – ±0.02 | Medium to High |

| Diameters (Critical) | ±0.01 – ±0.02 | ±0.005 – ±0.01 | High |

| Flatness/Perpendicularity | 0.05 – 0.1/100mm | 0.02 – 0.05/100mm | High |

Avoid Over-Specification

A common pitfall is over-specifying tolerances or surface finishes beyond what is functionally necessary. This adds complexity and cost without providing real value to the end product.

Our DFM experts collaborate with your design team to understand the true functional requirements of your **Complex Brass Parts DFM**. We then advise on optimal specifications that balance performance with cost-effectiveness.

Efficient CNC Machining Techniques

Optimal Workholding Fixture Design

Rigid and stable workholding is paramount for precision **CNC Machining Brass**. Improper fixturing can lead to chatter, part movement, and subsequent dimensional inaccuracies, especially for intricate geometries.

Custom-designed fixtures ensure parts are held securely, minimizing vibration and distortion. This also facilitates efficient loading and unloading, contributing to faster cycle times and better quality.

Tool Selection & Path Optimization

The choice of cutting tools and the optimization of tool paths are critical for brass machining. Tools with sharp edges, high rake angles, and polished flutes are often preferred to promote clean cuts and efficient chip evacuation.

Sophisticated CAM programming ensures optimized tool paths that reduce air cuts, manage cutting forces, and minimize tool changes. This directly impacts machining efficiency and surface finish for **Complex Brass Parts DFM**.

Multi-Axis Machining Applications

For truly complex brass parts with intricate geometries or multiple features on different faces, multi-axis (4-axis or 5-axis) CNC machining is invaluable. It reduces the need for multiple setups, which can introduce error.

This technology allows for continuous contouring and access to difficult-to-reach features in a single setup. The result is improved accuracy, better surface finish, and significantly reduced lead times for sophisticated designs.

Chip Management & Waste Reduction

Effective chip management is essential when **CNC Machining Brass** due to its brittle chip formation. Proper coolant application and chip breaking techniques prevent chip re-cutting and ensure a clean cutting zone.

Efficient chip evacuation not only protects the tool and part but also facilitates material recycling. This reduces waste and contributes to a more sustainable and cost-effective manufacturing process.

Partnering with Brass Machining Experts

Our DFM Consultation Services

At ‘ly-machining’, our DFM consultation services are designed to integrate seamlessly with your design process. We provide expert feedback on your **Complex Brass Parts DFM** designs, identifying potential manufacturability issues early.

Our engineers collaborate closely with your team, offering recommendations for material selection, geometric modifications, and tolerance optimization. This ensures your designs are optimized for both performance and cost.

Advanced Equipment & Expertise

We pride ourselves on our state-of-the-art CNC machining capabilities and a team of highly skilled engineers. Our facility is equipped with advanced multi-axis machines, precision tooling, and sophisticated inspection equipment.

This ensures we can consistently produce highly complex brass parts with exceptional accuracy and surface finish. Our processes adhere to rigorous quality standards, including ISO and AS9100.

Transparent Pricing & Quality Assurance

Transparency is a cornerstone of our service. We provide clear, detailed quotes that outline all manufacturing costs, ensuring there are no hidden fees. Our aim is to build long-term trust with our clients.

Our comprehensive quality assurance system monitors every stage of production. From raw material inspection to final dimensional verification, we guarantee that every part meets your precise specifications.

Featured Success Stories

**Case Study: Precision Valve Body Optimization**

Problem: A client approached ‘ly-machining’ with an intricate brass valve body design for a high-pressure fluid system. The design featured extremely thin internal walls and tight concentricity tolerances. Their previous supplier experienced high rejection rates due to distortion and inconsistent bore diameters during machining.

Solution: Our DFM team conducted an in-depth review of the client’s design. We recommended a slight increase in the wall thickness of a non-critical internal channel (0.3mm adjustment) and the addition of a small fillet radius in a specific corner. We then developed a multi-axis machining strategy with optimized tool paths and custom low-clamping force fixtures.

Result: By implementing these minor **DFM Guidelines Brass** adjustments, ‘ly-machining’ achieved a 99.7% first-pass yield on the valve bodies. The optimized process reduced machining time by 22% and completely eliminated material waste from scrapped parts. The client received high-quality, perfectly concentric valve bodies ahead of schedule, enabling them to meet urgent market demand.

Conclusion & Next Steps

Consult Our DFM Experts Today

Mastering **DFM Guidelines Brass** is essential for cost-effective and high-quality production of complex parts. By integrating our DFM expertise early, you transform challenging designs into manufacturable realities.

Our ‘ly-machining’ team is ready to apply our deep experience in **CNC Machining Brass** to your next project. We help you navigate material selection, optimize geometry, and ensure unparalleled precision.

Request a Custom Quote

Ready to optimize your complex brass part designs for peak manufacturability and unparalleled quality? Contact our DFM experts today for a complimentary design review and transparent quote, and let our technical excellence bring your vision to life.

What is DFM for brass parts?

Design for Manufacturability (DFM) for brass involves optimizing a part’s design to ensure it can be produced efficiently and cost-effectively. It considers material properties and machining processes.

This proactive approach minimizes production challenges. It also helps in achieving desired quality and performance.

Why is brass DFM important?

DFM is crucial for complex brass parts to prevent costly redesigns and manufacturing errors. It improves part quality, reduces machining time, and shortens lead times.

Proper **Brass Machinability Design** ensures your intricate components meet specifications reliably. It optimizes both cost and performance.

What brass alloys are best for CNC?

C36000 (Free Machining Brass) is often preferred due to its excellent machinability and short, brittle chips. Other alloys like C26000 (Cartridge Brass) are used for specific properties.

The optimal choice depends on the specific application’s strength, corrosion resistance, and formability requirements. Our experts can guide your material selection.