Frustrated with high CNC machining costs and unexpected production delays? You’ve perfected your design, but the quotes are staggering and the lead times are discouraging. This often stems from a design that isn’t optimized for manufacturing, leading to unnecessary complexity and expense.

The constant back-and-forth with machine shops, the budget overruns, and the compromised timelines can derail your entire project. It’s a common problem where innovative designs clash with the practical realities and limitations of CNC milling processes, leaving you to feel stuck.

Fortunately, by implementing Design for Manufacturability (DFM) principles, you can bridge this gap. This guide will show you how to refine your product design for efficient CNC machining, significantly reducing costs and accelerating your time to market.

Understanding these DFM principles is therefore crucial before you send your design for production. Moreover, a design optimized for CNC machining not only saves money but also enhances the final product’s quality and consistency. Consequently, let’s explore the key strategies that will transform your design into a manufacturing success.

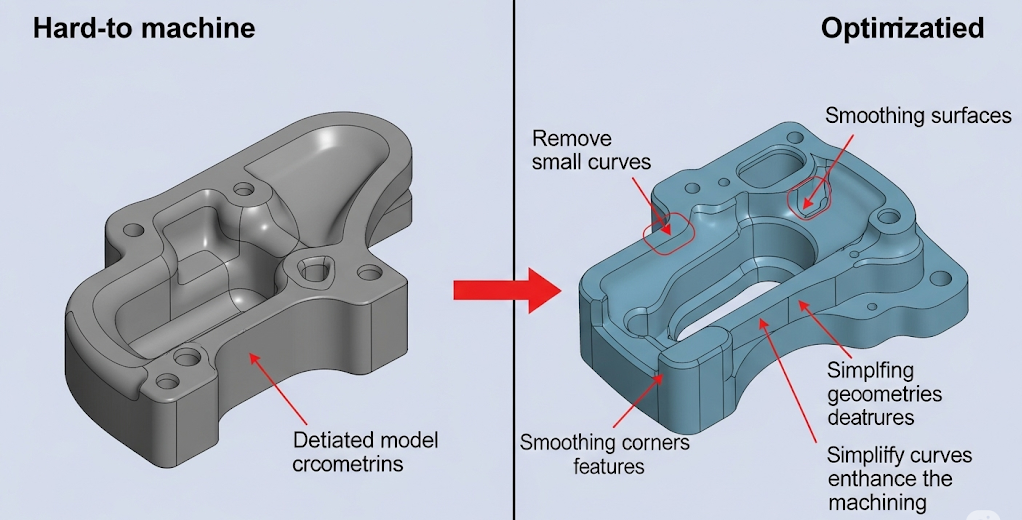

Simplify Geometry for Efficient CNC Milling

Complex shapes often require specialized tooling and multiple machine setups. Every additional setup increases both time and the potential for errors. Simplifying your design’s geometry is a direct path to cost reduction in CNC machining.

We recommend avoiding deep, narrow pockets and sharp internal corners. Instead, opt for generous corner radii, as standard cutting tools are round. This simple adjustment allows for faster, more continuous toolpaths during the CNC milling process.

Key Geometry Optimizations:

| Design Choice | Impact on CNC Machining | Recommendation |

| Complex, freeform surfaces | Requires 5-axis machining, longer programming | Use simpler, prismatic shapes where possible |

| Sharp internal corners | Requires smaller tools, slower speeds | Use a radius of at least 1/8th of the cavity depth |

| Deep, narrow pockets | Risk of tool breakage and poor chip evacuation | Design pockets with a depth-to-width ratio under 4:1 |

At ly-machining, we frequently collaborate with clients to identify these opportunities for simplification. By making small, strategic changes, we can often reduce machining time significantly, which directly translates to lower costs for your project.

Standardize Features and Tolerances

Non-standard hole sizes, unique thread types, and unnecessarily tight tolerances are common drivers of high CNC machining costs. Each non-standard element may require custom tooling or additional quality control steps.

Strive to use standard drill sizes and common thread specifications in your designs. This allows shops like ly-machining to use off-the-shelf tooling, which is more economical and readily available. This simple step can streamline the entire CNC milling workflow.

Furthermore, critically evaluate the required tolerances for each feature. While precision is important, applying tight tolerances across an entire part when only a few surfaces are critical is a costly mistake. Specify tighter tolerances only where they are functionally necessary. Looser tolerances on non-critical features will reduce both machining time and inspection efforts.

Select the Right Material for CNC Machining

Material choice profoundly impacts the manufacturability and cost of your part. Harder materials like stainless steel or titanium are more difficult and slower to machine than softer materials like aluminum or plastics.

Consider the functional requirements of your part. Does it need high strength, corrosion resistance, or heat tolerance? Align your material selection with these needs, but also consider the machinability. For prototypes or non-critical components, using a more machinable material can offer substantial savings.

Our team at ly-machining can provide expert guidance on material selection. We help you balance performance requirements with your budget and timeline, ensuring the chosen material is optimized for the CNC milling process.

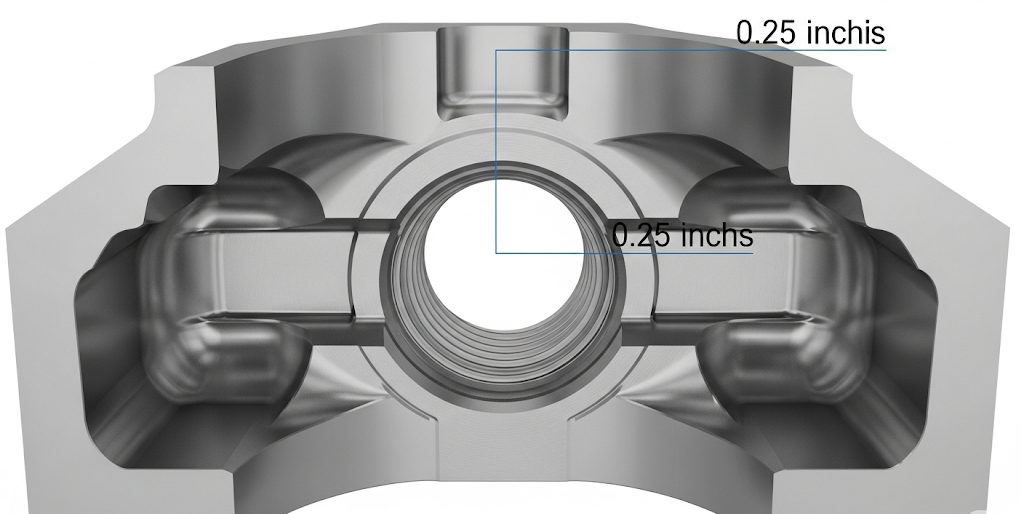

Optimize Wall Thickness and Feature Design

Thin walls present a significant challenge in CNC machining. They are prone to vibration and deformation during the milling process, which can lead to inaccuracies and a poor surface finish. This often forces the machinist to use slower speeds, increasing cycle time.

As a general rule, aim for a minimum wall thickness of 0.8mm for metals and 1.5mm for plastics. Maintaining a uniform wall thickness throughout the part also helps prevent warping and ensures dimensional stability.

Additionally, pay close attention to the design of small features. Features that are too small or delicate can be difficult to produce reliably with standard cutting tools. Combining or simplifying small features can improve the robustness of your design and make the CNC milling process more efficient.

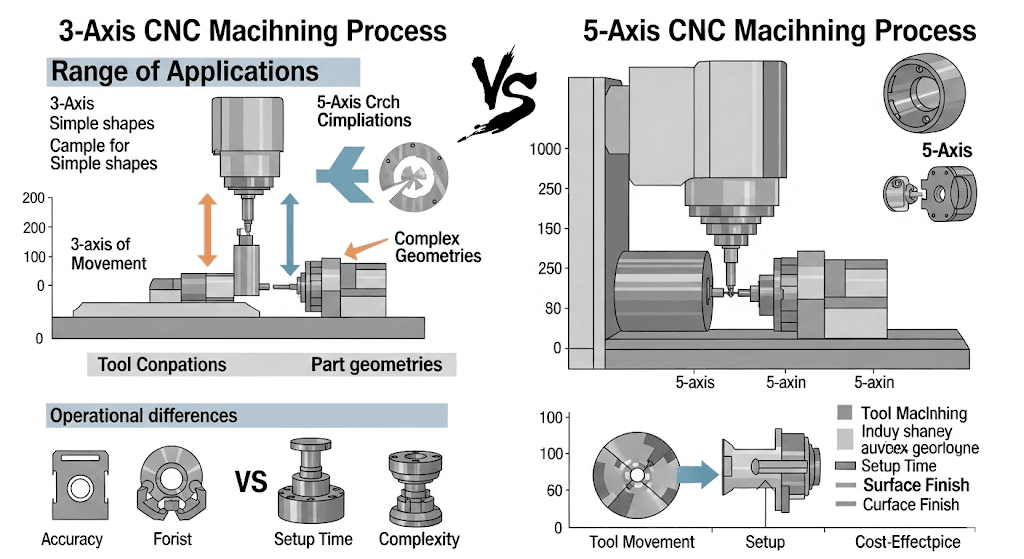

Reduce Machine Setups and Operations

Every time a part needs to be removed and re-fixtured in a different orientation, it introduces time and potential for error. A key goal of DFM for CNC machining is to minimize the number of required setups.

Try to design your part so that all features can be accessed from as few sides as possible, ideally just one. This allows the part to be machined in a single setup on a standard 3-axis machine. If features on multiple faces are unavoidable, consider if minor design tweaks could consolidate them.

For instance, could a through-hole eliminate the need for an operation on the opposite side? Could features be aligned to the same plane? These considerations are vital for cost-effective CNC milling. At ly-machining, our process engineers review designs to identify opportunities for setup reduction.

Relevant Questions

How does part volume affect DFM for CNC machining?

For low-volume production or prototyping, some DFM rules can be relaxed, as the cost of custom fixtures or multiple setups is spread over fewer parts. However, for high-volume production, optimizing for single-setup machining and using standard tooling becomes critically important to achieving a low per-unit cost. The principles of simplifying geometry and selecting machinable materials are beneficial across all production volumes.

Can DFM principles be applied to 5-axis CNC machining?

Absolutely. While 5-axis CNC machining allows for the creation of highly complex geometries in a single setup, DFM is still crucial. Optimizing designs for 5-axis work involves ensuring tool access, avoiding deep and narrow cavities where chips can’t escape, and designing features that can be cut with standard-length tools. Applying DFM can significantly reduce complex toolpath calculations and overall machining time, even on advanced machinery.

Frequently Asked Questions

1. What is the most common DFM mistake in CNC machining design?

The most frequent issue we see is the specification of unnecessarily tight tolerances. Designers often apply a blanket tolerance to the entire part, which dramatically increases machining time and inspection costs. It’s vital to apply tight tolerances only to critical functional surfaces and allow for looser, more economical tolerances on non-critical features.

2. How does corner radius impact the cost of CNC milling?

A generous internal corner radius is a key cost-saving measure. Sharp or small-radius internal corners require very small cutting tools, which must run at slower speeds and are more prone to breaking. By designing with a larger radius, a larger, more robust tool can be used, allowing for faster material removal and reducing overall cycle time and tool cost.

3. Why is uniform wall thickness important for CNC machining?

Maintaining a uniform wall thickness is crucial for preventing part warping and ensuring dimensional accuracy. Thin walls can vibrate or deflect under the force of the cutting tool, leading to an inconsistent finish and inaccurate dimensions. Uniformity helps distribute stress evenly and makes the part more stable during the CNC milling process.