Developing advanced drones often presents a significant challenge: achieving the delicate balance between structural integrity, minimal weight, and operational longevity. Designers frequently grapple with how the intrinsic properties of a component’s material will directly translate into flight performance and system reliability, especially when pushing the boundaries of current technology.

A misstep in this critical decision can lead to cascading issues, from compromised flight endurance due to excessive weight to structural failures under dynamic loads or premature degradation in harsh operating environments. Such outcomes can result in costly redesigns, prolonged development cycles, and, ultimately, a diminished market competitive advantage for innovative drone platforms.

However, through a meticulous, data-driven approach to material science and precision engineering, it is possible to transform these challenges into opportunities for unprecedented aerial innovation. The key lies in understanding how expert material selection, coupled with advanced manufacturing techniques, fundamentally redefines a drone’s capabilities.

Optimal material selection, precision CNC machining, and rigorous testing are critical to unlocking superior performance and reliability in drone components.

The Criticality of Drone Material Selection

Why Material Choice Defines Drone Performance

The choice of material for any drone component is not merely a manufacturing step; it is a foundational design decision. Every gram added or subtracted, and every micron of structural integrity, directly influences critical performance metrics. These include flight time, payload capacity, maneuverability, and overall operational efficiency.

The intrinsic properties of selected materials dictate how a drone will perform under varying operational stresses and environmental conditions. This directly impacts everything from battery life and range to resistance against vibration and temperature fluctuations. Therefore, a comprehensive understanding of material science is indispensable for optimal drone design.

Our Expertise in CNC Machined Drone Components

At ly-machining, located in Shenzhen, China, our deep technical expertise is centered on transforming advanced material specifications into high-precision CNC machined drone components. We operate as a trusted source manufacturer, providing a rigorous engineering approach to material selection and fabrication.

Our focus extends beyond mere manufacturing; we provide critical guidance on how specific material characteristics will interact with precise machining processes. This ensures the final component performs exactly as intended within the demanding context of modern drone applications.

Key Factors for Drone Parts Material Selection

Strength-to-Weight Ratio in Drone Components

For any airborne vehicle, the strength-to-weight ratio is a paramount consideration. Materials that offer exceptional strength while maintaining minimal density are highly sought after to maximize flight duration, increase payload capacity, and enhance overall agility. This critical balance directly influences a drone’s practical utility and operational envelope.

The mechanical loads on drone components, from propeller forces to landing impacts, necessitate materials that can withstand significant stress without deforming or failing. Simultaneously, every gram contributes to the overall weight, impacting energy consumption and maneuverability.

Environmental Resistance for Drone Operation

Drones operate in a diverse range of environments, from arid deserts to humid coastal regions, and at varying altitudes with distinct temperature profiles. The selected materials must exhibit robust resistance to environmental factors such as moisture, UV radiation, temperature extremes, and chemical exposure.

Components exposed to the elements, like frames, landing gear, and sensor housings, require materials that will not corrode, degrade, or lose their mechanical properties over time. This ensures long-term reliability and safety, particularly in critical applications.

Fatigue Life and Durability of Drone Materials

Drone components are subjected to repetitive stresses and vibrations during flight, leading to fatigue over their operational lifespan. A material’s ability to resist fatigue cracking and retain its structural integrity under cyclical loading is crucial for component longevity and safety.

Materials with high fatigue limits ensure that parts, such as motor mounts and propeller hubs, can withstand thousands of flight hours without unexpected failure. This directly contributes to the overall durability and reliability of the drone system, mitigating risks associated with material degradation.

Cost-Effectiveness for CNC Machined Drone Parts

While performance is often the primary driver, the overall cost-effectiveness of material selection remains a significant factor in drone manufacturing. This involves balancing material acquisition costs, machinability, tooling expenses, and the economic impact of post-processing.

Selecting a material that meets performance requirements without incurring excessive manufacturing costs is key to viable production. This strategic balance ensures that high-performance drone technology remains accessible and competitive in the market.

Common Materials for CNC Machined Drone Parts

Aluminum Alloys for Lightweight Drone Structures

Aluminum alloys are foundational in drone manufacturing due to their excellent strength-to-weight ratio and inherent machinability. Their versatility allows for broad application across various drone platforms, from commercial inspection UAVs to hobbyist quadcopters.

These alloys provide a robust yet lightweight solution for critical structural elements, contributing significantly to flight efficiency and overall payload capacity. Their widespread availability and relatively lower cost also make them a popular choice.

Al 6061: Versatility for General Drone Parts

Aluminum 6061 is a highly versatile alloy widely used for general-purpose drone components, including structural frames, landing gear, and mounting brackets. It offers a good combination of strength, weldability, and corrosion resistance. Its excellent machinability makes it a cost-effective choice for various designs.

It is particularly well-suited for parts where moderate strength is acceptable and ease of fabrication is a priority. This alloy provides a reliable and economical option for many non-critical drone applications.

Al 7075: High-Strength for Critical Drone Loads

Aluminum 7075 is an aerospace-grade alloy known for its exceptional strength, comparable to many steels, making it ideal for highly stressed drone components. Applications include critical structural elements, propeller hubs, and motor mounts where high tensile strength and yield strength are paramount.

Its superior mechanical properties, particularly after appropriate heat treatment, enable the design of lighter yet incredibly robust parts. This makes Al 7075 indispensable for high-performance and heavy-lift drone applications.

Titanium Alloys in High-Performance Drones

Titanium alloys represent the pinnacle of material selection for extreme-performance drone applications. Their unparalleled strength-to-weight ratio, combined with exceptional corrosion resistance and high-temperature tolerance, makes them ideal for the most demanding scenarios. While more costly, their benefits in critical situations are unmatched.

They are often reserved for specialized, high-value drone systems where component failure is not an option. This includes military, defense, and advanced industrial inspection drones operating in harsh or sensitive environments.

Ti-6Al-4V: Extreme Strength for Aerospace Drone Components

Titanium alloy Ti-6Al-4V is the workhorse of the aerospace industry and a prime choice for high-performance drone components. It offers an outstanding combination of high strength, low density, and excellent corrosion resistance. This makes it perfect for parts like critical airframe joints, landing gear struts, and highly loaded fasteners.

Its ability to withstand extreme temperatures and harsh environments ensures reliability in the most challenging operational contexts. Precision CNC machining is essential to process this robust yet difficult-to-machine material effectively.

High-Performance Plastics for Specialized Drone Needs

Advanced engineering plastics are increasingly utilized in drone manufacturing for their unique blend of properties, including light weight, electrical insulation, and chemical resistance. They are particularly suitable for specialized components where metallic properties are either unnecessary or detrimental.

These materials offer solutions for parts requiring specific thermal or dielectric properties, or for components that benefit from lower friction coefficients. Their use helps reduce overall weight and can simplify certain assembly processes.

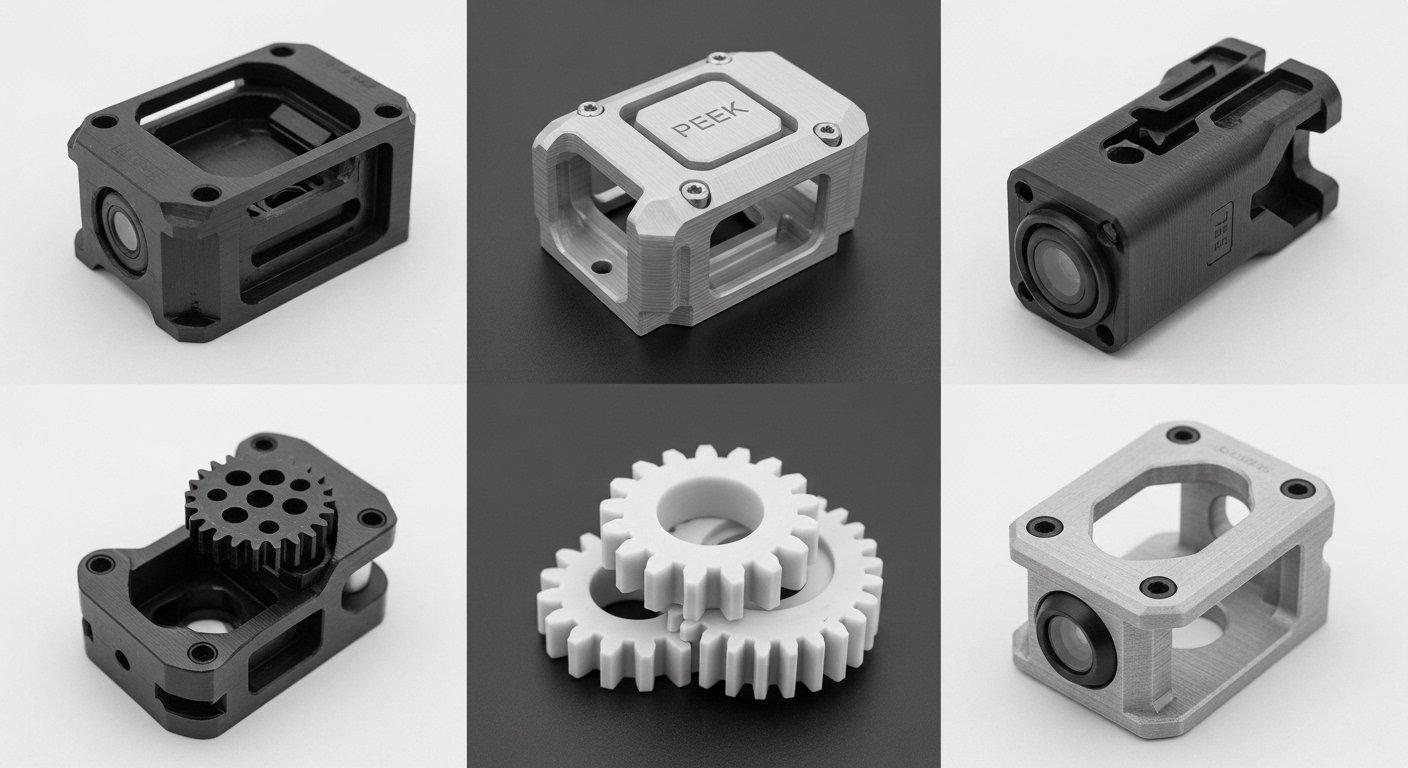

PEEK: Thermal Stability in Drone Electronics Housings

Polyether Ether Ketone (PEEK) is a high-performance thermoplastic renowned for its excellent thermal stability, chemical resistance, and mechanical strength at elevated temperatures. It is an ideal material for drone electronics housings, sensor enclosures, and connectors.

PEEK provides robust protection for sensitive electronic components against heat, moisture, and chemical exposure. Its lightweight nature also contributes to overall drone efficiency, making it a valuable material for specific internal applications.

Delrin (POM): Precision for Moving Drone Mechanisms

Delrin, a brand name for Polyoxymethylene (POM), is a strong, stiff thermoplastic with excellent dimensional stability and low friction properties. It is frequently chosen for precision-machined moving drone mechanisms, such as gears, bearings, and small linkages.

Its inherent lubricity and resistance to wear make it suitable for components requiring smooth, consistent motion without the need for external lubrication. This contributes to the longevity and quiet operation of mechanical drone systems.

Performance Analysis of CNC Machined Drone Materials

Mechanical Properties: Strength, Stiffness, Hardness

The mechanical properties of materials are fundamental to engineering durable and reliable drone components. Understanding tensile strength, yield strength, stiffness (elastic modulus), and hardness is critical for predicting how a part will behave under operational stresses. These properties dictate the material’s resistance to deformation and fracture.

Proper material selection based on these parameters ensures that drone parts can withstand the dynamic forces encountered during flight, landing, and accidental impacts. This is key to preventing catastrophic failures and ensuring operational safety.

Tensile Strength & Yield Strength for Drone Components

Tensile strength, the maximum stress a material can withstand before breaking, and yield strength, the stress at which a material begins to deform permanently, are critical for structural integrity. For drone components, these properties define the load-bearing capacity and resilience against structural failure.

High tensile and yield strengths are essential for parts under constant tension or compression, such as frame members, motor shafts, and propeller hubs. These metrics ensure that components can endure operational forces without permanent damage or failure.

Impact Resistance in Dynamic Drone Applications

Drones, especially those operating in challenging environments or performing complex maneuvers, are susceptible to impacts. The material’s ability to absorb energy and resist fracture under sudden, intense loads is crucial for component survival and overall drone durability.

Components like landing gear, protective guards, and certain structural elements require materials with high impact resistance. This property mitigates damage from hard landings or unforeseen collisions, extending the drone’s operational life.

Thermal Performance: Heat Dissipation for Drone Systems

Drone electronics, motors, and batteries generate significant heat during operation, which can compromise system performance and longevity if not properly managed. The thermal conductivity of component materials plays a vital role in dissipating this heat efficiently.

Materials used for motor housings, ESC mounts, and battery compartments must either conduct heat away effectively or insulate sensitive components from external thermal fluctuations. This ensures optimal operating temperatures and prevents thermal runaway.

Vibration Damping and Acoustic Properties for Drones

Vibration generated by motors and propellers can propagate throughout the drone structure, leading to reduced sensor accuracy, premature component wear, and structural fatigue. Materials with good vibration damping properties can significantly mitigate these detrimental effects.

Effective vibration damping enhances the clarity of sensor data, prolongs the lifespan of electronic components, and contributes to a quieter operational profile. This is especially important for inspection or surveillance drones where minimal acoustic signature is desired.

Corrosion Resistance for Outdoor Drone Use

Many drones operate outdoors, exposing their components to moisture, humidity, and potentially corrosive atmospheric conditions. The inherent corrosion resistance of a material is critical for maintaining structural integrity and aesthetic appeal over time.

Materials selected for external components must resist oxidation and other forms of chemical degradation. This ensures long-term reliability and reduces maintenance requirements, especially for drones deployed in marine or agricultural settings.

Optimizing CNC Machining for Drone Parts Materials

Machinability Considerations for Lightweight Alloys

While lightweight alloys like aluminum and titanium are highly desirable for drones, their specific properties present unique machining challenges. Optimizing cutting speeds, feed rates, and tool selection is critical to prevent material deformation, maintain surface integrity, and extend tool life.

Effective machining strategies account for material hardness, thermal expansion, and chip evacuation, ensuring that the finished parts meet exact specifications without defects. This precision is essential for achieving the designed performance of drone components.

Achieving Tight Tolerances in Drone Component Machining

Drone performance is often reliant on the precise fit and alignment of its components. Achieving exceptionally tight tolerances, often measured in microns, is non-negotiable for critical interfaces like motor mounts, bearing housings, and sensor integration points.

Our advanced multi-axis CNC machines and stringent quality control processes ensure that all components are manufactured to the exact specified dimensions. This level of precision guarantees optimal assembly, reduced vibration, and reliable operational performance.

Surface Finish Requirements for Aesthetic & Functional Drone Parts

The surface finish of CNC machined drone parts influences both aesthetic appeal and functional performance. A smooth finish can reduce aerodynamic drag, improve fatigue resistance, and enhance the effectiveness of protective coatings.

Conversely, specific textured finishes may be required for adhesion, grip, or light diffusion. Our machining capabilities ensure that the desired surface roughness (Ra) is consistently achieved, meeting both cosmetic and engineering specifications for optimal drone operation.

Post-Processing Techniques for Enhanced Drone Materials

Beyond machining, various post-processing techniques are often employed to further enhance material properties and performance. These include anodizing for increased corrosion resistance and hardness on aluminum, heat treatment for improved strength, or specialized coatings for wear protection.

These additional processes are carefully selected based on the material and the specific functional requirements of the drone component. They contribute significantly to the longevity, durability, and specialized capabilities of the final part.

Choosing Your Partner for Drone CNC Machining

The Value of a Source Manufacturer for Drone Parts

Partnering with a source manufacturer like ly-machining offers unparalleled advantages in drone component production. We control the entire manufacturing process, from raw material sourcing to final quality inspection, ensuring complete transparency and accountability.

This integrated approach guarantees consistent quality, optimized production schedules, and direct communication, eliminating intermediaries. It provides greater control over the manufacturing process and offers peace of mind regarding supply chain reliability.

Ensuring High-Quality Drone Components Production

High-quality drone components are the bedrock of reliable drone performance. Our commitment to quality is upheld through rigorous material verification, in-process inspections, and comprehensive final quality control using advanced metrology equipment.

Every component undergoes meticulous scrutiny to ensure it meets exact dimensional, aesthetic, and functional specifications. This stringent quality assurance protocol minimizes defects and ensures consistent performance across all batches.

Transparent Pricing for Drone Machining Projects

Understanding the total cost of ownership for drone components is vital for project budgeting and financial planning. We provide transparent, detailed pricing breakdowns that account for material costs, machining time, tooling, and any required post-processing.

Our clear pricing model ensures that clients receive accurate estimates without hidden fees. This approach fosters trust and enables effective decision-making throughout the drone development and production lifecycle.

Leveraging Deep Technical Expertise for Drone Solutions

Our team of engineers possesses extensive technical expertise in both material science and advanced CNC machining specifically for drone applications. We collaborate closely with clients to provide expert guidance on material selection, design for manufacturability (DFM), and process optimization.

This collaborative engineering approach ensures that design intent translates into optimal manufacturing outcomes. We leverage our knowledge to solve complex challenges, improve part performance, and innovate new solutions for the evolving drone industry.

Conclusion: Mastering Material Selection for Superior Drones

The strategic selection of materials for CNC machined drone components is a pivotal factor in achieving superior performance, reliability, and economic viability. From lightweight aluminum alloys to robust titanium and specialized plastics, each material offers distinct advantages that must be carefully matched to the drone’s specific operational requirements.

At ly-machining, our role extends beyond manufacturing; we serve as your technical partner, leveraging deep engineering expertise and advanced CNC capabilities to optimize every component. We ensure that your drone parts are not only precisely machined but also fundamentally designed for their intended application, maximizing flight efficiency and longevity.

Case Study: Enhancing Heavy-Lift Drone Performance

Challenge

A client developing a heavy-lift industrial inspection drone faced significant challenges with their existing motor mount design. The original aluminum 6061 mounts were exhibiting excessive vibration and localized fatigue cracking under sustained high-load operations, risking motor detachment and drone failure. The client needed a solution that offered greater structural rigidity and fatigue resistance without a substantial weight penalty.

Our Solution

Our engineering team conducted a thorough Finite Element Analysis (FEA) of the motor mount’s stress points and recommended a transition from Al 6061 to Al 7075-T6. We optimized the mount’s geometry for Al 7075’s superior strength-to-weight characteristics, employing precision 5-axis CNC machining to achieve tighter tolerances and an improved surface finish. This revised design capitalized on the material’s enhanced fatigue life.

Result

The redesigned Al 7075-T6 motor mounts successfully eliminated the vibration and fatigue issues, significantly improving the drone’s operational safety and reliability. The enhanced stiffness contributed to more stable flight characteristics, while the minimal weight increase maintained the drone’s impressive payload capacity. The client reported a substantial increase in component lifespan and overall system confidence, leading to successful deployment in critical industrial applications.

Invite readers to get a free quote or technical consultation.

FAQ Section

Why is material choice so critical?

Material choice directly impacts a drone’s flight performance, including weight, strength, durability, and resistance to environmental factors. It determines payload capacity, flight time, and the overall lifespan of the drone. Selecting the right material is fundamental for operational success and safety.

Which aluminum alloy is best for drones?

Al 6061 is versatile for general drone parts, balancing strength and machinability economically. Al 7075 is preferred for critical, high-stress components like propeller hubs and motor mounts, offering superior strength. The “best” depends entirely on the specific application’s demands.

What are high-performance plastics used for?

High-performance plastics like PEEK and Delrin are ideal for specialized drone needs where light weight, electrical insulation, thermal stability, or low friction are crucial. They are commonly used for electronics housings, gears, and sensor components where metal properties are not required.