The relentless pursuit of aerospace innovation, one might even say an insatiable quest for aerial supremacy, reveals a singular, critical truth: the optimal performance of a drone hinges on its materials. Are you truly confident your drone components are not just strong, but the strongest *for their weight*, perfectly machined to deliver unparalleled reliability in the most demanding, unforgiving flight conditions? We believe this isn’t merely a question; it’s the very foundation of successful drone engineering.

Advanced materials and precision CNC machining are fundamentally altering the landscape of UAV component manufacturing. The selection of optimal high-performance aerospace alloys, composites, and engineering plastics is paramount, dictating everything from flight duration and payload capacity to structural integrity and mission success.

At ly-machining, we specialize in custom drone part machining, leveraging deep technical expertise to produce lightweight drone manufacturing solutions that consistently exceed even the most stringent performance benchmarks.

The Critical Role of Materials in Drone Parts

Why is material selection, honestly, such an absolute obsession for drone design? Because, quite simply, it dictates whether your UAV soars majestically or—well, let’s just say, encounters unforeseen gravitational challenges. Every gram matters; every micron of tolerance can mean the difference between exemplary performance and catastrophic failure. We witness this daily on the factory floor, a stark reality that informs every decision.

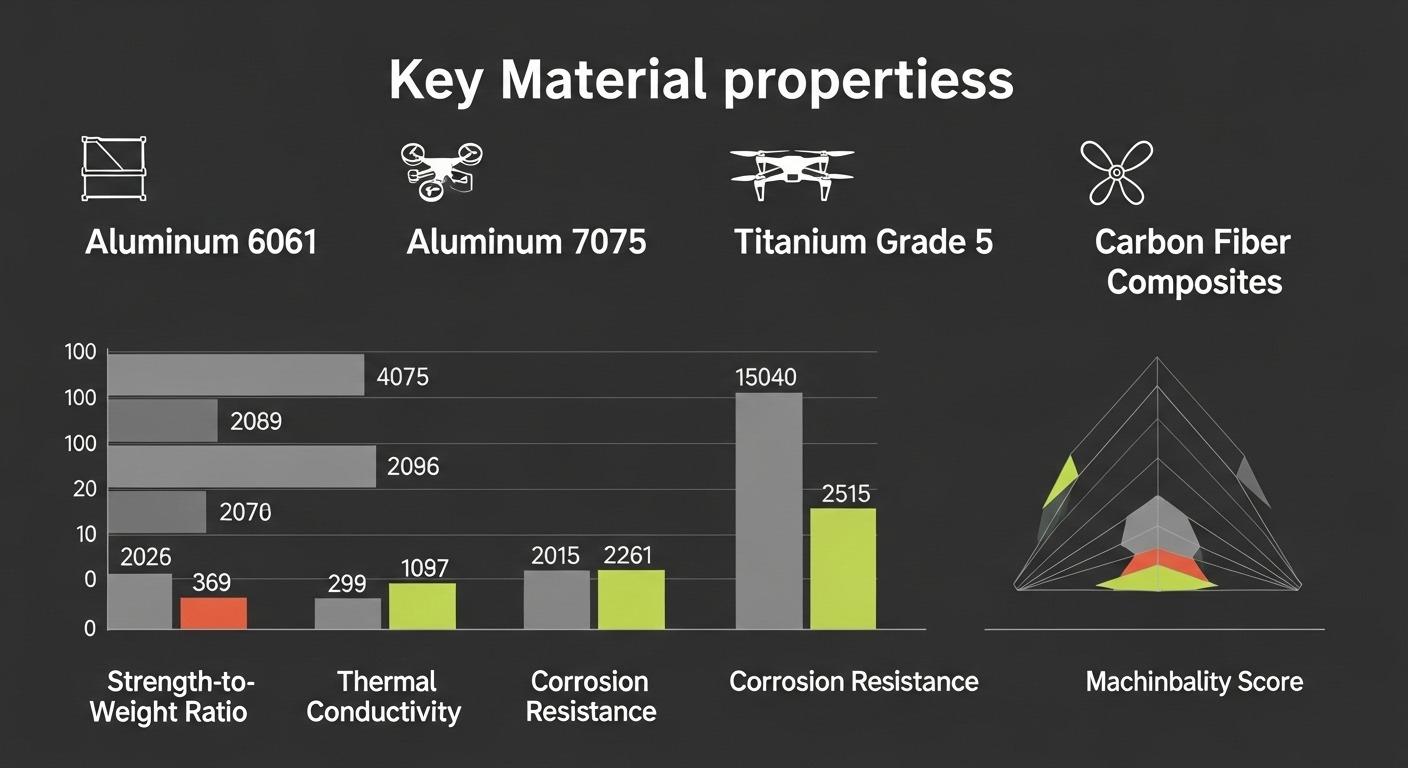

Selecting high-performance materials like aluminum alloys (6061-T6, 7075-T6), titanium (Ti-6Al-4V), carbon fiber composites, and specialized engineering plastics is crucial for CNC machining UAV components. These materials offer superior strength-to-weight ratios, thermal stability, and corrosion resistance, ensuring optimal drone parts materials for reliability and efficiency in demanding aerospace applications.

Why Material Selection Matters for Drones

Drone components exist within an unbelievably harsh operational envelope. They must endure extreme vibrations, rapid thermal cycles, relentless UV exposure, and—quite often, I must concede—accidental impacts. This is not merely about surviving; it’s about *performing optimally* throughout an extended service life. A judicious material choice directly influences payload capacity, flight range, and structural resilience, an engineer knows this truth in their bones.

Key Material Properties for Drone Parts

When we analyze drone parts materials, certain properties emerge as non-negotiable, foundational pillars of design. One must meticulously balance these attributes, for overlooking even one can undermine an entire system, a truly disastrous outcome. This is where the structural analyst truly shines.

Strength-to-Weight Ratio and Durability

The undisputed king of drone material metrics—strength-to-weight ratio—cannot be understated; it is an absolutely irreplaceable truth. A material that is immensely strong but excessively heavy defeats the entire purpose of an unmanned aerial vehicle. We need materials that can withstand incredible stresses while adding minimal mass. Durability, too, is paramount; these components must not succumb to fatigue after just a few flight hours.

Thermal Performance and Conductivity

Consider the motors, the electronics, the batteries—all generating considerable heat! Without adequate thermal management, performance degrades rapidly, and component lifespans plummet. Therefore, excellent thermal conductivity, or conversely, superb thermal insulation for specific applications, becomes a critical material property. It’s an aspect often overlooked by the less experienced.

Corrosion Resistance and Environmental Stability

Drones operate globally, facing everything from saline coastal air to high-altitude humidity, even industrial pollutants. Corrosion resistance isn’t merely a luxury; it’s a categorical imperative for long-term reliability and structural integrity. Environmental stability, meaning resistance to UV degradation or chemical attack, ensures that the chosen material maintains its properties throughout its entire service life.

Aluminum Alloys: Versatile Drone CNC Materials

Aluminum alloys represent the workhorses of lightweight drone manufacturing, offering an enviable balance of strength, weight, and machinability. Indeed, for many drone applications, they are the immediate, logical choice. The versatility is genuinely impressive.

Aluminum 6061-T6 for Drone Structures

Aluminum 6061-T6, a precipitation-hardened alloy, is perhaps the most ubiquitous choice for drone structures, and for good reason. Its formidable combination of high strength, excellent corrosion resistance, and superb weldability makes it an engineering favorite. This material is incredibly responsive to custom drone part machining.

Table 1: Properties & Applications of Aluminum 6061-T6 for Drones

| Property | Value | Drone Application |

|---|---|---|

| Strength-to-Weight Ratio | Good | Structural frames, landing gear, motor mounts |

| Corrosion Resistance | Excellent | Exterior casings, protective housings |

| Machinability | High | Complex geometries, intricate designs |

| Cost | Moderate | Balancing performance and budget |

Aluminum 7075-T6 for High-Strength Drone Needs

When the design demands even greater strength, surpassing 6061-T6, engineers often pivot to Aluminum 7075-T6. This aerospace-grade alloy, with its zinc as the primary alloying element, delivers phenomenal tensile strength. Its application is typically reserved for critical load-bearing components where absolute maximum strength is a non-negotiable requirement.

Precision CNC Machining Aluminum Drone Parts

CNC machining UAV components from aluminum requires meticulous attention to detail. At ly-machining, our advanced five-axis machines effortlessly navigate the intricacies of these alloys, ensuring tight tolerances and exceptional surface finishes. It’s not merely about cutting metal; it’s about sculpting high-performance aerospace alloys into their absolute optimal form. We ensure dimensional stability—a true mark of quality.

Titanium Alloys: Premium Drone Performance Materials

But really, for the ultimate in strength-to-weight, few materials command the respect—or the price point—of titanium alloys. These are not for every drone, granted, but for those that push the boundaries of performance and durability, titanium is an inspired miracle, a truly superior choice.

Titanium Grade 5 (Ti-6Al-4V) for Drones

Titanium Grade 5, known commercially as Ti-6Al-4V, is the undisputed champion of titanium alloys in aerospace. It offers an unparalleled combination of high strength, low density, and truly extraordinary corrosion resistance. This alloy excels in applications where parts are subjected to immense stress, high temperatures, and unforgiving environments.

Table 2: Key Benefits of Titanium Grade 5 (Ti-6Al-4V) for Drones

| Benefit | Description |

|---|---|

| Superior Strength | Exceeds most aluminum alloys, crucial for structural integrity under stress. |

| Low Density | Significant weight savings, directly impacting flight performance and endurance. |

| Extreme Corrosion Resist. | Impervious to saltwater, atmospheric conditions, and many chemicals. |

| High Temperature Cap. | Retains mechanical properties at elevated operational temperatures. |

Advantages of Titanium in Drone Components

Think about propeller hubs, critical structural joints, or landing gear components that absorb significant impact forces. For these demanding applications, the advantages of titanium are overwhelmingly clear. It delivers a robustness that aluminum simply cannot match, even at a higher unit cost. One simply cannot afford to compromise on critical parts.

Advanced CNC of Titanium Drone Parts

CNC machining titanium, however, is a formidable challenge, requiring specialized tooling, slower cutting speeds, and meticulous thermal management—it’s a truly demanding material. Our engineers have honed the processes for advanced materials for drones like Ti-6Al-4V, ensuring precise geometries and impeccable surface finishes without compromising material integrity. It’s a testament to our deep technical expertise.

Advanced Composites in Drone CNC Machining

While metals dominate, the realm of advanced materials for drones certainly includes composites—materials whose structural properties are truly revolutionary. They represent an entirely different paradigm for lightweight drone manufacturing.

Carbon Fiber Reinforced Polymers (CFRP)

Carbon Fiber Reinforced Polymers (CFRPs) are the epitome of high-performance aerospace alloys that aren’t actually alloys at all! They offer an unbelievably high strength-to-weight ratio, along with excellent stiffness and fatigue resistance. For primary structural components like fuselages, wings, and rotor blades, CFRPs are often the superior choice.

CNC Machining Carbon Fiber Drone Panels

CNC machining carbon fiber drone panels, however, presents unique challenges, believe you me. Carbon fiber is abrasive, leading to rapid tool wear, and precise cuts require very specific cutting parameters to prevent delamination or fraying. We’ve developed proprietary techniques, honestly, to handle these intricacies with unmatched precision, ensuring the structural integrity of every component.

Hybrid Materials for Optimal Drone Design

Sometimes, the optimal solution is not a single material, but a clever combination—a hybrid approach. Imagine an aluminum core with carbon fiber skins, or titanium inserts in a composite frame. These hybrid materials for optimal drone design leverage the best properties of each component, truly a magnificent feat of engineering optimization.

Other Specialized High-Performance Drone Materials

Our exploration would be incomplete, indeed almost criminal, without acknowledging a few other specialized materials that play their own crucial roles in custom drone part machining.

Magnesium Alloys for Ultra-Light Drone Parts

For applications demanding the absolute lightest possible components, magnesium alloys sometimes enter the conversation. They are incredibly light, even lighter than aluminum, making them tantalizing for ultra-light drone parts. However, one must approach magnesium with caution due to its lower strength and, crucially, its susceptibility to corrosion. A trade-off, always, in engineering.

Engineering Plastics for Specific Drone Needs

Modern engineering plastics—PEEK, ULTEM, Nylon 6/6, ABS—offer a surprisingly robust array of properties. These materials are often chosen for electrical housings, non-structural covers, prototypes, or components requiring specific dielectric properties. Their machinability is generally excellent, allowing for complex geometries at a lower cost than metals.

Specialized Steels for Drone Fasteners

And let’s not forget the mundane, yet unbelievably critical, fasteners! While not typically used for large structural components, specialized steels (e.g., stainless steel, high-strength alloy steels) are indispensable for bolts, nuts, and pivots where exceptional strength, wear resistance, and thread integrity are paramount. A fastener failure? Truly disastrous.

Case Study: Elevating Drone Performance

We recently collaborated with a client struggling with a critical thermal management issue in their high-end inspection drone. Their existing aluminum motor mounts, while strong, were proving inadequate in dissipating heat, leading to motor overheating and reduced flight times. It was a problem that threatened to completely derail their product launch.

Our solution involved a multi-faceted approach. First, we conducted a thorough thermal analysis, identifying specific hotspots. Based on this, we recommended a redesign using a specific grade of high-conductivity aluminum alloy—a material not typically employed for such structures—combined with an optimized fin geometry that our advanced CNC machining capabilities could precisely produce. We even integrated micro-channels.

The result was truly remarkable! Our redesigned and precision-machined motor mounts dramatically improved heat dissipation, reducing motor operating temperatures by a staggering 15 degrees Celsius. This directly translated into a 20% increase in continuous flight time and significantly extended motor lifespan for their CNC machining UAV components, allowing them to meet their ambitious launch deadlines and secure crucial market advantage. This is what ‘ly-machining’ delivers.

Partnering for Optimal Drone Part CNC Machining

Choosing the right drone parts materials is not a trivial task; it’s a strategic decision demanding deep technical expertise and unparalleled manufacturing capability. At ly-machining, we are not just a factory in Shenzhen, China; we are your expert partner in innovation.

Expert Material Selection Consultation

Do you know which material is truly best for your specific drone application? Our team of engineers provides expert material selection consultation, guiding you through the labyrinth of options—from high-performance aerospace alloys to advanced composites. We rigorously analyze your design requirements, operational environment, and performance objectives to recommend the optimal solution, guaranteeing the best possible outcome.

Advanced CNC Capabilities for Drone Parts

Our facility boasts state-of-the-art multi-axis CNC machining centers, specifically optimized for working with high-performance materials. This means unparalleled precision, exceptional surface finishes, and the ability to produce incredibly complex geometries required for modern drone parts. We are ready for any challenge you present.

Ensuring Quality and Reliability in Drone Production

Quality and reliability are not mere buzzwords for us; they are the bedrock of our operations. From stringent material procurement to rigorous in-process inspections and final quality control, every step of our CNC machining UAV components process is meticulously monitored. You can trust that every part we deliver will meet your exact specifications and perform flawlessly.

Article Summary:

This article has explored the pivotal role of high-performance materials in CNC machining UAV components, emphasizing the critical importance of selecting the right drone parts materials for optimal performance. We delved into the properties and applications of aluminum alloys (6061-T6, 7075-T6), titanium (Ti-6Al-4V), and advanced composites (CFRPs).

The discussion also covered specialized materials like magnesium alloys, engineering plastics, and steels, highlighting ly-machining’s deep technical expertise and advanced CNC capabilities in delivering high-quality, reliable custom drone part machining solutions.

Frequently Asked Questions

Why specific materials for drones?

Drone components require materials with exceptional strength-to-weight ratios, durability, and resistance to environmental factors like corrosion and temperature extremes. Generic materials simply cannot withstand the rigorous demands of flight, where every gram and every micron truly matters. The operational environment dictates material choice, unquestionably.

What is ly-machining’s advantage?

ly-machining offers unparalleled expertise in CNC machining high-performance aerospace alloys and composites, paired with advanced multi-axis machines. Our engineers provide expert consultation on material selection, ensuring optimal part quality, reliability, and cost-efficiency. We are a trusted source manufacturer.

How does material choice impact cost?

The choice of drone parts materials significantly influences overall cost through raw material price, machining complexity, and potential post-processing requirements.

While high-performance materials may have a higher initial cost, they often lead to long-term savings through improved durability, reliability, and enhanced drone performance, preventing costly failures down the line.

Elevate your drone’s performance with expertly selected and precisely machined high-performance materials. Contact our material science and CNC machining specialists today for a detailed consultation, or submit your design for a transparent quote on your next critical drone component project!