Top CNC Manufacturers for Precision Parts Quick Solution: Identifying...

Read More →Empower your innovation and accelerate product launch

Electronic products Parts

Focusing on high-precision metal and engineering plastic processing, we provide one-stop solutions from prototype to small batch production for your mobile phones, wearable devices, drones and high-end equipment.

Are you facing these challenges?

The sample accuracy is not up to standard, and repeated revisions slow down the entire R&D cycle? The supplier cannot understand your design intention, resulting in high communication costs?

The quotation is not transparent, with many hidden costs? The delivery date is delayed again and again, and the supply chain risk is high? No one is willing to take small batch orders?

Poor quality parts processing directly affects product quality and brand reputation, and high mold opening costs and slow time to market make you miss market opportunities.

Why Choose Us

Ultimate precision and quality. Our German imported 5-axis CNC equipment and experienced team of engineers ensure that the tolerance of each CNC machined part reaches ±0.005mm, meeting your most stringent design requirements.

Lightning response and delivery. Professional project managers provide one-on-one service, providing CNC machining quotes and manufacturability analysis (DFM) reports within 24 hours at the fastest, ensuring that your project starts on time and progresses seamlessly.

Flexibility to meet various needs. Whether it is a CNC machining proof or a million-level batch production, we can provide cost-effective solutions and support a variety of metal and plastic materials.

Service capabilities

CNC precision machining: Provide 3-axis, 4-axis, 5-axis CNC milling and turning services, suitable for all kinds of parts from simple brackets to complex radiators.

Multiple material options: Support customized processing of parts of aluminum alloy, stainless steel, copper, titanium alloy and engineering plastics such as ABS, PC, PEEK.

First-class surface treatment: Provide anodizing, sandblasting, electroplating, spraying, silk screen and other appearance treatment processes to create perfect product texture.

Strict quality inspection: Equipped with three-coordinate measuring machine (CMM), strict quality inspection is carried out throughout the process from raw materials to finished products, and inspection reports can be provided.

Key Problems We Solve

✓ [Shorten R&D cycle] Accelerate product verification and iteration through fast CNC processing proofing services.

✓ [Reduce manufacturing costs] Provide free DFM analysis to optimize your design and avoid unnecessary processing costs.

✓ [Improve product competitiveness] With high-precision precision parts processing and high-quality appearance, enhance the market value of your final product.

✓ [Ensure supply chain stability] As a reliable CNC processing plant, we promise to deliver on time and reduce your supply chain risks.

- Appearance and shell

- Precision functions

- Decoration

- Structure/support

Elevate Your Electronics with Precision CNC Machining

Flawless aesthetics and robust protection for any device.

Our CNC machining services for consumer electronics deliver unparalleled precision for metal and plastic enclosures. We create sophisticated, durable, and high-quality appearances and shells that make your products stand out.

Advantages of CNC Machining for Electronics:

Superior Precision & Complexity: Achieve intricate designs and tight tolerances (±0.01mm) that other methods can’t match, perfect for complex, high-end electronic housings.

Premium Material Options: Utilize a wide range of high-grade metals (Aluminum, Stainless Steel, Titanium) and plastics for exceptional durability and a premium feel.

Flawless Surface Finish: From smooth anodizing and sandblasting to polished and brushed textures, we deliver a perfect finish that enhances aesthetic appeal.

Strength & Durability: CNC-machined parts offer superior structural integrity compared to casting or molding, ensuring your electronics are well-protected.

Challenges & Our Expert Solutions:

Potential for Scratches & Deformation: The intricate nature of electronic shells makes them susceptible to cosmetic defects during production.

Our Prevention: We implement a rigorous quality control system at every stage. This includes custom fixtures to secure parts, optimized toolpaths to minimize stress, and meticulous post-machining handling protocols to prevent scratches and ensure perfect form.

High Cost for Mass Production: CNC machining can be more expensive for very high volumes.

Our Approach: We work with you to optimize designs for manufacturability (DFM) and select the most cost-effective processes and materials without compromising on quality, ensuring the best value for your investment.

The Value We Provide to Our Clients:

Unmatched Quality Assurance: Our multi-step inspection process guarantees that every part meets your exact specifications, ensuring a flawless final product.

Rapid Prototyping & Production: We accelerate your time-to-market with efficient programming and high-speed machining, delivering prototypes and production parts on schedule.

Expert Engineering Support: From material selection to design optimization, our experienced engineers collaborate with you to enhance performance and reduce costs.

Consistent & Reliable Partnership: We are your trusted manufacturing partner, dedicated to delivering exceptional results that elevate your brand and captivate your customers.

Partner with us to bring precision, quality, and a superior finish to your next electronic product.

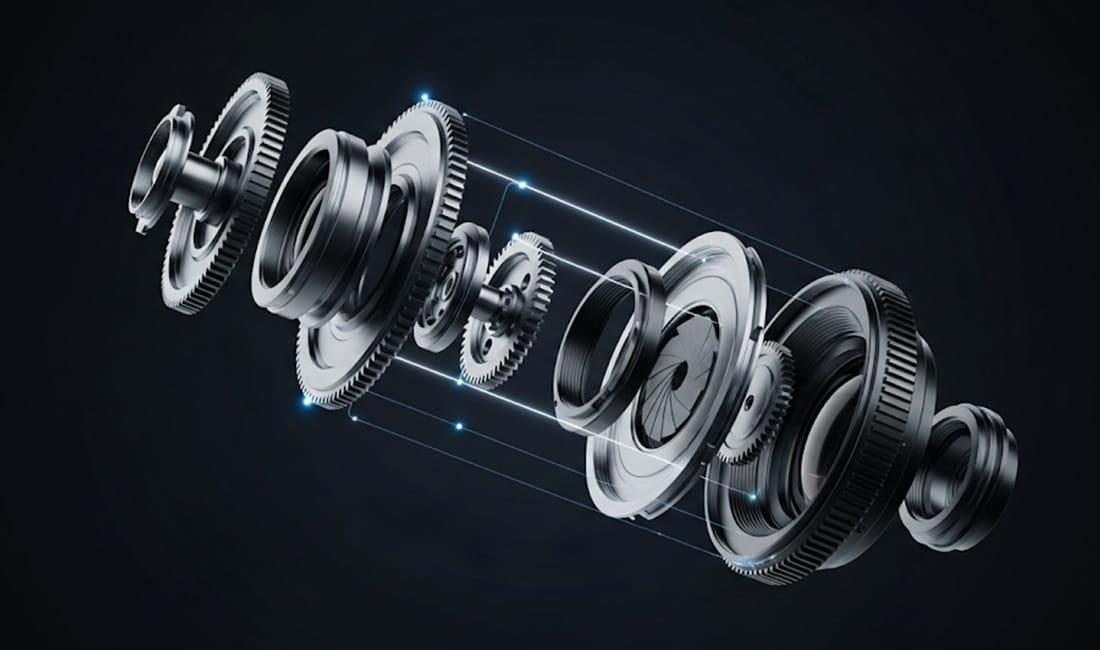

Precision CNC Machining for Functional & Moving Parts in Electronics

Engineered for Reliability. Machined for Performance.

For electronic devices requiring precision functions and moving parts—such as camera lens mechanisms, retractable connectors, and micro-actuators—our CNC machining services provide the ultimate solution for accuracy and dependability.

Why CNC Machining for Precision Moving Parts?

Unmatched Accuracy & Tight Tolerances: CNC machining is essential for creating components with the ultra-high precision (often within microns) required for smooth, reliable movement and perfect assembly. This is critical for parts like gears, sliders, and locking mechanisms.

Superior Material Properties: We machine from high-performance metals and engineering plastics that offer excellent wear resistance, low friction, and long-term stability—vital for the durability of any moving part.

Complex Geometries: We can produce intricate and complex internal and external features that are impossible to achieve with other methods, enabling innovative and compact product designs.

Exceptional Repeatability: Our automated CNC processes ensure that every component is identical, guaranteeing consistent performance across all your production units.

Challenges in Machining Precision Parts & Our Solutions:

Risk of Micro-Deformation & Dimensional Instability: Even minute inaccuracies can cause a mechanism to fail. The stress from machining or temperature fluctuations can affect tolerances.

Our Prevention Strategy: We employ a climate-controlled environment and advanced stress-relief machining techniques. Our multi-axis CNC machines minimize the need to re-fixture parts, reducing the risk of error. We use high-precision probes for in-process inspection to ensure dimensional accuracy throughout the entire process.

Surface Finish Criticality: The surface texture of moving parts directly impacts friction, wear, and overall performance.

Our Quality Control: We go beyond standard measurements, utilizing specialized tools to control surface roughness (Ra) precisely. We select optimal cutting tools and parameters to achieve the exact finish required for low-friction, smooth operation.

The Benefits for Our Clients:

Enhanced Product Reliability: By delivering components that meet exact specifications, we ensure your product’s mechanical functions perform flawlessly, reducing failure rates and warranty claims.

Accelerated Development Cycle: Our expertise in Design for Manufacturability (DFM) helps you optimize your designs for production, while our rapid prototyping allows for quick testing and iteration.

Guaranteed Performance: We provide comprehensive inspection reports with every batch, giving you full confidence in the quality and consistency of the parts you receive.

Competitive Advantage: Superior mechanical performance and reliability become key selling points for your product, setting you apart in a crowded market.

Trust us to machine the critical moving parts that drive the innovation and functionality of your electronic devices.

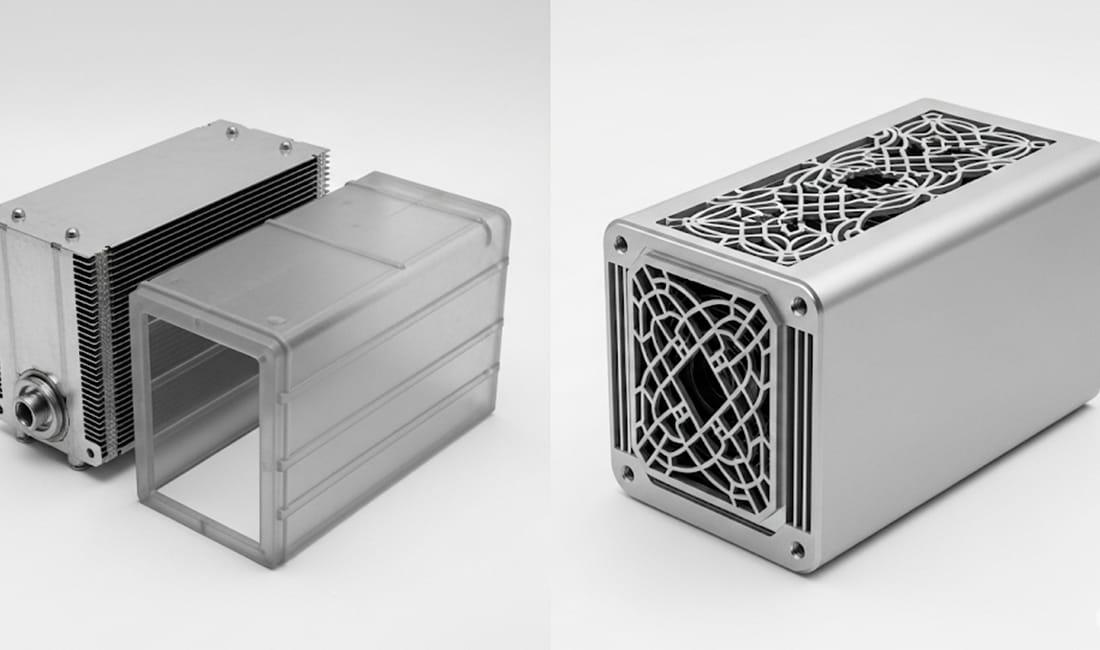

Precision CNC Machining for Electronic Decoration & Heat Dissipation

Where Aesthetic Excellence Meets Thermal Performance.

For electronic products that demand both a striking appearance and effective heat management, our CNC machining services offer the perfect synergy. We craft stunning decorative components and highly efficient thermal solutions, like custom heatsinks and ventilated chassis, from a single, precision-engineered piece.

Advantages of CNC for Decoration & Heat Dissipation:

Design Freedom: CNC machining allows for the creation of complex, intricate designs that combine brand aesthetics with functional cooling features like fins, pins, and micro-channels.

Superior Thermal Conductivity: Machining from solid blocks of high-conductivity materials like aluminum or copper creates a seamless thermal path, offering far more effective heat dissipation than assembled or cast parts.

Premium Finish & Feel: Achieve a flawless, high-end look with a variety of surface finishes, from anodizing and sandblasting to bead blasting, ensuring your product’s appearance matches its performance.

Integrated Strength: Create robust, single-piece components that serve as both the decorative housing and the functional cooling system, enhancing product durability.

Key Challenges & Our Expert Solutions:

Balancing Aesthetics and Function: The most beautiful design isn’t always the most thermally efficient. Achieving a perfect cosmetic finish on complex geometries like thin heatsink fins can be challenging.

Our Prevention: Our Design for Manufacturing (DFM) analysis is key. We collaborate with you to optimize your design, ensuring the geometry provides maximum surface area for cooling without compromising on the desired aesthetic. We use specialized cutting tools and multi-axis machining to create sharp, clean fins with a uniform, blemish-free finish.

Surface Imperfections: Scratches, tool marks, or inconsistent finishes can ruin the visual appeal and, in some cases, slightly hinder thermal radiation.

Our Quality Protocol: We implement stringent process controls and meticulous handling procedures from start to finish. Optimized toolpaths minimize contact marks, and our post-processing and finishing departments are experts in delivering consistent, high-quality cosmetic surfaces, all verified by rigorous visual and dimensional inspections.

The Value We Deliver to Our Clients:

Enhanced Product Performance & Longevity: By optimizing thermal management, our CNC components help your electronics run cooler, improving performance and extending their lifespan.

Elevated Brand Image: A premium look and feel directly translates to higher perceived value, strengthening your brand and justifying a premium price point.

Consolidated Supply Chain: We provide a single-source solution for complex components that serve dual purposes, simplifying your procurement and guaranteeing component compatibility.

Market Differentiation: Offer products that not only outperform the competition in thermal management but also stand out with unique and sophisticated visual designs.

Partner with us to create electronic components that are as cool as they look.

CNC Machining for Electronic Structural & Support Components

The Unseen Strength: Precision-Engineered for Ultimate Reliability.

For the internal frames, chassis, and support brackets that form the backbone of your electronic devices, our CNC machining services deliver uncompromising strength, precision, and stability. We build the core foundation that guarantees your product’s durability and longevity.

Advantages of CNC for Structural Components:

Exceptional Strength-to-Weight Ratio: We machine from solid blocks of high-strength materials like aircraft-grade aluminum or stainless steel, creating components that are incredibly strong and rigid without adding unnecessary weight.

Superior Structural Integrity: Unlike casting or stamping, CNC machining produces parts with a consistent internal grain structure, free from the voids or weak points that can lead to failure under stress or impact.

Precise Assembly & Alignment: Achieve exacting tolerances for mounting points, holes, and interfacing surfaces. This ensures perfect alignment of all internal components (PCBs, batteries, displays), which is critical for product function and reliability.

Complex Geometries for Compact Designs: Machine intricate internal structures, ribs, and pockets that maximize strength while fitting into complex and space-constrained device layouts.

Key Challenges & Our Proactive Solutions:

Risk of Internal Stress & Warping: Machining large amounts of material can introduce internal stresses, potentially causing the part to warp or deform over time, compromising alignment.

Our Prevention Strategy: We employ a multi-stage machining process that includes roughing, semi-finishing, and finishing passes, often combined with post-machining stress-relief treatments. This systematic approach removes material gradually and neutralizes internal stresses, guaranteeing the part’s long-term dimensional stability.

Maintaining Tight Tolerances Across the Part: For large or complex frames, ensuring all features are perfectly positioned relative to each other is a major challenge.

Our Precision Control: We utilize advanced 5-axis CNC machines that can access multiple faces of a part in a single setup. This minimizes cumulative errors from re-fixturing. Furthermore, our use of in-machine probing and CMM (Coordinate Measuring Machine) inspection verifies that all critical dimensions and geometric tolerances (GD&T) are met before the part is approved.

The Concrete Benefits for Our Clients:

Increased Product Durability & Robustness: Our precision-machined structural parts dramatically improve the resilience of your devices to drops, vibration, and daily wear-and-tear, reducing field failures.

Faster and More Reliable Assembly: With perfectly aligned components that fit together flawlessly every time, you can streamline your assembly process, reduce production time, and lower labor costs.

Enhanced Performance & Longevity: A stable internal structure protects sensitive components from stress and flexing, leading to more reliable performance and a longer product lifespan.

Design Confidence: Our manufacturing expertise gives your engineers the freedom to design innovative and robust products, knowing that the structural core will be manufactured to perfection.

Build your electronics on a foundation of strength. Partner with us for your critical structural components.

Simple Faq

Simple yet effective Elementor FAQ widget.

How is your CNC machining quotation calculated?

How small an order do you accept? What is the minimum order quantity (MOQ)?

How long does it take to CNC machine a typical aluminum alloy part?

Blog Post

Top Supplier for IR Lens Housing CNC Machining

Top Supplier for IR Lens Housing CNC Machining Precision in...

Read More →2026 Ranking: Top Recommended CNC Machining Manufacturers for Precision Parts

2026’s Top Recommended CNC Machining Manufacturers for Precision Parts ...

Read More →