Evaluating Top CNC Machining Manufacturers

Assessing CNC machining manufacturers requires examining technical expertise, robust quality control, proven reliability, transparent communication, and overall cost-effectiveness to ensure superior precision and project success.

A manufacturing partner is critical to project success, not just a vendor. Navigating the diverse landscape of CNC machining manufacturers requires a strategic approach. You need to identify a partner who offers both technical prowess and operational excellence.

This guide provides definitive metrics to empower your decision-making. We will reveal how to pinpoint a high-quality, transparent, and technically superior custom CNC parts manufacturing partner. This ensures your critical projects meet and exceed expectations.

Technical Expertise in CNC Machining

The foundation of any successful CNC machining service lies in deep technical expertise. This encompasses more than just operating machinery; it involves a profound understanding of material science, design principles, and complex manufacturing processes. A truly experienced manufacturer, like us at ly-machining, offers insights that prevent issues before they arise, critical for precision CNC machining.

Assessing machinery for precision CNC machining?

The quality and modernity of a CNC machining manufacturer’s equipment directly impact the precision and complexity of parts they can produce. Advanced multi-axis machines, particularly 5-axis CNC centers, allow for intricate geometries and tighter tolerances in custom CNC parts manufacturing. In our experience, investing in top-tier machinery is non-negotiable for superior output.

Manufacturers should provide details on their machine fleet, including brands, models, and maintenance schedules. This transparency offers insight into their commitment to consistent quality and cutting-edge CNC machining services. Verify their capabilities match your project’s demanding specifications.

How deep is material expertise in custom CNC parts?

Beyond machine operation, a leading CNC machining manufacturer possesses extensive material expertise. Different alloys and plastics behave uniquely under stress and during the machining process, impacting surface finish, strength, and overall part integrity. A common issue we see is manufacturers lacking nuanced understanding of specialized materials.

We specialize in a broad range of materials, including aluminum alloys, stainless steel, titanium, and engineered plastics. Our team understands how to select the optimal cutting parameters, tooling, and post-processing for each specific material. This ensures the best possible outcome for your custom CNC parts manufacturing needs.

| Material Type | Common Applications | Key Properties |

|---|---|---|

| Aluminum Alloys | Aerospace, Automotive | Lightweight, Corrosion Resistant, High Strength |

| Stainless Steel | Medical, Food Processing | High Strength, Corrosion Resistant |

| Titanium | Aerospace, Medical Implants | High Strength-to-Weight, Biocompatible |

| Engineering Plastics | Robotics, Electronics | Electrical Insulation, Chemical Resistance |

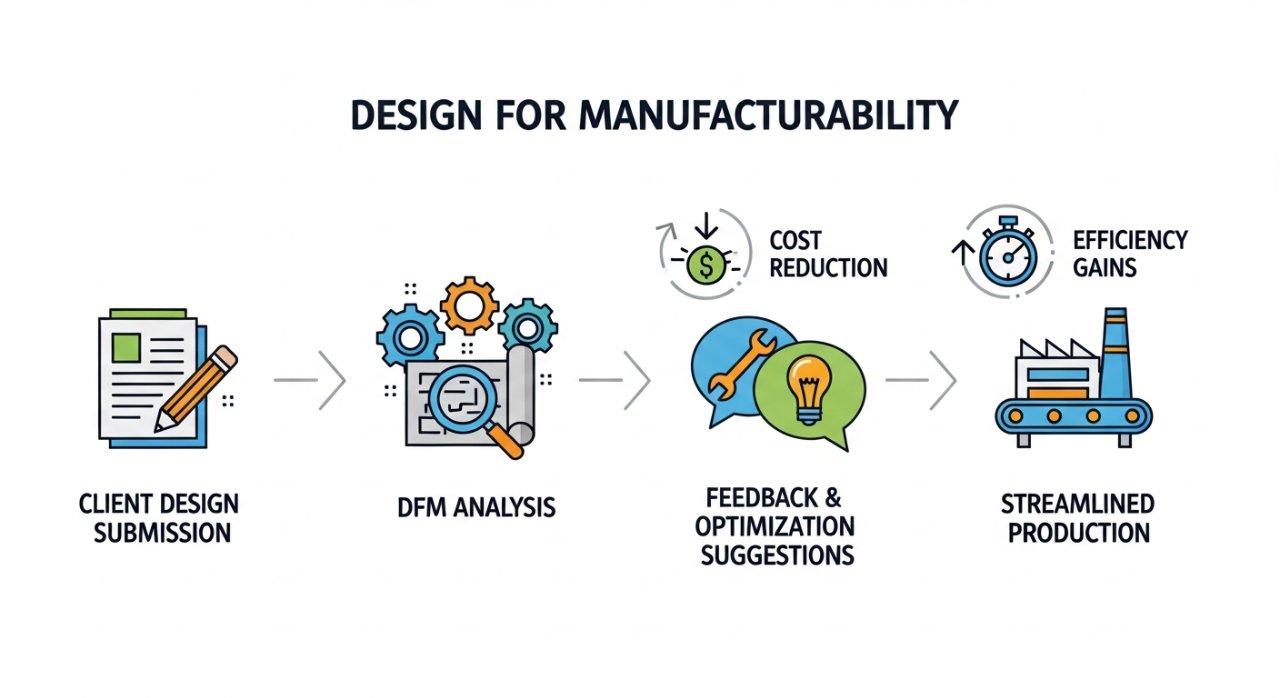

Evaluating design for manufacturability (DFM) for CNC machining?

Design for Manufacturability (DFM) is a critical service offered by expert CNC machining manufacturers. It involves reviewing your design files to identify potential manufacturing challenges, suggest optimizations, and reduce costs without compromising functionality. Early DFM input is invaluable for complex projects, ensuring designs are robust and feasible for precision CNC machining.

Our DFM reports provide detailed feedback, leveraging our deep technical knowledge to streamline the production of custom CNC parts. This proactive approach minimizes design iterations, reduces material waste, and accelerates time-to-market. It transforms potential manufacturing hurdles into opportunities for efficiency.

Quality Control for CNC Machining Services

Rigorous quality control is the bedrock of reliable CNC machining services. It assures that every part produced meets stringent specifications and performs as intended. A manufacturer’s commitment to quality should be evident throughout their entire production chain.

What quality certifications define top CNC machining manufacturers?

Industry certifications, such as ISO 9001 and IATF 16949, are non-negotiable indicators of a CNC machining manufacturer’s dedication to quality management systems. ISO 9001 demonstrates a general commitment to quality processes, while IATF 16949 is specifically critical for automotive parts, signifying even higher standards. These certifications ensure consistent processes and continuous improvement.

| Certification Standard | Focus Area | Industry Relevance |

|---|---|---|

| ISO 9001 | General Quality Management System | Broad industry application, foundational |

| IATF 16949 | Automotive Quality Management System | Automotive sector, higher demands for precision |

| AS9100 | Aerospace Quality Management System | Aerospace and Defense, extremely high reliability |

How do inspection processes ensure precision CNC machining?

Comprehensive inspection processes are vital for precision CNC machining. This includes first-article inspection, in-process checks, and final quality assurance using advanced metrology equipment. Tools like Coordinate Measuring Machines (CMMs), optical comparators, and various gauges ensure every dimension and feature is meticulously verified.

At ly-machining, our full-chain quality control is paramount. We employ a pristine quality control lab equipped with state-of-the-art instruments. This ensures that every custom CNC part meets the exact specifications and stringent tolerance requirements of demanding industries.

Is traceability crucial for custom CNC parts manufacturing?

Yes, full material and process traceability is absolutely crucial, especially for industries like aerospace, medical, and robotics. This means being able to track the origin of raw materials, every step of the manufacturing process, and all inspection data for each custom CNC part. It is vital for quality assurance and regulatory compliance.

Traceability provides a complete audit trail, offering peace of mind and supporting product recalls or failure analysis if necessary. A trustworthy CNC machining manufacturer will have robust systems in place to guarantee this level of transparency and accountability.

Reliability of CNC Machining Services

Reliability is about consistency and predictability in delivering CNC machining services. It encompasses meeting deadlines, maintaining quality over large volumes, and demonstrating stable operational performance.

Can lead times predict a CNC machining manufacturer’s efficiency?

Lead times are a strong indicator of a CNC machining manufacturer’s efficiency and organization. While rapid prototyping services may offer 24-hour turnaround, typical production lead times reflect their scheduling, production capacity, and supply chain management. Unrealistic lead times often signal potential quality or delivery issues.

It’s important to differentiate between quoted lead times and actual delivery performance. A manufacturer’s ability to consistently meet their promised timelines is a direct measure of their operational reliability and commitment.

What production capacity is ideal for custom CNC parts?

An ideal production capacity for custom CNC parts manufacturing is one that can flexibly scale to meet your demands without compromising quality or lead times. This means having a sufficient fleet of machines, skilled operators, and efficient workflow management. Our factory boasts over 80 machines, offering significant capacity.

For businesses with fluctuating demands or growing product lines, a manufacturer with ample and diverse machine capacity, including high-precision CNC centers and lathes, offers security. This prevents bottlenecks and ensures consistent supply, even for no minimum order quantity (MOQ) requests.

How does on-time delivery reflect a CNC machining service?

On-time delivery is a non-negotiable aspect of a reliable CNC machining service. It reflects a manufacturer’s project management capabilities, logistical efficiency, and commitment to customer schedules. Delays can have significant downstream impacts on your production and overall project timelines.

A reputable CNC machining manufacturer will have robust internal tracking systems and clear communication channels to keep you informed of your order’s status. They should proactively address any potential delays, rather than reacting to them.

Communication & Transparency in CNC Services

Effective communication and transparency build trust, fostering strong, long-term partnerships in CNC machining. This is particularly vital for custom CNC parts manufacturing where unique specifications require clear dialogue.

How transparent is pricing for custom CNC parts manufacturing?

Transparent pricing for custom CNC parts manufacturing means clear, itemized quotes without hidden fees or unexpected surcharges. A reputable source manufacturer will provide a detailed breakdown of costs, including materials, machining time, tooling, and any post-processing. This allows for accurate budgeting and fair comparison.

At ly-machining, we pride ourselves on offering factory-direct, transparent pricing. We believe in providing high-value solutions without compromising quality, ensuring you understand exactly what you’re paying for. This builds confidence and trust in our CNC machining services.

Why is effective communication vital in CNC machining?

Effective communication is paramount in CNC machining, particularly for complex projects. Clear, responsive, and proactive dialogue ensures that requirements are fully understood, technical challenges are addressed efficiently, and project updates are timely. Poor communication is a frequent pain point in the industry.

We prioritize open lines of communication, providing detailed DFM reports and regular project updates. Our engineering team is always ready for technical consultations, ensuring a collaborative approach to your custom CNC parts manufacturing.

What about intellectual property in CNC machining services?

Protecting intellectual property (IP) is a critical concern when outsourcing custom CNC parts manufacturing. A trustworthy CNC machining manufacturer must have robust confidentiality agreements and secure data handling protocols in place. This safeguards your proprietary designs and processes.

Always ensure that a non-disclosure agreement (NDA) is in place before sharing sensitive design files. A reputable CNC machining service will understand and respect the importance of IP protection, building a foundation of trust.

Cost-Effectiveness of CNC Machining

Cost-effectiveness in CNC machining is not merely about the lowest price. It involves balancing upfront costs with the long-term value, quality, and reliability offered by the manufacturer.

Balancing price with value from CNC machining manufacturers?

True value from CNC machining manufacturers is a combination of competitive pricing, superior quality, reliable delivery, and excellent technical support. A significantly lower price can often indicate compromises in material quality, precision, or service. These compromises can lead to costly rework or project delays down the line.

Consider the total cost of ownership, including potential costs from subpar parts or missed deadlines. Our transparent, factory-direct pricing ensures you receive high-quality, precision CNC machined parts that deliver long-term value and reduce overall project risk.

Does DFM reduce costs in custom CNC parts manufacturing?

Yes, absolutely. Engaging in Design for Manufacturability (DFM) early in the design phase is one of the most effective ways to reduce costs in custom CNC parts manufacturing. By identifying potential issues and optimizing designs for efficient production, DFM minimizes material waste, reduces machining time, and prevents costly re-designs or tooling changes.

Our DFM expertise helps clients achieve significant cost savings by streamlining processes and selecting the most efficient manufacturing strategies. This proactive approach ensures your custom CNC parts are not only high-quality but also produced in the most cost-effective manner possible.

Making the Right Choice: Your CNC Partner

Selecting the right CNC machining partner is a strategic decision that impacts your project’s success, budget, and timeline. Careful evaluation based on key metrics ensures a reliable, high-quality outcome.

Key takeaways for selecting top CNC machining services.

When evaluating CNC machining services, prioritize technical expertise, a rigorous quality control system, and a proven track record of reliability. Look for transparent communication and a commitment to cost-effectiveness through DFM. These are the pillars of a successful partnership.

A source manufacturer like ly-machining, with advanced equipment, deep material knowledge, and comprehensive certifications, offers unparalleled value. We ensure precision, consistency, and a seamless experience for your custom CNC parts manufacturing needs.

Ready for a trusted CNC machining quote?

Choosing the right partner for precision CNC machining is a critical decision for your project’s success. With ly-machining, you gain a transparent source manufacturer committed to delivering high-quality, custom CNC parts manufacturing with deep technical expertise and efficient processes.

We are ready to empower your project with our advanced capabilities, from 5-axis machining to rapid prototyping and comprehensive DFM analysis. Partner with us for reliable, high-value CNC machining services that exceed expectations.

Case

A client approached us with a challenging project involving complex titanium components for a new aerospace application. Their previous supplier struggled to maintain the extremely tight tolerances and intricate internal geometries required, leading to significant delays and material waste. The design was pushing the limits of conventional 3-axis CNC machining.

Our solution began with an in-depth DFM review, leveraging our 5-axis CNC machining capabilities and extensive titanium expertise. We proposed optimized tool paths and fixturing strategies that allowed for continuous machining of complex features without re-clamping, drastically improving precision and efficiency. Our transparent pricing also provided a clear breakdown of the specialized processes required.

The result was the on-time delivery of precision CNC machined parts that not only met but exceeded the client’s stringent tolerance requirements. Our ability to handle complex geometries and specialized materials, combined with our full-chain quality control, turned a challenging project into a successful, high-value collaboration. This established a long-term partnership built on trust and technical excellence.

Ready to partner with a CNC machining manufacturer that consistently delivers high-quality parts with transparent pricing and deep technical expertise? Contact us today for a personalized consultation and a no-obligation, transparent quote on your next custom CNC parts manufacturing project.

**FAQ Section:**

What is DFM in CNC machining?

DFM, or Design for Manufacturability, is the process of optimizing a product’s design for efficient and cost-effective manufacturing. It involves analyzing design files to identify potential production issues and suggesting modifications. This proactive approach enhances manufacturability while reducing material waste and production time.

Why are certifications important for manufacturers?

Certifications like ISO 9001 and IATF 16949 are crucial because they validate a manufacturer’s adherence to stringent quality management systems. They demonstrate a commitment to consistent processes, continuous improvement, and the production of high-quality CNC machined parts. These standards provide a baseline for trustworthiness.

Can I get rapid prototyping for custom parts?

Yes, many advanced CNC machining manufacturers offer rapid prototyping services for custom parts. At ly-machining, we understand the need for speed in product development. We offer 24-hour rapid prototyping for select projects, ensuring quick turnaround without compromising precision.