Defining Excellence in CNC Machining

In an industry often defined by hidden complexities and unmet expectations, what truly separates a merely “good” CNC machining factory from one that delivers consistent, uncompromising excellence? The answer lies not just in machines, but in a profound commitment to precision, transparency, and technical mastery.

What if the secret to achieving your next project’s breakthrough—faster, more accurately, and without budget surprises—lies not just in your design, but in the unseen operational excellence of your CNC partner? This guide will illuminate the critical differentiators.

We invite you to uncover the pillars that define an excellent CNC manufacturer, ensuring your projects are executed with unparalleled precision, efficiency, and peace of mind.

Excellence in CNC: What to Seek

Setting the Scene: The Critical Choice

Navigating the landscape of manufacturing partners requires a keen eye for detail and a clear understanding of what constitutes true value. Choosing the right CNC machining factory is pivotal to project success.

Ignoring key indicators can lead to significant delays, escalating costs, and ultimately, compromised product quality. Many procurement managers face unreliable suppliers and inconsistent part output.

Navigating Industry Pain Points

Clients frequently encounter challenges such as opaque pricing, missed deadlines, and a lack of clear communication during critical production phases. Furthermore, finding a source CNC manufacturer capable of intricate geometries and tight tolerances remains a persistent struggle.

The deepest fear revolves around project delays, budget overruns, or product failures, all stemming from a subpar manufacturing partner. These concerns underscore the need for a truly excellent CNC manufacturer.

Elevating Your Project with an Excellent Factory

An excellent CNC machining factory transforms these challenges into reliable successes through a combination of technical expertise and rigorous operational protocols. It’s about more than just producing parts; it’s about partnership.

By choosing a superior partner, you mitigate risks, enhance product quality, and ensure predictable project timelines. The focus shifts from problem-solving to proactive innovation and efficient delivery of high-quality CNC parts.

Your Journey Ahead: What This Guide Offers

This guide serves as your comprehensive roadmap to identifying and collaborating with an elite CNC manufacturing partner. It offers insights from an engineer’s perspective, focusing on actionable criteria.

We aim to demystify the complexities of high-precision manufacturing, providing the knowledge required to make informed decisions. Understanding these core principles is vital for any successful project.

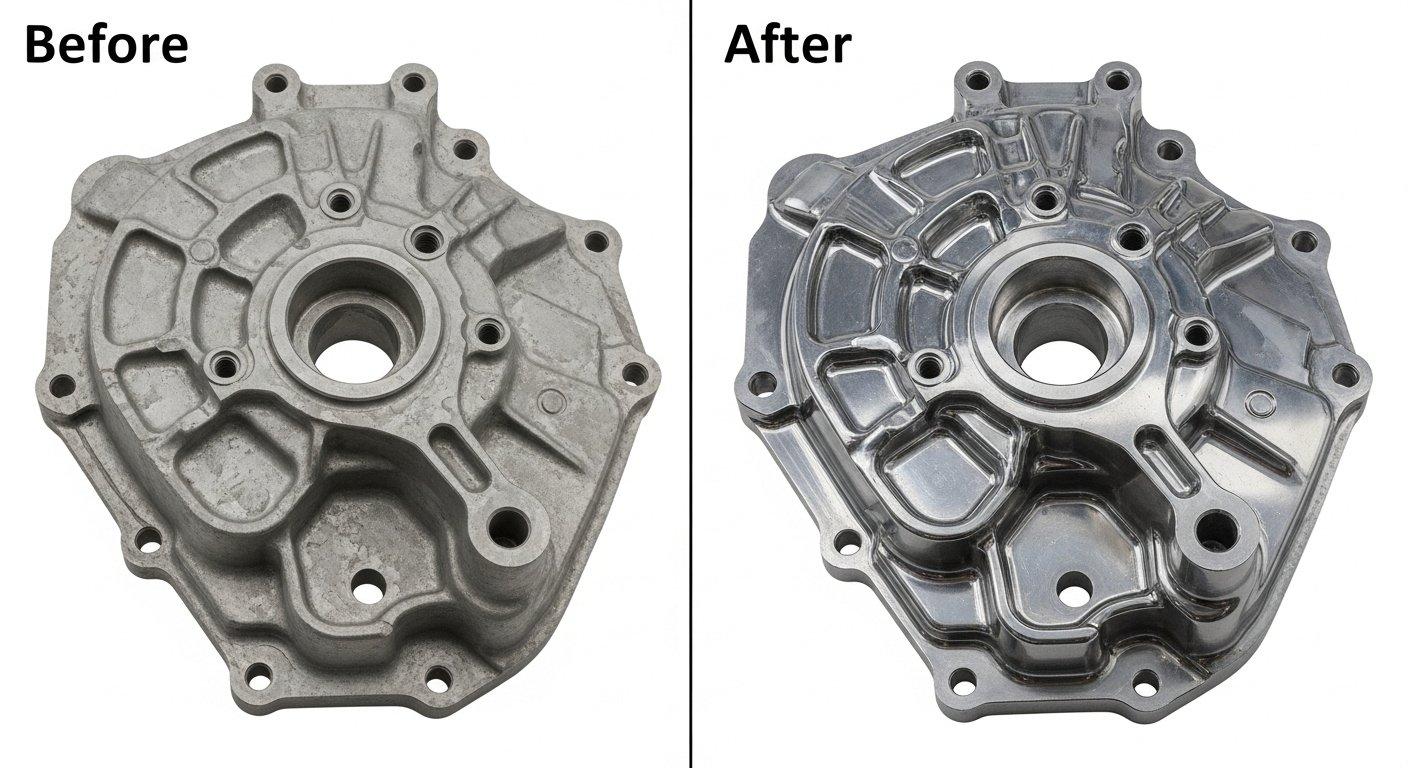

Solving Your Core CNC Challenges

We address common client dilemmas, from ensuring material certification to achieving optimal surface finishes. Our insights cover how deep technical knowledge translates into tangible benefits for your projects.

The objective is to empower you with the criteria for selecting a partner who can consistently deliver high-quality CNC parts. This alleviates anxieties about quality, delivery, and hidden costs.

Exploring Key Pillars of a Top CNC Manufacturer

We will delve into the critical factors that define excellence, including advanced machinery, robust quality control, and a commitment to continuous improvement. These pillars form the bedrock of a dependable source CNC manufacturer.

Understanding these foundational elements enables you to benchmark potential partners effectively. This ensures your investment yields superior results and long-term value.

CNC Strength

Defining Excellence: Superior CNC

True excellence in CNC machining goes beyond possessing state-of-the-art equipment; it encompasses an unparalleled commitment to precision, consistency, and innovation. It is about the holistic integration of technology and expertise.

An excellent CNC manufacturer distinguishes itself through meticulous attention to detail at every stage of the manufacturing process. This commitment ensures the delivery of high-quality CNC parts consistently.

The Foundation of Unwavering Quality

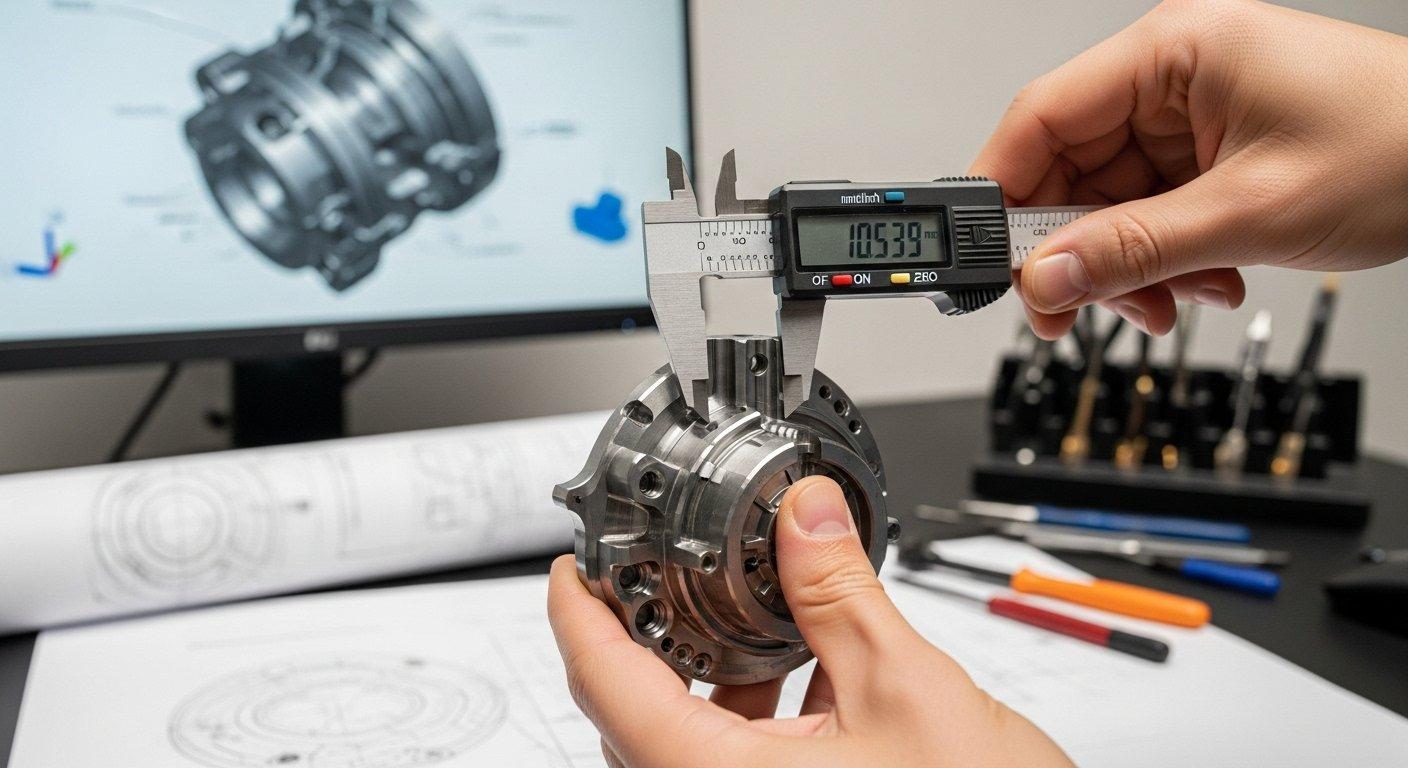

Unwavering quality begins with a robust infrastructure, including climate-controlled environments and regularly calibrated machinery. This foundation is critical for maintaining tight tolerances and repeatable results.

Furthermore, a highly skilled workforce, continuously trained in the latest techniques and technologies, forms the intellectual backbone of any excellent CNC machining factory. Their expertise directly impacts part integrity.

Understanding Advanced Machining Logic

Advanced machining logic involves sophisticated programming, toolpath optimization, and real-time process monitoring. These elements are crucial for tackling complex geometries and demanding material specifications.

For example, utilizing 5-axis machining centers significantly enhances geometric flexibility and reduces setup times. This leads to higher precision and superior surface finishes on even the most intricate parts.

Expertise in Action: Your Direct Benefits

The profound technical know-how of an excellent CNC manufacturer directly translates into tangible benefits for clients. It manifests in reduced lead times, improved design for manufacturability (DFM), and cost efficiencies.

Collaboration with engineers provides critical feedback on design optimization, preemptively addressing potential manufacturing challenges. This proactive approach saves time and resources in the long run.

Smart Operations

Structured Steps to Flawless Production

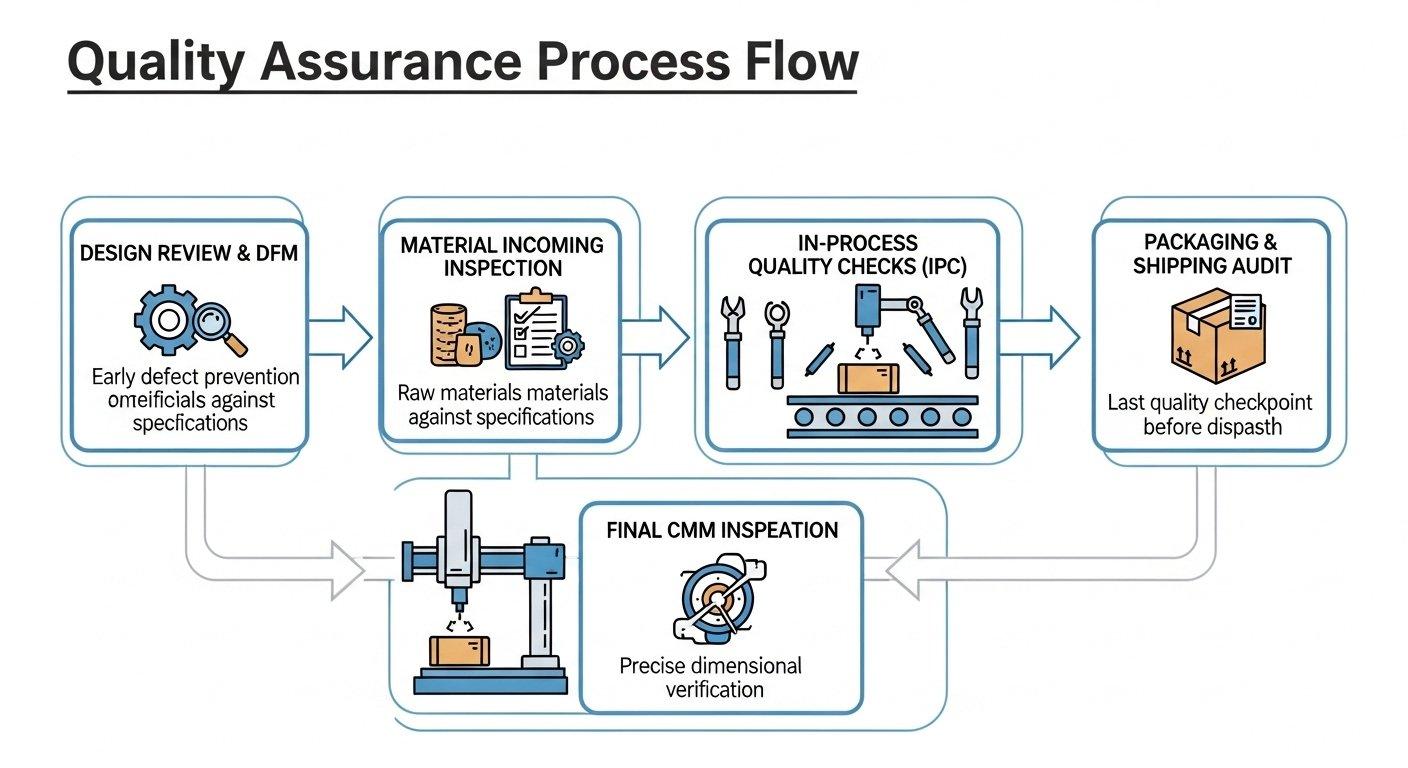

A methodical approach to production is fundamental to consistently delivering high-quality CNC parts. Each step is carefully orchestrated, from initial design review to final inspection and delivery.

This structured workflow minimizes errors, optimizes resource utilization, and ensures traceability throughout the entire manufacturing cycle. It is a hallmark of an excellent CNC manufacturer.

Our Detailed Machining Workflow

Our process begins with a comprehensive Design for Manufacturability (DFM) analysis, identifying potential challenges and suggesting optimizations. This collaborative step ensures design intent aligns with manufacturing capabilities.

Following DFM approval, precise CAD/CAM programming translates designs into machine-ready instructions. Material procurement adheres to strict certification standards, guaranteeing component integrity.

The machining phase utilizes advanced CNC equipment, monitored by experienced technicians for real-time quality control. This leads into rigorous post-processing and surface finishing.

Navigating Common Production Pitfalls

Mitigating common production pitfalls, such as material defects or machining inconsistencies, requires proactive quality management. This involves in-process inspections and statistical process control.

An excellent CNC machining factory implements continuous improvement methodologies, learning from every project to refine processes further. This iterative approach boosts efficiency and reliability.

Proof in Practice: Client Success Stories

Real-world applications demonstrate the profound impact of partnering with an excellent CNC manufacturer. Success stories highlight how a collaborative approach yields exceptional outcomes.

These narratives showcase problem-solving ingenuity and commitment to client objectives, establishing a strong reputation for reliability. They reinforce the value proposition of a source CNC manufacturer.

Real-World Success: A Case Study

Case Study: Advanced Medical Device Component

Problem: A client in the medical device sector required a complex titanium component for a new surgical instrument. The part featured extremely tight tolerances (±0.005mm), intricate internal channels for fluidics, and a highly polished biocompatible surface finish. Several manufacturers had deemed the design unfeasible or quoted exorbitant costs with extended lead times. The primary concern was achieving flawless internal geometry without compromising surface integrity or material properties.

Our Solution: As an experienced source CNC manufacturer, ‘ly-machining’ deployed its deep technical expertise. Our engineers initiated an intensive DFM analysis, recommending minor design adjustments that preserved functionality while significantly improving machinability.

We utilized a 5-axis CNC machining center, programmed with advanced toolpath strategies, to navigate the intricate internal features and achieve the demanding tolerances. Custom fixtures were designed to ensure repeatable setups, and our dedicated quality team performed hourly in-process dimensional checks using optical comparators and CMMs. Post-machining, a specialized electropolishing technique was developed to achieve the required surface finish without altering the internal geometry or compromising biocompatibility.

Result: ‘ly-machining’ successfully delivered 500 units of the titanium component ahead of the revised schedule and within budget. The client reported that the parts exceeded specifications for dimensional accuracy and surface finish, integrating seamlessly into their final assembly. This partnership ensured the client could launch their new surgical instrument on time, solidifying their market position with a high-performance, reliable product. The client praised our transparent communication and engineering ingenuity.

Future Readiness

Solving Your Toughest Project Hurdles

Addressing complex project hurdles requires more than just machinery; it demands innovative problem-solving and a deep understanding of material science. An excellent CNC manufacturer acts as a true technical partner.

We engage actively with your challenges, offering expert guidance from initial concept through to final production. This collaborative approach ensures optimal outcomes, even for the most demanding specifications.

Addressing Common Client Questions

Clients often inquire about material compatibility, specialized surface treatments, and scalability for high-volume production. Our engineers provide detailed, evidence-based answers to these critical questions.

We also offer insights into optimizing designs for specific manufacturing processes, helping to reduce costs and enhance part performance. This expertise is a cornerstone of our service as a source CNC manufacturer.

Innovating for Tomorrow: CNC Trends

The CNC machining industry is continuously evolving, driven by advancements in automation, artificial intelligence, and new material sciences. An excellent CNC manufacturer stays at the forefront of these trends.

Embracing these innovations ensures that our capabilities remain cutting-edge, allowing us to offer superior solutions for future manufacturing challenges. This proactive approach benefits all our clients.

Advanced Strategies & Future Outlook

Advanced strategies include the integration of robotic automation for loading/unloading, predictive maintenance through IoT sensors, and AI-driven toolpath optimization. These enhance efficiency and reduce human error.

The future outlook for an excellent CNC machining factory involves even greater integration of digital twins and virtual manufacturing for comprehensive process simulation. This leads to unparalleled accuracy and speed.

Next Steps

Recapping Core Excellence

The journey to finding an excellent CNC manufacturer involves scrutinizing a factory’s commitment to quality, its technical expertise, and its operational transparency. These are non-negotiable criteria.

A true source CNC manufacturer provides not just parts, but a partnership built on trust and a shared goal of project success. This foundation is essential for complex, high-stakes endeavors.

Key Insights for Choosing Your CNC Partner

Look for a partner with proven capabilities in handling diverse materials and achieving demanding tolerances. Transparent communication and comprehensive quality assurance protocols are also paramount.

Prioritize factories that offer robust DFM support, ensuring your designs are optimized for efficient and high-quality production. This proactive collaboration streamlines the entire process.

Reinforcing the Value of an Excellent Factory

An excellent CNC machining factory mitigates project risks, ensures consistent quality, and provides reliable delivery, fostering long-term successful partnerships. They are an extension of your own engineering team.

The value extends beyond cost; it encompasses peace of mind, innovation, and the assurance that your high-quality CNC parts will perform as intended. This is the hallmark of a true industry leader.

Ready to Transform Your Projects?

If you are seeking a partner that embodies technical precision, unwavering quality, and transparent processes, ‘ly-machining’ is ready to collaborate. We are committed to turning your vision into reality.

Discover how our deep technical expertise and dedication as a source CNC manufacturer can elevate your next project. We are equipped to handle your most demanding requirements.

Connect with Our CNC Experts Today

Invite readers to get a free quote or technical consultation.

FAQ Section

How do you ensure part quality?

We uphold rigorous multi-stage quality control. This begins with DFM analysis and material incoming inspection, extending through in-process dimensional checks.

Our final inspection uses advanced CMMs and optical comparators. Every step ensures high-quality CNC parts.

What materials can you machine?

We specialize in a broad spectrum of materials. This includes various grades of aluminum, stainless steels, titanium, and engineering plastics.

Our expertise allows us to machine exotic alloys. We provide solutions for diverse industry requirements.

Can you assist with DFM?

Absolutely, our engineering team provides comprehensive Design for Manufacturability (DFM) support. We collaborate closely with clients.

Our DFM insights optimize designs for production efficiency. This helps reduce costs and enhance component performance.