Achieve compliant food-grade PP CNC parts through expert PP plastic customization, strictly adhering to food contact regulations and advanced CNC machining standards for safety and performance.

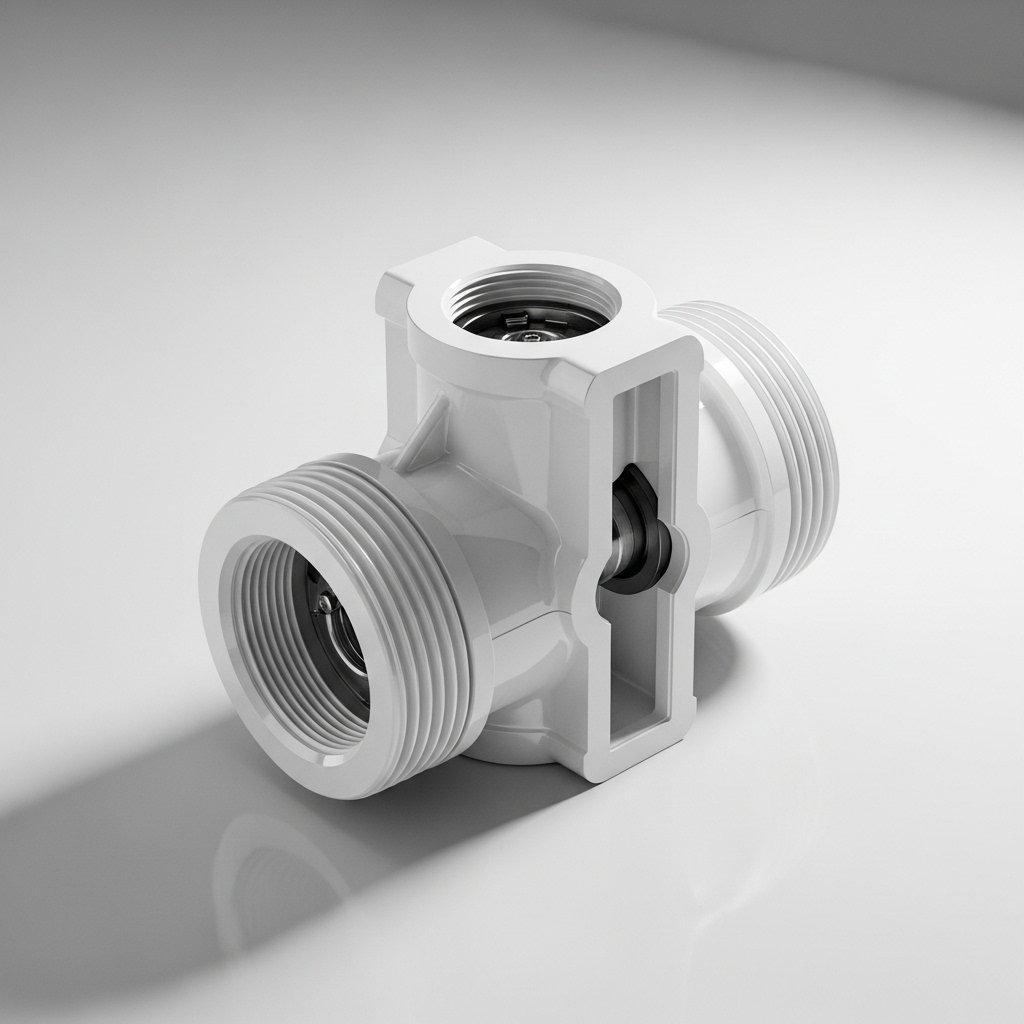

The demand for high-performance, compliant components in food, beverage, and medical industries is non-negotiable. Custom food-grade PP CNC parts require more than just the right material; they demand an uncompromising approach to design, machining, and quality control.

Navigating the complexities of food contact regulations and ensuring true material integrity can be daunting for many clients. This guide outlines the essential standards and best practices we employ at ly-machining to deliver custom PP components that meet the most stringent safety and functional requirements.

Understanding Food-Grade PP: Material & Compliance

What is Food-Grade PP Plastic?

Food-grade PP (Polypropylene) plastic is a type of thermoplastic polymer specifically engineered to be safe for direct contact with food and beverages. It is distinguished by its inertness, non-toxic nature, and resistance to chemical leaching.

Unlike standard PP, food-grade variants are manufactured from virgin resins, ensuring no harmful additives or contaminants are present. This material is rigorously tested to prevent any migration of substances into food products, safeguarding consumer health.

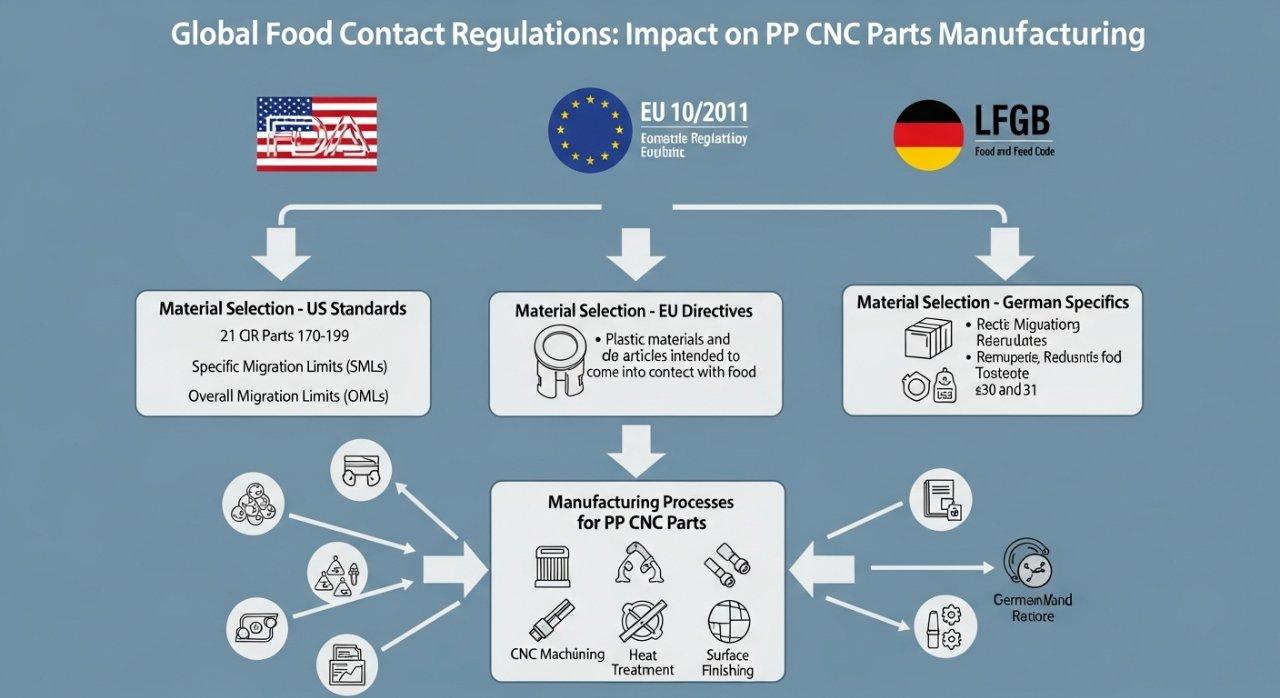

Key Food-Grade Compliance Standards

Adherence to specific food contact regulations is paramount for any food-grade PP component. In our experience, understanding these global benchmarks is critical for successful PP plastic customization.

Commonly referenced standards include the U.S. FDA regulations (e.g., 21 CFR 177.1520 for polypropylene), European Union Regulation 10/2011, and Germany’s LFGB. These frameworks dictate allowable material compositions and migration limits.

Table: Key Food Contact Regulatory Bodies & Standards

| Regulatory Body | Key Regulation Example | Focus |

|---|---|---|

| U.S. FDA | 21 CFR 177.1520 | Indirect food additives; safe use of polymeric olefin articles. |

| European Union | Regulation (EU) 10/2011 | Plastic materials and articles intended to come into contact with food. |

| Germany | LFGB | General food and feed code covering all food contact materials. |

Advantages of Food-Grade PP in CNC Parts

Food-grade PP offers a unique combination of properties that make it ideal for CNC machining standards in food contact applications. Its excellent chemical resistance ensures stability when exposed to various food products and cleaning agents.

The material also boasts high heat resistance, making it suitable for processes involving sterilization or hot-fill applications. Its good mechanical strength and low density contribute to durable yet lightweight custom food-grade PP CNC parts.

Table: Food-Grade PP Material Advantages

| Property | Benefit for Food Contact Applications |

|---|---|

| Chemical Resistance | Inertness to acids, bases, and solvents; extended lifespan. |

| Temperature Resistance | Withstands sterilization temperatures; versatile usage. |

| Low Moisture Absorption | Prevents bacterial growth; maintains dimensional stability. |

| High Strength-to-Weight | Durable, lightweight components; reduced system load. |

Design Considerations for Food-Grade PP Parts

Design Phase: Material & Geometry Limits

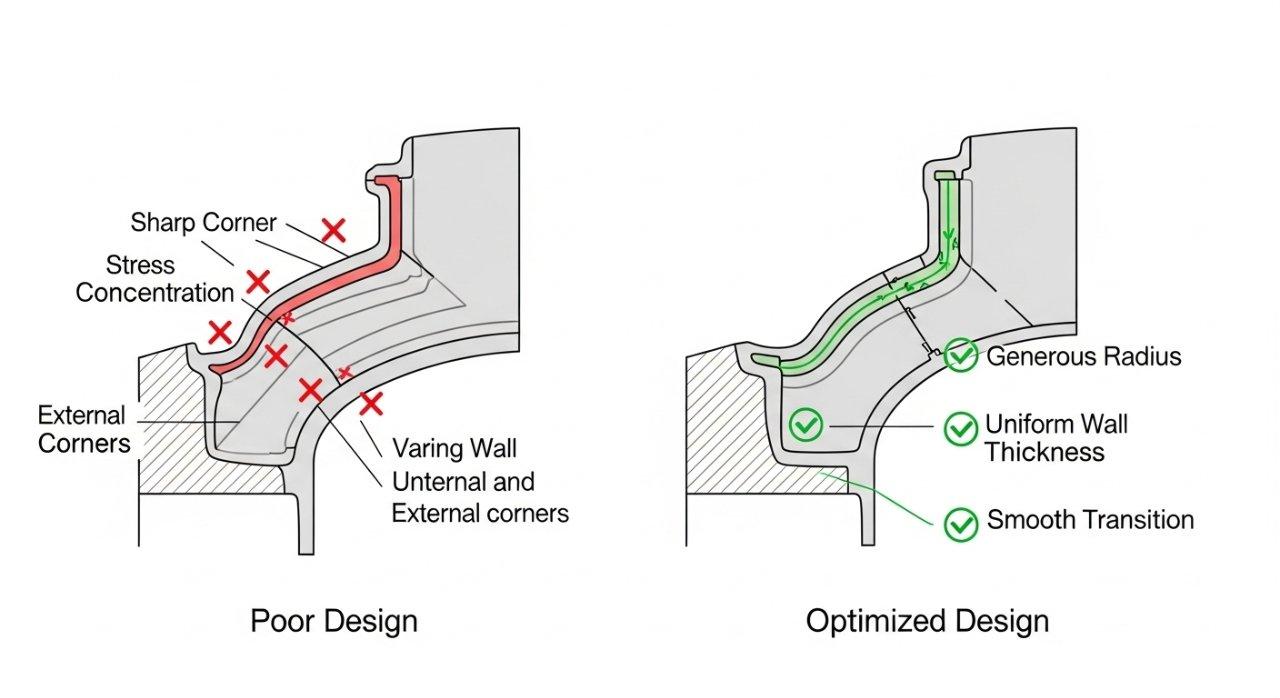

Effective PP plastic customization begins with meticulous design, factoring in the specific properties of food-grade PP. The material’s inherent flexibility can influence achievable wall thicknesses and structural integrity.

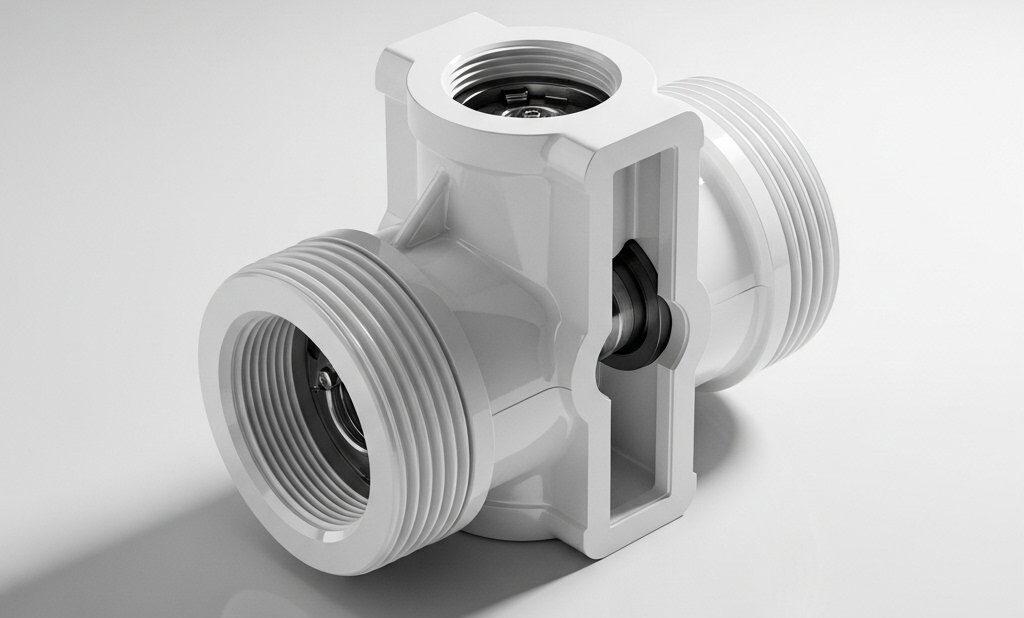

Our engineers collaborate closely with clients to optimize geometries, ensuring manufacturability while meeting functional requirements. This includes advising on minimum radii and avoiding sharp internal corners that can trap particles.

Surface Finish & Hygiene Requirements

For food-grade components, surface finish is not merely aesthetic; it’s critical for hygiene. A smooth, non-porous surface prevents microbial adhesion and facilitates thorough cleaning.

We prioritize achieving low surface roughness values (e.g., Ra < 0.8 µm) in our CNC machining standards for food-grade PP. This often requires specific toolpaths, cutting parameters, and post-machining polishing techniques.

Tolerance & Dimensional Accuracy Needs

Precision in food-grade PP CNC parts is essential for proper assembly and function within critical systems. In our experience, maintaining tight tolerances can be challenging due to PP’s relatively high coefficient of thermal expansion.

Our advanced CNC machining standards and temperature-controlled environments allow us to consistently hold tight dimensional accuracy. We work to ISO 2768-1 fine or even custom, tighter tolerances based on application demands.

Table: Typical Machining Tolerances for PP

| Feature Type | Standard Tolerance (mm) | Fine Tolerance (mm) |

|---|---|---|

| Linear | ±0.20 | ±0.05 |

| Angular | ±1.0° | ±0.5° |

| Hole Diameter | ±0.15 | ±0.03 |

Optimizing Design for Cost Reduction

Smart design choices can significantly reduce the overall cost of custom food-grade PP CNC parts without compromising quality. Simplifying complex geometries and minimizing material waste are key considerations.

Our engineering consultation includes design for manufacturability (DFM) reviews, identifying opportunities for streamlined production. This expertise helps clients achieve efficient PP plastic customization.

Machining Standards for Food-Grade PP CNC

Unique CNC Challenges for Food-Grade PP

Machining food-grade PP presents specific challenges beyond standard plastic machining. The material’s relatively low melting point and flexibility require careful control of cutting speeds, feed rates, and tool geometry.

A common issue we see is localized melting or burr formation if parameters are not perfectly optimized. Our extensive experience with food-grade PP CNC parts allows us to mitigate these issues effectively.

Dedicated Equipment & Clean Environment

To prevent cross-contamination, dedicated machining equipment and a meticulously clean production environment are non-negotiable for food-grade PP CNC parts. We operate segregated work cells.

Our facilities include temperature and humidity-controlled areas, ensuring optimal machining conditions and preventing environmental contaminants from affecting the material’s integrity. This adheres to stringent CNC machining standards.

Parameter Optimization & Tool Selection

Achieving superior surface finish and dimensional accuracy requires precise parameter optimization. This involves selecting appropriate cutting tools, such as sharp, polished carbide inserts, and optimizing spindle speeds and feed rates.

We utilize advanced CAM software and conduct extensive testing to fine-tune our CNC machining standards for food-grade PP. This ensures material integrity and minimizes stress on the component.

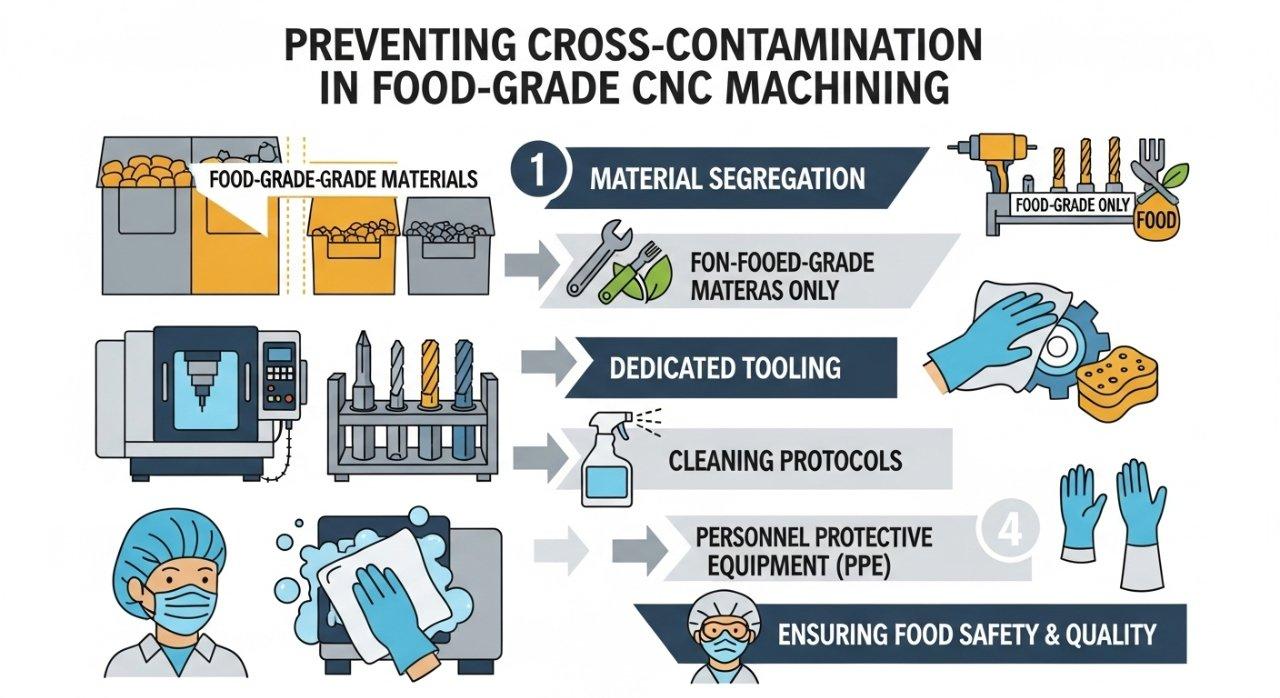

Preventing Cross-Contamination

Cross-contamination is a critical concern in food-grade manufacturing. Our protocols for custom food-grade PP CNC parts include strict material segregation, dedicated tooling, and thorough cleaning procedures between production runs.

All personnel working on food-grade projects are trained on contamination prevention and wear appropriate protective equipment. This systematic approach guarantees the purity of every PP plastic customization project.

Quality Control & Traceability Standards

Raw Material Sourcing & Certification

Trustworthiness begins with raw materials. We only source virgin, certified food-grade PP resins from reputable suppliers with comprehensive documentation.

Each batch of raw material for food-grade PP CNC parts comes with a Certificate of Analysis (CoA) and material safety data sheets (MSDS), verifying compliance with relevant food contact regulations.

In-Process Quality Inspection

During production, our technicians perform continuous in-process quality inspections. This includes checking dimensional accuracy, surface finish, and visual defects at various stages of the CNC machining standards.

Statistical Process Control (SPC) methods are employed to monitor key parameters, ensuring consistency and proactively addressing any deviations. This is vital for reliable PP plastic customization.

Final Part Inspection & Acceptance

Before packaging, every custom food-grade PP CNC part undergoes a rigorous final inspection. This comprehensive check verifies all specifications, including critical dimensions, surface finish, and any specified functional tests.

Our quality assurance team utilizes precision measurement equipment, including CMMs and optical comparators, to ensure absolute conformity to design requirements and food contact regulations.

Comprehensive Traceability System

A robust traceability system is fundamental for food-grade components. We implement a complete lot traceability system, linking every finished custom food-grade PP CNC part back to its raw material batch, machining parameters, and inspection records.

This allows for rapid identification and recall if necessary, providing our clients with complete peace of mind and demonstrating our commitment to the highest CNC machining standards.

Choosing Your Food-Grade PP CNC Partner

Assessing Technical & Expertise

When selecting a partner for food-grade PP CNC parts, assess their technical expertise beyond basic machining. Look for a team with deep knowledge of material science, food contact regulations, and design for hygiene.

In our experience, a partner who offers engineering consultation from the outset demonstrates true expertise and foresight in PP plastic customization.

Reviewing Quality Management Systems

A robust Quality Management System (QMS), such as ISO 9001 and ideally ISO 13485 (for medical devices, which often overlap with food-grade hygiene standards), is crucial. This signifies a systematic approach to quality for custom food-grade PP CNC parts.

Request documentation of their QMS, process validation protocols, and specific procedures for food-grade material handling.

Transparent Pricing & Communication

Transparency in pricing and clear communication are hallmarks of a trustworthy manufacturing partner. For critical food-grade PP CNC parts, you need a partner who can articulate costs, lead times, and any potential challenges upfront.

At ly-machining, we pride ourselves on clear, consistent communication throughout the entire PP plastic customization process, ensuring no surprises.

Case Study: Successful PP Part Customization

Problem: A client in the dairy industry faced recurring contamination issues with their existing liquid dispensing components, despite using ‘food-safe’ plastics. Their previous supplier lacked the specialized CNC machining standards required, resulting in micro-pitting and inconsistent surface finishes. This led to bacterial harborage and costly product recalls.

Our Solution: After an in-depth engineering consultation, ly-machining redesigned the client’s custom food-grade PP CNC parts. We specified a higher-grade virgin food-grade PP, optimized the geometry for improved cleanability, and implemented our dedicated cleanroom CNC machining processes. Our advanced surface finishing techniques achieved an Ra value significantly lower than their previous supplier.

Result: The new food-grade PP CNC parts passed all stringent hygiene tests, eliminating contamination incidents. The client reported enhanced product safety, reduced operational downtime from fewer cleanings, and regained consumer confidence. Our transparent compliance documentation also streamlined their regulatory audits, solidifying their trust in our PP plastic customization capabilities.

Custom Food-Grade PP Part Process

Fast Response: Quote from Requirement

Our streamlined process for custom food-grade PP CNC parts begins with a rapid response to your inquiry. We understand the urgency of bringing critical components to market.

Provide us with your specifications, and our team will quickly prepare a detailed and transparent quote for your PP plastic customization project.

Engineering Consultation & Design Review

Upon receiving your requirements, our expert engineers initiate a thorough consultation and design review. We assess manufacturability, material suitability, and compliance with food contact regulations.

This proactive approach ensures that your custom food-grade PP CNC parts are optimized for performance, cost-efficiency, and adherence to the highest CNC machining standards from the outset.

Sample Production & Validation

For critical applications, we recommend initial sample production for rigorous validation. This allows you to test the custom food-grade PP CNC parts in your specific environment before full-scale production.

We work with you to ensure these samples meet all functional, dimensional, and regulatory criteria, providing complete confidence in the final product.

Mass Production & Delivery

Once samples are validated, we move to efficient mass production, leveraging our advanced CNC machining standards and stringent quality control protocols. Our production scheduling ensures on-time delivery.

We coordinate logistics to get your custom food-grade PP CNC parts to you efficiently and securely, complete with all necessary certifications and documentation.

Conclusion: Customize Your Food-Grade PP

Summary: Why Expert Customization Matters

Custom food-grade PP CNC parts demand a manufacturing partner with unparalleled expertise and a commitment to the highest food contact regulations and CNC machining standards. From material selection to final inspection, every step is critical.

At ly-machining, we combine our deep technical knowledge with advanced manufacturing capabilities to deliver compliant, high-performance PP plastic customization solutions, ensuring the safety and success of your products.

Contact Our Expert Team Today (CTA)

Ready to elevate your custom food-grade PP CNC parts to the highest standard? Connect with our expert engineering team today for a transparent consultation and a detailed quote tailored to your project’s unique specifications.

What makes PP “food-grade”?

Food-grade PP is manufactured from virgin resin without harmful additives, ensuring it’s inert and won’t leach chemicals into food. It undergoes strict testing to comply with regulations like FDA and EU 10/2011.

This ensures the material is safe for direct and prolonged contact with food products. It’s a critical distinction from standard industrial-grade PP.

How do you ensure hygiene during machining?

We prevent contamination through dedicated machining cells, strict material segregation, and a temperature-controlled, clean environment. Our staff adheres to stringent hygiene protocols and uses specialized tooling.

This ensures every custom food-grade PP CNC part maintains its purity and meets critical food contact regulations.

Can you meet tight tolerances for PP?

Yes, despite PP’s characteristics, our advanced CNC machining standards, optimized parameters, and climate-controlled facilities enable us to hold tight tolerances. We regularly achieve ISO 2768-1 fine or even tighter tolerances.

This precision is crucial for the proper fit and function of complex custom food-grade PP CNC parts.