The journey from an intricate bicycle component design to a tangible, high-performance part often presents significant manufacturing challenges. Achieving the exact geometric precision, material integrity, and surface finish demanded by modern bicycle engineering can be a daunting task for many suppliers.

Inconsistencies in manufacturing can lead to critical failures, costly redesigns, and delayed product launches, directly impacting brand reputation and market competitiveness. The struggle to find a manufacturing partner who genuinely understands the nuances of custom bicycle CNC production, from complex geometries to specialized material requirements, is a common industry pain point. Without deep technical expertise, innovative designs risk remaining mere concepts rather than becoming reliable, high-performance realities.

Discover how partnering with a dedicated source manufacturer who possesses profound engineering knowledge and advanced CNC machining capabilities can transform your most ambitious bicycle component designs into flawless physical components, ensuring unparalleled precision and guaranteed quality.

Precision CNC machining transforms intricate bicycle part blueprints into high-performance realities through expert engineering, advanced material processing, and stringent quality assurance.

Design Interpretation and Blueprint Preparation

Translating a visionary bicycle part design into a manufacturable reality begins with a meticulous interpretation of engineering blueprints. This initial phase is critical for establishing the foundation of precision CNC bicycle parts. Our engineers in Shenzhen, China collaborate closely to ensure every detail is accurately understood.

Translating Bicycle Part Designs into Machinable Models

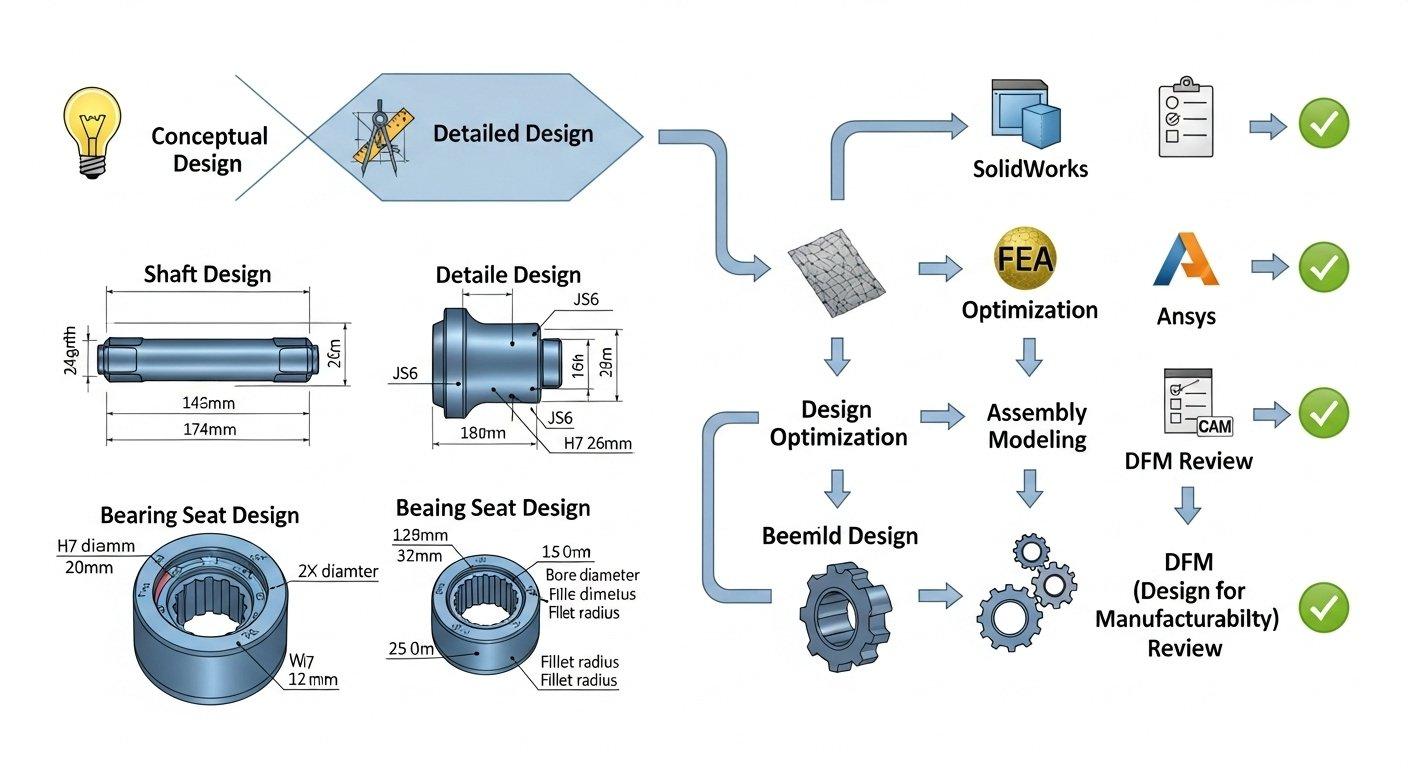

The transition from a conceptual design to a machinable model is a cornerstone of custom bicycle CNC production. This involves leveraging advanced software and engineering expertise to prepare the design for optimal manufacturing. Each feature of the bicycle part must be considered.

CAD Modeling for Optimal CNC Machining of Bicycle Parts

Comprehensive Computer-Aided Design (CAD) modeling is essential for transforming a design into a precise, digital representation. Our process ensures that geometries are optimized for machining efficiency, minimizing potential errors and material waste. This detailed preparation ensures superior bicycle component manufacturing.

Understanding Tolerances and Critical Dimensions

Defining and adhering to strict tolerances and critical dimensions is paramount for the functionality and safety of bicycle components. We utilize advanced metrology techniques and engineering experience to establish realistic yet precise specifications, guaranteeing component fit and performance. This precision bike parts CNC approach is non-negotiable.

Material Selection for Bicycle Component CNC Manufacturing

The choice of material significantly impacts a bicycle component’s performance, durability, and machinability. Our expertise in bicycle parts engineering guides clients in selecting optimal materials for their specific application. This selection process is a crucial step for achieving desired outcomes.

Common Materials: Aluminum, Titanium, Steel Alloys

We work extensively with a range of high-performance materials tailored for bicycle component manufacturing. Each material offers distinct properties that influence factors such as weight, strength, and corrosion resistance. Our facility is equipped to handle these diverse specifications.

Material Properties Impacting CNC Machining and Part Performance

Understanding the thermal, mechanical, and chemical properties of selected materials is vital for both machining success and final part performance. This knowledge informs our tooling choices, machining parameters, and post-processing treatments. We ensure material integrity from start to finish.

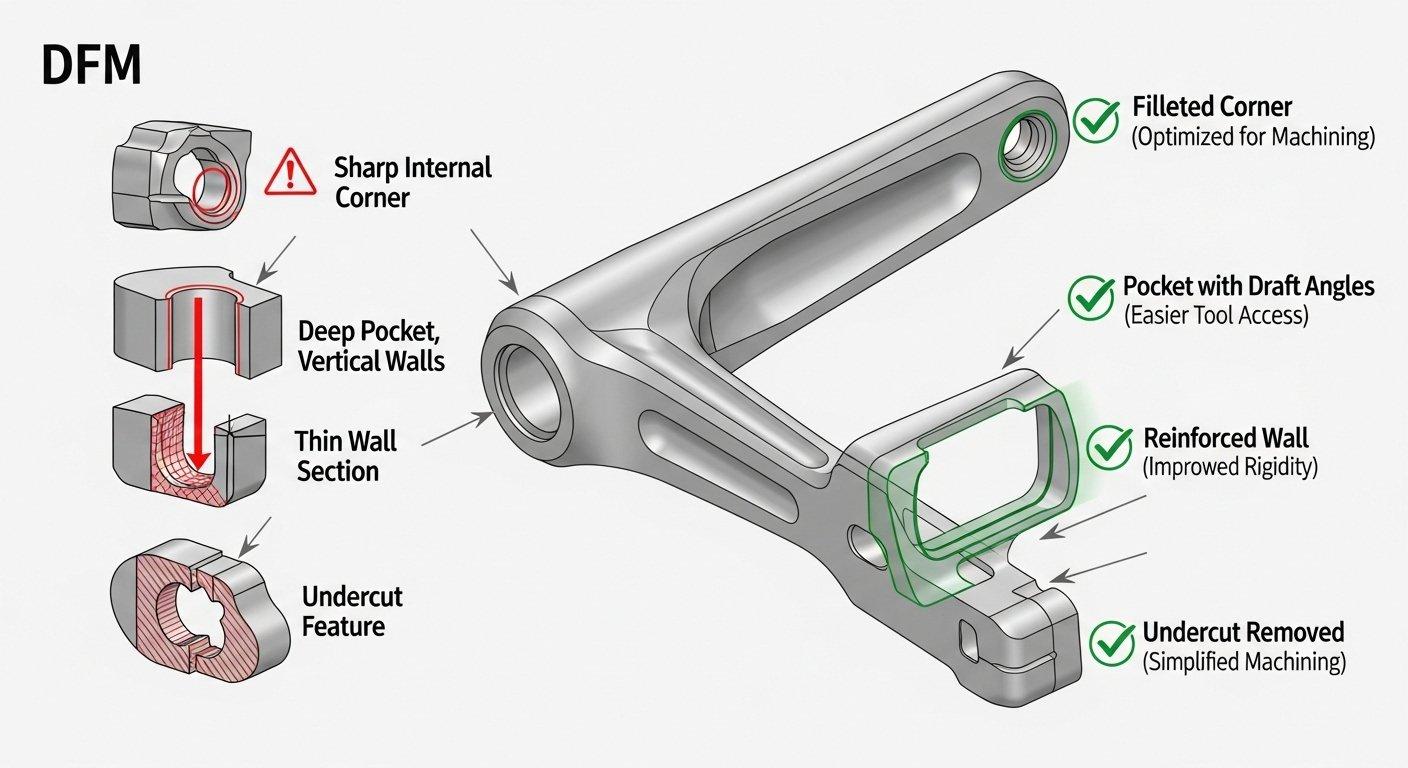

Design for Manufacturability (DFM) for Bicycle Parts

Implementing Design for Manufacturability (DFM) principles early in the design cycle is key to optimizing production efficiency and cost-effectiveness. Our engineers provide expert consultation to refine designs for streamlined CNC machining bicycle parts. This proactive approach saves time and resources.

Optimizing Geometries for Efficient CNC Machining

Streamlining part geometries reduces machining time, tool wear, and the potential for errors. This involves simplifying complex features where possible without compromising performance or aesthetics. Our DFM insights are invaluable for efficient bicycle component manufacturing.

Cost-Effective Design Strategies

Integrating cost-effective design strategies focuses on balancing performance requirements with manufacturing practicality. This includes minimizing material usage, reducing the number of machining setups, and selecting standard features where appropriate. We aim for optimal value without sacrificing quality.

| Material Type | Key Advantage | Typical Bicycle Part Application | Machinability Notes |

|---|---|---|---|

| Aluminum Alloys | Lightweight, Strong | Frames, Crank Arms, Hubs | Excellent, high-speed machining possible |

| Titanium Alloys | High Strength-to-Weight, Corrosion Resistant | High-End Frames, Bolts, Spindles | Challenging, requires specific tooling and speeds |

| Stainless Steels | High Strength, Corrosion Resistant | Bolts, Bearings, Brake Components | Good, but harder than aluminum |

| Carbon Steels | High Strength, Wear Resistant | Axles, Cogs | Good, but requires heat treatment for hardness |

Core CNC Machining Process Steps

The precision manufacturing of bicycle components relies on a meticulously executed CNC machining process. Each stage is carefully controlled to translate digital designs into physical parts with unparalleled accuracy. Our advanced facility ensures this transformation.

Setting Up the CNC Machine for Bicycle Component Production

Proper machine setup is fundamental to achieving consistent quality and precision. This critical phase involves selecting appropriate tooling and securing the workpiece, laying the groundwork for accurate material removal. Every setup is tailored for precision bike parts CNC.

Tooling Selection and Fixturing for Precision

Selecting the correct cutting tools and robust fixturing solutions prevents vibrations, ensures rigidity, and maintains dimensional accuracy throughout the machining process. Our expertise guarantees optimal tool-path generation and component stability. This is paramount for custom bicycle CNC production.

Programming CNC Machines: G-code and CAM Software

Advanced Computer-Aided Manufacturing (CAM) software is used to generate precise G-code from the CAD models. This code directs the CNC machine’s movements, dictating tool paths, speeds, and feeds, ensuring efficient and accurate material removal for every bicycle part. Our engineers are proficient in complex programming.

Rough Machining: Shaping the Bicycle Part from Raw Stock

Rough machining is the initial phase where significant amounts of material are removed from the raw stock. This creates the basic shape of the bicycle part, bringing it closer to the final geometry while leaving sufficient material for subsequent finishing passes. Efficiency is key here.

Material Removal Strategies for Efficiency

Our engineers employ optimized material removal strategies to maximize efficiency while minimizing stress on the workpiece and tooling. This involves careful consideration of cutting depths, widths, and feed rates to achieve rapid material reduction. This sets the stage for precision.

Initial Dimensional Accuracy Checks

Even during rough machining, initial dimensional accuracy checks are performed to ensure the part is progressing as expected. This proactive approach identifies potential issues early, preventing costly rework later in the production cycle. Quality is monitored at every stage.

Finish Machining: Achieving Final Precision and Surface Quality

Finish machining refines the bicycle part to its final dimensions, achieving the tight tolerances and superior surface finishes required for high-performance components. This stage demands exceptional precision and control from our CNC machining bicycle parts processes.

High-Speed Machining Techniques for Bicycle Parts

We utilize high-speed machining (HSM) techniques to achieve superior surface quality, reduce machining time, and extend tool life, particularly for complex geometries. This method is crucial for producing the smooth, aesthetic, and functional surfaces demanded by bicycle component manufacturing.

Surface Finish Requirements for Aesthetics and Functionality

The desired surface finish for bicycle parts often serves both aesthetic and functional purposes, influencing friction, corrosion resistance, and overall component integration. We meticulously control machining parameters to meet these exacting specifications. Our expertise ensures a flawless result.

Post-Processing and Surface Finishing

After the core machining processes, post-processing and surface finishing enhance the durability, aesthetics, and performance of CNC bicycle components. This stage is crucial for protecting the parts and preparing them for assembly.

Deburring and Edge Finishing for Bicycle Parts

Deburring meticulously removes any residual burrs or sharp edges left by machining. This improves component safety, functionality, and aesthetic appeal, ensuring a smooth, clean finish. This manual or automated process is critical for quality.

Specialized Surface Treatments and Coatings

To further enhance performance and durability, we offer a range of specialized surface treatments and coatings. These processes significantly contribute to the longevity and aesthetic quality of precision bike parts CNC.

Anodizing, Polishing, and Laser Engraving

Anodizing provides a durable, corrosion-resistant, and aesthetically pleasing finish, often available in various colors. Polishing achieves a high-luster surface. Laser engraving adds permanent, high-contrast markings for branding or part identification. These are common for aluminum bicycle machining.

Enhancing Durability and Corrosion Resistance

Coatings and treatments like hard anodizing or specific anti-corrosion applications dramatically improve a component’s resistance to wear, abrasion, and environmental degradation. This is vital for bicycle parts exposed to diverse conditions. We ensure maximum component lifespan.

| Surface Treatment | Primary Benefit | Typical Application | Aesthetic Impact |

|---|---|---|---|

| Anodizing (Type II) | Corrosion & Wear Resistance | Aluminum Frames, Hubs, Crank Arms | Various colors, matte or glossy |

| Hard Anodizing (Type III) | Extreme Hardness & Abrasion Resistance | Bearing Races, High-Wear Components | Darker, matte finish |

| Polishing | High Luster, Smooth Finish | Aesthetic Components, Low Friction Areas | Mirror-like or satin sheen |

| Laser Engraving | Permanent Marking, Branding | Logos, Serial Numbers, Part IDs | High contrast, precise detail |

Final Cleaning and Inspection Preparation

Prior to final inspection, all components undergo a rigorous cleaning process to remove any machining oils, debris, or contaminants. This ensures a pristine surface for accurate quality assessment and subsequent packaging. This step prepares components for their final journey.

Quality Control and Assembly Integration

Maintaining stringent quality control throughout every phase of CNC bicycle component production is paramount. Our comprehensive approach ensures that every part meets or exceeds specifications, from material integrity to final dimensions.

In-Process Quality Assurance Throughout CNC Machining

Quality assurance is not a final check but an ongoing process integrated into every machining step. This proactive strategy minimizes defects and ensures consistent adherence to design intent. Early detection is key to efficient bicycle component manufacturing.

Dimensional Verification using CMM and Gauges

Utilizing advanced Coordinate Measuring Machines (CMMs) and precision gauges, we perform frequent dimensional verification. This ensures that every contour, hole, and surface conforms precisely to the blueprint’s exacting specifications for custom bicycle CNC production.

Material Integrity and Stress Testing for Bicycle Components

Beyond dimensions, material integrity is crucial. We conduct tests to verify the material’s structural soundness, hardness, and freedom from internal defects. This ensures the bicycle parts can withstand the operational stresses they will encounter.

| Inspection Method | Purpose | Typical Use for Bicycle Parts |

|---|---|---|

| Coordinate Measuring Machine (CMM) | High-precision 3D dimensional verification | Complex geometries, tight tolerances |

| Calipers & Micrometers | Basic dimensional checks (length, diameter) | General part measurements |

| Go/No-Go Gauges | Rapid verification of critical features | Hole diameters, slot widths |

| Surface Roughness Tester | Quantifies surface texture and finish | Bearing surfaces, aesthetic parts |

| Hardness Tester | Measures material resistance to indentation | Heat-treated axles, cogs |

Final Inspection of Finished Bicycle Parts

Before shipment, every finished bicycle part undergoes a thorough final inspection. This comprehensive review confirms compliance with all specified requirements and industry standards. This is the last checkpoint before dispatch.

Visual Inspection for Flaws and Defects

Highly trained inspectors conduct meticulous visual examinations to detect any surface flaws, aesthetic imperfections, or minor defects that could compromise performance or appearance. This human element is irreplaceable in quality control.

Adherence to Specifications and Industry Standards

Our final inspection verifies that all CNC machined bicycle parts strictly adhere to client specifications and relevant industry standards. This unwavering commitment ensures the reliability and safety of the components in their intended application.

Packaging and Logistics for Safe Delivery of Bicycle Parts

Appropriate packaging is essential to protect the precision machined components during transit. We use methods that prevent damage, corrosion, and contamination, ensuring parts arrive in perfect condition, ready for assembly.

Partnering with a Source Manufacturer for Your Bicycle Parts

Collaborating with a dedicated source manufacturer like ly-machining offers distinct advantages for your bicycle component projects. Our integrated approach guarantees precision, transparency, and innovation from our 中国深圳 facility.

Advantages of Our Deep Technical Expertise and Transparent Pricing

Our deep technical expertise in bicycle parts engineering allows us to tackle even the most complex designs with confidence. Coupled with transparent pricing models, we ensure clients receive exceptional value and clarity throughout the manufacturing process.

Achieving High-Quality Bicycle Parts from Blueprint to Reality

Our comprehensive process, from meticulous design interpretation to rigorous quality control, ensures that every bicycle part meets the highest standards of precision and performance. We bridge the gap between your blueprint and a high-quality reality.

Driving Innovation in Bicycle Component Manufacturing

By partnering with us, you gain a manufacturing ally committed to innovation. We continuously invest in cutting-edge CNC technologies and advanced processes to support the evolving demands of the bicycle industry, pushing the boundaries of what is possible.

Case Study: Advancing Lightweight Crank Arms

A leading performance bicycle brand approached us with a challenge: to produce a new series of ultralight crank arms from a specific high-strength aluminum alloy, requiring exceptionally tight tolerances for the pedal spindle interface and intricate internal webbing for weight reduction. Previous suppliers struggled with maintaining dimensional accuracy across varying wall thicknesses and achieving the desired surface finish without compromising structural integrity.

Our solution involved a multi-axis CNC machining strategy, integrating custom-designed fixtures to minimize deflection and employing specialized high-speed milling tools to manage material removal effectively.

We developed a unique CAM program that optimized tool paths for both roughing and finishing operations, ensuring the delicate internal structures were accurately machined while maintaining the critical external dimensions and surface finish requirements. Intensive in-process CMM inspections were performed after each major machining phase.

The result was a crank arm that not only met all specified weight targets and dimensional tolerances but also exceeded the client’s expectations for surface quality and structural integrity.

Our efficient production process also led to a 15% reduction in lead time compared to previous manufacturing attempts, allowing the client to accelerate their product launch and gain a competitive edge in the high-performance cycling market.

Conclusion: Your Partner for Precision CNC Bicycle Components

For over two decades, ly-machining in Shenzhen, China has been dedicated to transforming complex bicycle component designs into high-precision, reliable physical products. Our commitment to engineering excellence, advanced manufacturing techniques, and meticulous quality control ensures that your innovative visions are realized with unparalleled accuracy.

We understand the critical demands of the bicycle industry and stand ready to apply our expertise to your most challenging projects. Our role as a source manufacturer means we offer not just manufacturing services, but a comprehensive partnership grounded in technical insight and transparent processes.

Invite readers to get a free quote or technical consultation.

What materials do you machine?

We specialize in machining a wide range of materials crucial for bicycle components, including various aluminum alloys, titanium alloys, and high-strength steel alloys. Our expertise extends to selecting the optimal material for your specific performance and durability requirements. Each material is processed with tailored parameters to ensure peak quality.

How do you ensure precision?

Precision is guaranteed through a multi-faceted approach, starting with advanced CAD/CAM programming and optimized multi-axis CNC machining. We integrate continuous in-process quality checks using CMMs and precision gauges, alongside a rigorous final inspection phase. This comprehensive system ensures every part meets exact specifications.

Can you assist with DFM?

Absolutely. Our experienced engineering team is adept at providing Design for Manufacturability (DFM) consultation. We help optimize your bicycle component designs for efficient CNC production, which can reduce manufacturing costs, improve part performance, and accelerate time-to-market. Our collaboration ensures practical and effective designs.