Achieve unparalleled precision in brass CNC machining through expert material selection and advanced processing for critical component performance and reliability.

Is your project’s success hinging on the elusive balance of brass machinability, strength, and corrosion resistance? Mastering high-end brass CNC starts long before the first cut – it begins with expert material selection. In our experience, the foundation of a superior brass component lies in understanding its intended application and matching it with the perfect alloy.

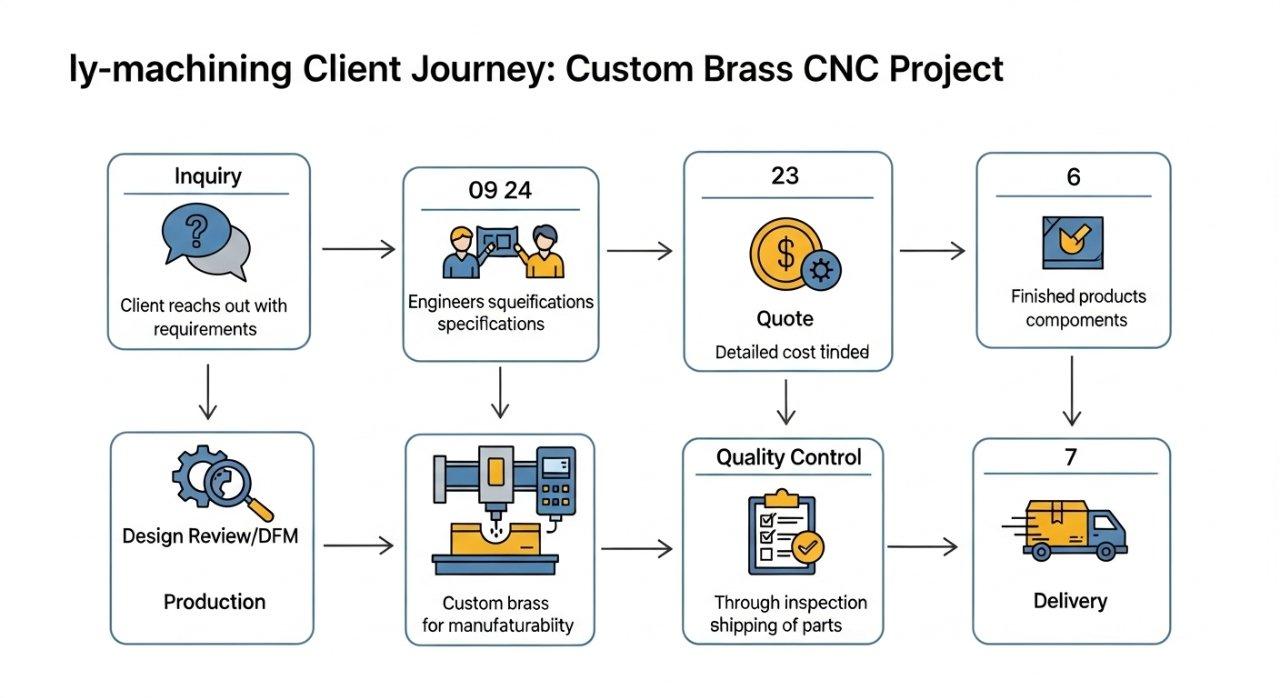

This guide from ‘ly-machining’ delves into the critical decisions and advanced techniques required for premium brass CNC machining, ensuring your components meet the most stringent specifications. We’ll explore material properties, process optimizations, and quality assurance that define true high-end production.

Unlocking Precision with High-End Brass

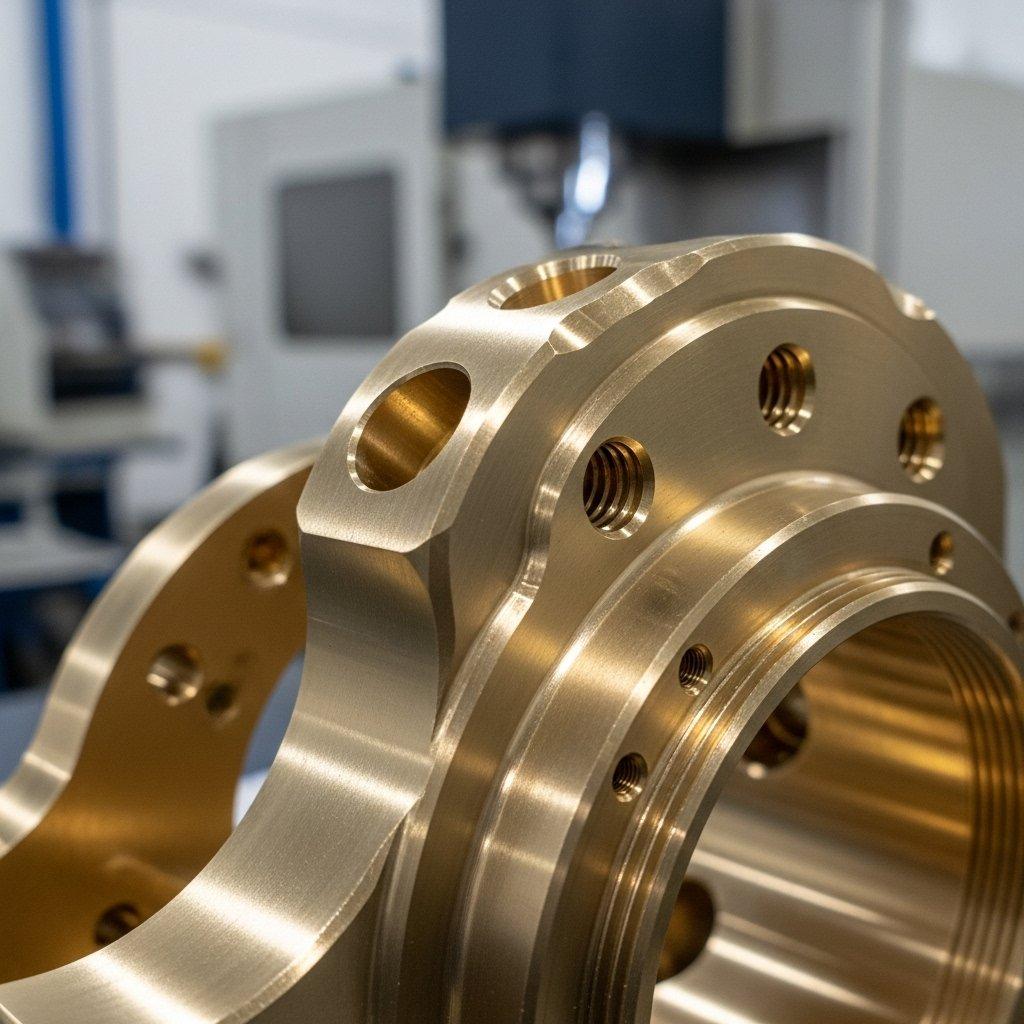

Producing high-end brass components demands more than just operating a CNC machine; it requires a deep understanding of material science and precision engineering. At ‘ly-machining’, we specialize in transforming design specifications into reality, leveraging our extensive experience in brass CNC machining. Our commitment ensures every component exhibits superior quality.

Why Brass for High-Performance?

Brass alloys offer a unique combination of properties that make them indispensable for high-performance applications. They boast excellent machinability, making complex geometries achievable with high precision. This inherent characteristic reduces tool wear and cycle times.

Furthermore, brass provides good corrosion resistance, particularly in various environments, making it suitable for electrical, plumbing, and marine applications. Its aesthetic appeal also lends itself well to decorative and consumer products.

Common Challenges in Brass CNC

Despite its advantages, brass presents specific challenges in high-end CNC machining. Issues like burr formation, chip control, and maintaining tight tolerances are common. These require specialized knowledge and optimized machining strategies.

We often encounter customer designs that, while brilliant, don’t fully account for brass’s characteristics. This necessitates DFM (Design for Manufacturability) collaboration to prevent costly rework and delays.

Achieving Tight Tolerances

Achieving sub-micron tolerances in brass CNC machining is a testament to true expertise. Brass can be prone to thermal expansion, affecting dimensional stability during and after the machining process. Our approach factors in these variables.

We meticulously control machine environment temperatures, use precise fixturing, and apply optimized tool paths. This ensures the final dimensions consistently meet the most demanding specifications, even for intricate medical or aerospace parts.

Surface Finish Perfection

A perfect surface finish is non-negotiable for high-end brass components, impacting both aesthetics and functionality. Imperfections can lead to premature wear, reduced sealing effectiveness, or signal lower quality.

Our process focuses on selecting the correct tool geometry, cutting parameters, and coolant strategies to minimize chatter and prevent surface defects. This results in components with a smooth, bright, and consistent finish.

Brass Material Selection for CNC Success

The journey to an exceptional brass component unequivocally begins with informed material selection. This critical choice impacts machinability, mechanical properties, and ultimately, the performance and longevity of the finished part.

In our experience, a thorough understanding of application requirements is paramount. We guide clients through the nuances of various brass alloys, ensuring the selected material precisely matches the functional demands.

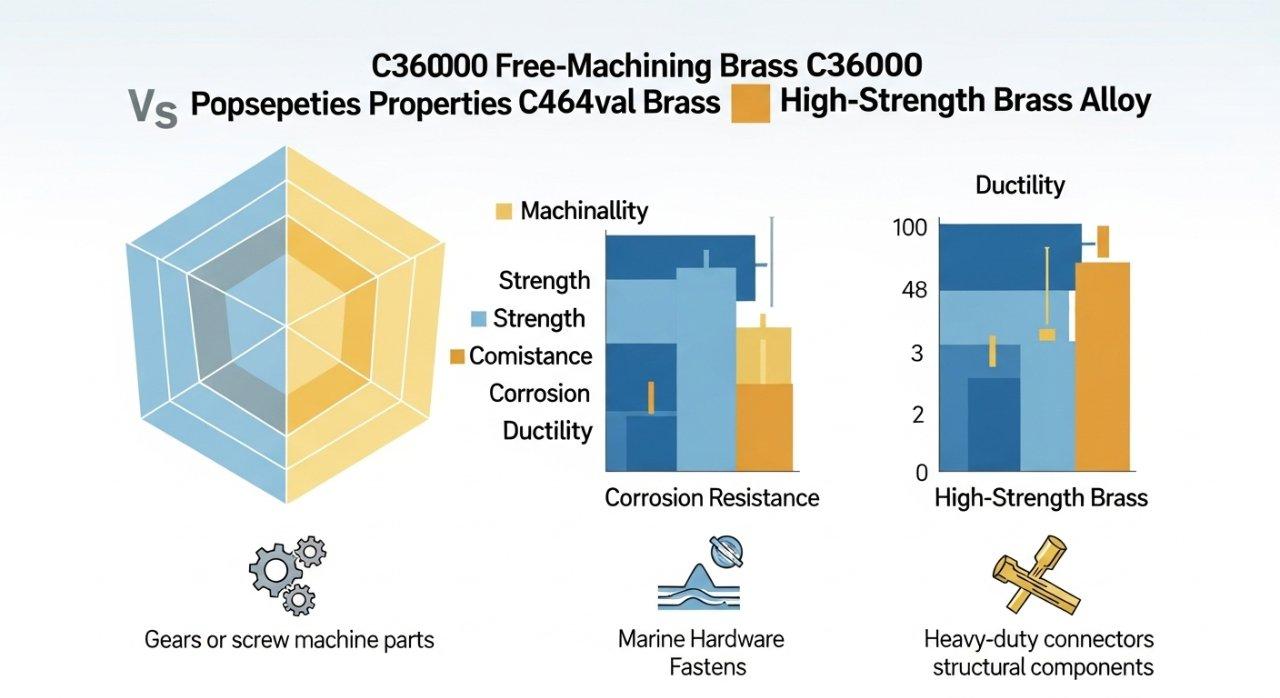

Key Brass Alloys & Properties

Different brass alloys offer distinct properties, making them suitable for specific applications. Understanding their composition and characteristics is vital for optimal material selection. We regularly work with a wide range of standard and specialized brass alloys.

Here is a summary of commonly used brass alloys for CNC machining:

| Alloy Designation | Key Characteristics | Typical Applications |

|---|---|---|

| C36000 | Excellent machinability, good strength, economical | Screws, fittings, gears, general purpose components |

| C26000 | High ductility, good formability, corrosion resistance | Deep-drawn parts, electrical connectors, ammunition |

| C46400 | High strength, good corrosion resistance (especially seawater) | Marine hardware, valve stems, propeller shafts |

| C48500 | Good machinability, moderate strength, general purpose | Architectural, fasteners, plumbing fittings |

Free-Machining Brass (C36000)

C36000, also known as Free-Machining Brass, is renowned for its exceptional machinability, often considered the industry standard. Its lead content (around 2.5-3.7%) acts as a chip breaker, enabling high cutting speeds and excellent surface finishes.

This alloy is ideal for components requiring intricate details and tight tolerances where production efficiency is crucial. It’s a workhorse in our facility for high-volume precision parts due to its predictable behavior under machining.

Naval Brass (C46400)

Naval Brass (C46400) is a high-strength, corrosion-resistant alloy, particularly valued for marine and corrosive environments. Its composition, including tin, provides enhanced resistance to dezincification and saltwater corrosion.

We recommend C46400 for applications like marine hardware, valve stems, and fasteners exposed to harsh conditions. Its machinability is good, though slightly less than C36000, requiring more robust tooling and optimized parameters.

High-Strength Brass

Beyond the common alloys, various high-strength brass formulations exist, designed for applications demanding superior mechanical properties. These often contain additional alloying elements like manganese, aluminum, or silicon.

These alloys offer increased tensile strength and hardness but may present greater machining challenges. Our engineers have expertise in developing specific machining strategies for these tougher brass grades.

Matching Alloy to Application

Selecting the right brass alloy is a delicate balance of material cost, mechanical requirements, environmental exposure, and machinability. A misstep here can lead to premature component failure or excessive manufacturing costs.

We work closely with our clients to understand the entire application lifecycle. This holistic approach ensures the chosen brass alloy delivers optimal performance and value.

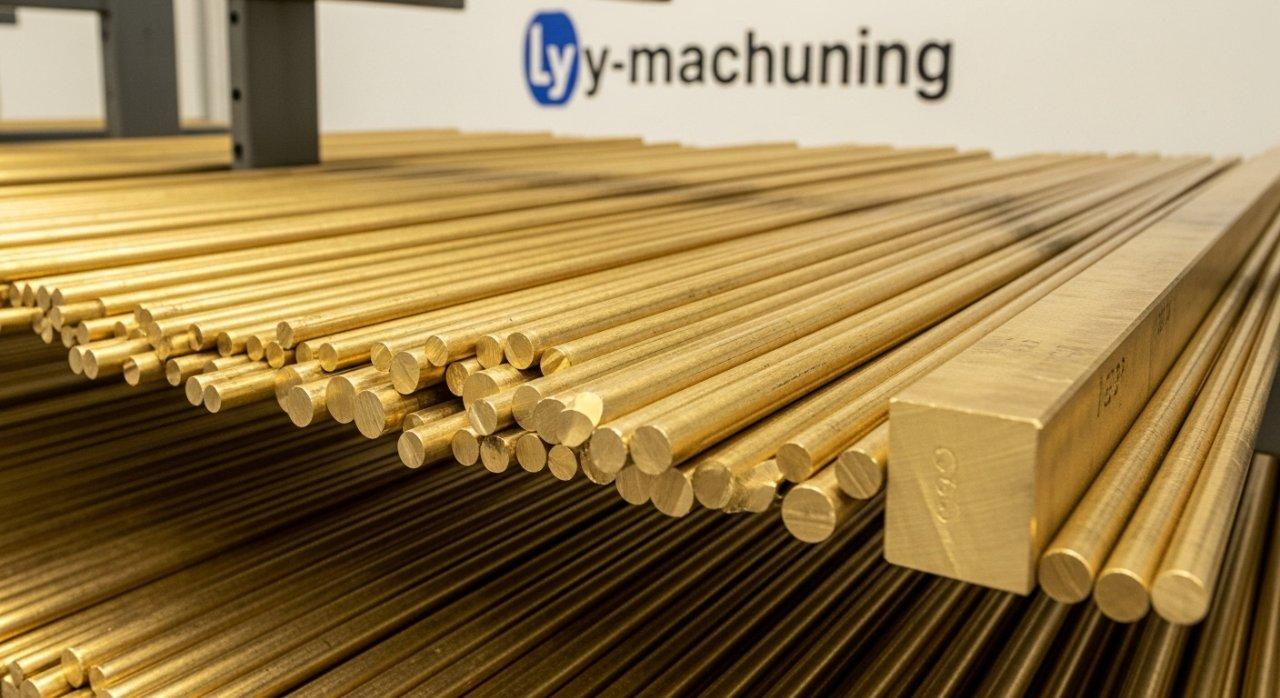

Impact of Brass Quality on Machining

The quality of the raw brass stock profoundly impacts the CNC machining process and the final product. Inconsistent material properties, inclusions, or variations in grain structure can lead to unpredictable machining behavior.

We source only premium-grade brass from trusted suppliers, adhering to stringent material specifications. This commitment to quality raw materials is a cornerstone of our high-end brass machining capabilities.

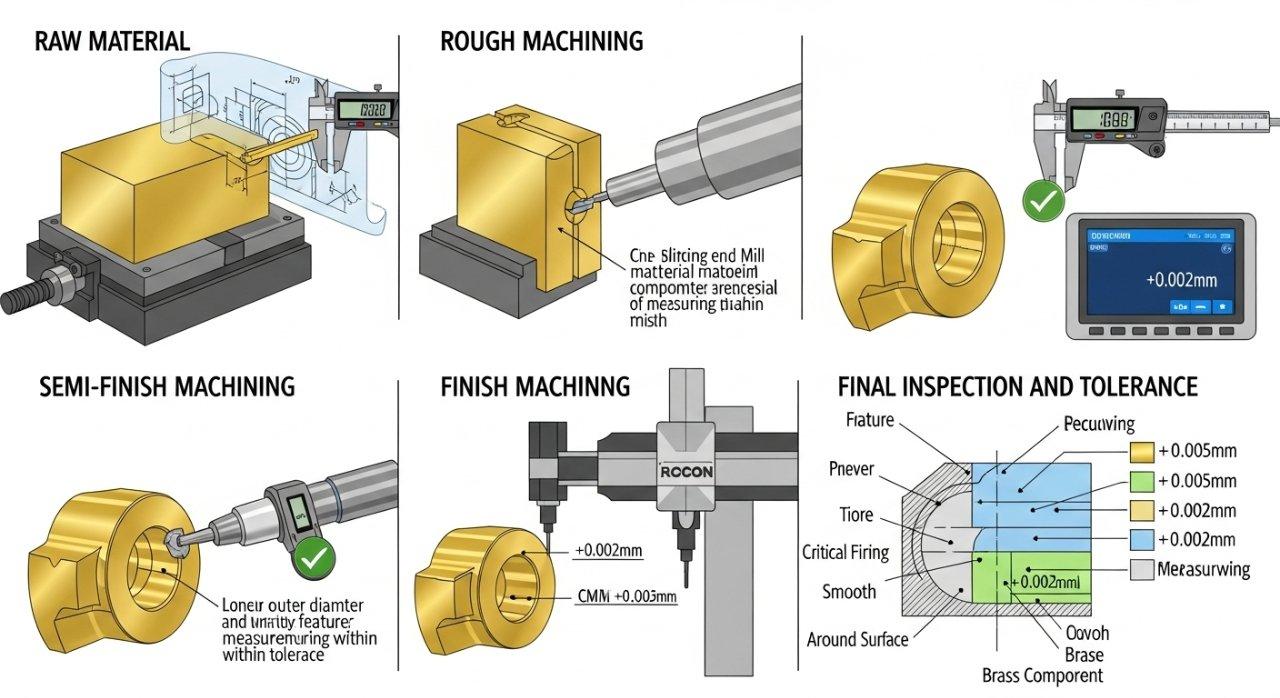

Advanced CNC Machining Processes for Brass

Our commitment to high-end brass CNC machining is reflected in our advanced processes, meticulously optimized for superior quality and efficiency. We leverage state-of-the-art machinery and proprietary techniques to overcome brass’s inherent challenges.

This involves a comprehensive approach from tooling selection to post-processing, all managed by our team of experienced engineers. Every step is designed to maximize precision and minimize defects.

Optimized Tooling & Parameters

The success of high-precision brass machining hinges significantly on optimized tooling and carefully calibrated parameters. We invest in the latest cutting tool technologies and continuously refine our machining strategies.

This meticulous attention to detail ensures consistent quality, extended tool life, and efficient material removal. It’s a key factor in distinguishing high-end brass CNC work.

Tool Geometry & Coatings

For brass, specialized tool geometries are essential to manage chip formation and achieve desired surface finishes. Tools with high rake angles and polished flutes are often preferred to prevent chip welding and facilitate smooth evacuation.

Coatings like TiN or TiAlN can extend tool life, especially for tougher brass alloys, by reducing friction and wear. We precisely select tools based on the specific brass alloy and the features being machined.

Feeds, Speeds, & Coolants

Optimal feeds and speeds are critical for brass CNC machining to prevent burr formation, maintain surface integrity, and control heat. Too slow, and surface finish can suffer; too fast, and burring or tool wear can accelerate.

We utilize advanced simulation software and extensive empirical data to determine the ideal cutting parameters for each job. Proper coolant application is also vital for chip evacuation and thermal management, preventing dimensional inaccuracies.

Precision Machining Techniques

Beyond standard operations, high-end brass CNC machining employs specific techniques to achieve the utmost precision and complexity. These methods push the boundaries of what’s possible with brass.

Our engineers are adept at implementing these advanced techniques, ensuring that even the most challenging designs are executed flawlessly.

Multi-Axis CNC Advantages

Multi-axis CNC machines (4-axis and 5-axis) offer significant advantages for complex brass components. They allow for machining multiple faces in a single setup, drastically reducing setup times and improving accuracy by minimizing repositioning errors.

This capability is particularly beneficial for parts with intricate features, undercuts, or angled holes. In our experience, multi-axis machining is indispensable for high-end brass parts.

Minimizing Burrs & Defects

Burr formation is a common challenge with brass due to its ductility. Our process incorporates several strategies to minimize burrs, including optimized tool paths, sharp tooling, and specific cutting parameters.

We also employ advanced deburring techniques as a standard part of our post-machining operations. This ensures clean edges and perfect surface quality without compromising dimensional accuracy.

Post-Processing & Finishing Brass

Post-processing plays a crucial role in achieving the final desired characteristics of high-end brass components. This can include additional deburring, cleaning, surface treatments, or specialized finishes.

We offer a range of finishing options, including polishing, plating, and passivation, tailored to the component’s aesthetic and functional requirements. Every step is carefully controlled to maintain the part’s integrity.

Our Expertise in Brass CNC Machining

At ‘ly-machining’, our decades of experience in high-precision CNC machining, particularly with brass, set us apart. We don’t just machine parts; we engineer solutions. Our factory operates under stringent quality control, adhering to industry best practices.

Our team of dedicated engineers provides unparalleled technical support, from design review to final inspection. We are your reliable partner for the most demanding brass projects.

Transparent Pricing & Value

We believe in providing transparent pricing without compromising on quality or service. Our quotes are detailed, reflecting the true cost of high-end brass CNC machining, including material sourcing, precise manufacturing, and rigorous quality checks.

We aim to deliver exceptional value, ensuring that your investment in our services translates directly into superior, long-lasting components. We focus on long-term partnerships built on trust and consistent performance.

Source Manufacturer Advantage

As a direct source manufacturer, ‘ly-machining’ offers distinct advantages. We maintain complete control over the entire production process, from raw material inspection to final packaging. This vertical integration guarantees consistency and accountability.

Working directly with us eliminates intermediaries, leading to better communication, shorter lead times, and competitive pricing. You gain direct access to our engineering expertise and production capabilities.

Quality Assurance & Inspection

Quality is not just a department; it’s ingrained in every aspect of our high-end brass CNC machining process. We implement robust quality assurance protocols at every stage, from initial material verification to final dimensional inspection.

Our inspection capabilities include CMM (Coordinate Measuring Machine) and optical inspection systems, ensuring that every component meets the exact specifications. We are committed to achieving zero defects.

—

**Case Study: Optimizing a Critical Fluidic Connector**

**Problem:** A client in the medical device industry required a series of miniature brass fluidic connectors for a new diagnostic instrument. The connectors demanded extremely tight internal bore concentricity (within 0.005mm) and a flawless, burr-free internal surface finish to prevent fluid stagnation and ensure aseptic operation. Initial attempts with other manufacturers resulted in inconsistent concentricity and persistent micro-burrs, leading to high rejection rates.

**Our Solution:** Our engineering team conducted a comprehensive DFM review, recommending a specific free-machining brass alloy (C36000) for its machinability, combined with a multi-axis CNC machining strategy. We developed custom tooling with optimized rake angles and polished flutes, tailored specifically for the internal bore features. Precise control of cutting parameters (feeds, speeds, and high-pressure coolant delivery) was implemented to ensure clean chip evacuation and prevent burr formation at the micro-level. Post-machining, a specialized micro-deburring process was integrated, followed by meticulous optical inspection to verify concentricity and surface finish.

**Result:** ‘ly-machining’ successfully produced the brass fluidic connectors, consistently achieving the required 0.005mm concentricity and a perfectly smooth, burr-free internal surface. The client experienced a significant reduction in rejection rates, improved instrument reliability, and faster assembly times due to the consistent quality of the components. This partnership enabled the client to accelerate their product launch with confidence.

—

Partner with Us for Brass Precision

Choosing the right partner for your high-end brass CNC machining needs is a decision that impacts your project’s success. At ‘ly-machining’, we combine unparalleled technical expertise with a commitment to quality and customer satisfaction.

We are ready to tackle your most complex brass component challenges, delivering solutions that meet the highest standards of precision and reliability. Your success is our priority.

Request a Custom Brass Quote

Ready to experience the ‘ly-machining’ difference? Contact us today to request a custom quote for your high-end brass CNC machining project. Provide your specifications, and our team will prepare a detailed and transparent proposal.

We are dedicated to providing competitive pricing without compromising the superior quality you expect. Let’s start building your precision brass components.

Consult Our Technical Experts

Do you have complex design requirements or challenging material questions for your brass components? Our team of seasoned engineers is available for a comprehensive technical consultation.

We offer expert guidance on material selection, design optimization for manufacturability, and process refinement. Leverage our deep knowledge to ensure the optimal outcome for your project.

—

Frequently Asked Questions

What brass alloys do you machine?

We machine a wide range of brass alloys, including C36000 Free-Machining Brass, C26000 Cartridge Brass, C46400 Naval Brass, and various high-strength brass formulations. Our selection depends on the specific application requirements.

We work closely with clients to recommend the most suitable alloy based on machinability, strength, corrosion resistance, and cost. This ensures optimal performance for your components.

How do you ensure tight tolerances?

Achieving tight tolerances in high-end brass machining involves a multi-faceted approach. We utilize advanced multi-axis CNC machines, precise tooling, and meticulously optimized cutting parameters.

Environmental controls, specialized fixturing, and in-process and post-process CMM inspection further guarantee dimensional accuracy. Our robust quality control system ensures consistent precision.

Can you help with design optimization?

Yes, our experienced engineering team provides comprehensive Design for Manufacturability (DFM) services. We review your designs to identify potential machining challenges specific to brass.

We offer recommendations for material selection, feature optimization, and tolerance adjustments. This collaborative approach streamlines production and enhances part performance.