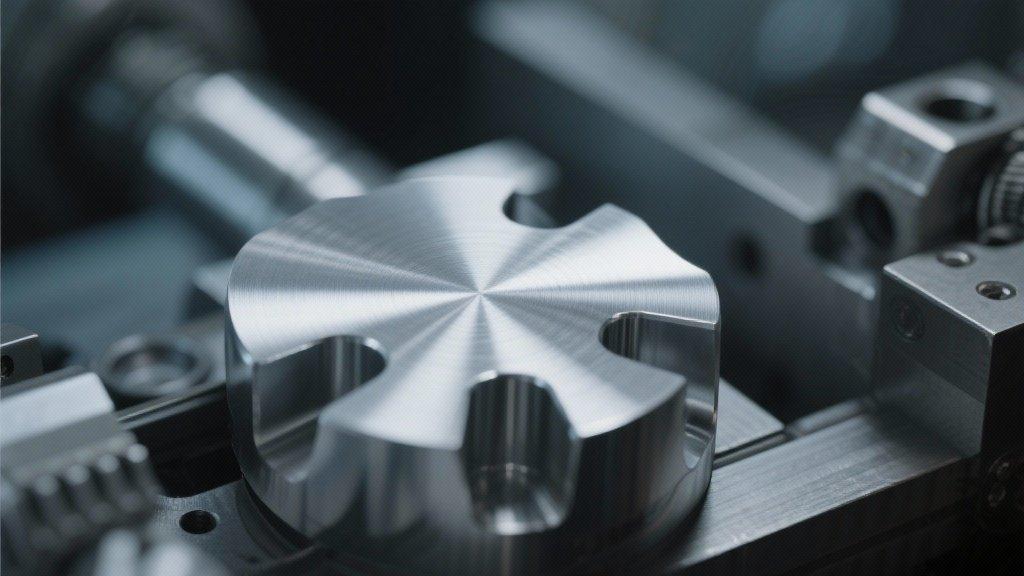

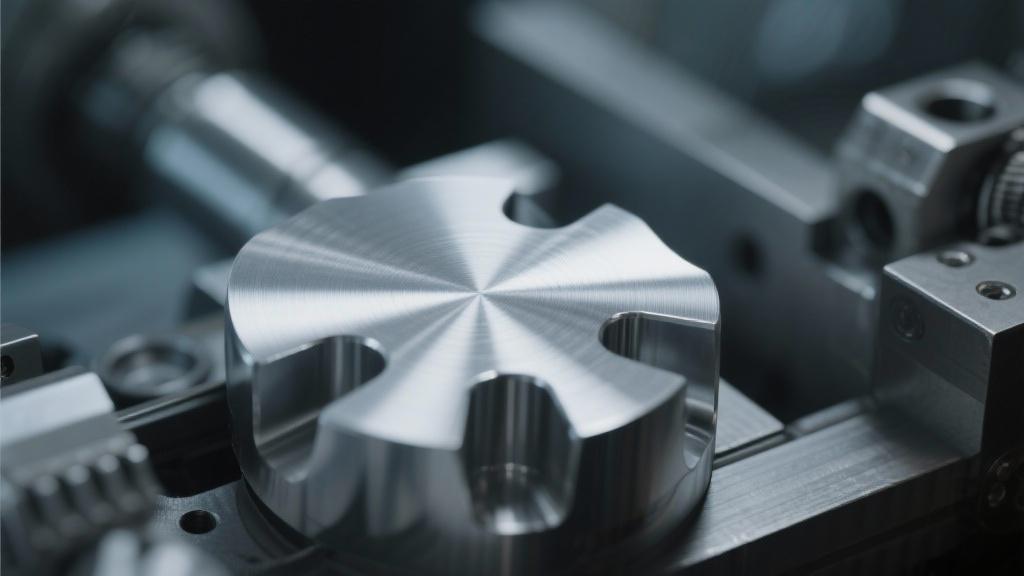

Answer: Improving the surface finish in aluminum machining is a challenge every machinist faces. You might have experienced situations where the final product just didn’t meet the desired quality. No worries—let’s dive into some effective ways to enhance that finish.

One of the most crucial aspects is choosing the right tooling. The material and geometry of the cutting tools can significantly impact surface quality. For example, using carbide tools can provide better wear resistance and sharper edges than high-speed steel (HSS) tools. Additionally, consider the coating on the tools. Coatings like TiN (Titanium Nitride) can reduce friction, allowing for smoother cuts.

Next up is the machining parameters—speed, feed rate, and depth of cut. You typically want to find the optimal balance here. If you’re cutting too fast, you might generate excessive heat, leading to a rough surface. Conversely, too slow could mean the tool is not cutting efficiently. It’s often a good idea to refer to the manufacturer’s guidelines and conduct some test runs to determine the best settings for your specific application.

Another key factor is the type of coolant used during machining. A good coolant not only lubricates the cutting area but also helps in dissipating heat, thus reducing thermal deformation. Water-soluble coolants are popular; they can effectively enhance surface finishes by ensuring precise cuts and minimizing tool wear.

You may also want to consider your machining strategy. Techniques like climb milling, where the cutting tool engages the workpiece at the top and exits at the bottom, can yield a better surface finish than conventional milling. Tools that helix or spiral down through the material can also create smoother surfaces due to more gradual entry and exit points.

Don’t overlook the importance of consistency in your processes. Maintaining a stable environment where temperature and humidity are controlled will ensure less variability in machining. It’s like keeping your workspace organized—it leads to better outcomes!

Then there’s the matter of post-processing. Even with all the best machining practices, you may still want to buff or polish the part for that ultimate sheen. Techniques like anodizing or bead blasting can elevate the surface finish significantly.

Lastly, continuous improvement is essential. Keep learning and adapting. Technologies in machining evolve quickly, and staying updated on new methods can lead to even better surface finishes. Many professionals find that CNC technology offers superior control and finish quality compared to manual machining.

What’s your experience with improving surface finishes? I’d love to hear your thoughts or any extra tips you might have! Be sure to test these strategies and see how they work for you!

What are the key factors that affect surface finish in aluminum machining?

Several key factors affect surface finish in aluminum machining, including tooling materials, machining parameters, and coolant types. Using the right combination can help achieve a smoother finish.

Additionally, factors such as tool geometry and the type of machining strategies employed can also play a significant role in the final output quality. It’s all about finding that perfect balance.

How can I select the right tooling for better surface finish?

Choosing the right tooling starts with understanding the material and the geometric design of your cutting tools. Carbide tools often provide better performance compared to high-speed steel due to their durability and sharper edges.

Moreover, considering coatings on the tools, like TiN, can enhance performance by reducing friction and heat. So, make sure to explore different options that suit your specific machining needs.

What machining parameters should I optimize for a smoother finish?

Machining parameters such as speed, feed rate, and depth of cut are crucial for achieving a good surface finish. You’ll want to run some tests to find the sweet spot—too fast might generate heat and rough surfaces, while too slow can lead to inefficient cuts.

Checking manufacturer guidelines and adjusting these parameters accordingly can make a huge difference in the quality of your finished product.

How does coolant type impact surface finish?

The type of coolant you use can significantly affect the surface finish during the machining process. A good coolant not only lubricates but also helps to reduce heat, which is vital for maintaining surface integrity.

Water-soluble coolants are often recommended because they can improve cutting efficiency and overall surface quality. Experimenting with different coolants could lead you to find the best fit for your work.

Are there post-processing techniques to enhance surface finish further?

Yes, after machining, various post-processing techniques like polishing or anodizing can greatly enhance your surface finish. These methods help to achieve that shiny, professional look many machinists aim for.

For instance, anodizing can also increase corrosion resistance, making it both a functional and aesthetic improvement. It’s worth considering these options after the primary machining is complete.