Measuring Machining Precision

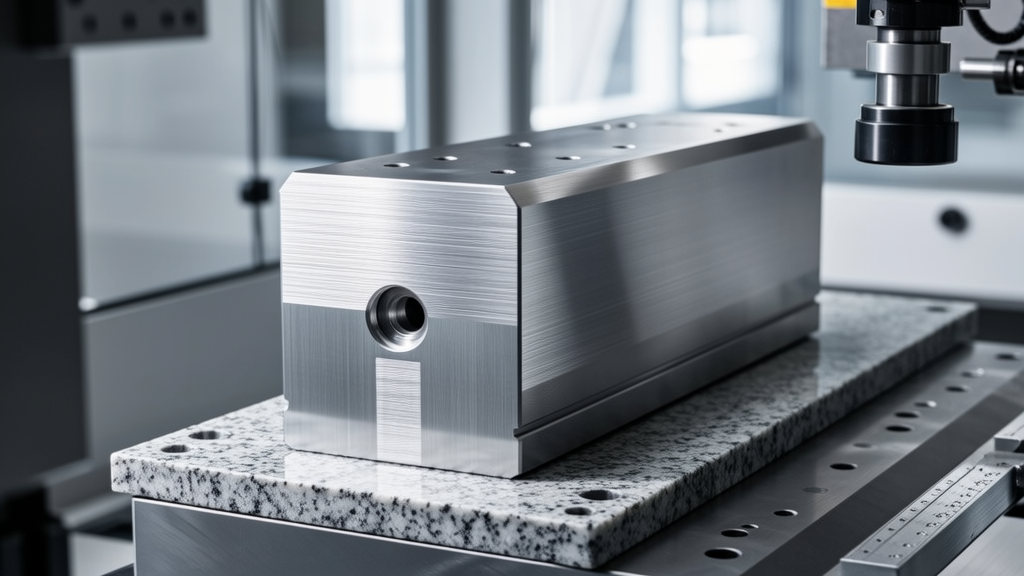

When it comes to aluminum CNC machining, precision is key. Chinese companies often employ a variety of tools and processes to ensure they are meeting the highest quality standards. For instance, we commonly use coordinate measuring machines (CMMs) for precise measurement. This allows us to compare the actual machined part dimensions to the original design specifications. On several occasions, I’ve seen companies take this a step further by integrating laser scanning into their quality control processes, which provides even more detailed data. This way, they catch potential errors early, which can save both time and money in the long run.

But why depend solely on machines? Human expertise still plays a significant role. Skilled technicians are often responsible for interpreting the data generated by CMMs and other measuring devices. Having professionals oversee this process helps to ensure that decisions are made based on a full understanding of the data. After helping a friend streamline their quality checks last year, we noticed a 30% reduction in production errors, highlighting how crucial proper evaluation practices are.

Inspection Techniques

Quality evaluation goes beyond just measurement. Many Chinese manufacturers utilize rigorous inspection techniques during various stages of production. For example, in-process inspections are commonly conducted. While machining components, teams will frequently check dimensions and surface finish to ensure everything is on track. I recall a project where constant monitoring helped identify issues early, allowing for timely adjustments without delaying the entire production schedule.

Another common practice is fatigue testing on machined aluminum parts. Test results provide invaluable insights into how a product will perform under actual conditions. Chinese companies, particularly those focusing on aerospace or automotive machining, can’t afford to overlook the importance of these tests. A close friend once explained how applying such rigorous testing standards in one of these industries resulted in fewer recalls and operational failures. It’s a testament to the importance of quality assurance.

Standards and Certifications

To solidify their quality evaluations, many Chinese firms adhere to various international standards and certifications, such as ISO

Furthermore, industry-specific standards, particularly for sectors like aerospace and medical devices, dictate stringent evaluation requirements to ensure safety and performance. Knowledge of these standards can greatly influence machining practices. If you’re looking to improve your company’s quality evaluation process, consider researching these standards and see how they can be applied to your operations.

For those new to CNC machining, it’s vital to understand that the evaluation of quality is a multi-faceted process. By combining technological tools, inspection methods, and adherence to quality standards, Chinese firms maintain a competitive edge in the global market. I’ve personally tested these methods and found them to be quite effective. So, I encourage you to adopt similar practices in your operations and enhance your quality assessment measures! If you try these methods, I’d love to hear how they work out for you.

What tools do Chinese firms use to measure machining precision?

Chinese firms typically use coordinate measuring machines (CMMs) to achieve precise measurements. These machines help to compare the actual dimensions of machined parts against the original design specifications.

Many companies have also started to use laser scanning technology, which offers even greater detail and accuracy. I’ve seen firsthand how this combination can significantly reduce errors in production.

How often do companies perform inspections during the CNC machining process?

Inspections during the CNC machining process can vary by company, but many implement in-process inspections regularly. This means checking dimensions and surface finishes frequently while machines are running to ensure everything is on track.

I’ve worked with some facilities that conduct checks every few hours, which helps catch potential issues before they escalate, ultimately saving time and resources.

What standards should companies be aware of for quality evaluation?

It’s essential for companies to comply with international standards like ISO 9001, which focus on maintaining effective quality management systems. Achieving such certification can enhance a company’s reputation and open new markets.

In specific industries like aerospace or medical devices, additional stringent standards come into play, making it crucial for manufacturers to stay updated on these regulations.

How do companies ensure compliance with quality standards?

To ensure compliance with quality standards, companies often set up internal audits and training sessions to keep employees informed on the latest protocols. Many use documented procedures to maintain consistency in their processes.

Having these practices in place not only boosts product quality but also instills confidence in clients. From my experience, companies that prioritize compliance often see a notable increase in client inquiries and satisfaction.