When I chat with colleagues in the manufacturing sector, one consistent theme surfaces: the rapid evolution in design aesthetics and functional capabilities, largely thanks to Shenzhen’s CNC machining prowess. This city has become synonymous with high-quality, cost-effective CNC services that empower designers to push the boundaries of what’s possible. So, what’s driving this trend, and how can it affect your product designs?

Understanding the Impact of CNC Machining

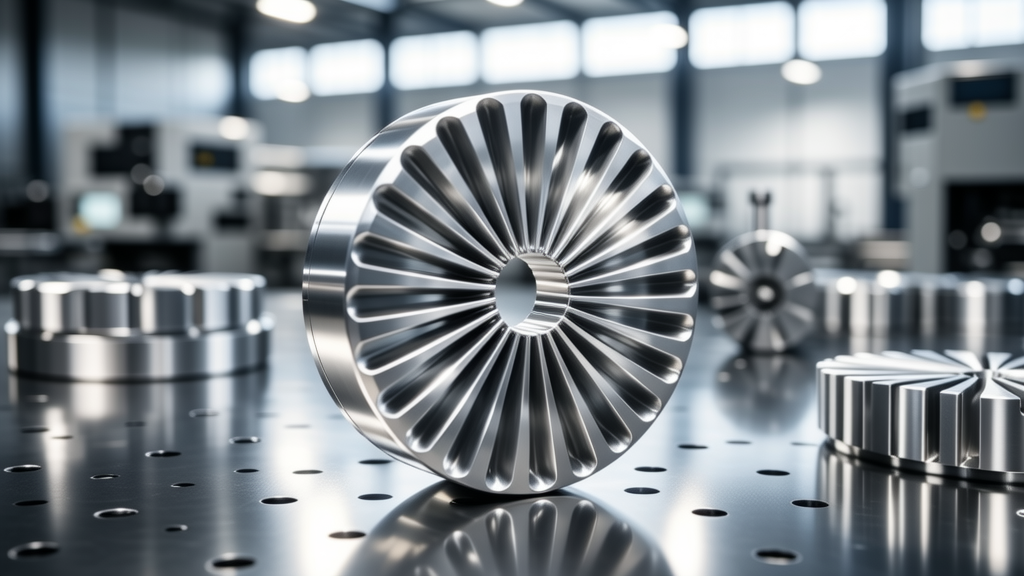

CNC machining in Shenzhen has changed the game for product designers across various industries. The precision and speed of modern CNC machines allow for intricate designs that were once only possible through traditional methods, or expensive prototyping. But what does this mean in practical terms?

Enhanced Design Freedom

First and foremost, CNC machining provides a level of design freedom that is revolutionary. As designers, we often feel limited by the capabilities of manufacturing. However, with CNC technology, I can create complex geometries without fearing that they won’t be producible. For instance, I worked on a project with a startup that needed an innovative housing for their electronics. They had a novel design in mind, and we were able to use CNC machining to realize this vision flawlessly, within deadlines we originally thought were tight.

Shorter Production Times

When time is of the essence, the speed of CNC machining plays a huge role. Compared to traditional manufacturing methods, CNC machines can often operate around the clock and produce parts faster than manual processes. One of our clients, for instance, was able to launch their product two weeks early because we utilized CNC machining for their housings rather than conventional techniques. The faster turnaround time allows you, as a designer, to iterate quickly – you can test, modify, and improve your designs in rapid cycles that traditional methods simply can’t match.

The Specific Benefits of Shenzhen’s CNC Machining

Now, let’s talk about the specific advantages that Shenzhen’s CNC machining can offer.

Cost Efficiency

Shenzhen has gained a reputation for being a cost-effective manufacturing hub. The lower labor costs, combined with advanced technologies, can offer significant savings. I once assisted a friend whose startup was struggling with production costs. After moving their machining operations to Shenzhen, they saw their costs drop by about 30%. This is crucial for startups and small businesses that need to maintain tight budgets while still producing high-quality products.

Access to Advanced Technologies

In Shenzhen, many manufacturing firms invest heavily in the latest CNC technologies. This means access to the newest materials and machining techniques, allowing designers like you to work with better tools. A client needed highly durable components for their new gadgets; leveraging Shenzhen’s advanced CNC services, we accessed materials that enhanced the end product significantly. By keeping abreast of the latest advances, you can elevate your designs and stand out in a crowded marketplace.

Prototyping Made Easier

One of the game-changers is the effectiveness of rapid prototyping. With CNC machining, you can go from design to prototype in a matter of days, not weeks or months. This quick turnaround is essential for any product development cycle. When I worked with an automotive design firm, we could create and test prototypes almost immediately, leading to faster feedback loops. This direct involvement leads to significantly improved final products and customer satisfaction.

Global Networking Opportunities

Being in Shenzhen opens doors to a global network of suppliers, manufacturers, and designers. This city is a melting pot of creatives and engineers who can collaborate on projects. For example, I attended a design trade show in Shenzhen and connected with several manufacturers and designers from different sectors. This kind of networking can lead to new ideas, techniques, and collaborations that you wouldn’t typically find elsewhere.

Conclusion on Product Design Trends and Shenzhen CNC Machining

Shenzhen’s CNC machining serves as a catalyst for modern product design, offering enhanced creativity, reduced production times, and cost-effective solutions. By leveraging these innovative techniques, designer can explore their imaginations, create prototypes swiftly, and ultimately deliver products that meet the demands of today’s consumers. If you haven’t considered tapping into Shenzhen’s machining capabilities yet, it may be time to rethink your approach to product design.

If you’re thinking about partnering with a CNC machining service, feel free to reach out and share your thoughts or experiences. It’s always great to share and learn from each other in this ever-evolving field!

How does CNC machining in Shenzhen enhance design freedom?

CNC machining in Shenzhen allows designers to explore more intricate and complex designs without worrying about manufacturing limitations. With advanced technology, you can create detailed geometries that were previously thought impossible.

This level of design freedom not only encourages creativity but also enables more innovative products that can stand out in the market. I once helped a startup realize a unique housing design, and it turned out beautifully thanks to these capabilities.

What are the production advantages of using Shenzhen CNC machining?

The production advantages of Shenzhen’s CNC machining are quite significant. Most notably, these machines operate efficiently, leading to faster turnaround times for projects. Unlike traditional manufacturing, where timelines can stretch for weeks, CNC machining can often get parts produced in just a few days.

This quick production means that you can iterate designs rapidly, allowing for timely feedback and improvements. If you have a strict deadline to meet, Shenzhen’s CNC solutions can be a lifesaver.

Why is cost efficiency a consideration in Shenzhen’s CNC machining?

Cost efficiency is a huge factor when considering Shenzhen’s CNC machining services. The city’s competitive pricing, combined with modern technology, means that you can access high-quality manufacturing at a lower cost compared to many places globally.

Many startups have realized savings of up to 30% by shifting their production to Shenzhen. This is crucial for those adhering to tight budgets while aiming to produce high-quality products.

How does rapid prototyping work with Shenzhen CNC machining?

Rapid prototyping is one of the standout features of Shenzhen’s CNC machining capabilities. It allows designers to transform ideas into physical prototypes in just a matter of days, rather than the weeks or months that traditional methods require.

This speed enables an agile design process where you can test concepts quickly. I’ve worked with companies that were able to finalize prototypes two weeks ahead of schedule due to this invaluable resource.

What networking opportunities exist in Shenzhen for product designers?

Shenzhen is a vibrant hub filled with networking opportunities for product designers. By being in this environment, you can connect with other manufacturers, suppliers, and designers who are also pushing the envelope in product innovation.

Attending trade shows and local meetups can lead to collaborations and fresh ideas. These interactions can be instrumental in developing your projects and tapping into a global market.