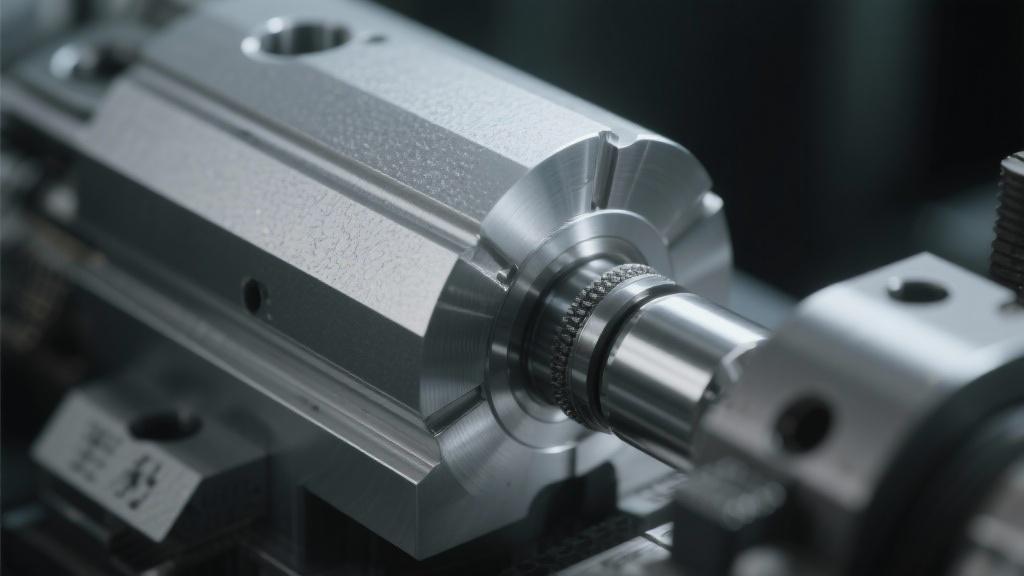

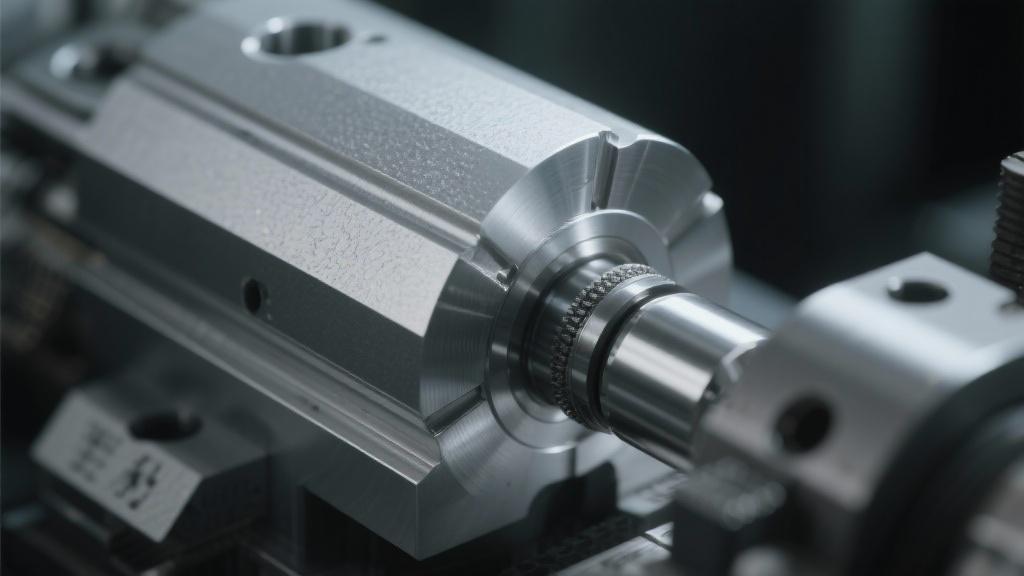

Surface roughness, often a result of machining processes, plays a significant role in determining how aluminum components will behave under stress. Rougher surfaces may lead to stress concentrations and reduced fatigue resistance, while smoother finishes often enhance load-bearing capabilities. Throughout this discussion, we will explore various studies and findings that demonstrate the impact of different surface textures on mechanical properties such as tensile strength, yield strength, and hardness.

We will also look into practical applications and implications for design, fabrication, and quality control, providing insight into best practices for achieving optimal surface finishes that contribute to mechanical strength. Whether you’re an engineer, designer, or manufacturer, understanding these dynamics will empower you to make informed decisions that ultimately enhance the reliability and performance of your CNC machined aluminum parts. Join us as we uncover the critical connections between surface roughness and mechanical strength in this essential exploration of material science and engineering.

对于CNC加工铝件,表面粗糙度对其机械强度的影响是一个不可忽视的重要因素。许多用户在设计和制造过程中可能没有意识到表面处理的细微差别会导致最终产品性能的显著变化。方形或圆形切割、磨削和铣削等加工方法常常会造成不同程度的表面粗糙度,这不仅影响了铝件的外观,也影响了其承载能力和耐用性。

当你考虑表面粗糙度时,了解它如何影响材料的性能是至关重要的。一般来说,较大的表面粗糙度会产生更多的应力集中,这可能导致疲劳失效或断裂。 适当的表面处理能够显著提高机械强度。不同的粗糙度等级与具体的机械性能相联系, 平滑表面通常表现出更好的拉伸强度和疲劳性能。

在这篇文章中,我们将探讨不同表面粗糙度对CNC加工铝件的影响,并提供一些最佳实践,以帮助你在产品设计和制造过程中做出更明智的选择。 我们将分析各种表面处理方法及其对粗糙度的影响,接下来将讨论表面特性如何在不同应用中影响材料的行为。了解这些知识不仅能帮助你优化铝件的性能,还能在生产成本和材料使用上实现更大的效率。

节目设计、质量控制与工艺改进是影响最终产品性能的重要环节。保持表面处理均匀和符合标准,可以降低后期加工的风险,同时确保产品在使用中的可靠性与安全性。我们将提供关于如何优化表面粗糙度以提高铝件机械强度的详细 让你的制造流程更加高效和经济。

在本文中,我们将以图表的方式 不同表面粗糙度等级与机械强度之间的关系,并引用行业内的几项研究成果,以提高你对这一议题的理解与应用能力。通过全面掌握这方面的知识,你将能够在自己的项目中体现出更高的专业性和竞争力。

What is surface roughness in CNC machined aluminum?

Surface roughness refers to the small, finely spaced irregularities on the surface of a machined aluminum part. These characteristics can significantly influence how the material performs under load.

Essentially, the rougher the surface, the more uneven it may be, which can create points of weakness in the material during stress conditions.

How does a rough surface affect mechanical strength?

A rough surface can lead to stress concentrations which often result in lower fatigue resistance. This means that over time and with repeated loads, the rougher surfaces are more likely to develop cracks and fail.

Conversely, smoother surfaces generally distribute stress more evenly, enhancing the overall mechanical strength and durability of aluminum components.

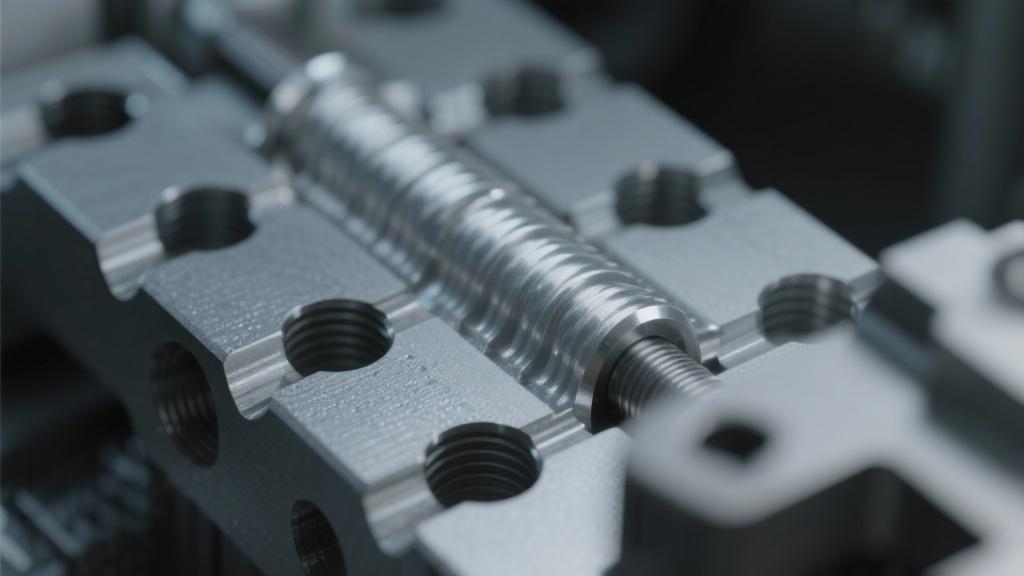

What are the typical surface roughness measurements for CNC machined aluminum?

Surface roughness is typically measured using the Ra value, which indicates the average roughness in micrometers. For CNC machined aluminum, Ra values can range from 0.1 to 3.2 micrometers depending on the machining process and desired finish.

Achieving the ideal surface finish often involves a balance between acceptable roughness and the mechanical properties required for the application.

How can surface finish be improved to enhance strength?

Improving surface finish can involve various techniques such as polishing, grinding, or using specialized coatings. Each method can help to achieve a smoother final surface, which is crucial for enhancing mechanical strength.

For example, by applying an anodized coating, the surface can become not only smoother but also more resistant to corrosion and wear, contributing to overall durability.

Are there any specific industries that benefit from smoother aluminum surfaces?

Yes, several industries, including aerospace, automotive, and medical, benefit greatly from smoother aluminum surfaces. These sectors often require components that can withstand significant mechanical stress and fatigue over time.

In these industries, achieving optimal surface roughness is critical for both safety and performance, as even minor surface imperfections can have major repercussions.