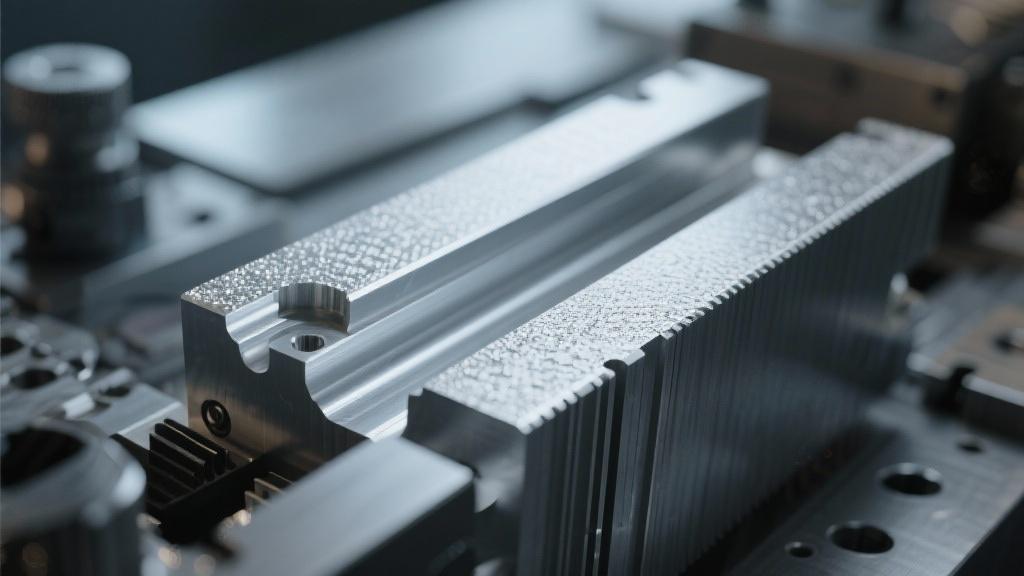

We explore how different machining parameters and techniques can impact surface texture, leading to varying roughness levels that potentially affect the end product’s reliability. By understanding the implications of surface roughness, manufacturers can make informed choices that enhance durability and efficiency while minimizing unexpected failures.

Moreover, this article highlights real-world examples and industry standards that underscore the importance of achieving optimal surface finishes. Whether you are designing components for aerospace, automotive, or consumer products, grasping how surface roughness affects performance can give you a competitive edge. Join us as we unravel the science behind surface roughness and its implications for CNC machined aluminum parts, empowering you to produce superior products that meet rigorous performance requirements.

When exploring the impact of surface roughness on CNC machined aluminum parts, it’s essential to understand that even subtle variations can lead to significant differences in performance. The surface finish influences not just esthetics but also critical factors like friction, wear, and fatigue resistance, which are vital for the durability and reliability of parts in various applications.

One common question you might have is: Why does surface roughness matter? The roughness of a surface affects how it interacts with other components. A smoother surface generally reduces friction, which is crucial for components that require high performance and low wear, such as gears or bearings. Conversely, a rougher surface can sometimes enhance grip or bonding in certain applications. Understanding these nuances can help you make informed decisions about the machining process.

Key Points to Consider

The following table summarizes the effects of different surface roughness levels on aluminum parts’ performance characteristics:

| Surface Roughness (Ra) | Friction Coefficient | Wear Resistance | Fatigue Strength | Applications |

|---|---|---|---|---|

| <0.2 μm | Low | High | High | Aerospace, Automotive |

| 0.2 | Medium | Medium | Medium | General Components |

| >1.6 μm | High | Low | Lower | DIY Projects |

As you can see from the table, smoother finishes generally lead to better performance in wear resistance and fatigue strength, particularly in high-performance applications. This is crucial for industries like aerospace and automotive, where component failure is not an option.

How to Achieve Desired Surface Roughness

To achieve the desired surface roughness, you can manipulate several factors during the CNC machining process:

Understanding how surface roughness affects performance is crucial for making informed decisions about your machining needs. By optimizing the machining parameters and comprehensively evaluating the application requirements, you can enhance the performance of the components produced, leading to better overall outcomes in your projects. Trust parts manufactured by ly-machining to meet your high standards for surface quality and performance, ensuring your components excel in their intended applications.

What is surface roughness and why is it important?

Surface roughness refers to the texture of a machined surface, typically measured in micrometers (μm). A smoother surface generally improves performance by reducing friction and wear.

It’s crucial in applications like aerospace and automotive where component reliability is paramount. Proper surface roughness can lead to enhanced durability and efficiency.

How does surface roughness affect wear resistance?

The relationship between surface roughness and wear resistance is significant. Generally, lower roughness levels, such as below 0.2 μm, result in better wear resistance, especially in high-duty applications.

Conversely, higher roughness levels above 1.6 μm can lead to increased wear and potential failure, making it essential to optimize surface finishes accordingly.

What factors can influence surface roughness in CNC machining?

Several factors affect surface roughness, including cutting tool selection, feed rate, and machining speed. For instance, a slower feed rate typically results in a finer finish.

Additionally, the use of appropriate coolants and machining techniques can further enhance the surface quality, allowing for specific roughness levels tailored to your requirements.

How can I achieve the desired surface roughness for my project?

To achieve the desired surface roughness, you can adjust several machining parameters and consider post-processing techniques. It’s essential to control the cutting speed and feed rate effectively during the machining process.

Moreover, post-processing methods like polishing or anodizing can help achieve a smoother finish after initial machining, enhancing aesthetics and functionality.

What are some standard surface roughness measurements for CNC machined aluminum?

Standard surface roughness measurements typically range from below 0.2 μm for high-precision applications up to 1.6 μm for general components. Understanding these ranges helps you determine the suitable finish for your specific application.

In high-stress environments, targeting the lower end of this range can lead to improved performance and reliability.