We’ll cover key aspects such as tool selection, machining parameters, and the importance of tool geometry. You’ll learn how different materials respond to various machining techniques and how adjusting feed rates and spindle speeds can yield smoother surfaces. Additionally, we’ll explore the role of cutting fluids and lubricants in reducing friction and heat, ultimately leading to a better finish.

Practical tips and real-world examples will be shared to provide you with actionable insights you can apply right away. By the end of this article, you’ll be equipped with the knowledge to optimize your CNC machining processes and produce workpieces with superior surface finishes that meet or exceed industry standards. Whether you’re focused on improving existing workflows or tackling new projects, this guide is designed to help you elevate your machining skills and achieve exceptional results.

What characteristics should I look for in a CNC machining service?

When people consider CNC machining services, they often have specific qualities or capabilities in mind that can make a significant difference in the outcome of their projects. So, if you’re looking to choose a CNC machining supplier, you might be wondering: What attributes should I focus on to ensure I’m making the right choice? Here are some of the key factors you might want to consider, along with some insights based on experience and knowledge in the field.

- Precision and Accuracy

One of the most important aspects of CNC machining is, of course, precision. You want to work with a service provider that guarantees highly accurate machining processes. From my own experience, if a CNC shop touts its ability to maintain tolerances of ±0.001 inches or better, they’re likely using advanced equipment and techniques. This is crucial, especially if you’re manufacturing parts that will be integrated into critical machinery or assemblies.

What to Ask:

- What are your standard tolerances, and can you provide examples of past projects?

- Material Variety and Capability

Another significant point to think about is the materials the CNC machining service can handle. Various industries use different materials, and having a supplier that can work with a wide range of metals, plastics, and composites can be a game-changer. For example, I helped a client who initially went for aluminum but later needed stainless steel parts. The transition was seamless because their supplier was versatile.

What to Look For:

- A list of compatible materials and an overview of some successful projects using those materials.

- Technology and Equipment

Keeping up with the latest technology can significantly affect both the quality and efficiency of CNC machining processes. A reliable service provider should have state-of-the-art CNC machines, as well as additional technologies like automation and quality control measures.

Understanding Technology:

- Investing in updated equipment often reflects a company’s commitment to quality. Can they showcase recent upgrades or acquisitions?

- Customer Service and Support

Sometimes overlooked, customer service is essential, especially when timelines are tight or adjustments are necessary. Having a responsive team can save you from a lot of headaches. From my experience, I’ve found that suppliers who communicate regularly and are open to making changes usually lead to better project outcomes.

Points to Inquire:

- How do you handle urgent requests or potential problems in ongoing projects?

- Experience and Credibility

Lastly, you want to consider the company’s experience in the industry. Generally, the more experienced the service provider is, the better they will understand the nuances of machining various components. You’ll want a company that can provide references or case studies.

Establishing Credibility:

- Look for reviews or testimonials from past clients. Trustworthy companies often earn repeat business.

In the realm of CNC machining, choosing the right service provider can influence the success of your projects. By asking the right questions and focusing on crucial factors such as precision, material capability, technology, customer support, and experience, you can make an informed decision. Working with reliable suppliers like ly-machining can help ensure that your projects are completed successfully and to high standards. If you start following these tips, you might find a reliable partner that meets your machining needs perfectly!

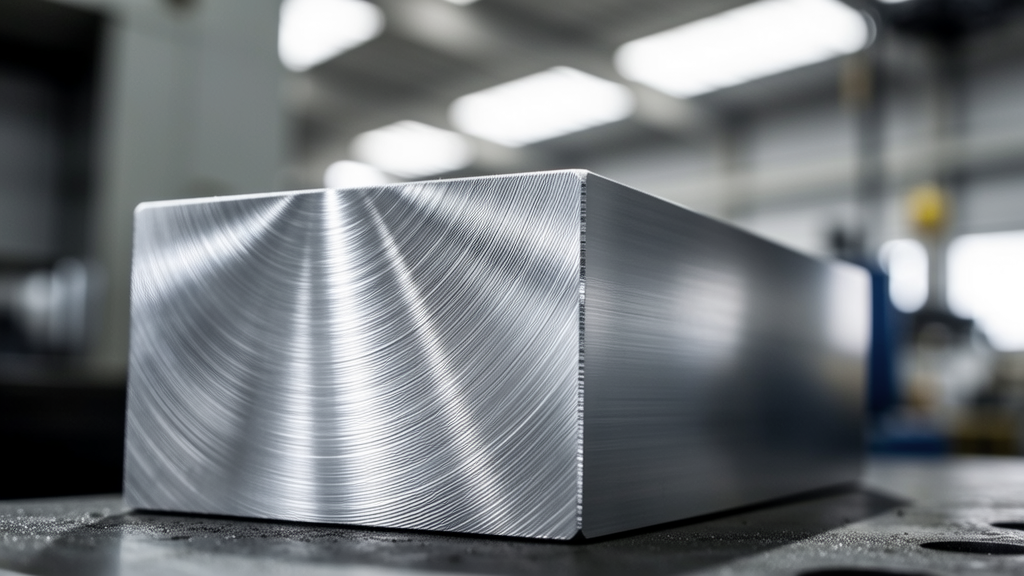

What are the most important factors to consider for surface finish quality in CNC machining?

When aiming for a high-quality surface finish, you should focus on several key factors including tool selection, machining parameters, and tool geometry. Each of these elements plays a crucial role in the final product’s finish.

Additionally, different materials may respond differently to various machining techniques, so it’s essential to understand how each one behaves. This can make a significant difference in achieving that smooth surface you’re looking for.

How can adjusting feed rates and spindle speeds impact surface finish?

Adjusting feed rates and spindle speeds is fundamental in CNC machining. Higher spindle speeds generally allow for better surface finishes, while lower feed rates can reduce tool marks on the surface.

Experimenting with these parameters can lead to smoother finishes, so it’s worthwhile to test different combinations to see what works best for your particular project.

What role do cutting fluids play in achieving a better surface finish?

Cutting fluids are essential as they help reduce friction and heat during the machining process, which can directly impact surface quality. By keeping the tool cool and lubricated, they reduce wear and tear, ultimately contributing to a smoother finish.

It’s important to choose the right cutting fluid for your material and machining conditions to maximize effectiveness.

How can I ensure the credibility of a CNC machining service provider?

To validate a CNC machining service provider’s credibility, check their experience in the industry and ask for references or case studies. A company that can demonstrate successful past projects is often more reliable.

Additionally, reading customer reviews or testimonials can give you insights into their reputation and quality of service.

What specifications or tolerances should I expect from a good CNC machining service?

A reputable CNC machining service should be able to maintain tolerances of ±0.001 inches or better. This level of precision is crucial for many applications, so it’s important to clarify this during your initial conversations.

Asking for detailed examples of their past work can also help you gauge whether they meet these specifications consistently.