Understanding the influence of material properties, machining operations, and environmental conditions is key to optimizing surface quality. By implementing best practices during the machining process, manufacturers can minimize defects such as rough surfaces, burrs, and tool marks, leading to better product performance and customer satisfaction.

Moreover, we will highlight the importance of consistent inspection and quality control measures, ensuring that every component meets the required specifications. By focusing on continuous improvement and leveraging technology, businesses can achieve not only improved surface finishes but also increased production efficiency.

Whether you are a seasoned manufacturer or new to CNC machining, this article provides valuable insights and actionable tips to help you master the art of achieving flawless surface finishes. Join us as we unlock the secrets to enhancing the quality of CNC machined aluminum parts, setting your products apart in a crowded marketplace.

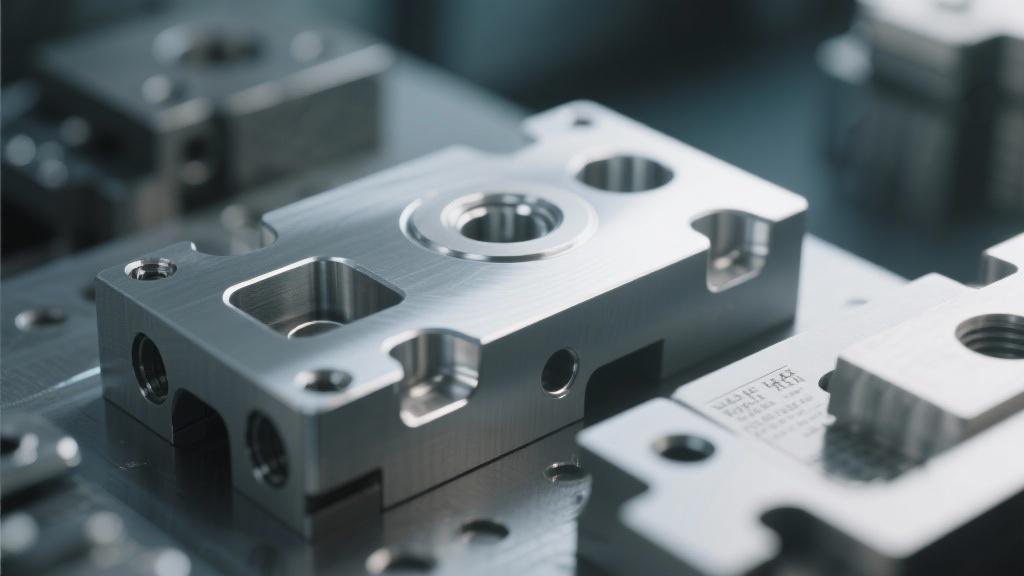

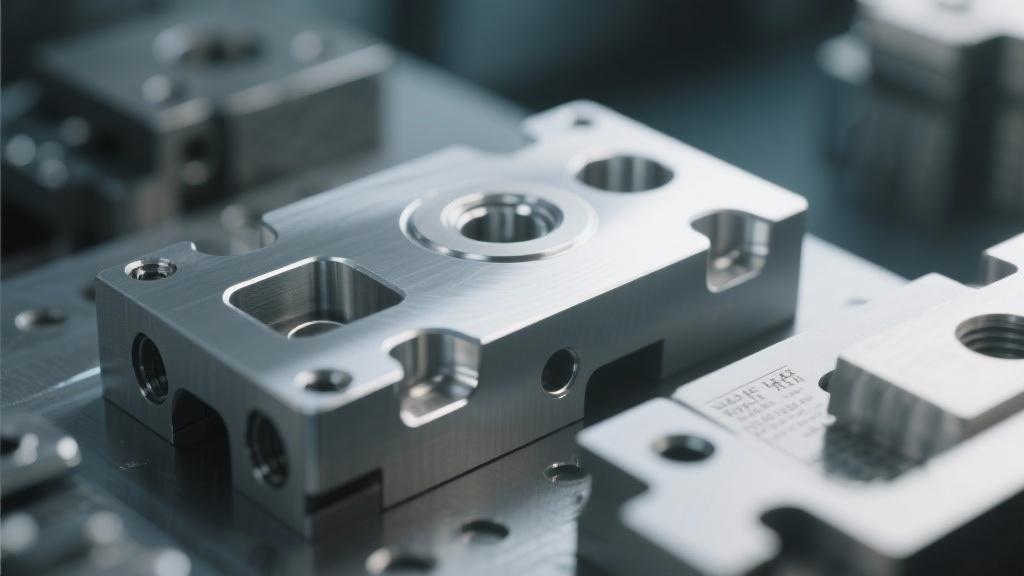

Achieving the perfect surface finish on CNC machined aluminum parts is a common challenge in the manufacturing industry. If you’ve ever struggled with rough edges or unsightly blemishes on your components, you’re not alone. Poor surface quality not only affects the aesthetic appeal of your products but can also compromise their functionality. So how can you significantly improve the surface finish of CNC machined aluminum parts? Let’s break it down.

Understanding the Basics of Surface Finish

To start, it’s essential to understand what surface finish means in the context of machining. Surface finish refers to the texture and smoothness of a part’s surface after machining. Multiple factors contribute to the final finish, including tool selection, machining parameters (like speed and feed rate), and the type of aluminum used. You might find that what works for one type of aluminum doesn’t yield the same results with another, so it’s worth doing some homework upfront.

Tooling and Machining Parameters

Choosing the right tools and appropriate machining parameters can significantly influence the surface finish. Here are some critical aspects to consider:

After you’ve optimized your tooling and parameters, it may be beneficial to conduct sample runs to evaluate the effect of different settings on your surface finish.

Post-Processing Techniques

Once machining is complete, the surface often still requires some enhancement. Here are some effective post-processing methods you might want to consider:

Incorporating Technology

Utilizing advanced technologies such as CNC machining software can provide insights into optimizing your machining processes. These tools often feature simulations that can forecast possible issues before production begins, further enhancing your surface finishes from the outset.

By following these steps—optimizing your machining parameters, employing effective tooling strategies, and considering post-processing techniques—you can markedly improve the surface finish of your CNC machined aluminum parts. Improvement doesn’t happen overnight, but with careful application of these practices, you’ll likely see significant enhancements in both quality and efficiency.

If you have further questions or are interested in custom solutions tailored to your specific needs, don’t hesitate to reach out to ly-machining for expert advice or service.

What factors influence the surface finish of CNC machined aluminum parts?

The surface finish of CNC machined aluminum parts is influenced by several factors including the material properties, chosen machining operations, and environmental conditions. Each of these aspects plays a crucial role in determining the quality of the final product.

For instance, the type of aluminum alloy can significantly affect the machining parameters and the resulting finish. Understanding these variables allows manufacturers to make informed decisions that improve surface quality.

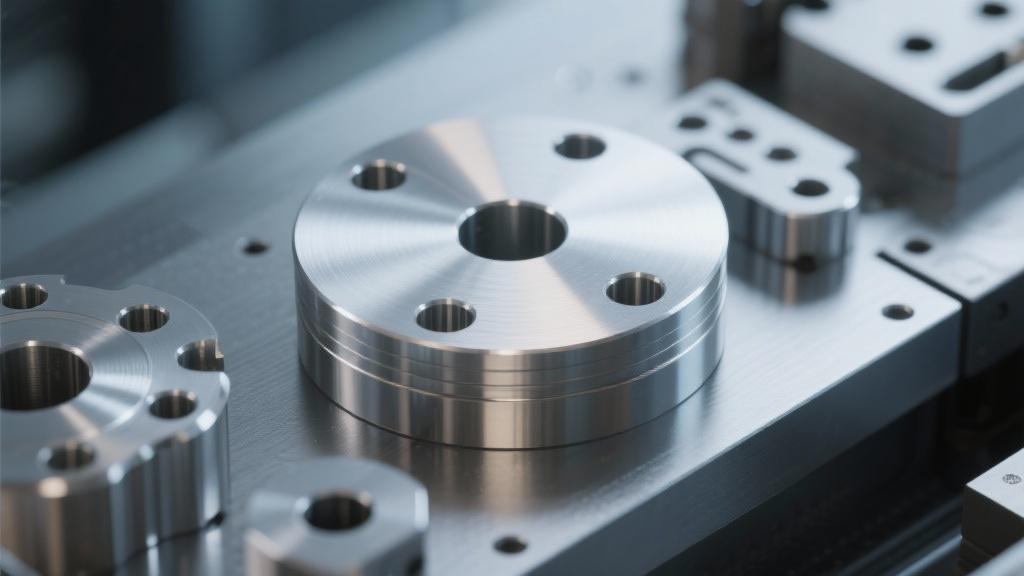

How can tooling affect the surface finish during machining?

The choice of tooling is essential when it comes to achieving a high-quality surface finish in CNC machining. Using sharp, high-quality tools made from carbide or high-speed steel typically leads to better results.

Additionally, the configuration of the tool, such as its geometry and coating, can impact how the material is cut. Selecting the right tooling helps to minimize defects like burrs and rough edges.

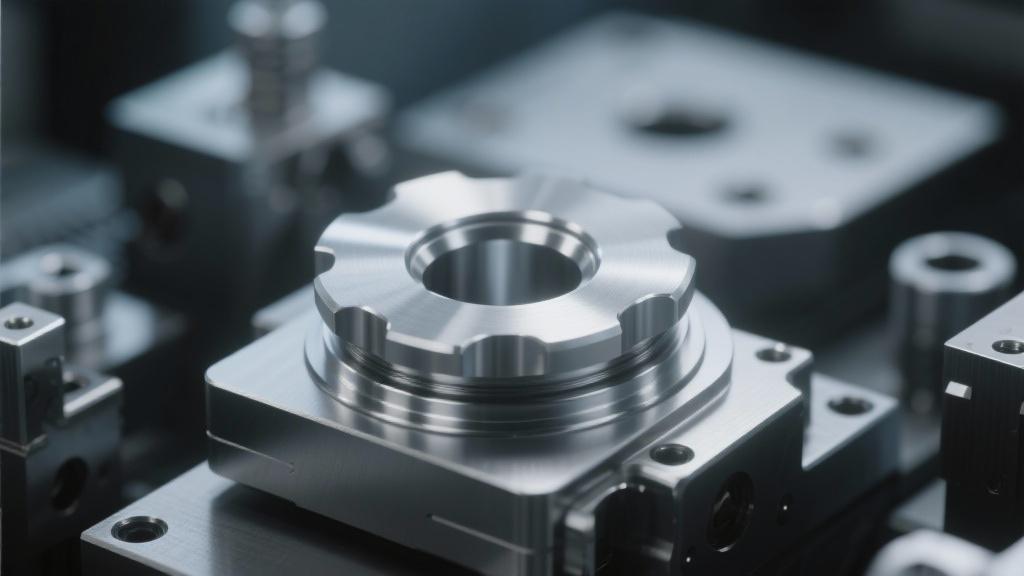

What post-processing techniques can improve the finish of aluminum parts?

Post-processing techniques such as polishing, anodizing, and deburring are effective ways to enhance the surface finish of aluminum parts. Polishing can remove minor imperfections, giving the surface a smooth feel.

Anodizing not only improves the appearance but also increases corrosion resistance. Each method contributes uniquely to the part’s overall quality and durability.

How important is technology in enhancing surface finish?

Incorporating advanced CNC machining technology plays a significant role in improving surface finishes. Software solutions can simulate machining processes and predict outcomes, allowing for adjustments before actual production.

By utilizing these technologies, manufacturers can refine their processes to consistently achieve better results, minimizing defects and enhancing product quality.

How often should quality control measures be implemented?

Consistent quality control measures should be integrated throughout the machining process. This includes regular inspections at different stages of production to ensure every component meets specified requirements.

Implementing these measures not only helps in identifying defects early but also contributes to overall customer satisfaction by maintaining product standards.