Is inconsistent surface roughness on your aluminum CNC parts costing you time, money, and product performance? Don’t let a critical specification be a blind spot. Discover the definitive methods and advanced techniques our high-end factory employs to precisely measure and guarantee the surface quality of your aluminum components. We transform complex engineering requirements into tangible, reliable products.

Precisely controlling and measuring aluminum surface roughness is critical for product performance, aesthetics, and overall functionality. At ly-machining, we specialize in delivering CNC machined aluminum parts that consistently meet the most demanding surface finish specifications. Our expertise ensures your designs are realized with unmatched precision and reliability.

Understanding Aluminum Surface Roughness: Why It Matters

The surface finish of a CNC machined aluminum part profoundly influences its interaction with other components and its environment. Neglecting this crucial aspect can lead to unforeseen challenges in assembly, operation, and longevity. Accurate aluminum surface roughness measurement is not merely a quality check; it is a fundamental requirement for functional integrity.

Impact on Performance: Functionality and Aesthetics

Surface roughness directly affects critical aspects like friction, wear resistance, fatigue life, corrosion resistance, and adhesion properties. A smoother finish typically reduces friction, which is vital for moving parts. Conversely, a specific roughness can enhance adhesion for coatings or paints.

Beyond functionality, surface finish dictates the aesthetic appeal of a part. High-end consumer electronics or visible aerospace components demand superior finishes for both tactile and visual quality. The correct surface roughness specification is key to fulfilling both functional and aesthetic design intentions.

Industry Standards and Specification Requirements

International and national standards provide a common language for specifying surface roughness. These standards ensure consistency and enable clear communication between designers, manufacturers, and quality control teams globally. Designers typically specify desired surface finishes using symbols on engineering drawings.

Commonly referenced standards include ISO 21920 (formerly ISO 4287, ISO 4288) and ASME B46.1. These standards define the various parameters and measurement procedures for surface texture. Understanding these specifications is essential for accurate production and verification.

Here is a comparison of common industry standards:

| Standard | Focus Area | Key Parameters Defined | Application Context |

|---|---|---|---|

| **ISO 21920** | Global geometrical product specification | Ra, Rz, Rq, RSm, Rk, Rpk, Rvk | Broad international use, highly detailed profiles |

| **ASME B46.1** | Surface texture (roughness, waviness, lay) | Ra, Rz, Rq, Rmax, Wt | Primarily North American, often for mechanical parts |

Key Surface Roughness Parameters for Aluminum

To precisely define and measure surface roughness, several parameters are used, each providing a specific insight into the surface texture. For aluminum, Ra and Rz are the most frequently specified values, offering a balance of information and practicality.

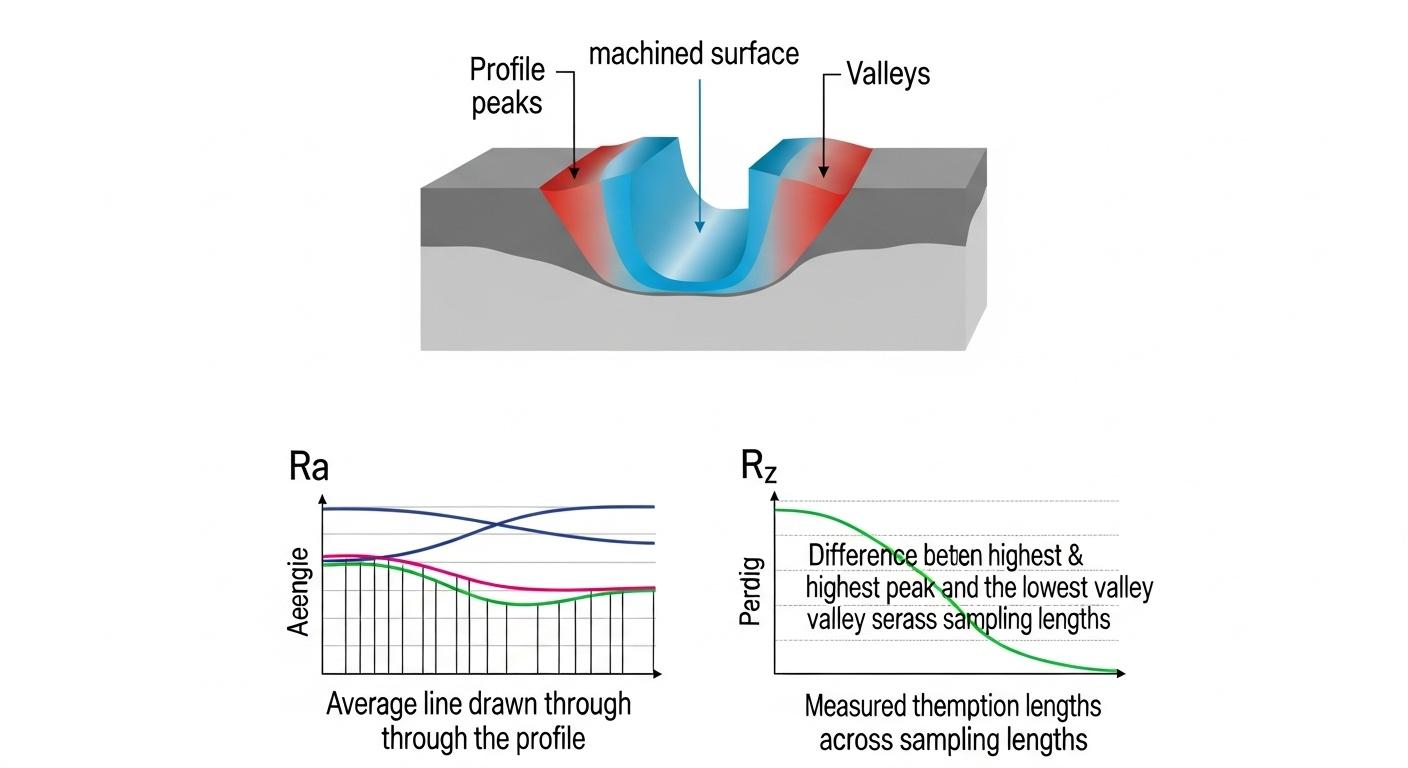

Ra (Arithmetic Average Roughness) Explained

Ra, or Arithmetic Average Roughness, is the most universally recognized and commonly specified surface roughness parameter. It represents the arithmetic mean of the absolute values of the profile deviations from the mean line within the sampling length.

Ra provides an overall assessment of the surface texture, giving a general indication of the average height of surface irregularities. While easy to measure and understand, Ra can sometimes obscure critical peaks or valleys that might impact part performance.

Rz (Ten-Point Mean Roughness) Definition

Rz, or Ten-Point Mean Roughness, measures the average of the five highest peaks and five deepest valleys within a given sampling length. Unlike Ra, Rz is more sensitive to extreme peaks and valleys on the surface.

This parameter is particularly useful for applications where deep scratches or high peaks are critical concerns, such as sealing surfaces or components subjected to high stress. Specifying both Ra and Rz often provides a more comprehensive picture of the machined aluminum finish.

Other Relevant Parameters: Ry, Rq, RSm

While Ra and Rz are primary, other parameters offer more specialized insights. Ry (Maximum Profile Peak-to-Valley Height) represents the maximum peak-to-valley height within a single sampling length, highlighting extreme deviations.

Rq (Root Mean Square Roughness) is the root mean square of the profile deviations, often preferred in scientific research due to its statistical properties. RSm (Mean Spacing of Profile Elements) indicates the average spacing between irregularities, influencing texture and appearance.

Each parameter provides a different lens through which to view the aluminum surface roughness, allowing engineers to select the most appropriate one for their specific application.

Essential Tools and Methods to Measure Aluminum Roughness

Accurate aluminum surface roughness measurement relies on specialized instruments and methodologies. Our factory utilizes a range of advanced tools, ensuring that every machined aluminum part meets the precise specifications required. The choice of method often depends on the required precision, part geometry, and material.

Contact Profilometers: Principles and Application

Contact profilometers are a widely used and highly reliable method for measuring surface roughness. These instruments use a diamond stylus, typically with a very small tip radius, which traces directly over the surface of the aluminum part.

The stylus movement, amplified by a transducer, generates a profile graph of the surface. This raw data is then processed to calculate various roughness parameters like Ra and Rz. They are excellent for detailed two-dimensional profile analysis and offer high resolution.

| Aspect | Description | Pros | Cons |

|---|---|---|---|

| **Principle** | Stylus physically traces surface, measuring vertical displacement. | High accuracy and resolution for 2D profiles. | Potential for surface damage, slower measurement speed. |

| **Application** | General-purpose roughness measurement, detailed profile analysis. | Established technology, widely accepted, cost-effective. | Not ideal for very soft materials or intricate geometries. |

Non-Contact Optical Methods: Precision Measurement

Non-contact optical methods offer a distinct advantage by measuring the surface without physical interaction, thus eliminating the risk of surface damage. These techniques include optical profilometry, white light interferometry, and confocal microscopy.

These methods use light to map the surface topography, providing three-dimensional data. They are particularly effective for delicate aluminum surfaces, complex geometries, or when extremely high measurement speed is required.

| Aspect | Description | Pros | Cons |

|---|---|---|---|

| **Principle** | Uses light (laser, white light) to map surface topography in 3D. | Non-destructive, high speed, suitable for delicate surfaces. | Can be sensitive to surface reflectivity, higher equipment cost. |

| **Application** | Micro-scale features, soft materials, 3D surface analysis, rapid QC. | Ideal for complex parts or online inspection. | Measurement depth can be limited by optical properties. |

Visual and Tactile Comparison Standards

For less critical applications or quick preliminary checks, visual and tactile comparison standards are sometimes used. These are physical blocks with known surface finishes (e.g., ground, milled, polished) that a quality inspector can compare by sight or touch to the actual part.

While not offering the precision of instrumental methods, these standards serve as a useful qualitative reference. They are valuable for initial assessment and for communicating desired surface textures on the shop floor.

Achieving Desired Surface Finishes on CNC Aluminum

Achieving specific aluminum surface roughness values is a testament to precision engineering and meticulous process control. Our deep understanding of material science and machining dynamics allows us to consistently meet stringent specifications.

Machining Process Parameters and Material Influence

The choice of machining parameters significantly affects the final surface finish. Factors such as cutting speed, feed rate, depth of cut, tool geometry, and coolant application all play a crucial role. For aluminum, the alloy type also influences machinability and achievable surface roughness.

Softer aluminum alloys may require different parameters than harder, high-strength variants to prevent smearing or burr formation. Optimizing these parameters through extensive testing and experience is key to producing high-quality machined aluminum finish consistently.

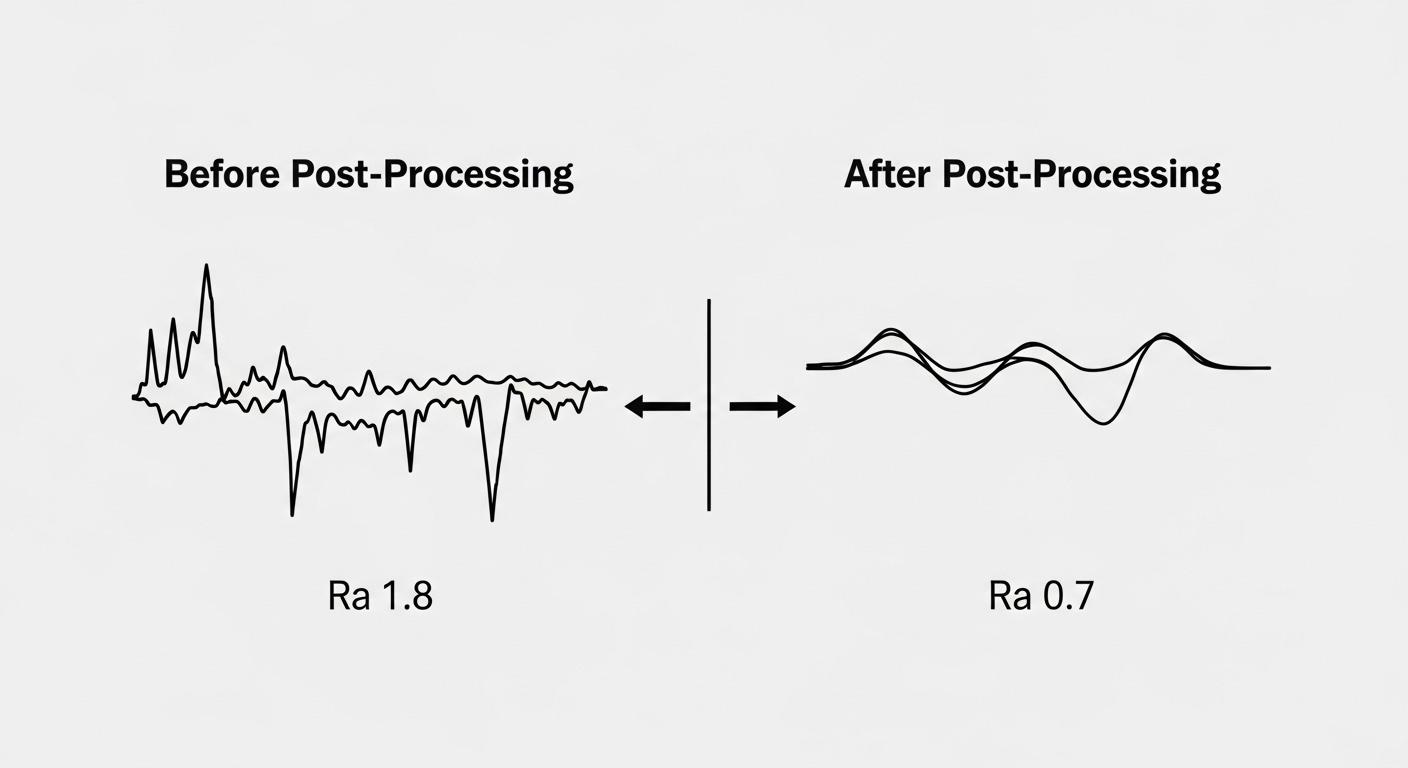

Post-Processing Techniques for Surface Enhancement

When the required surface roughness cannot be achieved through primary machining alone, post-processing techniques are employed. These methods refine the surface to meet tighter specifications or enhance specific properties.

Common techniques include vibratory finishing, shot peening, polishing, and anodizing. Each method offers different benefits, from deburring and smoothing to increasing hardness and corrosion resistance, impacting the final aluminum surface roughness measurement.

Here is a brief overview of common post-processing techniques for aluminum:

| Technique | Primary Effect on Surface | Typical Ra Improvement | Application Example |

|---|---|---|---|

| **Vibratory Finishing** | Deburring, edge rounding, light surface smoothing | Reduces Ra by 20-50% | General parts, preparing for anodizing |

| **Bead Blasting** | Creates uniform matte finish, stress relief | Ra 1.6-6.3 μm (63-250 μin) | Aesthetic finish, fatigue resistance |

| **Polishing/Buffing** | Creates highly reflective, smooth surface, improves aesthetics | Achieves Ra < 0.2 μm (8 μin) | Decorative parts, optical applications |

| **Anodizing** | Increases corrosion/wear resistance, can seal micro-pores | Minimal change, depends on pre-finish | Protective coatings, aesthetic coloration |

Quality Control for Consistent Roughness

Consistent quality in surface roughness is paramount for reliable production. Our quality control processes involve stringent in-process checks and final inspections. We employ trained technicians and calibrated equipment to monitor and verify surface finish at every critical stage of manufacturing.

This systematic approach minimizes variations and ensures that every batch of CNC machined aluminum parts adheres to the exact specifications. Our commitment to robust QC practices builds confidence and trust, delivering the consistent quality our clients expect.

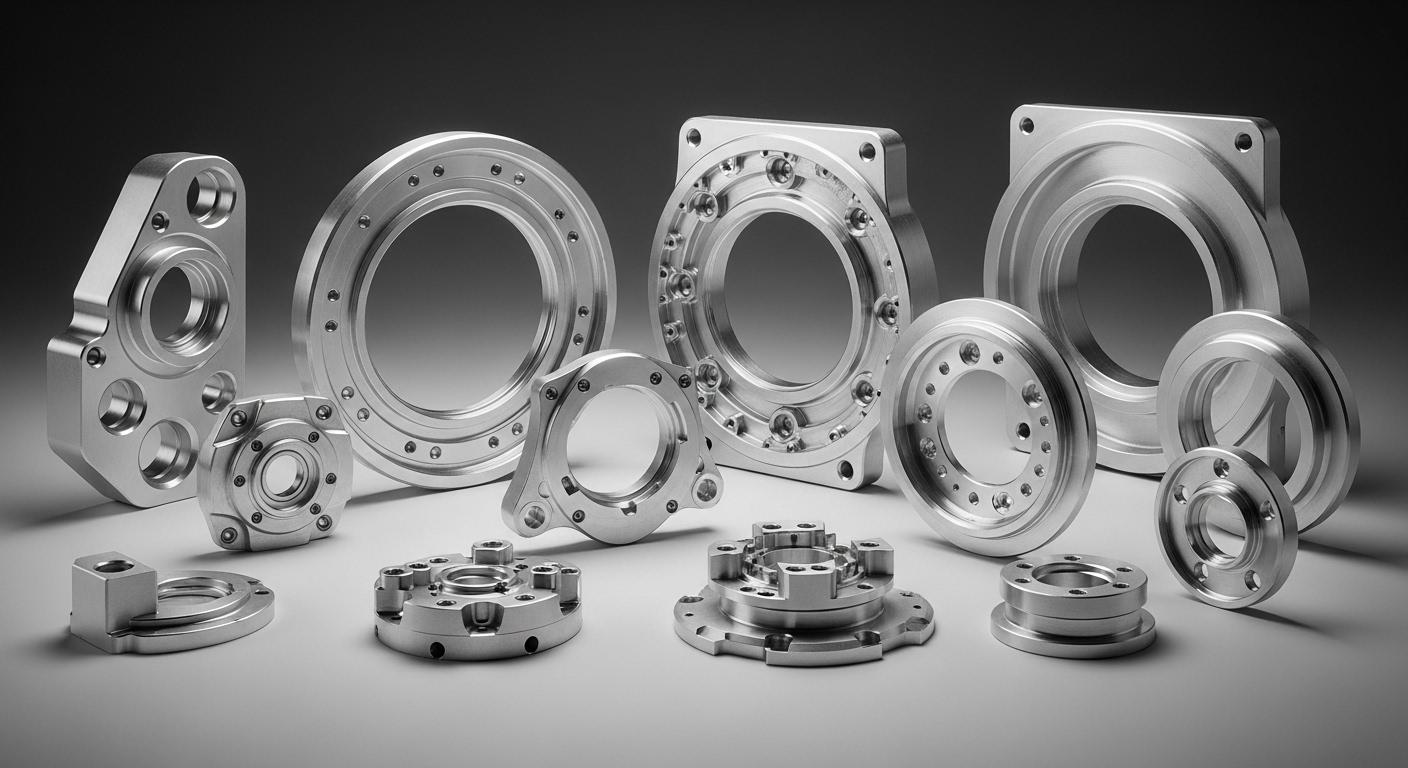

Partnering for Precision: Expert Aluminum Machining

At ly-machining, we are more than just a manufacturing facility; we are a partner dedicated to precision. Located in Shenzhen, China, our high-end factory leverages cutting-edge technology and deep technical expertise to produce aluminum components of unparalleled quality. We understand the nuances of aluminum surface roughness measurement and control.

Our Factory’s Advanced Measurement Capabilities

Our state-of-the-art QC laboratory is equipped with advanced surface profilometers, optical measurement systems, and other metrology tools. This comprehensive suite allows us to perform precise Ra Rz measurement aluminum parts, covering a wide range of geometries and finish requirements.

Our skilled technicians are experts in interpreting complex surface finish specifications and executing accurate measurements. This capability ensures that every part we produce is rigorously verified against your technical drawings, providing complete assurance of quality.

[IMAGE PLACEER 16:9: A panoramic, brightly lit photo of ly-machining’s CNC workshop floor. Advanced multi-axis CNC milling machines are actively working on aluminum blocks, with sparks or coolant visible. The focus should be on the clean, organized environment and the scale of operations, showcasing high-tech manufacturing.]

Ensuring Your Aluminum Part Specifications

We meticulously review your technical drawings and engage in detailed consultations to understand the critical requirements for your aluminum parts. This proactive approach allows us to anticipate challenges and implement optimal machining and post-processing strategies from the outset.

Our process controls are designed to mitigate risks associated with surface finish deviations, ensuring that the final CNC machined aluminum finish not only meets but often exceeds expectations. Your specifications are our blueprints for precision.

Transparent Pricing for High-Quality CNC Parts

Our “source manufacturer” advantage means we offer transparent pricing without compromising on quality. We provide detailed quotes that reflect the true cost of achieving your specified aluminum surface roughness, considering material, machining processes, post-processing, and rigorous quality control.

There are no hidden costs, only a commitment to delivering exceptional value for high-quality CNC parts. Our efficiency and expertise translate into reliable delivery and competitive pricing, ensuring your project stays on schedule and within budget.

Article Summary:

This article provided a comprehensive guide to measuring surface roughness on CNC machined aluminum parts. We explained why surface roughness matters for performance and aesthetics, detailed key parameters like Ra and Rz, and explored essential measurement tools such as contact and non-contact profilometers. The article also covered how machining parameters and post-processing techniques influence the final aluminum surface finish, emphasizing our factory’s rigorous quality control processes and advanced measurement capabilities to ensure precise and consistent results for every client.

Call to Action:

Ready to ensure your aluminum CNC parts meet the most stringent surface roughness specifications? Leverage our unparalleled expertise. Contact our engineering team today for a detailed consultation, request a precise quote for your project, or send us your technical drawings for a complimentary surface finish analysis.

Frequently Asked Questions about Aluminum Surface Roughness

What is the typical range of Ra values achievable for CNC machined aluminum parts?

The achievable Ra (Arithmetic Average Roughness) for CNC machined aluminum parts varies significantly based on the specific machining process, aluminum alloy, and post-processing techniques employed. For standard CNC milling or turning, an Ra of 0.8 μm to 3.2 μm (32 to 125 μin) is commonly achievable. With precision machining, optimized cutting parameters, and specialized tools, we can achieve finer finishes, often down to Ra 0.4 μm (16 μin). For highly critical applications requiring an even smoother finish, post-processing methods such as polishing or specialized grinding can reduce Ra values to less than 0.2 μm (8 μin), depending on the part geometry and specific requirements. We always recommend consulting with our engineers to define the most cost-effective and functionally appropriate Ra value for your project.

How does the choice of aluminum alloy affect surface roughness and its measurement?

The specific aluminum alloy significantly impacts both the achievable surface roughness and the considerations for its measurement. Softer alloys (e.g., 1000 or 5000 series) are prone to material smearing, burr formation, and built-up edge during machining, which can lead to a rougher, inconsistent surface. Harder alloys (e.g., 6061, 7075) generally offer better machinability for finer finishes, as they produce smaller, more predictable chips. For measurement, the reflectivity of different alloys can affect optical methods, requiring calibration or specific settings. Our experience with a wide range of aluminum alloys allows us to select optimal machining strategies and measurement techniques tailored to the material’s characteristics, ensuring accurate results and consistent quality regardless of the alloy.

What are the cost implications of specifying a very fine surface finish (low Ra/Rz) for aluminum parts?

Specifying a very fine surface finish (low Ra or Rz value) for aluminum parts generally increases manufacturing costs due to several factors. Achieving tighter roughness tolerances often requires slower feed rates, lighter depths of cut, and higher spindle speeds, which translates to longer machining times. It may also necessitate the use of specialized, sharper cutting tools that wear faster, or dedicated finishing passes. Furthermore, very fine finishes often demand additional post-processing steps like polishing, lapping, or specialized grinding, which are labor-intensive and add to the overall cost. Increased quality control measures, including more frequent and precise surface roughness measurements with advanced equipment, also contribute to the higher cost. We always strive for cost-efficiency without compromising quality; our engineering team can advise on the optimal balance between surface finish requirements and budgetary considerations for your project.