Demystifying Your CNC Machining Quote

The opacity inherent in many CNC machining quotes often proves a perpetual bane, a truly exasperating challenge, for procurement managers and design engineers across every industry. This inscrutable labyrinth of figures and technical jargon, it often—and quite tragically—conceals hidden costs, compromises on the very bedrock of component quality, and inevitably, quite unnecessarily, derails critical project timelines!

At ly-machining, nestled in the vibrant industrial heart of Shenzhen, China, we contend with unwavering conviction that true project triumph, real success, hinges not merely on the passive act of receiving a quotation, but profoundly, comprehensively, understanding its every granular, vital component—a clarity we champion as a direct, unvarnished source manufacturer.

Understanding your CNC machining quote is absolutely pivotal for project fiscal health and undeniable technical integrity. A meticulously detailed quote, straight from a transparent source manufacturer like ly-machining, empowers truly informed decisions, substantially mitigates those insidious hidden costs, and absolutely ensures unparalleled component quality. This structured, deeply analytical approach is, quite simply, the bedrock for superior project outcomes.

Understanding Core CNC Quote Components

Dissecting the architecture of a CNC machining quote reveals its true nature: a precise projection of resources, not just a price tag. Our specific angle here is always about seeing the quote not as an obstacle, but as a critical blueprint for project optimization. Ignoring this granular detail would be an unbelievably foolish mistake!

Material Costs: Selection and Impact

Raw material selection stands as a foundational—indeed, a fundamentally unyielding—cost driver. A common pitfall, to be perfectly honest, is underestimating the cascading impact material choices have on everything else.

Raw Material Grade and Volume

The specific alloy, its grade, and the sheer volume required dictate an immense portion of initial expenditure. A bulk order of aerospace-grade titanium, for instance, exhibits vastly different cost dynamics compared to a modest batch of standard aluminum 6061; this is, dare I say, painfully obvious, yet often overlooked in initial budgeting! We see this continually.

Material Certification Requirements

Demanding stringent certifications—think AS9100 or specific medical-grade approvals—will inherently elevate costs, but this expenditure is absolutely non-negotiable for critical applications. These aren’t mere line items; they are guarantees of compliance, assurances of performance, truly!

An Illustrative Material Cost Breakdown

To fully appreciate the nuanced cost implications, consider these typical material classifications. It’s not just about the metal itself, but what comes with it, what processes it demands.

| Material Type | Typical Cost Factor | Processing Difficulty | Application Examples |

|---|---|---|---|

| Aluminum Alloys | Low to Medium | Low | Prototyping, Housings |

| Stainless Steels | Medium to High | Medium | Medical, Food Processing |

| Titanium Alloys | Very High | High | Aerospace, Implants |

| Engineering Plastics | Medium | Low to Medium | Insulators, Wear Parts |

Machining Time and Labor Costs

Here’s where the real magic—or absolute nightmare, depending on the design—happens. This section is often the largest variable. We, as engineers, calculate this with meticulous, almost obsessive, precision.

Machine Setup and Programming

Initial setup, the jigging, and the exhaustive G-code programming for a complex part can consume significant engineering hours before the first chip ever flies. This non-recurring effort is absolutely critical, a foundational investment.

Tooling Wear and Consumption

Every cutting tool possesses a finite lifespan, a brutal truth! High-precision machining of hardened alloys means faster tool degradation, requiring frequent, costly replacements, an unavoidable operational reality.

Complexity of Part Geometry

A part bristling with intricate features, tight tolerances, and multiple axis operations—a geometric marvel, some might say—demands dramatically more machine time and specialized expertise. Simple parts? Not so much, obviously.

Post-Processing and Finishing Fees

Machining a part is but one chapter in its life; often, it’s not even the final one. The finishing touches—these are absolutely crucial for functionality and aesthetics.

Surface Treatment Options

Anodizing, passivation, plating—these processes fundamentally alter a part’s properties and, undeniably, its final cost. Aesthetic demands, corrosion resistance requirements, they all add up, don’t they?

Heat Treatment Processes

To achieve specific material hardness or stress relief, heat treatment is frequently indispensable. This external service, a distinct step in the production chain, represents a clear additional expenditure.

Deburring and Cleaning

A critical, often underestimated, manual process is the meticulous removal of burrs and thorough cleaning. Precision components demand immaculate surfaces, a truly non-negotiable requirement.

Quality Control and Inspection

Quality is not an afterthought for us, it’s the very air we breathe! Any engineer will tell you, a flawed component is worse than no component at all, an absolute disaster.

Standard vs. Advanced QC Measures

Basic dimensional checks are standard, yes, but demanding CMM reports, optical inspections, or non-destructive testing (NDT) introduces layers of cost reflective of the required assurance. This is about risk mitigation, nothing less.

Inspection Report Documentation

Detailed inspection reports, material traceability certificates—these are more than just paperwork; they’re verifiable proof of compliance. Generating and maintaining them, however, constitutes a clear labor cost.

Levels of Quality Assurance and Cost

Different projects necessitate varying degrees of quality scrutiny. Here’s a pragmatic look at how these levels influence overall expenditure. The more rigorous, the higher the investment, naturally.

| QC Level | Description | Cost Impact | Typical Applications |

|---|---|---|---|

| Basic (Batch Check) | Random sampling, visual inspection, basic caliper checks. | Low | Non-critical, prototypes |

| Standard | 100% visual, dimension checks on key features, first article inspection. | Medium | General industrial, consumer |

| Advanced | CMM verification, NDT, full traceability, detailed reports, statistical process control. | High (Significant) | Aerospace, Medical, Automotive |

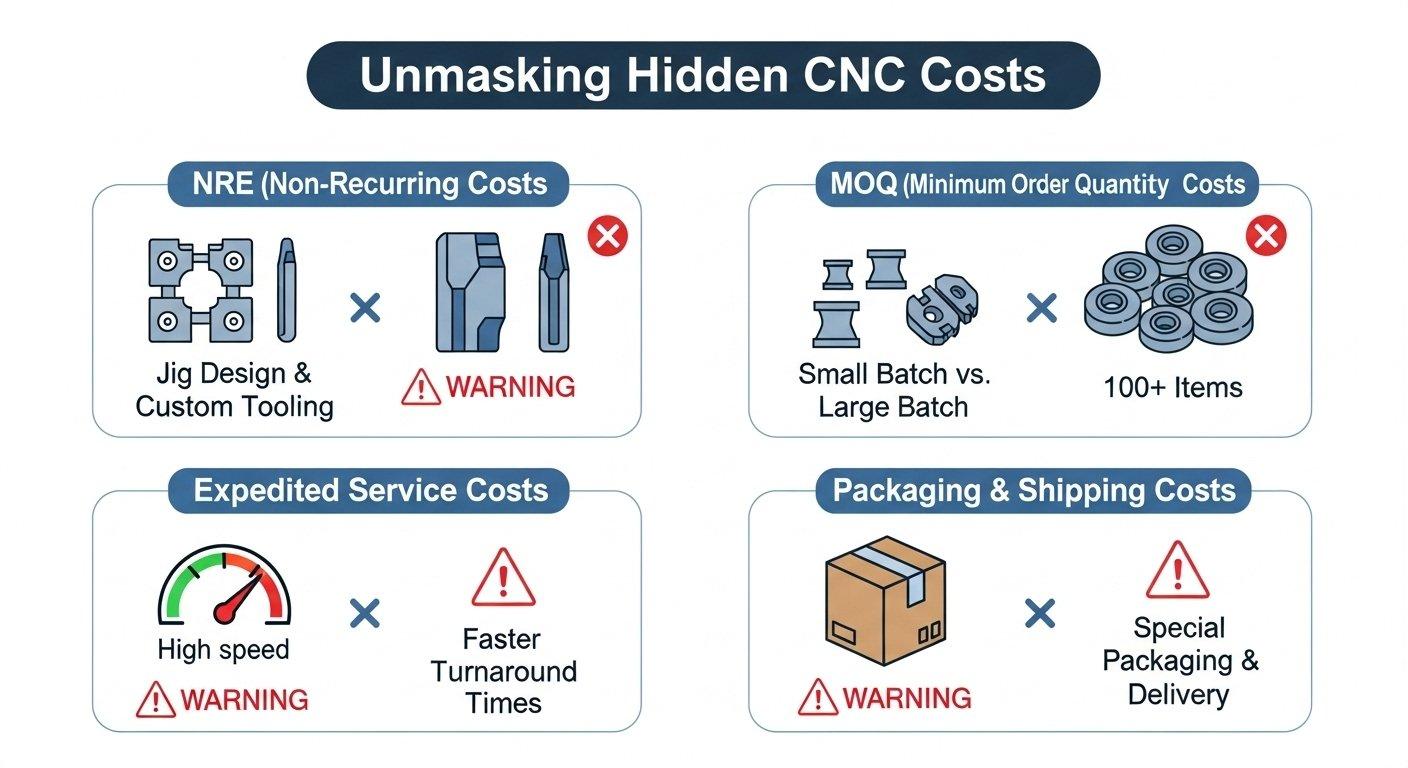

Decoding Hidden Costs in CNC Quotes

Ah, the “hidden” costs—these are the specters that haunt project budgets, truly! Our perspective, as engineers who live and breathe manufacturing, is that transparency, proactive disclosure, utterly eradicates these unwelcome surprises. We hate them, you hate them; so, let’s talk about them frankly.

Non-Recurring Engineering (NRE) Charges

Often a substantial initial investment, NRE covers the unique, one-time engineering efforts necessary for production. This isn’t just arbitrary; it’s a foundational expense.

Jig and Fixture Development

For complex geometries or high-volume runs, custom jigs and fixtures are indispensable for repeatability and precision. Their design and fabrication are pure NRE, a crucial upfront investment.

Custom Tooling Costs

Specialized cutting tools, perhaps for an unusually deep pocket or an intricate profile, contribute to NRE. These aren’t off-the-shelf items; they’re engineered solutions.

Minimum Order Quantity (MOQ)

Factories operate on economies of scale. An MOQ isn’t a punitive measure; it reflects the overhead of setup, programming, and material procurement spread across a viable production run. Ignore this at your project’s peril!

Expedited Service Surcharges

Need it yesterday? That’s going to cost you! Expedited production demands sacrificing optimal scheduling, potentially incurring overtime, and prioritizing your order over others. It’s a premium for speed, a simple equation.

Packaging and Shipping Costs

Don’t forget the final leg of the journey! Specialized packaging for delicate parts or international freight charges can be substantial, and utterly essential, additions to the overall project cost.

Evaluating Your CNC Machining Partner

Choosing a partner is not just about the lowest bid; it’s an exercise in risk assessment and strategic alliance, truly! From our specific factory perspective, it’s about a shared commitment to excellence.

The Advantage of a Source Manufacturer

This is where ly-machining distinguishes itself. Dealing directly with us, a source manufacturer, cuts through so much industrial noise, so much unnecessary layering.

Direct Communication and Control

When you speak with us, you’re speaking directly to the engineers, to the people on the shop floor! This streamlined communication minimizes misinterpretations and accelerates problem-solving, a huge, undeniable benefit.

Cost Efficiency from No Middlemen

Eliminating brokers, agents, and resellers inherently strips away layers of markups. This direct channel translates into a more competitive, and let’s be brutally honest, transparent pricing structure for you. No one needs unnecessary intermediaries; they only add cost and confusion.

Assessing Quality Standards and Certifications

A factory’s certifications are not merely framed documents on a wall; they represent a fundamental, disciplined commitment to process and output quality, a deep-seated philosophical approach.

ISO, AS9100, and Industry Compliance

Certifications like ISO 9001, AS9100 for aerospace, or ISO 13485 for medical devices, are non-negotiable benchmarks. They tell you, unequivocally, that the factory adheres to globally recognized, rigorous standards. We hold these deeply.

Supplier’s Track Record and Reputation

Past performance is an incredibly strong predictor of future reliability, indeed it is. Investigating a supplier’s history—their reputation for delivery, for quality, for problem resolution—is absolutely paramount.

Technical Expertise and DFM Capabilities

This is where an engineer truly shines, where our value proposition becomes undeniably clear. Our technical acumen is not a luxury; it’s an absolute necessity.

Collaborative Design Feedback

An excellent manufacturing partner, like us, doesn’t just execute; we collaborate, we suggest, we improve! Proactive Design for Manufacturability (DFM) feedback can profoundly optimize a part for both performance and cost.

Optimizing for Manufacturability

Early DFM consultation can prevent monumental headaches down the line, can it not? Simple design tweaks—a radius change here, a tolerance adjustment there—yield massive savings and improved yields. It’s an inspiring miracle of engineering synergy, truly.

Comparing CNC Machining Quotes Effectively

Comparing quotes isn’t just about lining up the bottom-line numbers. No, no, no! It’s a deeply analytical process requiring a systematic approach, a structural deconstruction, if you will.

Standardizing Your Request for Quote (RFQ)

An incomplete or ambiguous RFQ is an invitation to confusion, a guaranteed pathway to receiving disparate, incomparable quotes! Provide clear, comprehensive specifications—every single time.

Identifying Key Cost Drivers for Your Part

Before even looking at quotes, understand what factors will predominantly influence your part’s cost. Is it the material? Is it the complexity? Is it the surface finish? Each part has its own unique, critical cost personality.

The Role of Transparency in Pricing

A transparent quote, one that meticulously breaks down costs—material, labor, tooling, finishing, QC—allows for genuine, apples-to-apples comparison. Anything less, frankly, smells suspicious. We offer nothing less!

Long-Term Value vs. Upfront Cost

Oh, the age-old dilemma! The lowest upfront bid, that tempting, alluring figure, often conceals hidden risks—quality issues, delays, rework. Long-term value, encompassing reliability, consistent quality, and on-time delivery, *always* eclipses a marginally cheaper, potentially disastrous, initial price.

A Pragmatic Quote Comparison Metric

When evaluating quotes, consider these essential dimensions. Do not, I repeat, do not simply glance at the total.

| Evaluation Metric | What to Look For | Why it Matters |

|---|---|---|

| Cost Breakdown Detail | Itemized material, labor, tooling, QC, finishing. | Reveals cost drivers, allows true comparison. |

| Lead Time Reliability | Realistic, consistent, proven track record. | Critical for project scheduling, avoids delays. |

| DFM Feedback | Proactive suggestions for cost/performance. | Indicates expertise, saves money long-term. |

| Quality Assurance | Certifications, inspection processes, reports. | Guarantees part conformity and reliability. |

| Communication Clarity | Responsiveness, technical understanding. | Essential for seamless project execution. |

Empowering Your Procurement Decisions

Ultimately, this entire exercise—this structural analysis—is about empowerment. It’s about giving *you* the tools, the insights, to make decisions that resonate with success, not just expediency.

Asking the Right Questions to Suppliers

Never be afraid to interrogate a quote! A reputable supplier welcomes detailed questions, because they have nothing to hide. Ask about material sourcing, about QC processes, about lead time breakdowns. Demand answers!

Building Trust with Your CNC Partner

Trust isn’t conjured from thin air; it’s meticulously built, piece by painstaking piece, through transparent dealings, consistent quality, and exceptional communication. It’s an investment, a collaborative endeavor.

Future-Proofing Your Supply Chain

In an increasingly volatile global economy, a reliable, transparent, and technically capable manufacturing partner is an invaluable asset. It’s a strategic advantage, a bulwark against unforeseen disruptions. That’s what we offer.

Wait, I need to clarify this. When I talk about future-proofing, I’m really emphasizing the *relationship* aspect—the technical partnership beyond just the transaction. Many companies only look at the immediate cost. But really, think about the long-term implications of a weak link in your supply chain; it’s truly an unbelievably foolish mistake to ignore this crucial component. We’ve seen, firsthand, projects unravel because of a short-sighted sourcing strategy.

A Case Study in Transparent Partnership: The Medical Device Breakthrough

A rapidly scaling medical device company approached ly-machining facing immense pressure: their current supplier provided opaque quotes, delivered inconsistent quality on intricate titanium implants, and constantly missed deadlines. Their project, a true marvel of biomechanical engineering, was floundering. They were, frankly, desperate for clarity and reliability.

Their initial RFQ was complex, detailing extreme tolerance requirements and specific surface finishes.

Our engineering team, through meticulous DFM analysis, identified several opportunities for minor design adjustments that would preserve functionality but significantly reduce machining time and material waste. We presented a comprehensive quote, not just a price, but a detailed breakdown of every single cost component—material certification, multi-axis machining time, specialized deburring for biocompatibility, and 100% CMM inspection, complete with projected savings from our DFM suggestions.

The result was nothing short of phenomenal! By understanding the *why* behind each cost and embracing our DFM recommendations, they reduced their unit cost by 18% on the critical implant component. More importantly, our transparent process and consistent on-time delivery accelerated their market entry by three weeks, a truly inspiring miracle in the medical sector! This wasn’t just a transaction; it was a partnership founded on technical precision and an unwavering commitment to transparency.

Article Summary

Navigating CNC machining quotes demands a precise, structural understanding, not just a casual glance at the bottom line. This discourse, framed from the engineer’s invaluable perspective, has illuminated core cost components—materials, machining time, post-processing, and rigorous quality control—and exposed those oft-hidden charges like NRE and MOQs.

Critically, we’ve underscored the paramount advantages of partnering with a transparent source manufacturer, such as ly-machining, where deep technical expertise, especially in DFM, and unwavering commitment to quality coalesce to deliver not just parts, but truly optimized project success. Trust, built on meticulous analysis and absolute transparency, remains the bedrock for robust supply chains and unparalleled engineering outcomes.

FAQ Section

Why are CNC quotes so complex?

They are inherently complex because they reflect a multitude of variables. From material grade and geometry intricacy to machine time, tooling, and post-processing, each factor contributes uniquely.

A comprehensive quote transparently breaks down these elements, offering a clear cost landscape. It’s an engineering document, not merely a sales sheet.

How can I reduce my part costs?

Optimizing designs for manufacturability (DFM) is paramount. Simple changes to tolerances, radii, or feature depths can drastically cut machining time and material waste.

Engaging with a source manufacturer like ly-machining early for DFM feedback provides significant cost-saving opportunities, a truly invaluable consultation.

What is a “transparent” quote?

A transparent quote provides a detailed, itemized breakdown of all cost drivers. This includes specific line items for material, machine time, tooling, setup, quality control, and any post-processing.

It empowers you to understand precisely what you are paying for, allowing for informed decisions and preventing hidden surprises later on.