What precision can aluminum CNC machining achieve?

Aluminum CNC machining can achieve extremely tight tolerances, often down to +/- 0.005 mm (0.0002 inches) or even finer for specialized applications, depending on the machine, material, and process control. Our factory consistently delivers sub-micron surface finishes and geometric accuracy for critical components.

- Unveiling aluminum CNC machining precision capabilities.

- Factors influencing tight tolerances and surface finish.

- Advanced techniques for achieving exceptional accuracy.

- Material selection’s impact on machining precision.

- Quality control and metrology in high-precision parts.

- Cost-effective strategies for complex aluminum components.

- Partnering with a skilled source factory for excellence.

Mastering Aluminum CNC Machining: A Deep Dive into Precision Capabilities

Are you an engineer, product designer, or procurement specialist wrestling with the demanding requirements of modern manufacturing? The challenge of achieving exact specifications, especially with lightweight yet durable materials like aluminum, is constant. Tolerances are shrinking, surface finishes must be flawless, and component reliability is non-negotiable.

Many experience the frustration of prototypes failing to meet design intent, or production runs plagued by inconsistencies. The quest for ultra-high precision in aluminum CNC machining can feel like navigating a complex maze, impacting project timelines and budgets.

We understand these pressures. As a leading source factory with extensive technical autonomy, our mission is to cut through the complexity. We provide advanced aluminum CNC machining solutions that not only meet but often exceed the most stringent precision requirements, ensuring your components function perfectly and perform reliably.

The Essence of Precision

Precision in aluminum CNC machining is not just a buzzword; it is the cornerstone of functionality and performance for countless applications. It refers to the degree of exactness with which a machined part conforms to its specified dimensions and geometric tolerances. For industries ranging from aerospace to medical devices, this exactness is absolutely critical.

Our core advantage lies in our unwavering commitment to high precision. We consistently achieve superior dimensional accuracy, geometric accuracy, and surface finish, setting new benchmarks in the industry.

Defining Achievable Tolerances

When we talk about precision, we often refer to dimensional tolerances. These are the permissible variations in the size of a part. For standard aluminum CNC machining, tolerances of +/- 0.025 mm (0.001 inches) are common.

However, for specialized applications, our advanced equipment and technical expertise allow us to achieve tolerances as tight as +/- 0.005 mm (0.0002 inches) or even finer. This high precision is crucial for parts requiring exact fits, such as mating components in complex assemblies.

Geometric tolerances, including flatness, concentricity, perpendicularity, and true position, are equally vital. Our sophisticated process control ensures that these geometric features are held to exacting standards, preventing misalignments and functional failures.

The Importance of Surface Finish

A component’s surface quality directly impacts its performance and longevity. A rough surface can lead to increased friction, premature wear, and even stress concentrations that compromise structural integrity.

Our factory prioritizes exceptional surface finish, understanding its role in fatigue resistance, corrosion prevention, and aesthetic appeal. We regularly achieve Ra (Roughness average) values below 0.8 µm, and for specific requirements, we can deliver finishes down to Ra 0.2 µm or better, especially for optical or fluidic applications.

This superior surface quality is a testament to our technical highlights, including optimized cutting parameters, advanced tooling, and meticulous post-machining processes.

Factors Shaping Accuracy

Achieving unparalleled precision in aluminum CNC machining is a multifaceted endeavor, influenced by a complex interplay of material properties, equipment capabilities, and operational expertise. Each factor contributes significantly to the final outcome.

As a source factory, our deep technical understanding allows us to meticulously control these variables, ensuring every component meets the most demanding specifications.

Material Selection and Properties

The specific aluminum alloy chosen plays a profound role in machining precision. Alloys like 6061, 7075, and 2024 each possess distinct mechanical properties, including hardness, tensile strength, and thermal expansion coefficients.

For instance, 7075 aluminum, known for its high strength, can be more challenging to machine with ultra-fine features compared to softer alloys. Its chip formation characteristics require specific cutting strategies to prevent burrs and ensure clean cuts.

Our expertise in material adaptation ensures we select the optimal alloy for your application, considering both performance requirements and machinability. This strategic selection is part of our full-process service, guiding clients from design to material choice.

- **Alloy Properties Impact:**

- Hardness: Affects tool wear and cutting forces.

- Ductility: Influences chip formation and surface finish.

- Thermal Expansion: Critical for maintaining tolerances during temperature fluctuations.

- Microstructure: Can affect material removal and burr formation.

Equipment Strength and Calibration

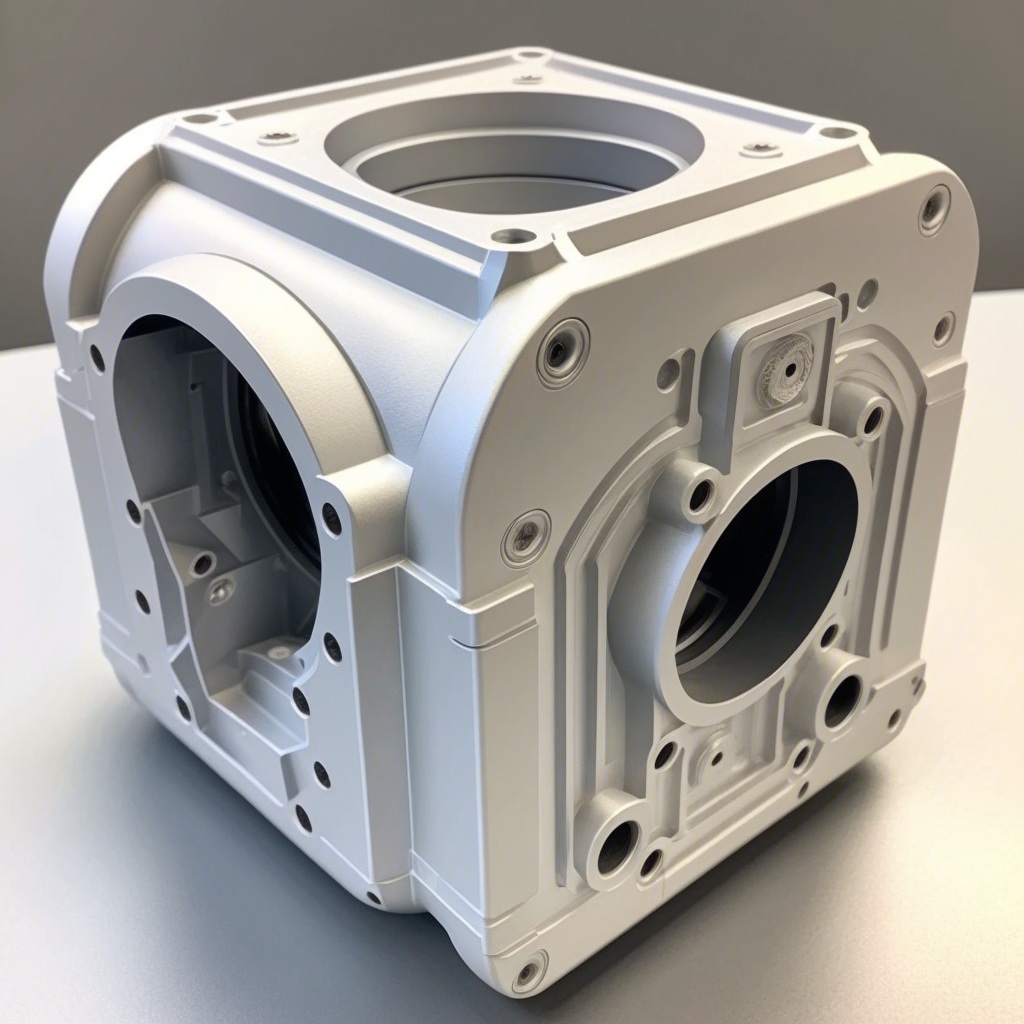

The backbone of high-precision machining is our equipment strength. We deploy a comprehensive suite of state-of-the-art CNC machines, including multi-axis machining centers (3-axis, 4-axis, and 5-axis), high-speed spindles, and advanced EDM machines.

Our 5-axis machines, for example, allow for the machining of complex geometries in a single setup, minimizing repositioning errors and maximizing geometric accuracy. The rigidity of our machines, combined with high-resolution encoders and thermal compensation systems, ensures consistent and repeatable precision.

Regular, rigorous calibration of all equipment is a critical component of our quality control. We adhere to strict maintenance schedules and use precision metrology tools to verify machine accuracy, guaranteeing that every cut is exactly as programmed.

**Table: Impact of Equipment Type on Achievable Precision**

| Equipment Type | Typical Achievable Dimensional Tolerance (mm) | Typical Achievable Surface Roughness (Ra µm) | Key Precision Advantage |

|---|---|---|---|

| 3-Axis CNC Mill | +/- 0.025 to 0.050 | 0.8 to 3.2 | Good for basic shapes, cost-effective for simpler parts. |

| 5-Axis CNC Mill | +/- 0.005 to 0.025 | 0.2 to 0.8 | Complex geometries, reduced setups, superior geometric accuracy. |

| High-Speed CNC Mill | +/- 0.005 to 0.020 | 0.1 to 0.4 | Fine features, excellent surface finishes, faster cycles. |

| Precision Grinding | +/- 0.001 to 0.005 | 0.05 to 0.2 | Ultra-high flatness, parallelism, and surface finish. |

Environmental Controls

Environmental stability within the machining facility is often overlooked but profoundly impacts precision. Fluctuations in temperature can cause thermal expansion or contraction of both the machine and the workpiece, leading to dimensional inaccuracies.

Our machining environment is meticulously controlled, with stringent temperature and humidity regulation. This stable environment minimizes thermal distortion, allowing us to maintain the tightest tolerances over extended machining operations.

Dust and vibration are also carefully managed. Our facility design incorporates features to isolate vibrations and maintain a clean atmosphere, protecting delicate tooling and sensitive metrology equipment.

Advanced Machining Techniques

Leveraging cutting-edge technology and refined processes is how we achieve the exceptional precision our clients demand. Our technical experts continuously push the boundaries of what aluminum CNC machining can achieve.

These advanced techniques, combined with our technical knowledge, form our core processing capabilities, positioning us as leaders in complex structure processing and specialized material processing.

Tooling and Cutting Strategies

The choice of tooling is paramount. We utilize high-quality, specialized cutting tools, often with advanced coatings (e.g., TiAlN, DLC) that enhance hardness, reduce friction, and extend tool life. Sharp, well-maintained tools are crucial for clean cuts and superior surface finishes.

Our engineers develop optimized cutting strategies for each specific aluminum alloy and part geometry. This includes selecting appropriate feed rates, spindle speeds, depth of cut, and coolant application methods. For example, high-speed machining (HSM) techniques with lighter cuts and faster feeds significantly reduce heat generation and improve surface quality.

We employ advanced CAM software for toolpath optimization, ensuring efficient material removal while minimizing tool deflection and vibration, both critical for maintaining tight tolerances.

**Success Case Highlight:**

For a client in the semiconductor industry, we machined a complex aluminum manifold with intricate internal channels. By implementing multi-flute carbide end mills and a specialized high-pressure coolant system, we achieved an internal surface finish of Ra 0.4 µm, crucial for precise gas flow, and dimensional accuracy within +/- 0.008 mm across all critical features. This success was a direct result of our focused processing expertise and optimized tooling strategy.

Multi-Axis Machining Expertise

Our extensive experience with multi-axis machining, particularly 5-axis CNC, is a significant differentiator. This capability allows for intricate and complex structure processing that would be impossible or highly inefficient with conventional 3-axis machines.

5-axis machining enables the cutting tool to approach the workpiece from virtually any angle, minimizing setups and eliminating the need for manual repositioning. This reduces cumulative errors and drastically improves geometric accuracy and consistency across complex parts.

This capability is particularly vital for aerospace and medical components, where organic shapes, undercut features, and compound angles are common. Our design flexibility extends to realizing these complex geometries with unparalleled precision.

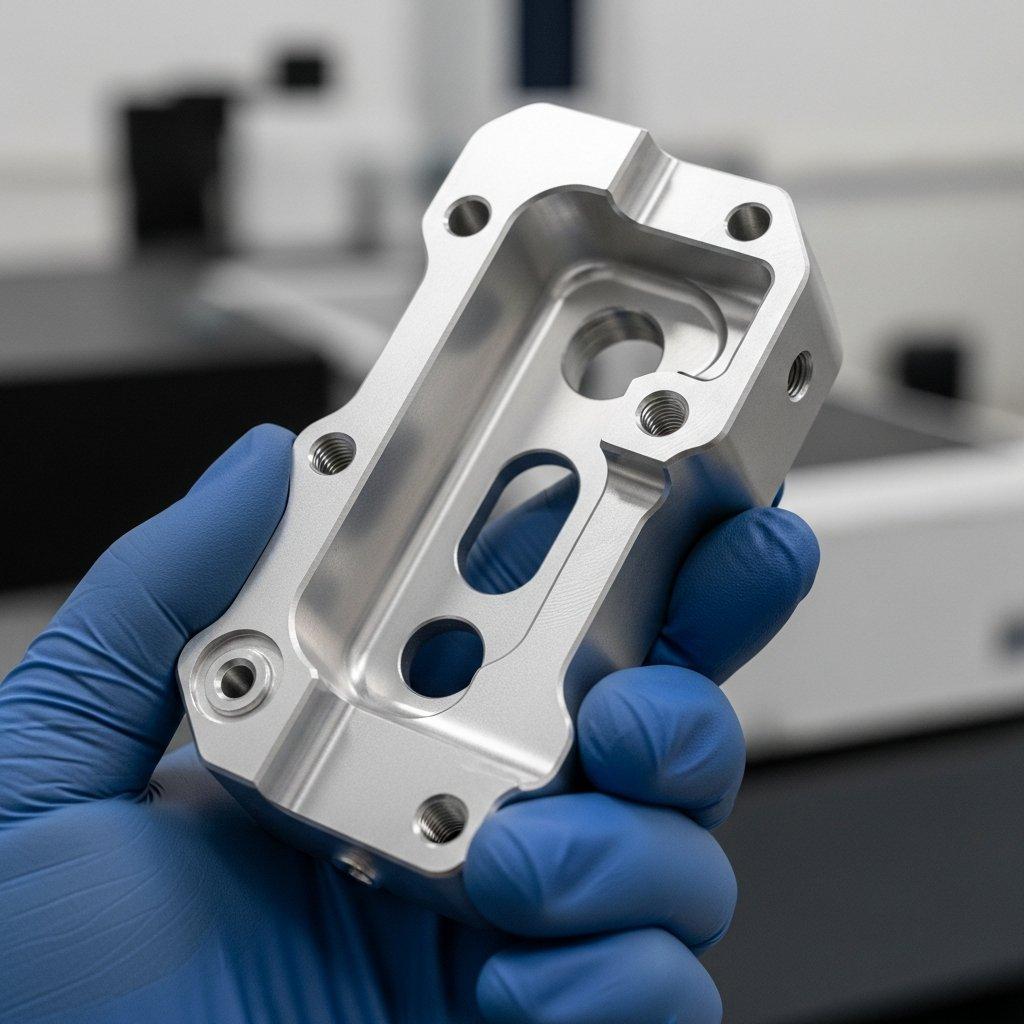

Post-Machining Processes

Precision doesn’t end when the part leaves the CNC machine. Post-machining processes are equally important for achieving final specifications and enhancing performance. These include deburring, vibratory finishing, polishing, and specialized surface treatments.

Deburring, often performed manually or through automated methods, removes sharp edges and small burrs that can impact assembly and function. Polishing can further refine surface finishes, crucial for optical or sealing surfaces.

Anodizing, passivating, or chemical conversion coatings can be applied to enhance corrosion resistance, hardness, or electrical conductivity, tailored to the application’s needs. Our full-process service includes these essential steps, ensuring a complete and ready-to-use component.

Quality Control & Validation

Maintaining consistently high precision requires a robust and continuous quality control system throughout the entire manufacturing chain. Our full-chain quality control is an integral part of our operation, not merely a final inspection step.

This commitment to quality is reinforced by our comprehensive technical procedures and unwavering dedication to industry certifications, providing our clients with absolute confidence in every part we produce.

In-Process Monitoring

Quality control begins at the machining stage. We utilize advanced in-process monitoring systems, including laser tool measurement, touch probes, and acoustic emission sensors. These technologies allow for real-time detection of tool wear, dimensional deviations, and potential machining issues.

Automated probing systems on our CNC machines can verify critical dimensions during the machining cycle, allowing for immediate adjustments and preventing the production of out-of-spec parts. This proactive approach significantly enhances efficiency and reduces scrap rates.

Our skilled operators are also continuously monitoring machine performance and part quality, applying their extensive industry experience to identify and address any anomalies immediately.

Metrology and Inspection

Upon completion of machining, every part undergoes rigorous inspection using state-of-the-art metrology equipment. Our inspection lab is equipped with Coordinate Measuring Machines (CMMs) with sub-micron accuracy, optical comparators, profile projectors, and surface roughness testers.

The CMMs perform highly accurate 3D measurements, verifying all critical dimensions and geometric tolerances against the original CAD model. Statistical Process Control (SPC) is utilized to analyze measurement data, ensuring process stability and identifying any trends that might lead to deviations.

This comprehensive inspection ensures that every component leaving our facility adheres strictly to the specified precision requirements, backed by verifiable data.

Certifications and Compliance

Our factory holds multiple industry certifications that underscore our commitment to quality and precision. These quality certifications include ISO 9001 for general quality management and specialized certifications like AS9100 for aerospace components, demonstrating our adherence to the most stringent industry standards.

These certifications are not just badges; they represent a deeply embedded culture of quality, continuous improvement, and rigorous process adherence. They provide independent validation of our capabilities and our ability to consistently deliver high-precision parts.

For clients in regulated industries, our compliance with these international standards offers peace of mind and significantly streamlines their qualification processes. Our technical autonomy allows us to integrate these standards seamlessly into our proprietary processes.

**Success Case Highlight:**

We partnered with a global medical device manufacturer to produce precision aluminum components for a new surgical instrument. Our AS9100 certified processes and strict quality control protocols, including 100% CMM inspection of critical features, ensured that every batch met the exceptionally tight +/- 0.005 mm tolerances and Ra 0.2 µm surface finish. This meticulous approach directly contributed to the client’s successful FDA approval for their product.

Partnering for Precision Success

Choosing the right manufacturing partner is as crucial as the design itself when precision is paramount. As a leading source factory with a strong global presence, we offer more than just machining services; we provide a complete partnership approach, ensuring your project’s success from concept to delivery.

Our reputation as a professional CNC machining factory with substantial industry experience is built on consistently delivering high-quality, cost-effective solutions tailored to complex needs.

Strategic Selection of a Manufacturing Partner

When seeking a partner for high-precision aluminum CNC machining, consider several critical factors. Beyond just quoting the lowest price, evaluate a factory’s technical capabilities, quality control systems, and commitment to customer service.

Look for a partner that demonstrates robust equipment strength, proven expertise in advanced machining techniques, and comprehensive quality certifications. A factory with extensive industry experience and a track record of successful projects, especially in complex areas, is invaluable.

Our factory offers a unique combination of all these attributes, positioning us as the preferred choice for demanding projects. Our processing expertise in aluminum is particularly deep, ensuring optimal results for your specific applications.

Our Comprehensive Service Offerings

We pride ourselves on offering full-process service, encompassing every stage of your project. This begins with expert design for manufacturability (DFM) consultation, where our engineers work with you to optimize designs for precision and cost-efficiency.

Our services extend through material procurement, advanced CNC machining, precision post-processing, assembly, and rigorous final inspection. We also manage logistics, offering fast delivery solutions to clients worldwide, including international orders.

This end-to-end capability simplifies your supply chain, reduces coordination efforts, and ensures seamless execution, all under one roof. Our full-chain quality control ensures consistent excellence at every step.

- **Our Service Advantages:**

- Expert DFM consultation.

- Optimized material sourcing.

- Advanced multi-axis machining.

- Comprehensive post-processing (finishing, coatings).

- Precision assembly and testing.

- Global logistics and fast delivery.

- Dedicated customer support.

Commitment to Innovation and R&D

Our status as a technology-leading manufacturer is sustained by a continuous commitment to innovation and research and development. We invest significantly in exploring new machining technologies, tooling advancements, and process optimizations.

This includes developing proprietary techniques for enhancing surface finish, improving material utilization, and reducing cycle times for complex aluminum components. Our technical autonomy allows us to rapidly adapt and integrate these innovations into our production lines.

This forward-thinking approach ensures that our clients always benefit from the latest advancements, keeping them at the forefront of their respective industries. Our specific patent technologies often solve common industry challenges, providing a unique competitive edge.

Tailored Solutions and Scalable Production

We understand that every project is unique, with distinct requirements for precision, volume, and budget. Whether you need a small batch of highly specialized prototypes or large-scale production runs, our scalable capacity ensures we can meet your needs efficiently.

Our flexible manufacturing system allows us to adapt quickly to changing demands, delivering both high-precision, small-batch components and larger volumes without compromising on quality or lead times. Our pricing logic is transparent, designed to offer maximum value without hidden costs, making us a cost-effective choice for both small and large orders.

We serve a global clientele, adept at managing international orders and providing seamless support regardless of geographical location. Our export capabilities are robust, ensuring timely and compliant delivery to any destination.

Conclusion

The pursuit of precision in aluminum CNC machining is a journey that demands expertise, advanced technology, and an unwavering commitment to quality. As we have explored, achieving exceptionally tight tolerances and superior surface finishes is a complex interplay of material science, cutting-edge equipment, environmental control, and meticulous process management. Our factory stands at the forefront of this endeavor, leveraging our core advantages, technical highlights, and full-chain quality control to deliver solutions that consistently exceed expectations.

We have demonstrated how our state-of-the-art equipment, advanced machining techniques, and comprehensive quality control systems, backed by industry certifications, ensure that every aluminum component we produce meets the most stringent requirements. Our commitment to innovation and full-process service makes us more than just a supplier; we are a strategic partner dedicated to bringing your most demanding designs to life with unparalleled accuracy and reliability.

If you are looking for a trusted source factory that can unlock the full precision potential of aluminum CNC machining for your next critical project, look no further. Contact our expert team today to discuss your specific requirements and discover how our advanced solutions can elevate your products. Let us help you achieve manufacturing excellence and bring your innovations to market with confidence.

Related Questions Section

**What are common challenges in high-precision aluminum CNC machining?**

High-precision aluminum CNC machining presents several challenges, primarily thermal expansion of the workpiece and machine, which can cause dimensional inaccuracies if not carefully controlled. Another significant challenge is achieving ultra-fine surface finishes without introducing micro-burrs or tool marks, requiring specialized tooling and optimized cutting strategies. Chip evacuation, especially in deep pockets or complex geometries, can also be difficult, potentially leading to tool breakage or surface damage. Furthermore, the selection of the correct aluminum alloy and its specific machinability characteristics is crucial; some alloys are prone to gumming or excessive wear, demanding precise parameter adjustments and advanced coolant systems. Our factory addresses these by employing temperature-controlled environments, advanced CAD/CAM software for toolpath optimization, high-pressure coolant systems, and rigorous in-process monitoring to ensure consistency and quality.

**How do material properties affect precision in aluminum CNC machining?**

Material properties profoundly impact the achievable precision in aluminum CNC machining. Hardness and tensile strength influence tool wear and cutting forces; softer alloys may be prone to built-up edge, while harder ones might increase tool deflection and necessitate slower feeds. The thermal conductivity and coefficient of thermal expansion of the alloy dictate how much the material will expand or contract during machining due to heat generation, which directly affects dimensional accuracy. For instance, aluminum’s relatively high thermal expansion means temperature control is vital. Ductility affects chip formation and surface finish; highly ductile alloys can create stringy chips that are difficult to evacuate, potentially marring the surface. Understanding these properties allows our engineers to select optimal cutting tools, speeds, feeds, and cooling methods to counteract negative effects and achieve the desired precision.

**What quality certifications should I look for in an aluminum CNC machining partner?**

When selecting an aluminum CNC machining partner for high-precision projects, several quality certifications signal a commitment to excellence and reliable processes. ISO 9001 is a foundational certification, indicating a robust general quality management system. For industries with stringent requirements, such as aerospace, medical, or defense, AS9100 (aerospace) or ISO 13485 (medical devices) are critical, as they demonstrate adherence to exceptionally high standards for risk management, traceability, and documentation. These certifications assure that the manufacturing facility follows rigorous protocols for process control, inspection, and continuous improvement. Our factory proudly holds multiple industry certifications, including ISO 9001 and AS9100, providing our clients with the highest level of confidence in our ability to consistently deliver precision components that meet their specific regulatory and performance demands.