In the relentless pursuit of ultimate speed, agility, and durability, every gram and micron counts for bicycle components. Designers and manufacturers constantly seek to push the boundaries of performance and rider experience.

Failing to master the intricacies of material selection and manufacturing precision can result in components that fall short of critical strength-to-weight targets or exhibit reduced fatigue life. This directly compromises rider safety, brand reputation, and the competitive edge in a demanding market.

Discover how mastering the intersection of advanced material science and precision CNC machining is not just an advantage, but a necessity for peak performance and innovation in the cycling industry.

Precision CNC machining, combined with judicious material selection, is paramount for producing high-performance, durable, and lightweight bicycle components that redefine rider experience.

The Core Value of CNC Machining in Bicycle Components

Precision & Performance in Bicycle Part Manufacturing

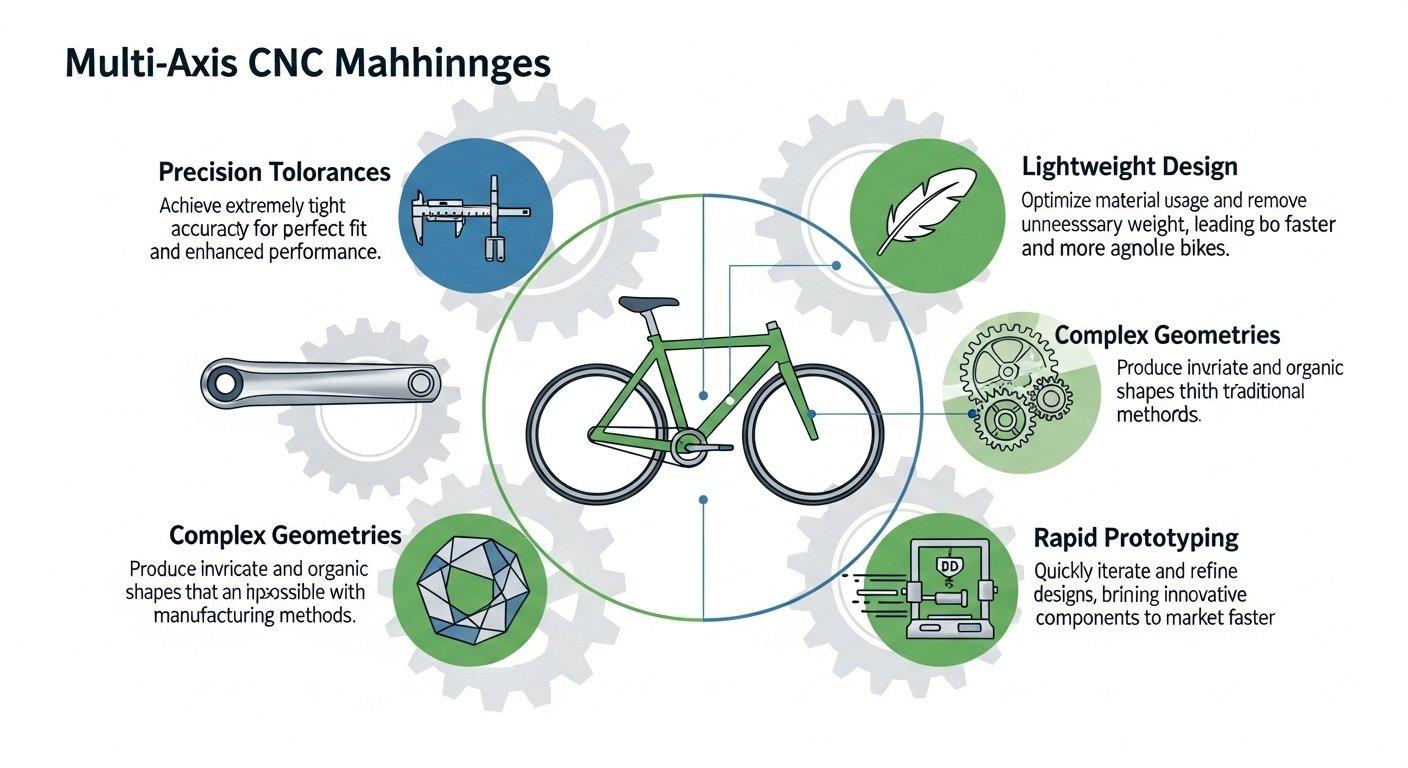

CNC machining offers unparalleled accuracy, enabling the creation of complex geometries and extremely tight tolerances. This precision is critical for the functional integrity and smooth operation of interconnected bicycle components, such as derailleur hangers and brake calipers.

The consistency achieved through CNC ensures optimal mechanical efficiency and reliable performance, directly impacting rider safety and the overall quality feel of the bicycle. It guarantees that every component meets rigorous engineering specifications.

Lightweighting & Durability Advantages for Cycling

Through sophisticated tool path optimization, CNC machining allows for strategic material removal to create internal structures that significantly reduce weight. This is achieved without compromising the structural integrity or strength of the component.

This advanced control over geometry enhances fatigue resistance and ensures consistent material properties across large production batches. Resulting parts exhibit superior durability under the stresses of competitive cycling and daily use.

Design Flexibility & Innovation in Bicycle Parts

CNC technology empowers engineers and designers to realize highly complex, organic shapes and intricate designs previously unattainable with traditional manufacturing methods. It unlocks new possibilities for aerodynamic and ergonomic optimization.

This flexibility also facilitates rapid prototyping and iterative design cycles, significantly accelerating new product development. Brands can quickly test and refine innovative bicycle parts, bringing cutting-edge solutions to market faster.

Critical Material Selection for CNC Bicycle Components

Strength-to-Weight Ratio and Fatigue Resistance Needs

For performance-oriented CNC bicycle components, a high strength-to-weight ratio is paramount, as every gram contributes to overall bike mass. Engineers must select materials that offer maximum strength with minimal weight.

Equally important is excellent fatigue resistance, as bicycle parts are subjected to countless stress cycles during riding. Materials must withstand repetitive loading without premature failure to ensure long-term reliability.

Corrosion Resistance and Environmental Durability

Bicycle components are frequently exposed to diverse environmental conditions, including rain, sweat, mud, and road salts. The chosen material must exhibit robust corrosion resistance to maintain aesthetic and structural integrity over time.

This durability ensures a longer service life and reduces the need for frequent maintenance or replacement, which is a key consideration for both manufacturers and end-users.

Cost-Effectiveness vs. Performance Demands

Material selection inherently involves a balance between performance and cost. While premium materials offer superior properties, their higher cost can impact the final product’s market positioning and accessibility.

Strategic material choice ensures that the component meets performance targets within an acceptable cost framework, aligning with the specific segment of the bicycle market it serves.

Machinability and Surface Finish Requirements

The ease with which a material can be machined directly influences production efficiency, tooling wear, and overall manufacturing costs. Materials with good machinability allow for faster processing and finer details.

Furthermore, the inherent properties of the material dictate the achievable surface finish. This is vital for both the aesthetic appeal of the part and its functional performance, particularly in areas of high friction or precision mating.

Key Material Selection Criteria

| Factor | Importance for Bicycle Parts |

|---|---|

| Strength-to-Weight Ratio | High (critical for performance) |

| Fatigue Resistance | High (repeated stress cycles) |

| Corrosion Resistance | Medium to High (environmental exposure) |

| Machinability | Medium to High (production efficiency) |

| Cost | Variable (performance vs. budget) |

Common Materials in CNC Machined Bicycle Parts

Aluminum Alloys (6061, 7075) for Bicycle Applications

Aluminum 6061 is highly valued for its good strength, excellent weldability, and corrosion resistance, making it a versatile choice for frames, stems, and general-purpose components. Its widespread use makes it cost-effective.

Aluminum 7075, an aerospace-grade alloy, offers significantly higher strength and is ideal for high-stress parts like crank arms, chainrings, and high-performance hubs. It provides an excellent strength-to-weight ratio for demanding applications.

Titanium Alloys (Ti-6Al-4V) for Premium Bike Parts

Ti-6Al-4V titanium alloy is celebrated for its exceptional strength-to-weight ratio, unparalleled corrosion resistance, and remarkable fatigue life. These properties make it the material of choice for high-end frames, spindles, and critical fasteners.

Its premium cost is offset by its superior performance and longevity, appealing to riders seeking the ultimate in durability and lightweight construction.

Stainless Steel (304, 316) for Specific Components

Stainless steel, particularly grades 304 and 316, offers excellent corrosion resistance and good strength, though it is denser than aluminum. It is indispensable for specific components where robust durability and environmental immunity are paramount.

Common applications include hardware, pivot points, small intricate mechanisms in shifting systems, and specific brake components where wear resistance is crucial.

Engineering Plastics for Lightweight, Specialized Use

Advanced engineering plastics like PEEK or glass-fiber reinforced Nylon are utilized for their very lightweight properties, low friction, and electrical insulating capabilities. These materials are suitable for specialized, non-structural components.

They find application in chain guides, derailleur pulley wheels, spacers, and small housings where reducing rotational mass and minimizing friction are primary objectives.

Common CNC Bicycle Materials Comparison

| Material | Key Properties | Typical Bicycle Use Cases |

|---|---|---|

| Aluminum 6061 | Good strength, weldable, corrosion-resistant | Stems, seatposts, basic chainrings |

| Aluminum 7075 | High strength, lightweight, aerospace-grade | Crank arms, high-performance chainrings |

| Titanium Ti-6Al-4V | Superb strength-to-weight, corrosion-resistant | High-end frames, spindles, critical fasteners |

| Stainless Steel 304/316 | High corrosion resistance, strong, durable | Bolts, pivots, small intricate mechanisms |

| Engineering Plastics | Very lightweight, low friction, insulating | Chain guides, pulley wheels, spacers |

Advanced CNC Processing Technology for Bicycle Parts

Multi-Axis CNC Machining for Complex Geometries

Multi-axis CNC machining, encompassing 3-axis, 4-axis, and particularly 5-axis capabilities, is crucial for producing intricate bicycle component geometries. It allows for machining complex curves and angles in a single setup, minimizing repositioning errors.

This capability is essential for parts like suspension linkages, integrated cockpits, and aerodynamic components, where seamless contours and precise interfaces are critical for performance and aesthetic integration.

High-Speed Machining (HSM) for Efficiency

High-Speed Machining (HSM) employs higher spindle speeds and feed rates with lighter depths of cut. This technique significantly reduces cycle times, especially for softer aluminum alloys, leading to greater production efficiency.

HSM also improves surface finish quality and minimizes heat buildup in the workpiece. This prevents material distortion and maintains critical tolerances, which is vital for high-performance bicycle parts.

Micro-Machining for Intricate Small Parts

Micro-machining techniques enable the creation of extremely small and highly precise components with exceptional detail. This method utilizes very fine tools and precise motion control to achieve intricate features and tight tolerances on miniature parts.

It is ideal for manufacturing internal mechanisms, small pivot pins, delicate sensor housings, or complex components found within modern electronic shifting systems.

Post-Processing and Surface Finishing for Bicycle Parts

Anodizing & Hard Anodizing for Durability & Aesthetics

Anodizing is a widely used electrochemical process that enhances the corrosion resistance, wear resistance, and aesthetic appeal of aluminum bicycle parts. It allows for a wide range of vibrant color options.

Hard anodizing creates a significantly thicker and denser oxide layer, providing superior abrasion and wear resistance. This is particularly beneficial for high-friction areas or components exposed to harsh conditions.

Polishing, Blasting, and Electroplating Options

Polishing can achieve a mirror-like finish, enhancing the visual appeal of components while also improving surface smoothness. Bead blasting or sandblasting creates a uniform matte or textured appearance, which can be desirable for grip or aesthetic purposes.

Electroplating, using materials like nickel or chrome, can be applied to enhance hardness, corrosion resistance, or to achieve specific metallic aesthetics, often seen on smaller hardware or intricate mechanisms.

Heat Treatment for Enhanced Material Properties

Heat treatment processes are critical for modifying the metallurgical properties of certain materials, such as aluminum and titanium alloys. For aluminum, processes like T6 tempering significantly increase strength and hardness.

For titanium components, specific heat treatments can relieve internal stresses induced during machining. This improves the material’s fatigue life and dimensional stability, ensuring long-term part integrity.

Quality Assurance & DFM in CNC Bicycle Part Production

Rigorous Inspection and Metrology Standards

Ensuring the highest quality in CNC machined bicycle components necessitates rigorous inspection protocols and advanced metrology. This includes using Coordinate Measuring Machines (CMM) and optical scanners to verify complex geometries and tight tolerances.

Every part undergoes thorough dimensional and geometric verification to ensure absolute adherence to design specifications and functional requirements.

Traceability and Material Certification

Complete traceability of raw materials is crucial for quality assurance and compliance. Each batch of material is accompanied by certification detailing its precise composition and mechanical properties.

This meticulous documentation ensures full accountability throughout the manufacturing process, from raw material sourcing to the final component, guaranteeing reliability and safety for critical bicycle parts.

Quality Assurance Milestones

| Phase | Key Activity | Purpose |

|---|---|---|

| Material Incoming | Certification check, spectral analysis | Verify material composition and properties |

| In-Process Inspection | Periodic dimensional checks, visual | Maintain critical tolerances during machining |

| Final Inspection | CMM scan, visual inspection, gauging | Confirm all specifications met, ensure quality |

| Documentation | Batch records, material certificates | Ensure traceability, compliance, and reliability |

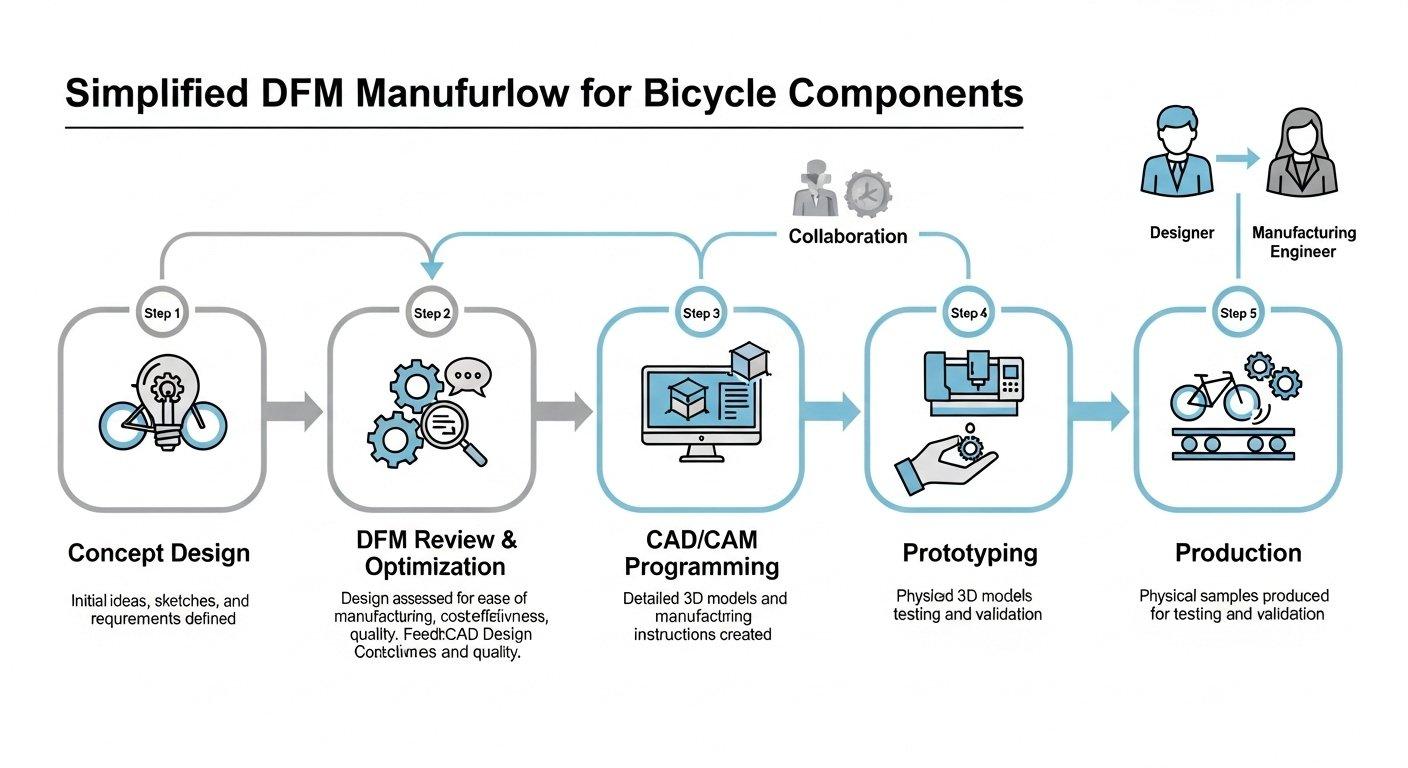

Design for Manufacturability (DFM) for Bicycle Components

Design for Manufacturability (DFM) is an essential collaborative approach that integrates manufacturing considerations early in the product design phase. This proactive strategy aims to optimize bicycle component designs for efficient, cost-effective, and high-quality production.

By identifying and addressing potential manufacturing challenges before production begins, DFM reduces lead times, minimizes material waste, and ensures that the final product meets both performance and cost targets.

Future Trends in CNC Bicycle Component Innovation

The future of CNC bicycle component innovation is characterized by continued exploration of advanced materials, including novel alloys, composites, and hybrid structures for even greater performance. Integration of additive manufacturing with subtractive methods is also emerging.

Furthermore, the integration of artificial intelligence and advanced automation in CNC programming and production processes promises further optimization of manufacturing efficiency, customization capabilities, and part quality.

Partnering for Excellence in CNC Bicycle Parts

The Benefits of a Source Manufacturer with Deep Expertise

Partnering with a source manufacturer like ly-machining, based in Shenzhen, China, provides direct access to deep engineering expertise and state-of-the-art facilities. This translates into unparalleled cost efficiencies and transparent communication throughout the project.

Working directly with the manufacturing origin streamlines the supply chain, reduces lead times, and offers greater control over every aspect of the production process, from material selection to final quality assurance.

Your Trusted Partner for High-Performance Bicycle Components

With a profound understanding of material science and advanced CNC processing, ly-machining stands as your trusted partner for high-performance bicycle components. Our commitment to precision, quality, and innovation ensures that your designs are transformed into superior realities.

We are dedicated to supporting your brand’s pursuit of excellence, providing the technical acumen and manufacturing capabilities necessary to achieve market leadership and enhance the ultimate rider experience.

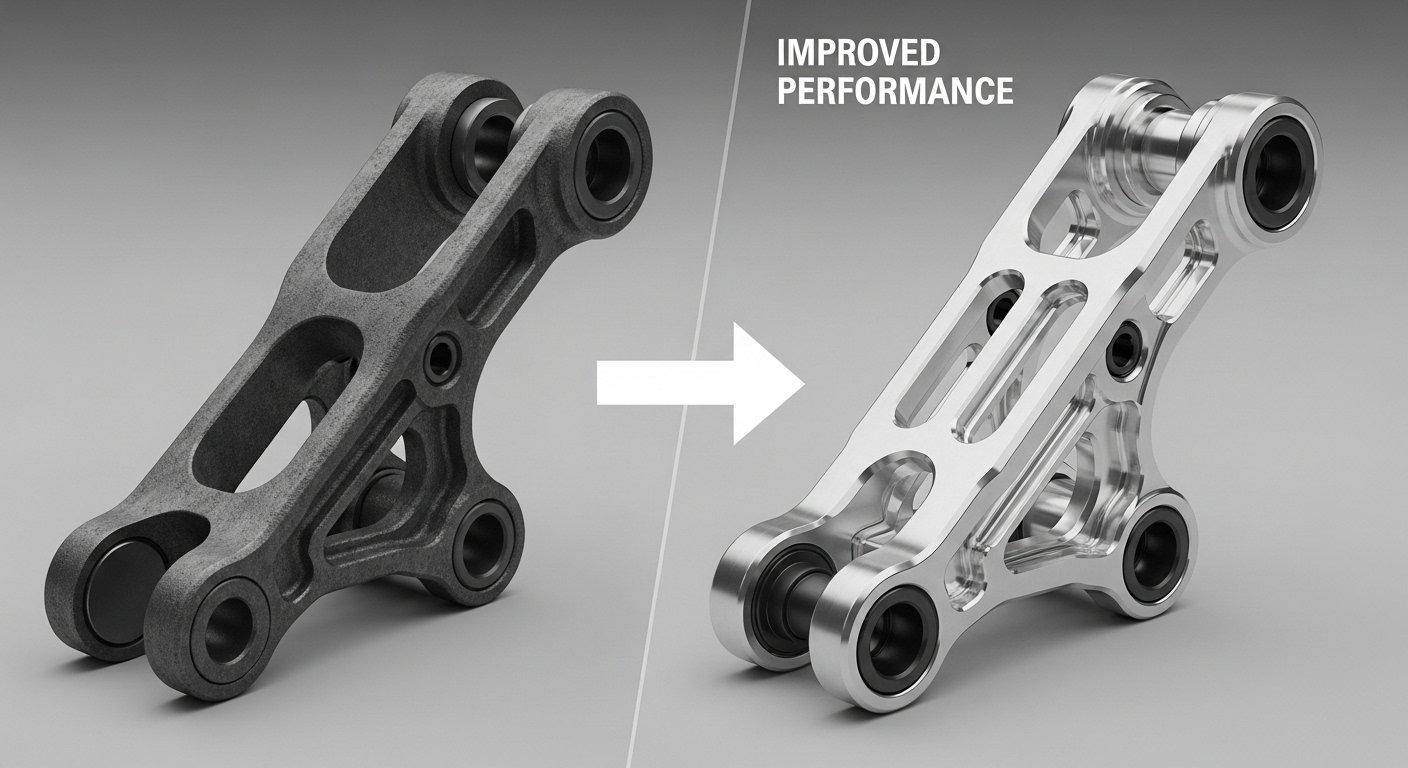

Case Study: Enhancing Suspension Linkage Performance

A client, a renowned high-end mountain bike manufacturer, sought to drastically reduce the weight of a critical suspension linkage while simultaneously increasing its rigidity and fatigue life. Their existing cast aluminum component was heavy and prone to flex under extreme riding conditions, impacting bike responsiveness.

Our engineering team collaborated closely, recommending a switch to precision CNC machined 7075-T6 aluminum. We optimized the part’s geometry through DFM principles, leveraging 5-axis machining to create intricate internal structures for weight reduction and integrated mounting points for enhanced stiffness. We also specified hard anodizing for superior wear resistance.

The redesigned linkage achieved a 28% weight reduction and a 15% increase in torsional rigidity, validated by FEA and physical testing. This enabled the client to launch a lighter, more responsive, and durable suspension system, significantly enhancing their bike’s performance and market appeal.

Ready to elevate your bicycle component designs? Get a free quote or technical consultation from our expert engineering team today.

Why CNC for bicycle components?

Precision CNC machining offers unparalleled accuracy, enabling the creation of complex geometries and tight tolerances critical for high-performance bicycle parts. This leads to superior mechanical function, enhanced durability, and significant weight savings.

What materials are best for bike parts?

Optimal material selection depends on specific component requirements. High-strength aluminum alloys (6061, 7075) are common for their strength-to-weight ratio. Titanium (Ti-6Al-4V) is preferred for premium parts requiring extreme durability and corrosion resistance.

How does DFM improve components?

Design for Manufacturability (DFM) integrates manufacturing considerations early in the design process. This minimizes production challenges, reduces costs, and optimizes part performance, ensuring efficient and effective component realization.