Choosing the right material for your custom CNC machined part is not merely a technical specification; it is a foundational decision that profoundly influences performance, cost, and ultimately, your project’s success. An incorrect choice can lead to significant delays and compromised product integrity.

Many engineers and procurement specialists face an overwhelming array of options, struggling to balance precise technical requirements with economic viability. This article serves as your comprehensive guide, illuminating the properties and applications of 10 essential materials critical for modern custom CNC machining.

We will provide the expert insights necessary to confidently navigate material selection, ensuring your components achieve optimal functionality and value.

Selecting the optimal custom CNC machining materials is paramount for achieving superior part performance and cost-efficiency.

Material Choices Matter

Setting the Scene: The Critical Decision

Avoid Costly Errors: The Material Dilemma

The selection of custom CNC machining materials is a decision that extends far beyond initial cost, directly impacting a product’s lifespan, functionality, and market viability. Overlooking crucial material properties can lead to component failure, costly redesigns, and a diminished return on investment.

Engineers frequently contend with trade-offs between strength, weight, corrosion resistance, and machinability, making the material dilemma a central challenge in product development. Our factory’s deep technical expertise assists clients in navigating these complexities effectively.

Precision Parts: Your Performance Foundation

Every precision part begins with its foundational material, which dictates its inherent capabilities and limitations in its intended application. The material choice sets the stage for how a component will perform under stress, temperature, or corrosive environments.

Understanding the specific attributes of various industrial CNC materials is therefore critical to engineering success and to ensuring the longevity and reliability of the final product. We consistently deliver high-quality parts by emphasizing this foundational understanding.

Your Expert Guide: What You’ll Discover

Navigate Material Selection with Clarity

This guide is meticulously crafted to demystify the vast landscape of materials available for custom CNC machining, offering a clear framework for informed decision-making. We will delve into the unique characteristics and best-use cases for each of 10 essential materials.

Our objective is to empower you with the knowledge to make strategic material choices that align precisely with your project’s functional and budgetary requirements. This serves as an invaluable CNC material selection guide for your engineering needs.

Unlock Key Alloys, Benefits, & Our Expertise

By exploring the properties of key alloys and engineering plastics, you will gain insights into their respective advantages and specific applications. This knowledge, combined with our source manufacturer capabilities, ensures optimal results.

Our transparent pricing model and deep technical expertise mean you not only receive superior parts but also benefit from a collaborative partnership. We guide you through the intricacies of choosing the right precision machining alloys for your designs.

Core Metals: Strength & Versatility

Aluminum Alloys: Light & Machinable

Aluminum alloys are widely favored in custom CNC machining for their exceptional strength-to-weight ratio and excellent machinability, making them indispensable across various industries. They offer a versatile combination of properties ideal for diverse applications.

Their inherent corrosion resistance and ability to take on various surface finishes further enhance their appeal for components requiring both performance and aesthetic quality. These attributes make aluminum a staple among industrial CNC materials.

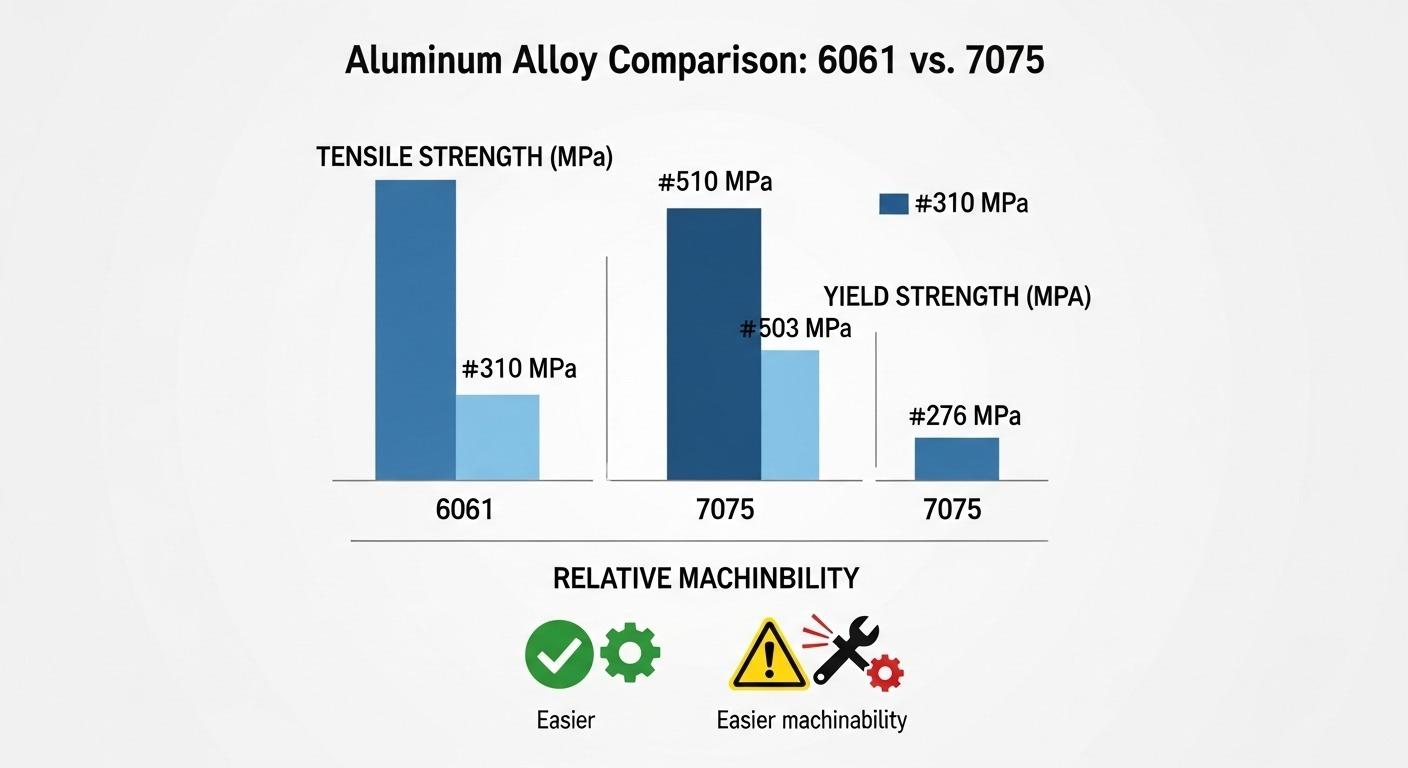

Aluminum 6061: General Purpose Workhorse

Aluminum 6061 is arguably the most common and versatile aluminum alloy for CNC machining due to its superb mechanical properties and good weldability. It offers a respectable balance of strength, corrosion resistance, and machinability.

It is frequently specified for structural components, frames, fixtures, and automotive parts where moderate strength is sufficient. Its ease of machining makes it a cost-effective choice for many custom CNC machining materials applications.

Table: Aluminum 6061 Properties

| Property | Value / Characteristic |

|---|---|

| Tensile Strength | 124-310 MPa |

| Yield Strength | 55-276 MPa |

| Density | 2.70 g/cm³ |

| Machinability | Excellent |

| Corrosion Res. | Good |

Aluminum 7075: Demanding High Strength

Aluminum 7075 stands out for its remarkably high strength, comparable to many steels, making it suitable for applications requiring maximum durability. This alloy achieves its strength through zinc as the primary alloying element.

It is extensively used in aerospace, automotive, and sporting goods industries where components are subjected to high stresses and extreme conditions. However, its machinability is lower than 6061, requiring specialized tooling and machining strategies for precision machining alloys.

Table: Aluminum 7075 Properties

| Property | Value / Characteristic |

|---|---|

| Tensile Strength | 503-572 MPa |

| Yield Strength | 434-503 MPa |

| Density | 2.81 g/cm³ |

| Machinability | Good (Challenging) |

| Corrosion Res. | Moderate |

Stainless Steels: Durable & Corrosion Resistant

Stainless steels are distinguished by their exceptional resistance to corrosion, high strength, and aesthetic appeal, making them ideal for environments demanding durability and hygiene. Their chromium content forms a passive layer, preventing rust.

They are widely employed in medical devices, food processing equipment, marine applications, and consumer products where longevity and resistance to degradation are critical. Our factory regularly machines these precision machining alloys.

Stainless Steel 303: Ease of Machining

Stainless Steel 303 is a free-machining grade, specifically designed for improved machinability compared to other stainless steels, primarily due to the addition of sulfur. This makes it a preferred choice for complex parts requiring extensive CNC machining.

While offering good corrosion resistance, it is slightly less resistant than 304 or 316. It is often used for shafts, gears, valves, and fasteners where good machinability and moderate corrosion resistance are key.

Table: Stainless Steel 303 Properties

| Property | Value / Characteristic |

|---|---|

| Tensile Strength | 515 MPa |

| Yield Strength | 205 MPa |

| Density | 7.90 g/cm³ |

| Machinability | Excellent |

| Corrosion Res. | Good |

Stainless Steel 304/316: Superior Rust Protection

Stainless Steel 304 and 316 are austenitic grades known for their superior corrosion resistance and excellent mechanical properties, with 316 offering enhanced resistance, particularly to chlorides. They are non-magnetic in their annealed state.

These grades are essential for chemical processing, marine environments, pharmaceutical equipment, and architectural applications. Our capabilities with custom CNC machining materials ensure high-quality parts from these robust alloys.

Table: Stainless Steel 304/316 Properties

| Property | SS 304 Value / Char. | SS 316 Value / Char. |

|---|---|---|

| Tensile Strength | 515 MPa | 579 MPa |

| Yield Strength | 205 MPa | 290 MPa |

| Density | 8.00 g/cm³ | 8.00 g/cm³ |

| Machinability | Good | Good |

| Corrosion Res. | Excellent | Superior (Chlorides) |

Advanced Alloys: Precision & Resilience

Specialty Steels: Hardness & Wear Resistance

Specialty steels are engineered to deliver superior performance in demanding applications, characterized by their exceptional hardness, strength, and wear resistance. These properties are often achieved through precise alloying and heat treatment.

They are indispensable in tooling, heavy machinery, and high-stress components where conventional steels would fail rapidly. Our precision machining alloys expertise extends to these complex materials.

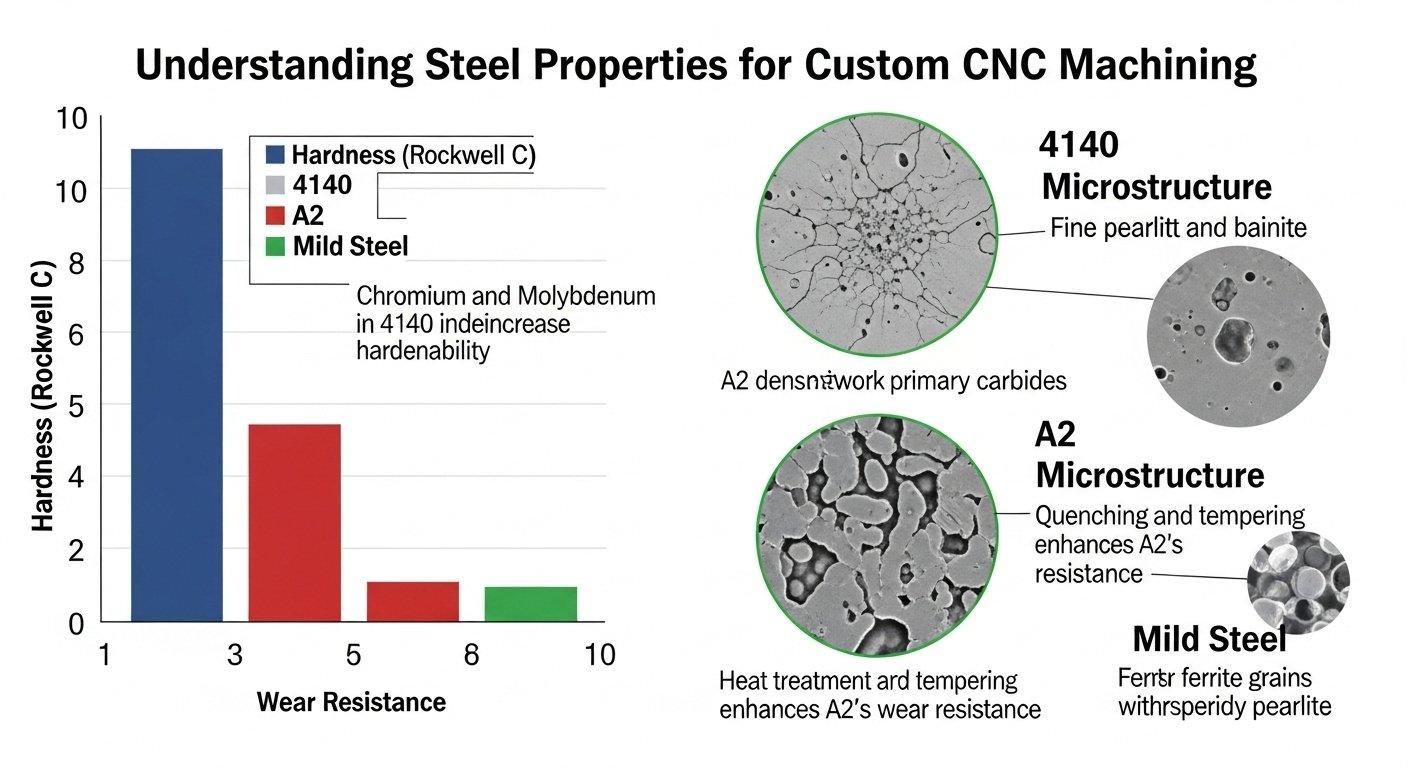

4140 Alloy Steel: Toughness for Heavy Loads

4140 Alloy Steel is a chromium-molybdenum alloy steel renowned for its excellent toughness, high fatigue strength, and good wear resistance. It responds well to heat treatment, allowing for a wide range of strength and hardness.

This material is frequently specified for heavy-duty components such as shafts, gears, bolts, and connecting rods in automotive and industrial machinery. It is a critical industrial CNC material for high-performance applications.

Table: 4140 Alloy Steel Properties

| Property | Value / Characteristic |

|---|---|

| Tensile Strength | 655-1080 MPa |

| Yield Strength | 415-760 MPa |

| Density | 7.85 g/cm³ |

| Machinability | Good (Heat Treated) |

| Wear Resistance | High |

A2 Tool Steel: High Wear, Extended Life

A2 Tool Steel is a versatile, air-hardening, medium-alloy tool steel known for its exceptional wear resistance and dimensional stability during heat treatment. It offers a good balance of toughness and hardness.

It is typically used for dies, punches, molds, and other cutting or forming tools where prolonged service life and resistance to abrasion are paramount. Machining A2 requires specialized techniques due to its inherent hardness, reinforcing the importance of an expert CNC material selection guide.

Table: A2 Tool Steel Properties

| Property | Value / Characteristic |

|---|---|

| Hardness (HRC) | 57-62 (Heat Treated) |

| Wear Resistance | Very High |

| Density | 7.85 g/cm³ |

| Machinability | Moderate (Annealed) |

| Dimensional Stab. | Excellent |

Titanium Alloys: Ultimate Strength-to-Weight

Titanium alloys are celebrated for their unparalleled strength-to-weight ratio, excellent corrosion resistance, and biocompatibility, making them indispensable for highly critical applications. They outperform many other metals in demanding environments.

Their unique combination of properties makes them ideal for aerospace, medical implants, high-performance automotive, and marine industries. Working with these precision machining alloys requires significant expertise.

Ti 6Al-4V (Grade 5): Aerospace & Medical Use

Ti 6Al-4V, commonly known as Grade 5 titanium, is the most widely used titanium alloy, accounting for 50% of all titanium usage. It offers an excellent balance of strength, ductility, and fracture toughness.

Its superior properties make it the material of choice for aerospace components, surgical implants, and high-performance sports equipment. Machining Ti 6Al-4V requires specific cutting parameters and tooling due to its low thermal conductivity and high reactivity.

Table: Ti 6Al-4V (Grade 5) Properties

| Property | Value / Characteristic |

|---|---|

| Tensile Strength | 895-1000 MPa |

| Yield Strength | 828-930 MPa |

| Density | 4.43 g/cm³ |

| Machinability | Challenging |

| Corrosion Res. | Excellent |

Beyond Metals: Specialized Performance

Engineering Plastics: Lightweight & Insulating

Engineering plastics offer a distinct set of advantages for custom CNC machining, including lightweight properties, electrical insulation, and chemical resistance. They are often chosen when metallic properties are either unnecessary or undesirable.

These materials are excellent for components needing reduced weight, thermal stability, or biocompatibility, expanding the scope of industrial CNC materials beyond traditional metals. Their versatility supports a wide range of applications.

Delrin (Acetal): Low Friction, High Accuracy

Delrin, a brand name for Acetal homopolymer (POM), is a high-strength, low-friction engineering plastic known for its excellent dimensional stability and machinability. It maintains its properties well across a range of temperatures.

It is frequently used for gears, bearings, bushings, and other mechanical components where self-lubrication and precision are critical. Delrin offers a cost-effective alternative to metals in many applications, simplifying the CNC material selection guide.

Table: Delrin (Acetal) Properties

| Property | Value / Characteristic |

|---|---|

| Tensile Strength | 69 MPa |

| Density | 1.41 g/cm³ |

| Machinability | Excellent |

| Friction Coeff. | Low |

| Water Absorption | Low |

PEEK: Extreme Temperatures, High Strength

PEEK (Polyether Ether Ketone) is a high-performance engineering plastic renowned for its outstanding mechanical strength, chemical resistance, and ability to withstand extreme temperatures. It is often considered a metal replacement in demanding environments.

It finds extensive use in medical, aerospace, and oil & gas industries for components such as electrical connectors, pump gears, and surgical instruments. Machining PEEK to high tolerances showcases precision machining alloys capabilities in plastics.

Table: PEEK Properties

| Property | Value / Characteristic |

|---|---|

| Tensile Strength | 92-100 MPa |

| Density | 1.30 g/cm³ |

| Max Cont. Temp. | 260°C |

| Chemical Res. | Excellent |

| Biocompatibility | Excellent |

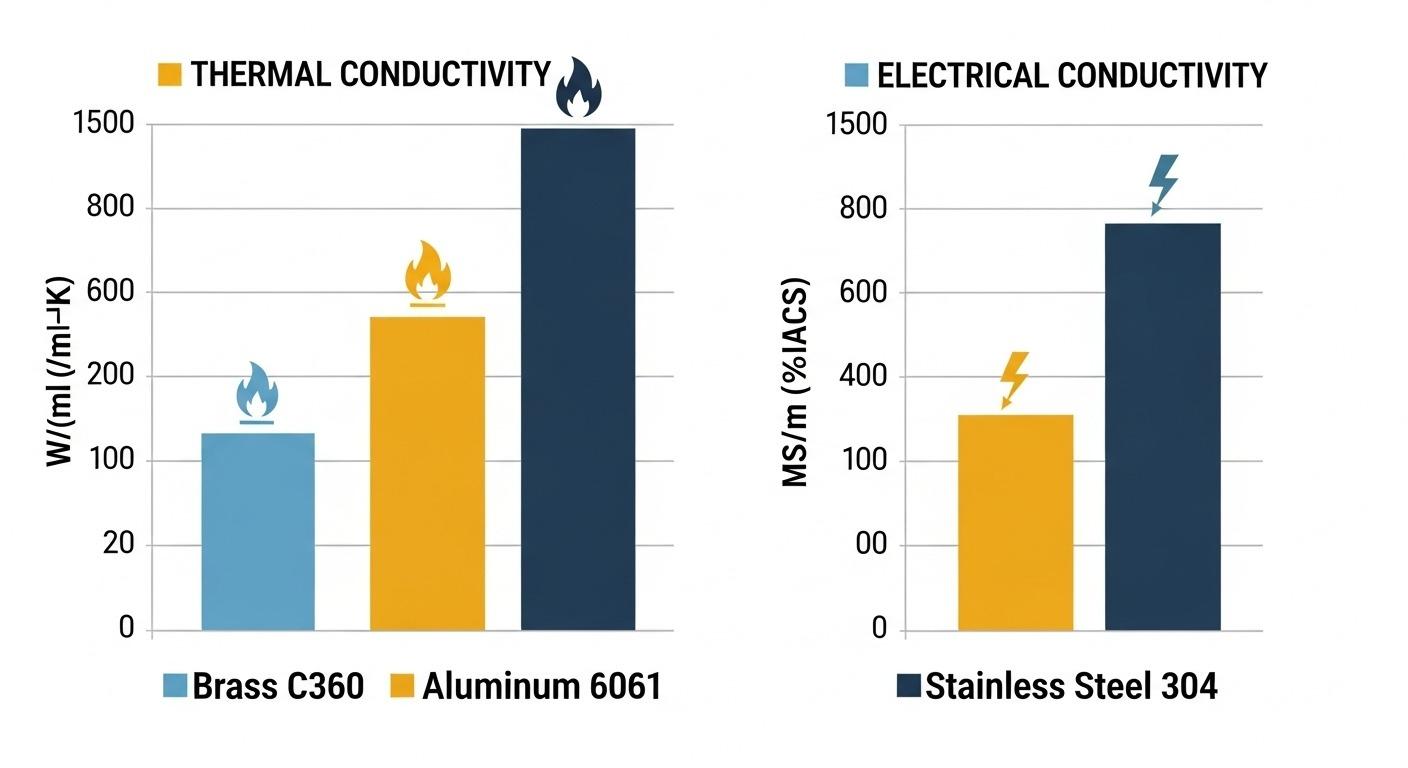

Copper Alloys: Conductivity & Thermal Management

Copper alloys are distinguished by their excellent electrical and thermal conductivity, making them crucial for applications requiring efficient energy transfer. They also possess good corrosion resistance and aesthetic qualities.

These materials are widely used in electronics, electrical components, plumbing, and decorative elements. Our factory produces high-quality parts from these specialized industrial CNC materials.

Brass (C360): Machinability & Electrical Uses

Brass C360, also known as Free Machining Brass, is specifically formulated for superior machinability due to its lead content. It offers good strength, corrosion resistance, and excellent electrical conductivity.

It is the preferred choice for fittings, connectors, valves, and various electrical components where intricate geometries and high production volumes are necessary. This makes it a highly valuable custom CNC machining material.

Table: Brass (C360) Properties

| Property | Value / Characteristic |

|---|---|

| Tensile Strength | 360-460 MPa |

| Electrical Cond. | 26% IACS |

| Density | 8.50 g/cm³ |

| Machinability | Excellent |

| Corrosion Res. | Good |

Strategic Selection: Optimal Part Success

Matching Material to Application: Our Process

The ultimate success of any custom CNC machining project hinges on matching the material’s inherent properties with the application’s specific demands. This requires a systematic approach, often involving iterative analysis and expert consultation.

Our engineering team collaborates closely with clients, scrutinizing performance criteria, operational environments, and desired lifespans to recommend the most suitable precision machining alloys. This ensures the delivery of high-quality parts every time.

Performance, Cost, & Machinability: The Balance

Achieving an optimal material selection involves a delicate balance between performance requirements, material cost, and machining feasibility. A material that is technically ideal but prohibitively expensive or difficult to machine may not be the best solution.

Our comprehensive CNC material selection guide considers all these factors, advising on choices that provide the best value without compromising critical specifications. We streamline this complex decision-making process.

Partnering for Perfection: Our Commitment

Transparent Pricing & Quality: Source Manufacturer

As a direct source manufacturer, we offer unparalleled transparency in our pricing, ensuring you understand the true cost of your high-quality parts without hidden fees or intermediaries. Our commitment to quality is ingrained in every process.

We guarantee consistent material integrity and adherence to specified tolerances, providing peace of mind from prototype to full-scale production. This direct relationship fosters trust and efficiency in custom CNC machining materials.

Deep Expertise: Custom Solutions for Complex Needs

Our team comprises seasoned engineers with deep technical expertise in a wide array of industrial CNC materials and machining processes. We thrive on challenges, offering bespoke solutions for even the most complex design requirements.

Whether it’s a novel alloy or an intricate geometry, we leverage our experience to deliver precise, reliable components. Partnering with us means gaining access to a wealth of knowledge and a dedication to engineering excellence.

Case Study

A prominent client in the medical device sector required a specialized surgical instrument component that demanded extreme biocompatibility, high strength, and intricate features. Their previous supplier struggled with maintaining tight tolerances using standard stainless steel, resulting in frequent rejections.

Our team at ly-machining engaged in a detailed technical consultation, reviewing the application’s specific sterile environment and stress requirements. We recommended transitioning from a standard 304 stainless steel to Ti 6Al-4V (Grade 5) titanium.

Leveraging our advanced 5-axis CNC machining capabilities and expertise with precision machining alloys, we successfully produced the complex component with unparalleled surface finish and dimensional accuracy. The client reported a 99% acceptance rate and superior instrument performance in clinical trials.

Call to Action

Ready to elevate your custom CNC machining project with optimized material selection and unparalleled precision? Contact our expert engineering team today for a personalized consultation and a transparent, competitive quote.

Let our deep technical expertise as a source manufacturer ensure your next project’s success, providing the high-quality parts you deserve.

Conclusion: Build Your Next Breakthrough

Key Insights: Your Material Mastery

Recap: The 10 Essential CNC Materials

This guide has explored ten essential custom CNC machining materials, from versatile aluminum and robust stainless steels to advanced titanium alloys and high-performance plastics. Each offers unique properties critical for diverse applications.

Understanding these industrial CNC materials empowers you to make informed decisions that directly impact your project’s technical success and economic viability. This knowledge is a cornerstone of modern engineering.

Choose Wisely: Optimize for Performance & Value

The selection process demands a careful weighing of performance requirements, budget constraints, and machinability. Making an informed choice ensures your components are not just functional, but optimized for their specific roles.

Our comprehensive CNC material selection guide provides the framework for this critical assessment, helping you achieve both superior performance and exceptional value in every part.

Your Next Step: Precision Machining Starts Here

Connect with Our Engineering Team for a Quote

With a foundational understanding of these key materials, your next step is to transform your designs into high-quality physical parts. Our factory stands ready to support your precision machining needs.

Reach out to our engineering specialists to discuss your project, leverage our deep technical expertise, and receive a transparent quote.

FAQ Section

What is the best material for CNC parts?

The “best” material depends entirely on the specific application’s requirements, including mechanical stress, environmental exposure, thermal properties, and budget. There is no single universal best material for all custom CNC machining projects.

For example, Aluminum 6061 is excellent for general purpose, while Ti 6Al-4V is superior for aerospace components due to its strength-to-weight ratio. Our CNC material selection guide emphasizes matching material to purpose.

How do you choose CNC materials?

Choosing CNC materials involves a systematic evaluation of several factors: required mechanical properties (strength, hardness), environmental conditions (corrosion, temperature), weight constraints, cost-effectiveness, and machinability. This comprehensive approach ensures optimal material selection.

Our engineering team provides expert consultation, leveraging our deep technical expertise to guide clients through this decision-making process. We ensure all critical parameters are considered for your precision machining alloys.

Why are material properties critical in CNC?

Material properties are critical in CNC machining because they dictate both the component’s final performance and the machining process itself. Properties like hardness, tensile strength, and thermal conductivity directly influence how a material behaves during cutting and in its end-use application.

Understanding these properties allows us to select appropriate tooling, cutting speeds, and feeds, ensuring efficient production of high-quality parts. It’s fundamental to working with industrial CNC materials.