Navigating PEEK CNC machining challenges to achieve high-precision PEEK parts requires specialized expertise in PEEK plastic processing, ensuring material integrity and superior performance.

When your product demands the superior properties of PEEK, but standard CNC struggles, where do you turn? The answer lies in understanding and mastering PEEK’s unique challenges. While PEEK offers unparalleled performance in extreme environments, its high-precision CNC machining presents formidable hurdles.

Are you struggling to achieve tight tolerances or pristine surface finishes on your critical PEEK components? Our factory possesses the deep technical expertise to transform these PEEK machining challenges into engineered success, delivering unparalleled performance and reliability.

PEEK Properties & CNC Machining Challenges

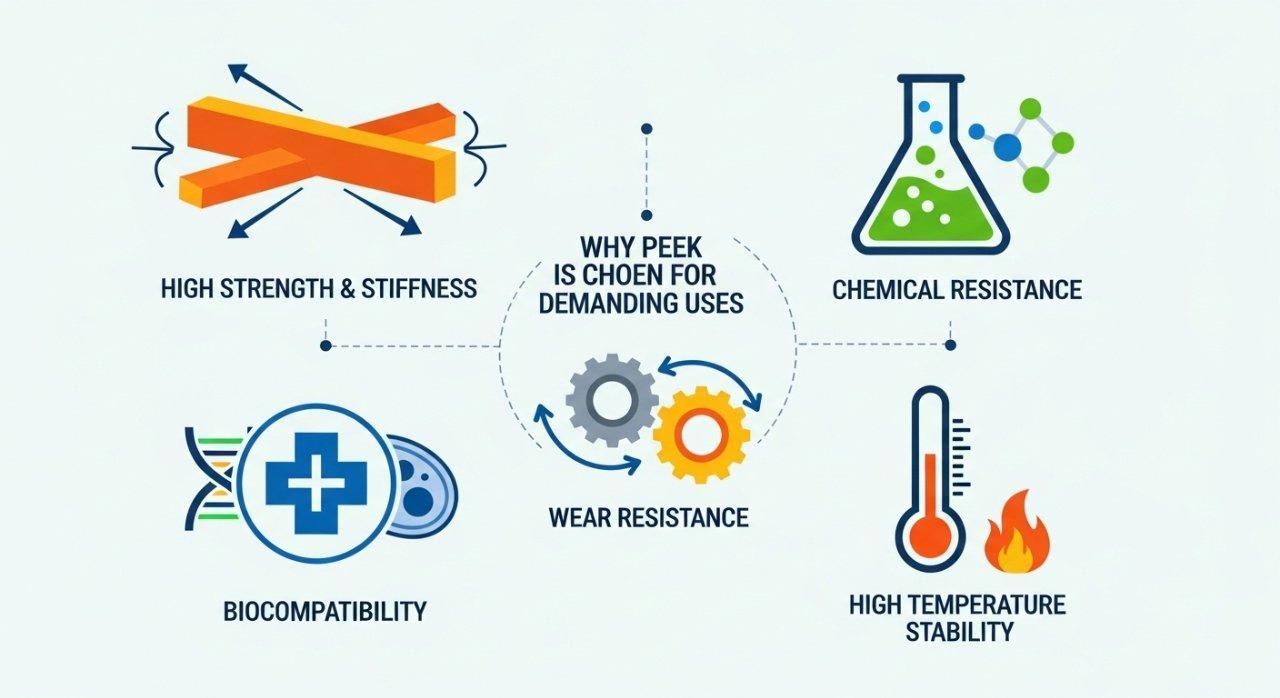

Why PEEK is chosen for demanding uses

PEEK (Polyether Ether Ketone) stands out as a high-performance thermoplastic, renowned for its exceptional strength-to-weight ratio. Its chemical resistance and excellent thermal stability make it indispensable.

In our experience, PEEK is increasingly specified for applications requiring operation in harsh environments. This includes exposure to aggressive chemicals, high temperatures, and significant mechanical loads, where other plastics fail.

These robust characteristics explain its widespread adoption in aerospace, medical devices, automotive, and semiconductor industries. Achieving high-precision PEEK parts is crucial for these critical applications.

Thermal expansion impact on PEEK parts

One of the significant PEEK machining challenges we routinely address is its relatively high coefficient of thermal expansion. This property causes material growth and shrinkage with temperature fluctuations.

During high-precision PEEK CNC machining, the heat generated from cutting significantly affects part dimensions. Inadequate management of this expansion can lead to out-of-tolerance parts, which are costly and time-consuming to correct.

Careful control of cutting parameters and effective cooling strategies are paramount. Without this, achieving the required accuracy for PEEK plastic processing becomes extremely difficult.

Material stress & internal crack risks

PEEK’s semi-crystalline structure means it can develop internal stresses during machining if not properly managed. Rapid heating and cooling cycles can induce stress, leading to material distortion.

In extreme cases, these internal stresses can manifest as micro-cracks or even delamination, compromising the structural integrity of the final high-precision PEEK component. This is a critical factor in PEEK machining challenges.

Our robust PEEK plastic processing protocols prioritize stress mitigation, ensuring the finished parts retain their inherent strength and reliability. We understand the delicate balance required to maintain material integrity.

Achieving fine PEEK surface finishes

Obtaining a smooth, burr-free surface finish on PEEK is a common hurdle in CNC machining. The material’s thermoplastic nature can lead to smearing, melting, or excessive burring if not processed correctly.

A poor surface finish not only affects aesthetics but also impacts the functional performance of the part. In medical or aerospace applications, surface quality is often a critical specification.

Our techniques for PEEK CNC machining focus on optimizing cutting parameters and tool geometry. This ensures we achieve the superior surface finishes required for even the most demanding high-precision PEEK applications.

Advanced Strategies for PEEK Precision CNC

Tooling selection for PEEK CNC success

The right tooling is fundamental to overcoming PEEK machining challenges. We exclusively use sharp, high-positive rake angle tools, typically made from carbide, specifically designed for plastics.

Tool coatings, such as diamond-like carbon (DLC), can significantly extend tool life and improve chip evacuation. These specialized tools minimize friction and heat buildup during PEEK plastic processing.

In our experience, investing in premium, application-specific tools pays dividends. It reduces rework and consistently achieves the fine tolerances associated with high-precision PEEK components.

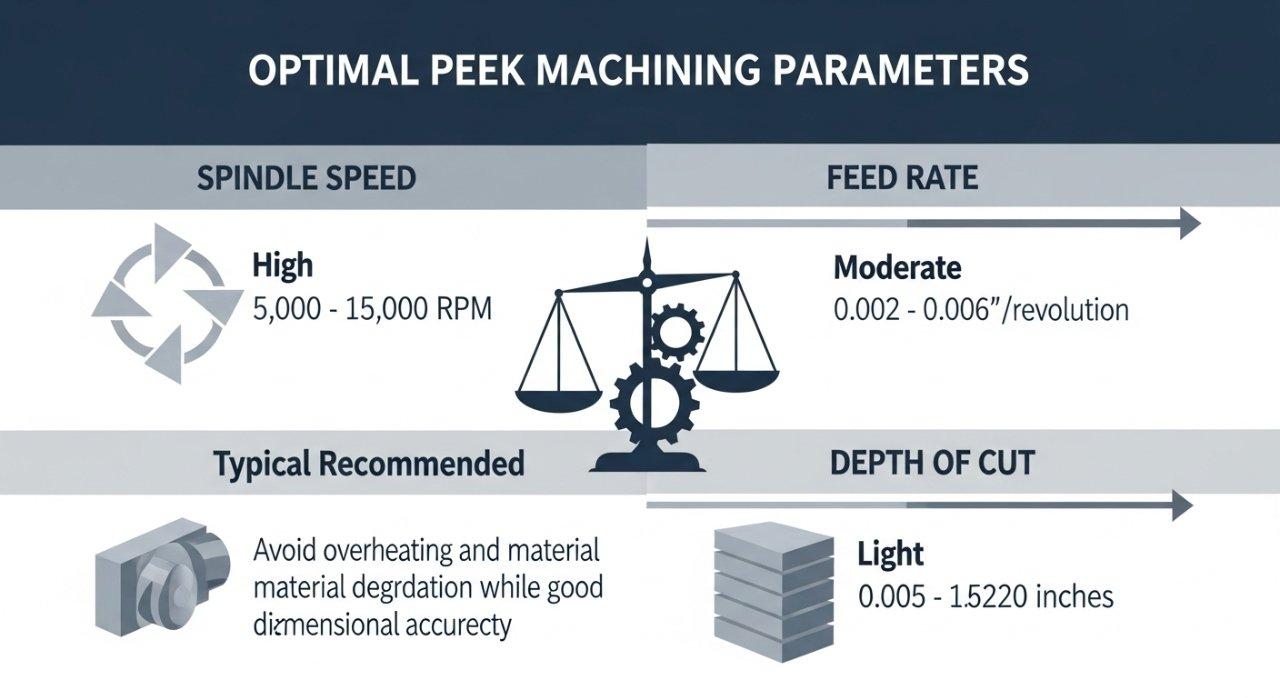

Optimal PEEK machining parameters

Establishing optimal speeds, feeds, and depths of cut is crucial for effective PEEK CNC machining. Parameters must balance material removal rates with heat generation and surface finish requirements.

For example, high spindle speeds combined with moderate feed rates often produce the best results for PEEK, preventing melting and promoting clean chip formation. Depth of cut should be carefully controlled.

We develop custom machining programs, continuously refined through extensive empirical testing. This ensures each PEEK component is processed under ideal conditions for high-precision PEEK manufacturing.

Fixturing & clamping PEEK parts

Secure and non-deforming fixturing is critical when machining PEEK. The material’s inherent flexibility, especially for thin-walled parts, necessitates careful clamping strategies to avoid distortion.

Over-clamping can induce stresses or warp the part, while under-clamping can lead to chatter and poor surface finishes. We design custom fixtures that evenly distribute clamping forces.

Our bespoke fixturing ensures dimensional stability throughout the PEEK CNC machining process. This method maintains the integrity of the part, preventing internal stresses and supporting high-precision PEEK outcomes.

Effective chip management in PEEK

Proper chip evacuation is often overlooked but vital for successful PEEK plastic processing. PEEK chips can be stringy and prone to re-welding to the workpiece or tool if not cleared efficiently.

Accumulated chips can lead to heat buildup, poor surface finishes, and even tool breakage. Our approach includes through-spindle coolant and optimized tool paths to facilitate chip removal.

This proactive chip management system is a cornerstone of our PEEK CNC machining strategy. It consistently contributes to achieving pristine surface finishes and tight tolerances on every part.

Cooling strategies for PEEK integrity

Managing thermal expansion and preventing material stress demands robust cooling strategies. We employ a combination of flood coolant and mist coolants depending on the specific application.

The coolant not only dissipates heat from the cutting zone but also lubricates the tool. This reduces friction and prevents the plastic from melting or smearing during high-precision PEEK operations.

Our carefully selected cooling methods are critical for maintaining dimensional stability. They also preserve the material integrity of PEEK components throughout the entire machining cycle.

Solving PEEK High-Precision Machining Issues

Preventing warping & deformation

Warping and deformation are common PEEK machining challenges primarily due to internal stresses and thermal expansion. Our multi-stage machining process is designed to mitigate these risks.

We utilize stress-relieving annealing steps between critical machining operations. This allows the material to relax, significantly reducing residual stresses that could cause distortion.

Coupled with optimized cutting parameters and precise coolant application, these measures ensure that high-precision PEEK parts maintain their intended geometry throughout production.

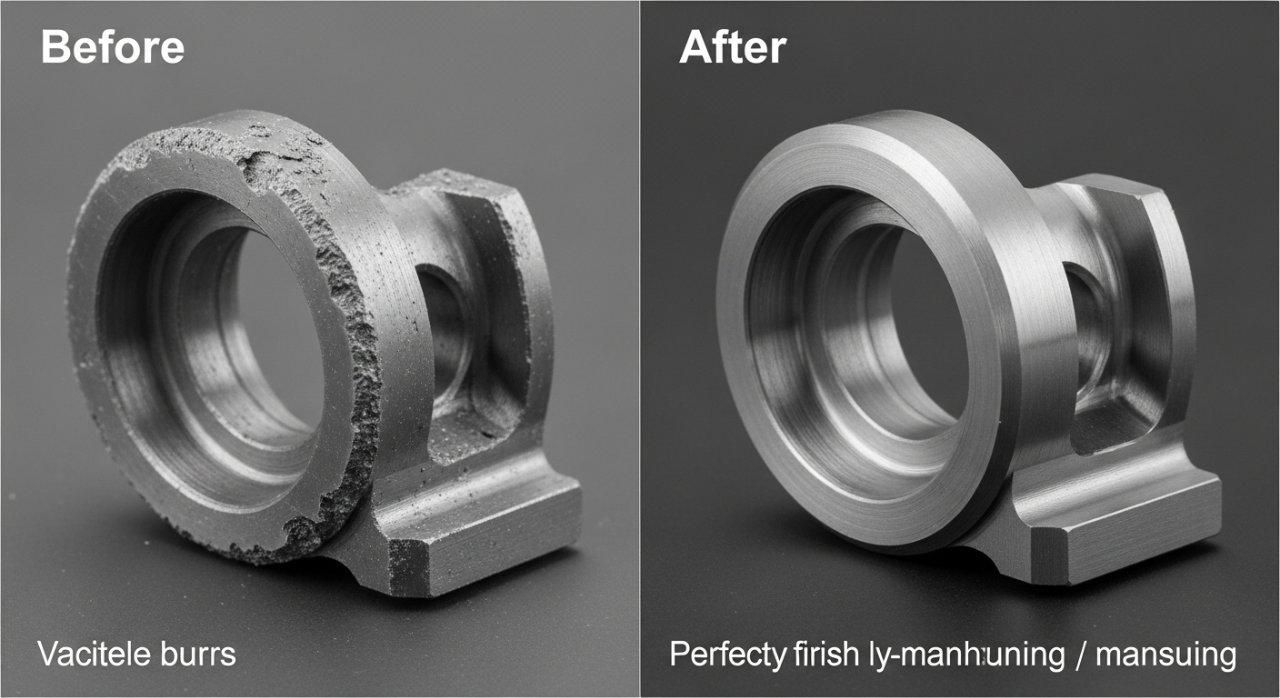

Minimizing burrs and edge chipping

Achieving crisp, burr-free edges on PEEK components requires meticulous attention to tool sharpness and cutting strategy. Dull tools are the primary cause of burr formation and edge chipping.

We consistently use freshly sharpened tools with specific geometries tailored for PEEK plastic processing. Our finishing passes are typically light and high-speed to shear material cleanly.

In our experience, incorporating specific chamfering or deburring tool paths as part of the CNC program eliminates the need for manual deburring. This maintains the high quality and precision of our PEEK parts.

Mitigating tool wear in PEEK CNC

While PEEK is not as abrasive as some metals, incorrect machining parameters can accelerate tool wear. Heat buildup and chip re-welding are primary contributors to premature tool degradation.

Our strategies focus on optimized chip evacuation, effective cooling, and appropriate tool coatings. These measures collectively reduce friction and extend the lifespan of our cutting tools.

Regular tool inspection and timely replacement are also integral to our quality control protocols. This commitment ensures consistent part quality and efficiency in our PEEK CNC machining operations.

Quality control for critical PEEK parts

For high-precision PEEK components, rigorous quality control is non-negotiable. Our factory implements a comprehensive inspection regime at various stages of the PEEK plastic processing cycle.

Utilizing advanced metrology equipment, such as CMMs (Coordinate Measuring Machines) and optical comparators, we verify all critical dimensions and geometric tolerances. This ensures every part meets exacting specifications.

Our adherence to industry standards, including ISO 9001 and AS9100 principles, underpins our commitment to delivering defect-free, high-quality PEEK parts. Trustworthiness is built on verifiable precision.

Why Choose Us for PEEK CNC Challenges?

Our technical expertise in PEEK

At ly-machining, our engineering team possesses profound technical expertise specifically in PEEK CNC machining. We have years of hands-on experience navigating the complexities of this advanced polymer.

We don’t just machine PEEK; we understand its material science, thermal behavior, and mechanical properties. This deep knowledge allows us to anticipate and overcome PEEK machining challenges proactively.

Our dedicated R&D continuously explores new techniques and tooling. This ensures we remain at the forefront of high-precision PEEK plastic processing, delivering unparalleled results for our clients.

Source manufacturer advantage for PEEK

As a direct source manufacturer, we offer a unique advantage in PEEK CNC machining. Our entire process, from material sourcing to final inspection, is controlled in-house.

This vertical integration ensures stringent quality control at every stage, providing end-to-end reliability. It also means we have direct oversight of lead times and production schedules, offering greater transparency.

Working with us means bypassing intermediaries, leading to more efficient communication and a direct partnership with the experts handling your high-precision PEEK project.

Transparent pricing & high-quality PEEK

We believe in fostering trust through transparent pricing, providing detailed quotes without hidden costs. Our focus is on delivering exceptional value through superior quality PEEK parts.

Our commitment to high-quality PEEK components is unwavering, backed by our robust quality management systems and experienced technicians. We guarantee parts that meet your exact specifications.

This combination of clear costs and assured quality provides peace of mind. It allows our clients to confidently integrate our high-precision PEEK components into their most critical applications.

Commitment to precision and reliability

Our factory’s core philosophy is built on unwavering commitment to precision and reliability. Every high-precision PEEK part undergoes meticulous inspection before shipment.

We stand by the quality of our PEEK CNC machining work. Our processes are designed to consistently produce parts that not only meet but often exceed industry standards.

Clients choose us because they require a partner who delivers reliable, repeatable precision for their most demanding PEEK plastic processing needs, every single time.

PEEK CNC Success Stories & Applications

Aerospace PEEK component case study

Problem: An aerospace client required complex PEEK bushings for a critical flight control system. The bushings demanded extremely tight tolerances (+/- 0.005mm) and a flawless surface finish to minimize friction and wear in extreme temperature fluctuations. Previous suppliers struggled with warping and inconsistent dimensions during PEEK plastic processing.

Our Solution: We implemented a multi-stage PEEK CNC machining process, including optimized tooling (DLC-coated carbide), precisely controlled cutting parameters to manage thermal expansion, and inter-stage stress relief annealing. Our custom fixturing ensured part stability.

Result: We successfully delivered 500 PEEK bushings, each meeting the stringent +/- 0.005mm tolerance and superior surface finish. Our solution prevented costly redesigns and product launch delays for the client.

Medical device PEEK machining example

Problem: A medical device manufacturer needed small, intricate PEEK components for a new surgical instrument. These parts required excellent biocompatibility, exceptional surface finish, and complex micro-features. The PEEK machining challenges included preventing burrs on delicate edges and maintaining material integrity for sterilization.

Our Solution: Utilizing ultra-sharp, micro-grain carbide tools and fine-tuned PEEK CNC machining strategies, we focused on very light finishing passes. A custom coolant system specifically designed for PEEK plastic processing ensured thermal stability and prevented material smearing.

Result: We supplied over 1,000 PEEK components with zero burrs, pristine surfaces, and all micro-features accurately reproduced. This enabled the client to achieve FDA approval ahead of schedule due to the consistently high quality of our high-precision PEEK parts.

High-performance industrial PEEK parts

Problem: An industrial automation company needed robust PEEK insulating blocks for high-voltage applications. These blocks required precise hole patterns and channel geometries for wiring, demanding high-precision PEEK with strict dielectric properties. The PEEK plastic processing had to avoid any internal voids or contaminants.

Our Solution: We developed a specific machining program that focused on controlled chip evacuation and thorough cleaning of the workpiece between operations to eliminate potential contamination. Our quality control included dielectric strength testing alongside dimensional checks.

Result: We provided PEEK insulating blocks that not only met all dimensional and geometric tolerances but also passed rigorous dielectric testing. This guaranteed the safety and reliability of their high-voltage systems.

Unlock Your PEEK Project’s Potential

Partner with our PEEK machining experts

Ready to overcome your PEEK machining challenges and achieve unparalleled precision? Our PEEK plastic processing experts are here to transform your vision into reality.

We offer comprehensive technical consultation, leveraging our deep expertise to optimize your designs for high-precision PEEK manufacturing. Let’s discuss how our capabilities align with your project’s unique demands.

Request a PEEK CNC precision quote

Contact our PEEK experts today for a confidential consultation or request a transparent, no-obligation quote for your next critical PEEK component. Let’s engineer your success together.

Frequently Asked Questions about PEEK Machining

What makes PEEK hard to machine?

PEEK’s semi-crystalline structure, high thermal expansion, and thermoplastic nature make it challenging. These properties necessitate specialized tooling, precise parameter control, and effective thermal management.

Without careful consideration, issues like warping, internal stress, and poor surface finishes can arise. This impacts the quality of high-precision PEEK components.

How do you achieve high precision with PEEK?

Achieving high-precision PEEK involves a multi-faceted approach. We use specialized sharp tools, optimized cutting parameters, and advanced cooling strategies to control heat and reduce stress.

We also implement custom fixturing, effective chip management, and stress-relieving processes. Rigorous quality control checks ensure critical tolerances are met consistently.

Can PEEK be machined to tight tolerances?

Yes, PEEK can be machined to very tight tolerances, often +/- 0.005mm or better. This requires extensive expertise in PEEK CNC machining and a deep understanding of the material’s behavior.

Our factory has proven capabilities in delivering high-precision PEEK parts. We consistently meet the most demanding specifications for critical applications.