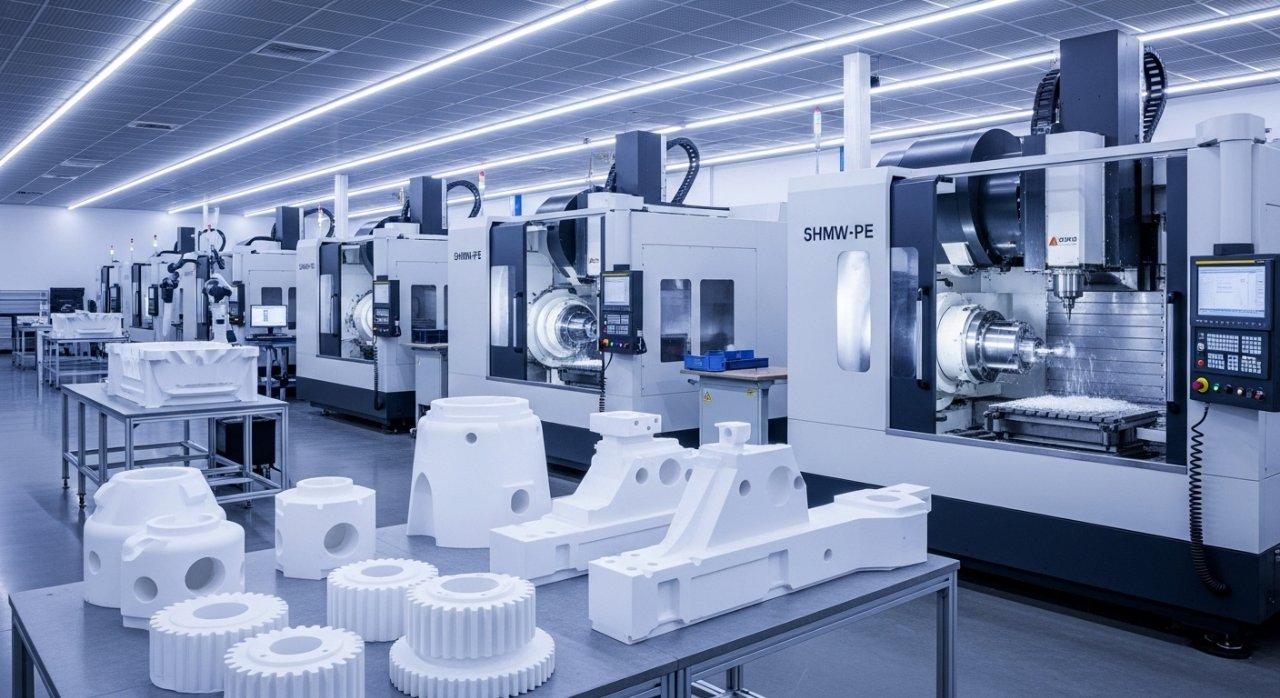

We master UHMW-PE dimensional stability in CNC machining. Our precision UHMW-PE machining leverages optimized processes and stress relief for consistent plastic CNC stability.

The inherent challenges of machining Ultra-High Molecular Weight Polyethylene (UHMW-PE) to tight tolerances can be a significant hurdle for many manufacturing projects. Its unique material properties often lead to dimensional instability, frustrating engineers and increasing costs.

In our experience, manufacturers frequently struggle with UHMW-PE components that warp, shrink, or fail to meet specifications after machining. These issues can compromise performance and derail project timelines.

This comprehensive guide, straight from our factory’s engineers, will delve into the science behind UHMW-PE’s behavior and outline the advanced CNC machining strategies we employ to ensure unparalleled precision and reliability for your critical components.

Challenges in UHMW-PE Dimensional Stability

Why UHMW-PE is Dimensionally Tricky

UHMW-PE is renowned for its exceptional wear resistance, low coefficient of friction, and high impact strength. However, these very properties, rooted in its long molecular chains, contribute to its machining complexities.

The material exhibits significant viscoelastic behavior and a high coefficient of thermal expansion. These characteristics make it prone to internal stress accumulation during manufacturing and subsequent relief post-machining.

This stress relief manifests as unpredictable dimensional changes, a critical concern for components requiring tight tolerances. Understanding this molecular behavior is the first step in mastering UHMW-PE dimensional stability.

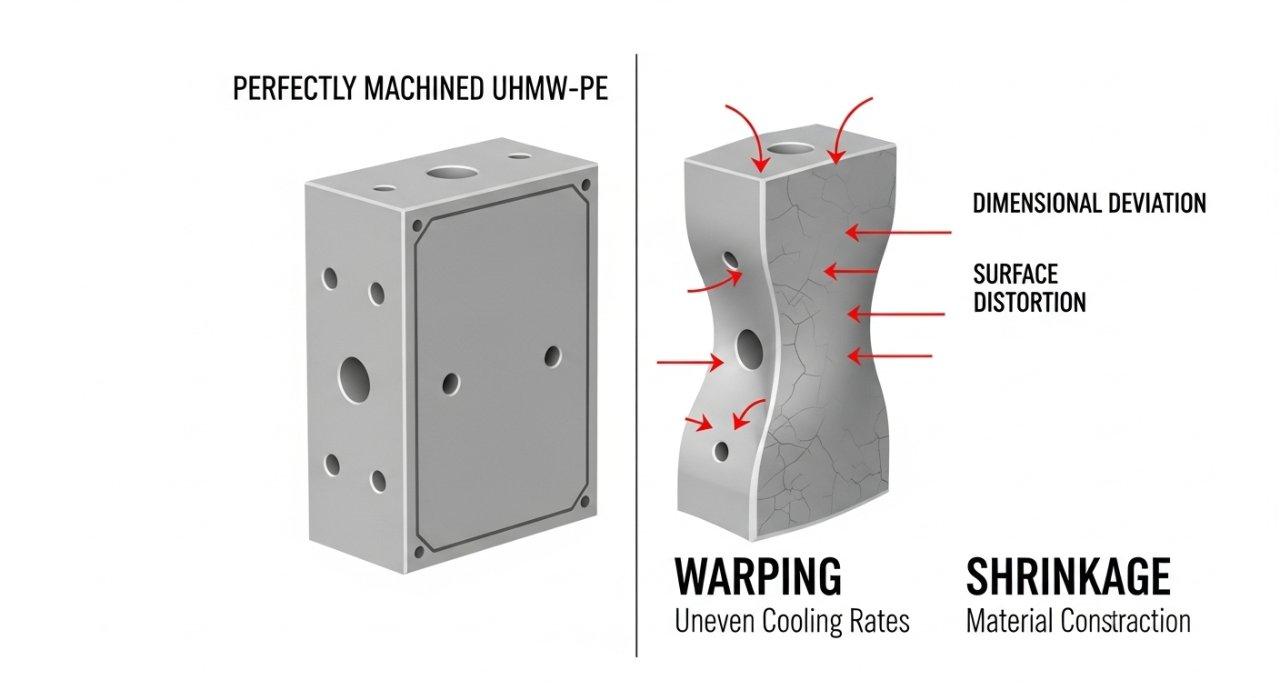

Common Issues: Warping & Shrinkage

The most prevalent issues we encounter with UHMW-PE CNC machining are warping and shrinkage. Warping occurs when internal stresses within the material are unevenly released, causing the part to deform.

Shrinkage, on the other hand, is often a consequence of thermal contraction as the material cools after machining. Both phenomena lead to components that fall outside specified dimensional tolerances.

Without meticulous process control, these issues can lead to a high scrap rate, escalating material and labor costs. Achieving reliable plastic CNC stability demands a proactive approach to these common problems.

Impact on Performance & Project Costs

Dimensional instability directly impacts the performance and reliability of engineered components. A part that does not fit or function as intended can lead to assembly line stoppages, product failures, and costly recalls.

For our clients, these issues translate into significant project delays and budget overruns. The need for rework or complete part replacement can severely undermine project profitability and market competitiveness.

Our expertise in precision UHMW-PE machining is specifically geared to mitigate these risks. We ensure that components consistently meet design specifications, safeguarding your project timelines and overall investment.

Deep Dive into UHMW-PE Material Properties

Thermal Expansion Coefficient & Heat

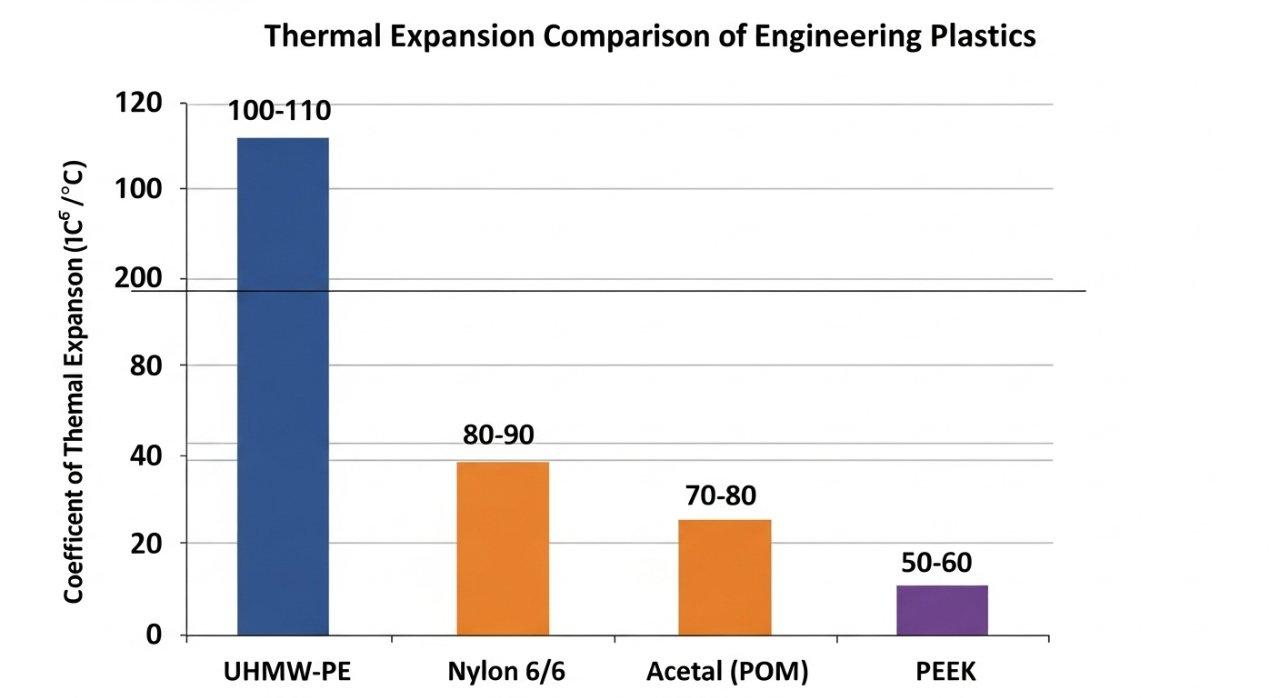

UHMW-PE possesses a relatively high coefficient of thermal expansion compared to many other engineering plastics and metals. This means it expands and contracts significantly with temperature fluctuations.

During the CNC machining process, heat is generated by friction between the cutting tool and the material. This localized heat causes expansion, and as the material cools, it contracts.

Uncontrolled thermal cycles can induce internal stresses and dimensional inaccuracies. Precise temperature management during machining is critical for maintaining UHMW-PE dimensional stability.

Stress Relaxation & Internal Stresses

UHMW-PE inherently contains internal stresses introduced during its manufacturing process (e.g., extrusion or compression molding). Machining cuts into the material, releasing these trapped stresses.

This stress relaxation is a primary driver of warpage and deformation. As material is removed, the remaining sections attempt to achieve a new equilibrium, often resulting in an altered shape.

Controlling stress relaxation requires specialized machining strategies. We focus on techniques that minimize stress build-up and manage its release gradually, crucial for precision UHMW-PE machining.

Moisture Absorption: A Hidden Factor

While UHMW-PE is generally considered to have low moisture absorption, it is not entirely impervious. Small amounts of absorbed moisture can still play a subtle role in dimensional changes, particularly in fluctuating humidity environments.

Over time, or under specific conditions, moisture absorption can lead to slight swelling. For applications demanding extreme precision, even minor changes can be significant.

Our controlled manufacturing environments and post-processing considerations account for these subtle factors. We ensure the material’s integrity is maintained throughout the production cycle.

Creep & Long-Term Stability Concerns

Creep is the tendency of a solid material to slowly deform permanently under the influence of mechanical stresses. UHMW-PE, being a viscoelastic polymer, exhibits creep behavior, especially under sustained loads and elevated temperatures.

While less impactful during the immediate machining phase, creep is a critical consideration for the long-term dimensional stability of UHMW-PE components in their final application. It affects part reliability over time.

Designing parts for UHMW-PE must account for this property, and our engineers can advise on suitable geometries and processing to minimize its effects. This ensures long-term plastic CNC stability in application.

| Material Property | UHMW-PE Value/Characteristic | Impact on Dimensional Stability |

|---|---|---|

| Coefficient of Thermal Expansion | Relatively High | Prone to expansion/contraction with temperature changes |

| Internal Stresses | Inherently present from manufacturing | Leads to warpage upon stress relaxation |

| Moisture Absorption Rate | Low, but not zero | Slight swelling possible in humid environments |

| Viscoelasticity (Creep) | Exhibits creep under sustained load | Long-term deformation affecting dimensional integrity |

Advanced CNC Strategies for UHMW-PE

Pre-Machining Stress Relieving Techniques

In our experience, one of the most effective ways to mitigate warpage is pre-machining stress relieving. This process involves carefully heating the UHMW-PE material to a specific temperature and then slowly cooling it.

This controlled thermal cycle helps to relax and homogenize internal stresses throughout the bulk material. By reducing inherent stresses before machining, we significantly improve UHMW-PE dimensional stability.

This crucial step minimizes unpredictable deformation once material is removed. It’s a cornerstone of our precision UHMW-PE machining approach.

Optimal Cutting Parameters & Tooling

Selecting the correct cutting parameters and tooling is paramount for successful UHMW-PE CNC machining. We utilize sharp, high-rake angle cutting tools specifically designed for plastics to minimize heat generation and material drag.

Maintaining a keen edge on tools is essential; dull tools generate excessive heat, exacerbating thermal expansion and stress-induced deformation. Our high-speed, low-feed rate strategies further reduce heat.

Proprietary cutting fluid mixtures and air blasts are employed to manage temperature effectively at the cutting interface. This ensures efficient chip evacuation and thermal control.

Fixturing & Clamping to Minimize Distortion

Proper fixturing and clamping are critical to prevent distortion during machining. UHMW-PE’s flexible nature means it can easily deform under improper clamping forces.

We design custom fixtures that provide adequate support without over-compressing the material. Our clamping techniques distribute force evenly, holding the workpiece securely without inducing new stresses.

This careful approach ensures the part remains stable throughout the machining process, maintaining its intended geometry. It is a vital aspect of achieving consistent plastic CNC stability.

Multi-Pass Machining for Precision

For achieving the tightest tolerances and superior UHMW-PE dimensional stability, we often employ multi-pass machining strategies. This involves removing material in several lighter cuts rather than one heavy cut.

Lighter cuts generate less heat and impart less stress on the material. The initial roughing passes remove the bulk of the material, allowing for a primary release of larger internal stresses.

Subsequent finishing passes then achieve the required precision with minimal residual stress. This incremental material removal is a hallmark of our precision UHMW-PE machining.

Post-Machining Annealing Processes

Even after meticulous machining, residual stresses can remain in the UHMW-PE part. Post-machining annealing is a controlled thermal treatment applied to the finished or near-finished component.

Similar to pre-machining stress relief, annealing further relaxes any remaining internal stresses. This significantly improves the long-term dimensional stability of the part, reducing the risk of warpage over time.

This final process ensures that the component maintains its precise dimensions even under varying operational conditions. It’s an advanced step many manufacturers overlook, but one we prioritize.

| CNC Strategy | Key Benefit for UHMW-PE Stability |

|---|---|

| Pre-Machining Stress Relieving | Reduces inherent material stresses before cutting |

| Optimal Cutting Parameters | Minimizes heat generation and material deformation |

| Custom Fixturing | Prevents distortion during clamping and machining |

| Multi-Pass Machining | Reduces stress build-up with gradual material removal |

| Post-Machining Annealing | Relaxes residual stresses for long-term dimensional integrity |

Achieving UHMW-PE Precision: Our Expertise

Source Manufacturer Advantage & Control

As a source manufacturer, we maintain complete control over every stage of the UHMW-PE CNC machining process. From raw material selection to final inspection, our integrated approach ensures consistent quality and accountability.

This vertical integration allows us to implement our specialized stress-relieving and machining protocols with unmatched rigor. We don’t just process parts; we engineer solutions for UHMW-PE dimensional stability.

Our clients benefit from a direct partnership, cutting out intermediaries and ensuring clear communication. This advantage is crucial for delivering precision UHMW-PE machining tailored to exact specifications.

High-Quality Parts: Process & Verification

Our commitment to high-quality UHMW-PE parts is embedded in our robust process and rigorous verification. We utilize advanced measurement equipment, including CMMs and optical comparators, to ensure every dimension meets the required tolerance.

Each batch undergoes thorough quality checks, documenting critical dimensions and surface finishes. This meticulous approach guarantees that parts not only meet but often exceed industry standards for UHMW-PE dimensional stability.

We adhere to strict quality management systems, providing traceable reports for absolute confidence in our precision UHMW-PE machining.

Transparent Pricing for Reliable Solutions

We believe in fostering trust through transparent pricing. Our quotes are detailed and upfront, reflecting the true cost of delivering high-quality, dimensionally stable UHMW-PE components.

There are no hidden fees or unexpected charges; our clients receive reliable solutions at competitive, clear prices. This allows for accurate budgeting and avoids costly surprises often associated with complex plastic CNC stability projects.

We provide exceptional value by eliminating scrap, rework, and delays, ultimately reducing your overall project costs.

Technical Team: Your Engineering Partner

Our technical team comprises experienced engineers with deep expertise in material science and advanced CNC machining. We work collaboratively with your R&D and design teams from concept to production.

Whether it’s optimizing part design for UHMW-PE dimensional stability or troubleshooting complex applications, our engineers provide invaluable insights and solutions. We are more than a supplier; we are an extension of your engineering department.

This partnership ensures that even the most challenging UHMW-PE projects are executed with precision and technical excellence.

Case Study: Precision UHMW-PE Success

Client’s Initial Stability Challenges

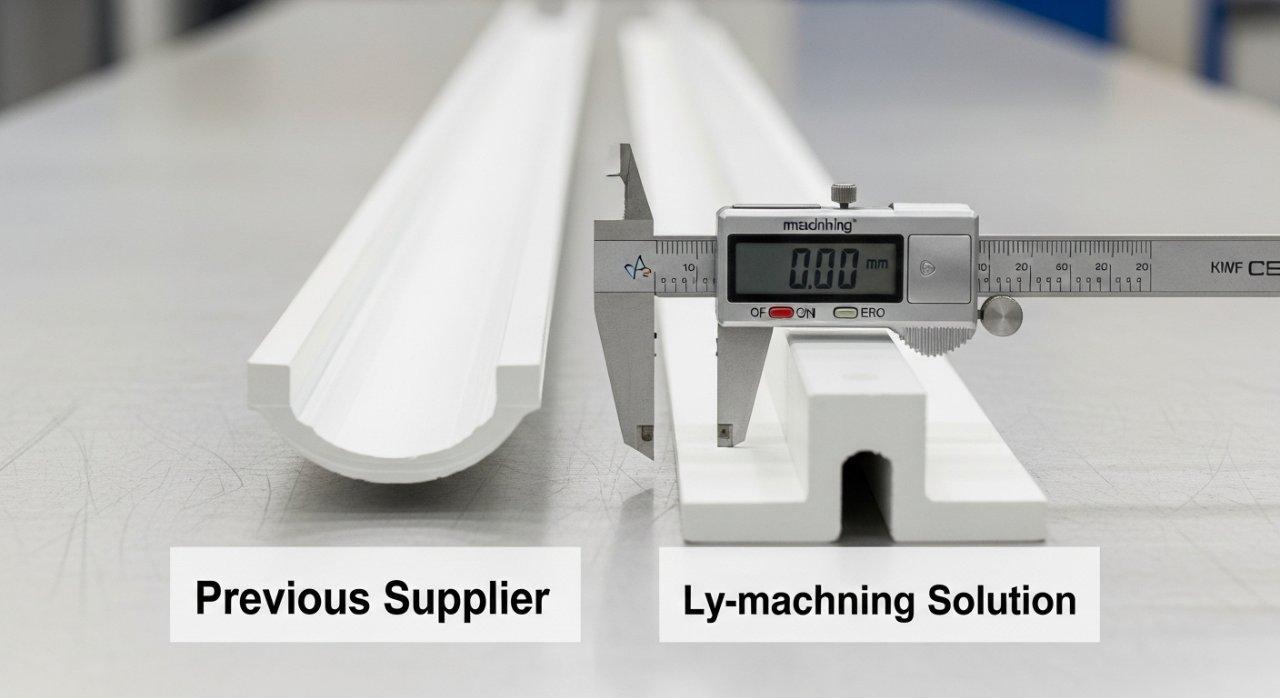

A client in the pharmaceutical industry approached us with a critical issue. Their existing supplier was unable to consistently machine UHMW-PE guide rails to the tight flatness tolerances required for automated bottling lines.

The rails experienced significant warpage after machining, causing costly assembly line stoppages and product damage. They faced high scrap rates and a serious bottleneck in their production schedule.

The lack of UHMW-PE dimensional stability was severely impacting their operational efficiency and profitability.

Our Solution: Tailored CNC Process

Our engineering team immediately recognized the deep-seated issues related to internal stresses and inadequate thermal management. We proposed a comprehensive solution involving several key steps.

First, we implemented a custom pre-machining stress-relieving protocol for the UHMW-PE blanks. Second, we developed optimized cutting parameters using specialized tooling and multi-pass machining.

Finally, a precise post-machining annealing process was integrated to stabilize the final dimensions. We carefully selected and monitored every parameter to achieve unparalleled plastic CNC stability.

Measurable Results & Project Success

The results were transformative. Our tailored process delivered UHMW-PE guide rails with flatness tolerances consistently within the client’s strict requirements.

The client experienced a dramatic reduction in scrap rates and completely eliminated assembly line stoppages due to guide rail issues. This led to significant cost savings and improved production throughput.

Our precision UHMW-PE machining enabled them to launch their new bottling line on schedule and with complete confidence in component reliability. This is a testament to our mastery of UHMW-PE dimensional stability.

Partner for UHMW-PE CNC Stability

Why Choose Our Machining Factory

Choosing our machining factory means partnering with experts who understand the unique challenges of UHMW-PE. We don’t just cut plastic; we apply scientific principles and decades of experience.

Our dedication to precision, combined with a transparent manufacturing process, ensures your components are delivered on time and to exact specifications. We are your reliable source for complex UHMW-PE projects.

We leverage advanced techniques and a deep understanding of material behavior to guarantee superior plastic CNC stability.

Get a Quote: Your Next Step

Ready to eliminate dimensional instability issues and achieve unparalleled precision for your UHMW-PE components? Contact our expert engineering team today for a complimentary consultation and transparent quote.

Let our deep technical expertise turn your challenging UHMW-PE projects into successful, high-performance realities. We are committed to providing the precision UHMW-PE machining solutions you deserve.

Frequently Asked Questions

What causes UHMW-PE warping?

Warping in UHMW-PE is primarily caused by the release of internal stresses trapped within the material during its manufacturing process. These stresses become unevenly relaxed as material is removed during CNC machining.

Uncontrolled heat generation during cutting can also exacerbate these issues. This leads to unpredictable dimensional changes and deformation of the finished part.

Can UHMW-PE achieve tight tolerances?

Yes, UHMW-PE can achieve tight tolerances, but it requires specialized knowledge and advanced CNC machining techniques. Standard approaches often fail due to the material’s unique properties.

Our factory employs pre-machining stress relief, optimized cutting parameters, and post-machining annealing to ensure precision UHMW-PE machining. We focus on controlling thermal expansion and stress relaxation.

How do you ensure UHMW-PE stability?

We ensure UHMW-PE dimensional stability through a multi-faceted approach. This includes pre-machining stress relieving, selecting optimal cutting parameters with specific tooling, and careful fixturing.

Additionally, we utilize multi-pass machining and post-machining annealing processes. These steps collectively mitigate internal stresses and thermal effects, guaranteeing consistent plastic CNC stability.