Measuring instrument CNC machining

Precision, every millimeter counts; quality, always consistent | Core components designed for top-level measuring instruments

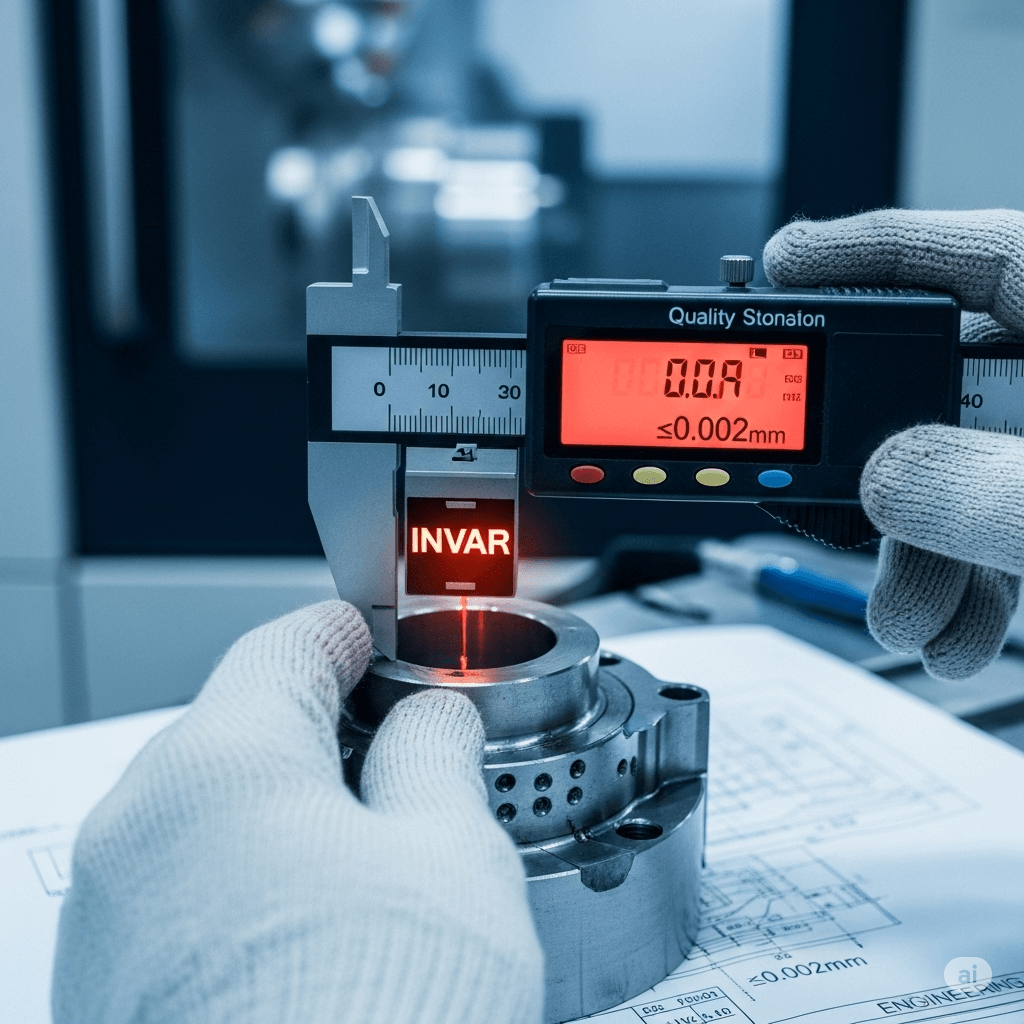

We not only process metal, but also build trust. With the extreme tolerance of ±0.001mm and the quality commitment of zero defect, we become your extended precision manufacturing department.

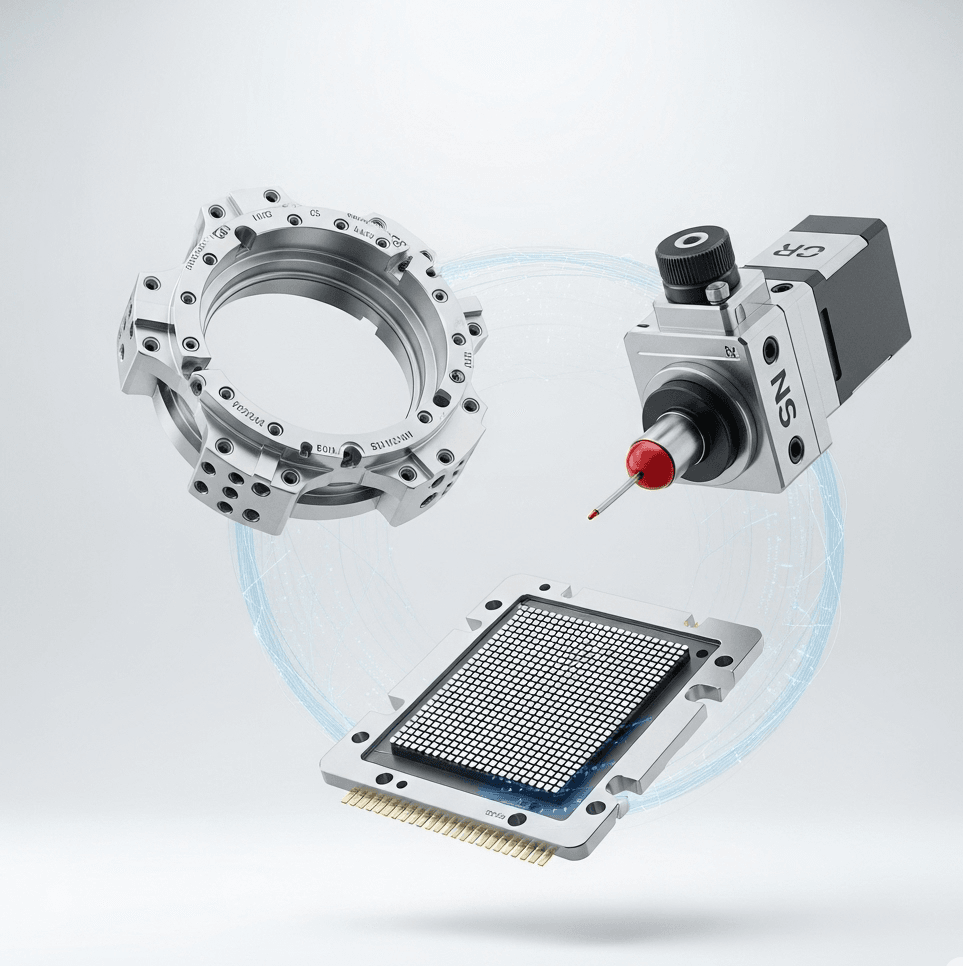

The accuracy of measuring instruments comes from the quality of each part. Any slight dimensional deviation or material deformation may cause the entire system to be inaccurate. We deeply understand the challenges you face when seeking extreme tolerances, special material processing and quality consistency, and are committed to providing high-determinacy CNC machining solutions to perfectly transform your design into highly stable physical parts.

Are you experiencing the following challenges?

Unable to meet tolerances: Existing suppliers have difficulty consistently meeting the stringent tolerances marked on your drawings, resulting in assembly difficulties and reduced performance.

Lack of material knowledge: Lack of experience with the processing characteristics of low thermal expansion materials such as Invar and Zerodur® causes parts to deform or fail to achieve the expected results.

Poor quality consistency: The first sample is qualified, but the quality fluctuates during mass production, affecting your production plan and market reputation.

Inefficient communication: Repeated technical communication fails to accurately understand the design intent, wasting your precious R&D time.

At ly-machining, we regard these challenges as our mission. We position ourselves as a deep partner in the precision instrument industry, committed to providing one-stop, high-determinacy CNC machining solutions to ensure that every detail of your design is perfectly realized, giving your instrument a solid and reliable foundation of precision.

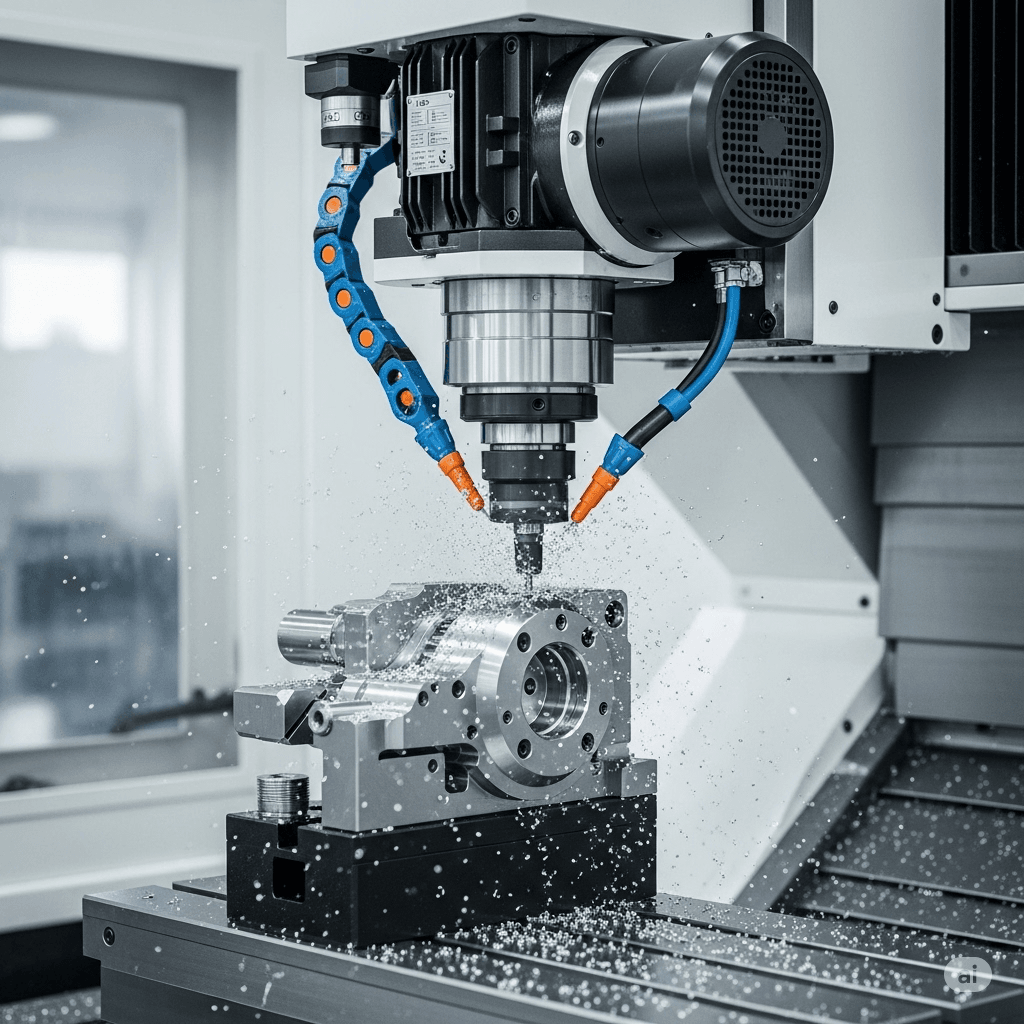

Parts processing is more than just "precision"

Strict tolerance requirements: How to achieve and stably maintain micron-level dimensional, geometric and positional tolerances?

Special material properties: How to overcome the deformation and stress of materials such as Invar alloy, titanium alloy, and engineering ceramics during processing?

Complex geometric structures: How to efficiently process optical and sensor components with complex surfaces and fine structures?

Extreme surface quality: How to obtain flawless, low-roughness surfaces to ensure optical and mechanical properties?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our solutions: technology, materials and quality

Special material processing experts: More than 10 years of experience in special material processing, especially good at precision molding of high thermal stability materials (Invar, Kovar) and high hardness materials (sapphire, ceramics).

Excellent surface treatment: Provide one-stop service from precision grinding, optical grade polishing to special coating, with surface finish up to Ra0.1μm.

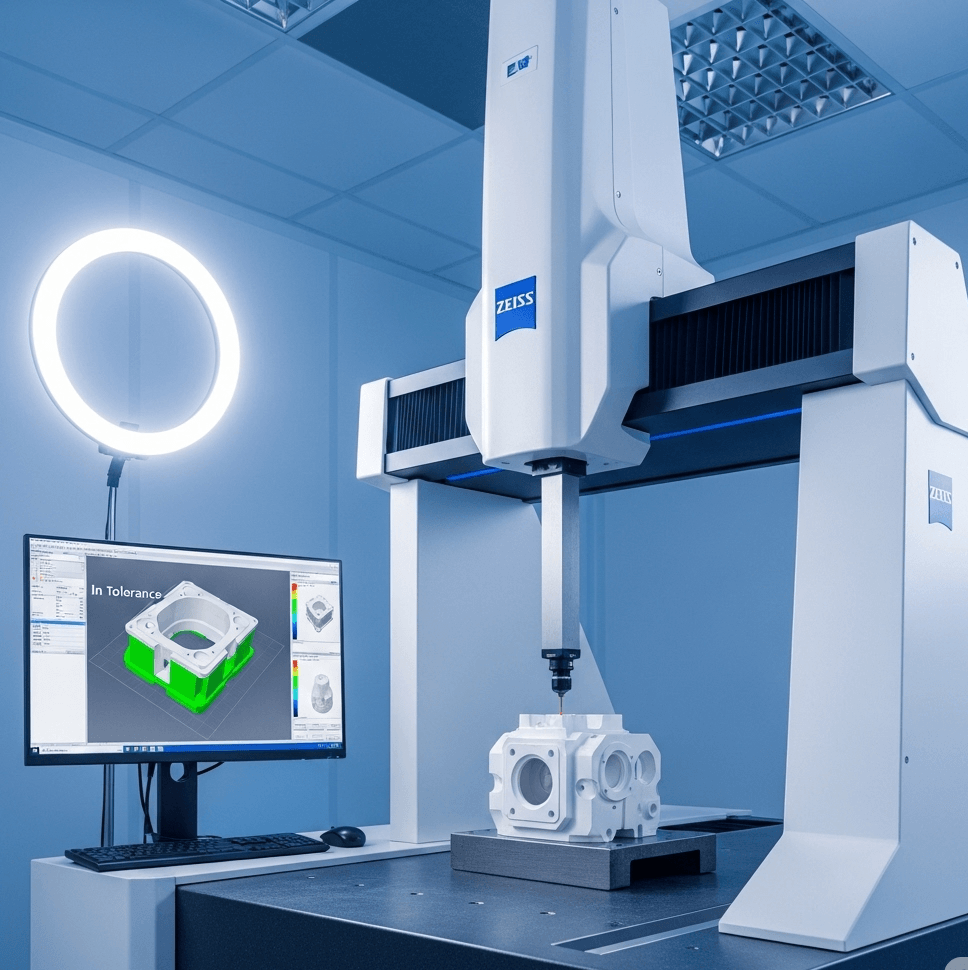

Strict quality control: Equipped with ZEISS three-coordinate measuring machine and laser interferometer, perform 100% full-size inspection, and provide complete traceable inspection reports.

We support precision measurement

Optical measuring instruments: theodolites, spectrometers, interferometers, mirror mounts, filter holders, etc.

Metrology and calibration equipment: coordinate measuring machine (CMM) probes, probe assemblies, standard gauges, etc.

Industrial sensors: core components and housings of high-precision pressure, displacement, and flow sensors.

Medical and scientific instruments: precision mechanical parts in medical imaging, gene sequencing, and mass spectrometers.