Medical Endoscope Optical Components Guide

For precision CNC machining optical components, choose recommended CNC machining manufacturers offering superior CNC machining services for optical lenses, prioritizing expertise, quality, and compliance.

In the critical realm of medical endoscopy, the clarity of vision can mean the difference between life-saving diagnosis and missed opportunities. Sourcing precision optical components for these intricate devices presents unique challenges that demand exceptional expertise and unwavering quality.

The wrong manufacturing partner can lead to costly delays, performance compromises, and even regulatory issues. Identifying an optical lens manufacturing supplier who truly understands the exacting requirements is paramount for medical device innovators.

This guide will illuminate the essential criteria for selecting a manufacturing partner, detailing the precision, technical depth, and compliance necessary to elevate your medical endoscope performance. Discover how a dedicated partner can safeguard your product’s integrity and accelerate your path to market.

Evaluating Medical Endoscope Component Makers

Selecting an optical lens manufacturing supplier for medical endoscopes goes far beyond standard CNC machining. These components are at the heart of diagnostic accuracy, demanding a level of precision that few manufacturers can consistently deliver. ly-machining understands this critical distinction.

Criticality of precision CNC machining optical components

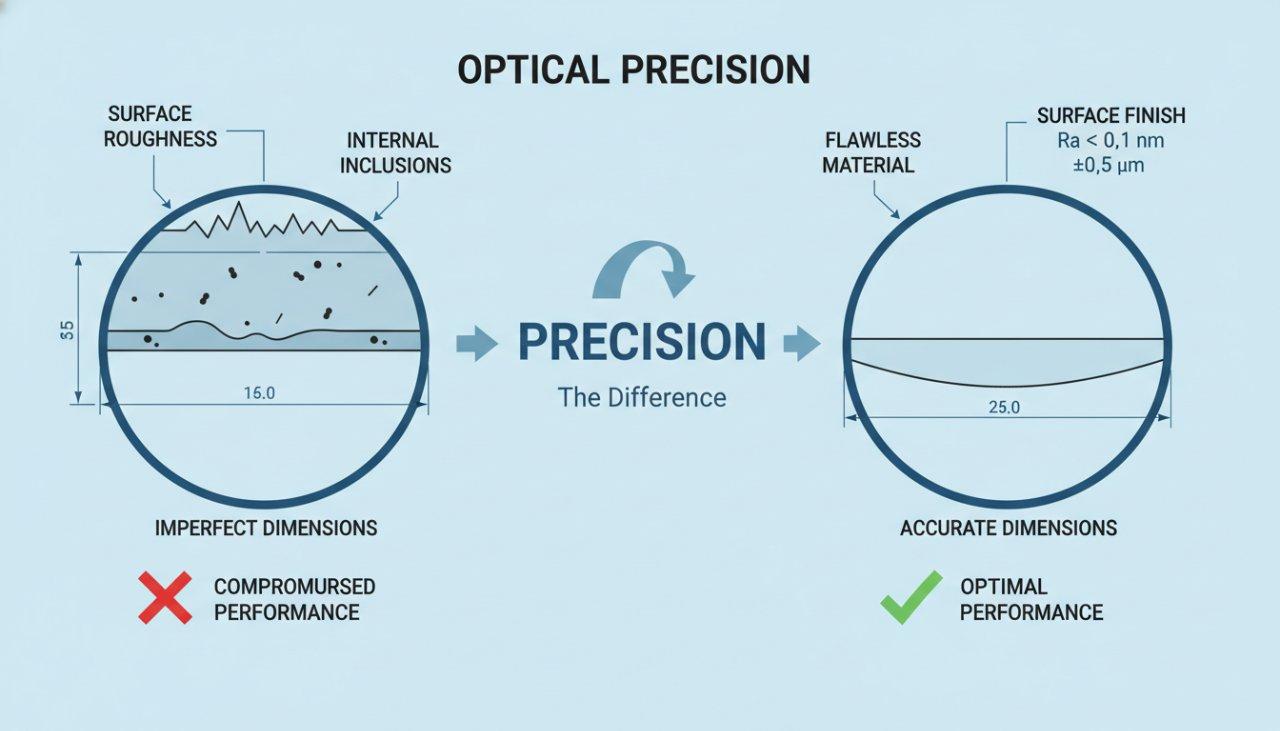

The performance of a medical endoscope is directly tied to the precision of its optical components. Even microscopic imperfections can lead to image distortion, reduced clarity, or compromised functionality, directly impacting clinical outcomes and patient safety.

Precision CNC machining optical components are engineered to micron-level tolerances, ensuring exact focal lengths, perfect alignment, and flawless surface finishes. This meticulous approach is non-negotiable for instruments used in sensitive medical procedures.

In ly-machining’s experience, achieving this level of precision requires specialized machinery, advanced tooling, and highly skilled technicians. Our focus is on repeatable accuracy for every single part.

Unique demands for optical lens manufacturing suppliers

Optical lens manufacturing suppliers must navigate a complex landscape of materials, geometries, and functional requirements. Unlike general machining, medical optical parts often involve exotic glasses, specialized polymers, and hybrid designs.

These materials demand specific cutting parameters and handling protocols to maintain their optical integrity and prevent contamination. A common issue ly-machining sees is suppliers underestimating the material-specific challenges.

Furthermore, medical endoscope components require biocompatibility, sterilization resistance, and often hermetic sealing. These considerations must be integrated into the design and manufacturing process from the very outset.

Criteria for Manufacturer Selection

Identifying the right Recommended CNC machining manufacturers for optical lens components requires a rigorous evaluation process. ly-machining encourages clients to delve deep into a potential partner’s capabilities, not just their price list.

Assessing technical expertise in CNC machining

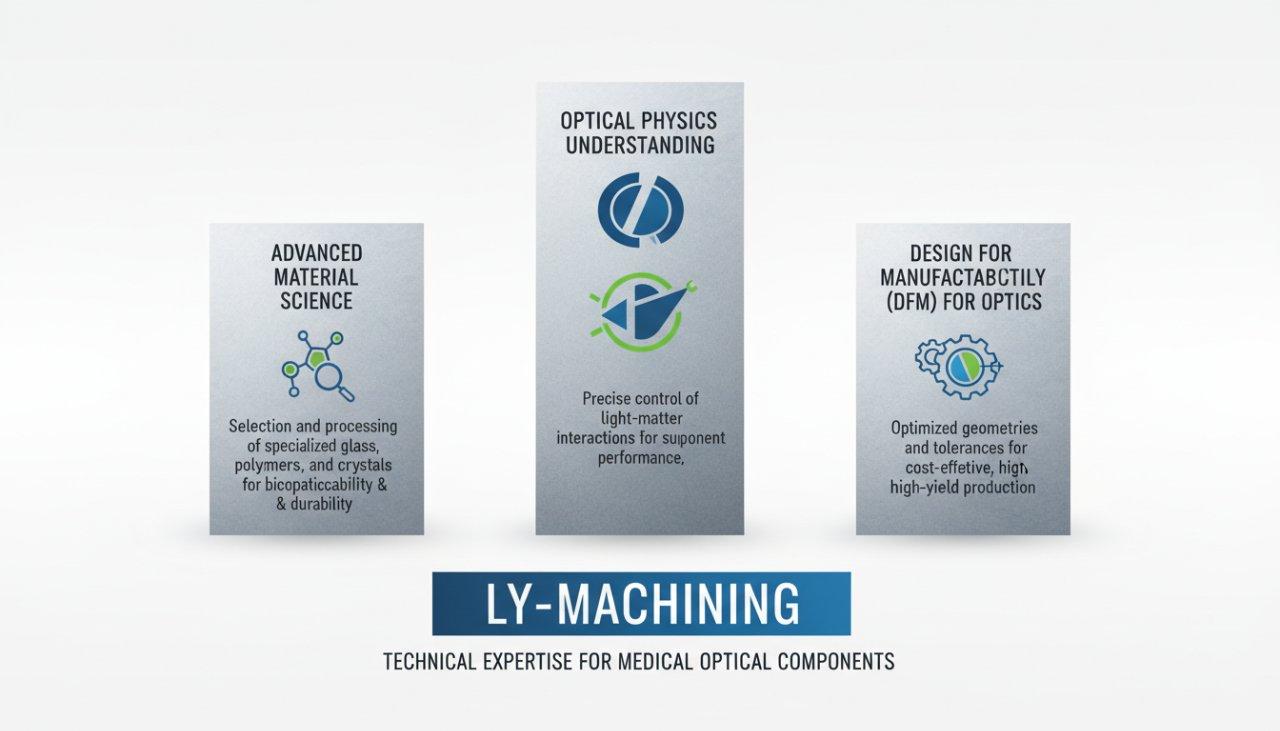

True technical expertise goes beyond owning advanced machines. It encompasses a deep understanding of optical physics, material science, and design for manufacturability (DFM) specific to medical devices.

ly-machining’s engineers collaborate closely with client R&D teams, offering insights on optimizing designs for the most effective CNC machining services for optical lenses. This proactive approach minimizes iterations and reduces overall project costs.

Our team’s ability to interpret complex optical drawings and translate them into precise machining programs is a cornerstone of our service. We are partners in innovation, not just fabricators.

Importance of robust quality control in CNC machining

Quality control for precision CNC machining optical components is an exhaustive, multi-stage process. It involves more than just final inspection; it is integrated into every step of the manufacturing workflow.

For medical devices, traceability is paramount. Every component, from raw material batch to finished part, must have a complete audit trail. ly-machining implements comprehensive documentation practices to ensure full compliance.

Our robust quality management system adheres strictly to industry standards, providing complete confidence in the integrity and consistency of every optical component we produce.

Table: Key Quality Control Focus Areas

| Quality Control Aspect | Description |

|---|---|

| Dimensional Accuracy | Micron-level verification of all critical dimensions. |

| Surface Finish | Non-contact optical profilometry for Ra, Rz values. |

| Optical Clarity | Visual inspection and advanced light transmission tests. |

| Material Integrity | Verification of material composition and absence of flaws. |

| Traceability | Batch and process recording for every component. |

Evaluating quality for precision CNC machining optical components

Evaluating quality means assessing a manufacturer’s commitment to consistent excellence. This includes their investment in metrology equipment specifically designed for optical components.

ly-machining utilizes advanced inspection tools such as CMMs, optical comparators, and surface roughness testers to ensure every precision CNC machining optical component meets specifications. We prioritize verifiable results.

Furthermore, our cleanroom manufacturing capabilities, where required, prevent contamination that could compromise optical performance. This controlled environment is crucial for sensitive medical applications.

Advanced Processing for Optical Parts

The journey from raw material to a perfectly formed medical endoscope optical component requires sophisticated processes and state-of-the-art machinery. ly-machining invests continuously in cutting-edge technology to meet these demands.

Advanced CNC machining services for optical lenses

ly-machining offers advanced CNC machining services for optical lenses, leveraging multi-axis CNC milling and turning centers capable of extremely fine feature generation. This allows for complex geometries that are impossible with traditional methods.

Our capabilities extend to micro-machining, producing intricate internal structures and precise lens seating areas. These advanced techniques are essential for the miniaturization and enhanced functionality of modern endoscopes.

We employ specialized cutting tools and optimized programming strategies to minimize stress on delicate optical materials, preserving their integrity and optical properties throughout the manufacturing process.

Material selection for precision CNC machining components

Choosing the right material is as critical as the machining process itself. Precision CNC machining optical components require materials with specific optical, mechanical, and biocompatibility properties.

ly-machining has extensive experience working with a wide range of medical-grade materials. This includes specialized glasses like fused silica and various optical polymers such as cyclic olefin copolymer (COC) or polymethyl methacrylate (PMMA).

Our material experts assist clients in selecting the optimal material that balances optical performance, durability, sterilization compatibility, and cost-effectiveness for their specific application.

Prototyping and scaling with optical lens manufacturing suppliers

From initial concept to full-scale production, optical lens manufacturing suppliers must offer seamless transition capabilities. ly-machining provides rapid prototyping services that help validate designs quickly and efficiently.

Our ability to scale production ensures consistent quality and timely delivery, whether for small batch runs or high-volume manufacturing. This flexibility is crucial for medical device companies facing evolving market demands.

ly-machining understands the critical pathway from development to market. Our integrated approach supports your product lifecycle, from initial concept to sustained, reliable supply.

Partnering with Optical Component Suppliers

A successful partnership with recommended CNC machining manufacturers is built on more than just technical capabilities; it requires transparency, effective communication, and a shared commitment to regulatory compliance.

Transparent pricing from optical lens manufacturing suppliers

Transparent pricing is a hallmark of a trustworthy partnership. ly-machining provides clear, detailed quotes without hidden fees, ensuring clients have a complete understanding of costs from the outset.

We believe that transparency fosters trust and enables better planning for our clients. A common pain point ly-machining addresses is the frustration with vague or fluctuating pricing from other optical lens manufacturing suppliers.

Our cost structures reflect the high investment in technology, expertise, and quality control necessary for medical-grade precision CNC machining optical components. Value is derived from assured quality and reliability.

Communication and project management for CNC machining

Effective communication and robust project management are vital, especially for complex projects involving CNC machining services for optical lenses. ly-machining assigns dedicated project managers to ensure seamless coordination.

Regular updates, proactive problem-solving, and open dialogue characterize ly-machining’s client interactions. We believe that clear communication prevents misunderstandings and accelerates project timelines.

Our team collaborates with clients, providing technical feedback and solutions throughout the manufacturing process. This ensures that expectations are always aligned with deliverables.

Regulatory compliance for Recommended CNC machining manufacturers

For medical endoscope components, regulatory compliance is non-negotiable. Recommended CNC machining manufacturers must demonstrate strict adherence to standards like ISO 13485 (Medical Devices Quality Management System) and ISO 9001.

ly-machining operates under a stringent quality management system that is fully compliant with ISO 13485. This certification underscores our commitment to manufacturing medical devices with the highest level of control and consistency.

Our documentation and traceability systems are designed to meet rigorous regulatory requirements, providing clients with complete confidence during audits and submissions. This proactive approach minimizes client risk.

Table: Key Regulatory & Quality Certifications

| Certification | Description | Benefits for Clients |

|---|---|---|

| ISO 13485 | Quality Management System for Medical Devices | Ensures regulatory compliance and patient safety. |

| ISO 9001 | General Quality Management System | Demonstrates consistent product and service quality. |

| RoHS/REACH | Restriction of Hazardous Substances/Registration, Evaluation, Authorization and Restriction of Chemicals | Guarantees compliance with environmental substance regulations. |

Choosing Your Endoscope Parts Partner

Ultimately, selecting a partner for precision CNC machining optical components comes down to trust, proven capability, and a shared vision for excellence. ly-machining stands ready to be that partner.

Why our CNC machining expertise stands out

ly-machining’s deep expertise in CNC machining services for optical lenses is unparalleled. Our specialized equipment, combined with decades of experience, allows us to tackle the most complex challenges in medical optics.

We are a source manufacturer, giving ly-machining direct control over every aspect of production, from raw material inspection to final quality assurance. This vertical integration ensures consistent, high-quality output.

Our commitment to innovation means continuously exploring new techniques and technologies to deliver superior precision CNC machining optical components. We are dedicated to pushing the boundaries of what is possible.

Case study: High-quality precision CNC machining optical components success

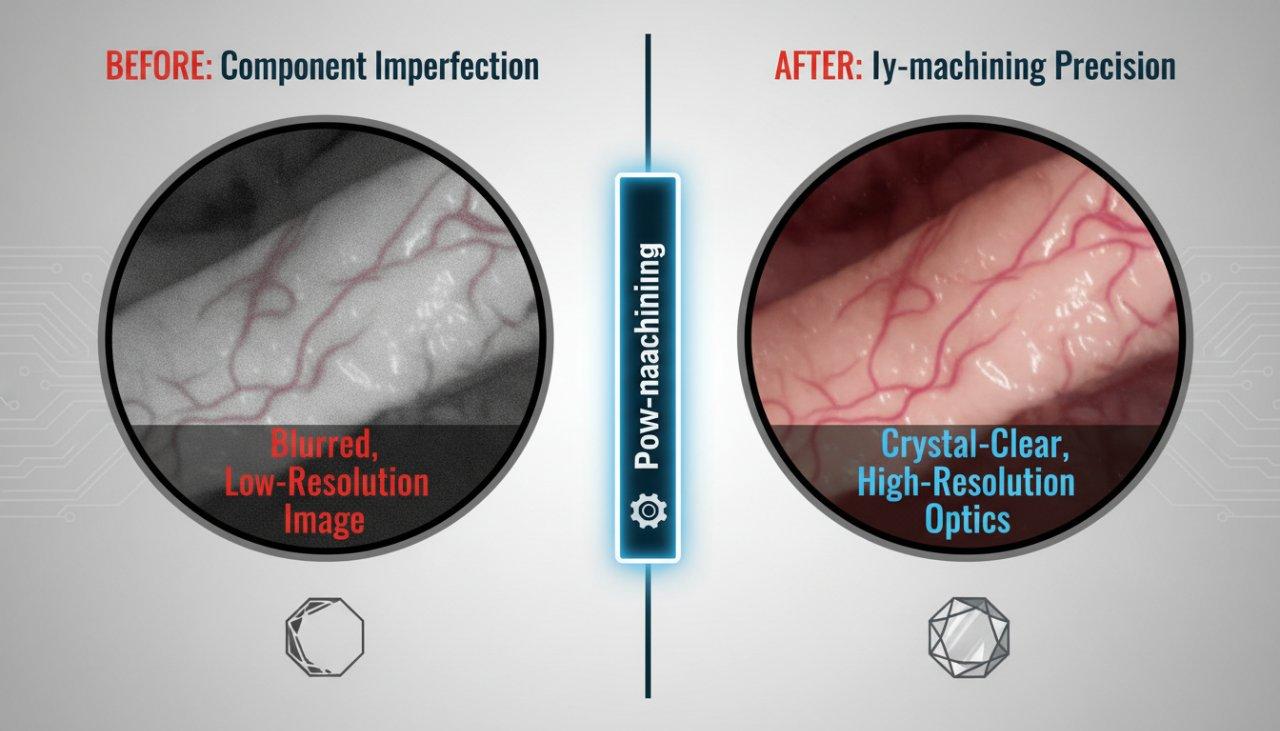

A client, a leading innovator in gastrointestinal endoscopy, faced persistent issues with their previous supplier regarding inconsistent surface finishes on crucial micro-lenses, leading to image degradation. This affected their product’s competitive edge.

ly-machining engaged with their R&D team, proposing a revised machining strategy utilizing advanced diamond tooling and a multi-axis CNC process optimized for their specific optical polymer. We also implemented a specialized non-contact optical inspection routine.

The result was a significant improvement in surface finish quality and consistency, leading to dramatically clearer endoscope images. The client achieved higher product reliability, reduced scrap rates, and secured faster market approval due to ly-machining’s high-quality precision CNC machining optical components.

Your Next Step in Component Sourcing

Making an informed decision about your medical endoscope optical component manufacturer is crucial for your product’s success and patient safety. ly-machining invites you to explore a partnership built on excellence.

Connect with Recommended CNC machining manufacturers

When seeking recommended CNC machining manufacturers for your critical optical components, look for partners who embody experience, expertise, authoritativeness, and trustworthiness. ly-machining exemplifies these core principles.

Reach out to ly-machining today to discuss your project requirements. Our engineering team is prepared to provide detailed technical insights and solutions tailored to your unique needs.

Elevate your medical device with optical components manufactured to the highest global standards.

What makes ly-machining unique for optical components?

ly-machining combines specialized CNC machining services for optical lenses with deep material science knowledge and a stringent ISO 13485 certified quality system. We offer end-to-end expertise.

Our focus on precision CNC machining optical components ensures that even the most complex designs are manufactured to exact specifications, meeting the uncompromising demands of the medical industry.

As a source manufacturer, ly-machining provides unparalleled quality control and transparent communication throughout your project’s lifecycle.

How does ly-machining ensure precision for optical parts?

ly-machining ensures precision through continuous investment in advanced multi-axis CNC machinery, specialized tooling, and highly skilled technicians. Our manufacturing processes are meticulously controlled.

We utilize state-of-the-art metrology equipment for in-process and final inspection, verifying micron-level tolerances and optical surface finishes. Every component undergoes rigorous quality checks.

Furthermore, ly-machining’s engineering team engages in Design for Manufacturability (DFM) analysis to optimize designs for ultimate precision and consistent quality from the outset.