Are you struggling to source vibrant, durable, and precisely finished multi-color aluminum CNC parts? Many businesses face frustrating setbacks with color inconsistencies, unreliable masking, and project delays when dealing with complex anodizing requirements. Finding a CNC machining partner who can truly master the art and science of multi-color anodizing feels like a monumental task.

These challenges lead to compromised product aesthetics, increased costs from rework, and potentially damaged brand reputation. When your components require distinct colors for functional coding or branding, any flaw—from fuzzy color boundaries to mismatched hues—is unacceptable. The technical complexity of the process means that without an expert partner, you risk wasting valuable time and resources on substandard parts that fail to meet your specifications.

The key to overcoming these hurdles lies in understanding the possibilities of modern multi-color anodizing and partnering with a specialist. By mastering advanced masking techniques and maintaining stringent process controls, it is entirely possible to achieve stunning, intricate, and perfectly replicated multi-color finishes on your aluminum CNC components. This guide will illuminate the path, empowering you to make informed decisions and secure a reliable manufacturing process for your high-quality parts.

Multi-color anodizing for aluminum CNC parts is a specialized finishing process that involves creating multiple distinct colored sections on a single component. The process uses a combination of electrochemical anodizing to grow a durable oxide layer and various masking techniques to isolate areas for different color dyes. This allows for intricate branding, functional color-coding, and enhanced aesthetics on precision-milled aluminum parts.

Now that we’ve outlined the core challenge and the solution, it’s time to delve deeper into the specifics. This article will therefore explore the technical nuances of the process, from initial CNC milling to the final sealing of the multi-hued surface. Subsequently, we will examine the critical role of masking and process control in achieving flawless results. Ultimately, understanding these elements is crucial for anyone involved in the design and procurement of high-quality aluminum CNC components.

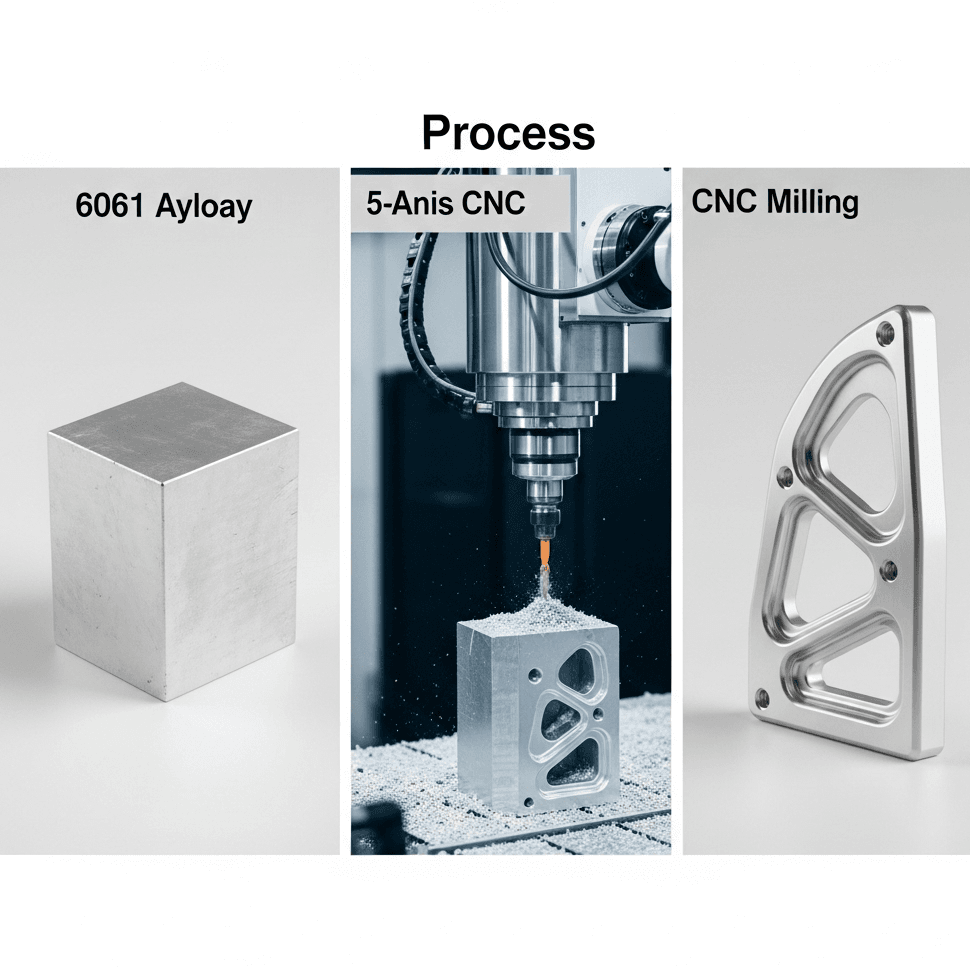

The Foundation: Precision Aluminum CNC Machining

Before any color can be applied, the foundation of the component must be perfect. This starts with superior Aluminum CNC machining. The choice of aluminum alloy and the quality of the CNC milling process directly impact the final anodized finish. Different alloys react differently to anodizing, affecting color absorption and consistency.

At ly-machining, our process begins with a thorough analysis of your project’s requirements. We consider the intended application, the desired aesthetic, and the functional demands of the part. This informs our selection of the ideal aluminum grade, whether it’s the versatile 6061 for general applications or the high-strength 7075 for aerospace and defense components where durability is paramount. Our advanced CNC machining centers ensure that every part is milled to exact specifications.

The surface finish achieved during CNC milling is another critical factor. A smooth, uniform surface created by a fine-tuned CNC machining process will accept dye more evenly, resulting in a richer, more consistent color. Conversely, a poorly finished surface can lead to a blotchy or streaky appearance after anodizing. We utilize precise cutting tools and optimal feeds and speeds to create a surface that is perfectly prepared for the subsequent anodizing steps. This meticulous attention to the initial Aluminum CNC phase is fundamental to the success of multi-color applications.

Understanding the Anodizing Process

Anodizing is an electrochemical process that enhances the natural oxide layer on the surface of aluminum parts. This layer is not a coating like paint; it is an integral part of the aluminum itself, making it incredibly durable and corrosion-resistant. For multi-color applications, this process is carefully controlled to create a porous anodic layer that can absorb colored dyes.

The process involves immersing the aluminum CNC part in an electrolytic acid bath, typically sulfuric acid, and passing an electric current through it. The part acts as the anode (positive electrode), and as current flows, oxygen is released at the surface, combining with the aluminum to form a hard, porous layer of aluminum oxide. The thickness and porosity of this layer are precisely controlled by adjusting the bath chemistry, temperature, and electrical current—parameters that are critical in any professional CNC machining and finishing operation.

There are two primary types of anodizing relevant to most applications:

| Anodizing Type | Typical Thickness | Key Characteristics | Best For |

| Type II (Sulfuric Acid) | 0.0002″ – 0.001″ | Good corrosion resistance, excellent for dyeing, decorative. | Most commercial and consumer products where aesthetics are key. |

| Type III (Hardcoat) | 0.001″ – 0.004″ | Superior hardness and density, enhanced wear resistance. | High-wear industrial, aerospace, and military applications. |

While Type III hardcoat can be dyed, the denser pore structure often results in darker or less vibrant colors, such as black or dark grays. Most vibrant multi-color applications utilize the Type II process, which offers the best canvas for a wide spectrum of brilliant colors. Understanding this distinction is vital when specifying requirements for your Aluminum CNC parts.

The Art of Masking in Multi-Color Anodizing

Achieving crisp, clean lines between different colors on an aluminum part is the hallmark of a quality multi-color anodizing job. This is accomplished through a meticulous process called masking. After the initial anodizing and first color dye bath, specific areas are masked off to protect them from subsequent colors or from having their color stripped. This is the most labor-intensive and technically challenging part of the process and requires immense skill.

Several masking techniques are employed, each with its own set of advantages depending on the geometry of the part and the complexity of the design. The choice of masking method is a critical decision in the overall CNC machining and finishing workflow.

1. Tape and Plug Masking

This is the most traditional method. High-temperature, chemical-resistant tapes are precisely cut and applied to flat or gently curved surfaces. For holes, threads, and bores, custom-sized silicone or rubber plugs are used. This method is effective for simpler geometric designs and is often the most cost-effective for low to medium-volume runs. However, it requires a steady hand and significant manual labor to ensure the tape edges are perfectly sealed to prevent “color bleeding,” where dye seeps under the mask.

2. Liquid Masking Agents

For more complex geometries, such as parts with intricate contours or textured surfaces produced by CNC milling, a paintable liquid masking agent is often used. This liquid is applied to the areas to be protected and then cured to form a durable, peelable rubbery layer. It provides excellent conformity to irregular surfaces where tape would wrinkle or fail. After the subsequent anodizing steps, the mask is manually peeled away.

3. Advanced Masking: Laser and Chemical

For the highest precision and repeatability, especially in high-volume production of complex Aluminum CNC components, advanced techniques come into play.

- Laser Masking: A laser is used to selectively ablate or etch away portions of the already-dyed anodic layer. This creates incredibly sharp and precise patterns, far beyond what is possible with manual masking. The laser can also be used to create a “mask” by altering the surface before dyeing, allowing for intricate logos, text, or schematic diagrams.

- Chemical Masking: This involves using screen printing or pad printing to apply a chemical resist to the surface. This resist prevents the underlying area from being affected during subsequent color stripping or dyeing cycles. It is highly effective for repeating patterns and logos on flat or slightly curved surfaces, blending the precision of printing with the durability of anodizing.

The expertise of a vendor like ly-machining is demonstrated in their ability to select and combine these techniques to achieve the desired outcome efficiently and effectively.

Controlling Quality: Ensuring Color Consistency and Durability

Quality control in a multi-color anodizing process is a multi-faceted endeavor that spans the entire manufacturing chain, from the initial Aluminum CNC machining to the final sealing of the part. Without rigorous checks at every stage, the final product can suffer from a host of defects that compromise both its appearance and performance.

A consistent process is key. This begins with the raw material; even different batches of the same aluminum alloy can have slight variations in their composition, leading to minor differences in color uptake. A quality-focused CNC machining partner will manage their material sourcing carefully to minimize this variability. Throughout the anodizing process itself, critical parameters must be electronically monitored and controlled.

These parameters include:

- Bath Concentration: The chemical makeup of the etch, desmut, anodizing, and dye baths must be kept within tight tolerances.

- Temperature: Even a few degrees of temperature fluctuation in the dye bath can alter the final shade of the color.

- Current Density & Voltage: The electrical parameters during the anodizing phase determine the thickness and porosity of the oxide layer, which directly impacts dye absorption.

- Immersion Time: The duration a part spends in each tank is timed precisely to ensure consistent results from part to part.

After anodizing, parts undergo a series of inspections. Visual inspection under controlled lighting is the first step to check for obvious defects like color bleeding, spotting, or inconsistencies. For more quantitative analysis, specialized equipment is used. Colorimeters can be used to measure the exact color shade and ensure it matches the customer-specified standard (e.g., a Pantone color). Eddy current or other non-destructive testing methods are used to verify that the anodic coating thickness meets the required specification, ensuring the part’s durability and corrosion resistance.

Finally, the sealing process is the last critical step. The porous oxide layer is sealed, typically in a hot deionized water or nickel acetate solution, to lock in the dyes and close the pores. An improper seal can lead to colors fading over time or “leaching” from the surface. Adhesion tests may also be performed to ensure the sealed coating is robust and will not flake or peel during use. This comprehensive approach to quality is what separates a premier Aluminum CNC provider from the rest.

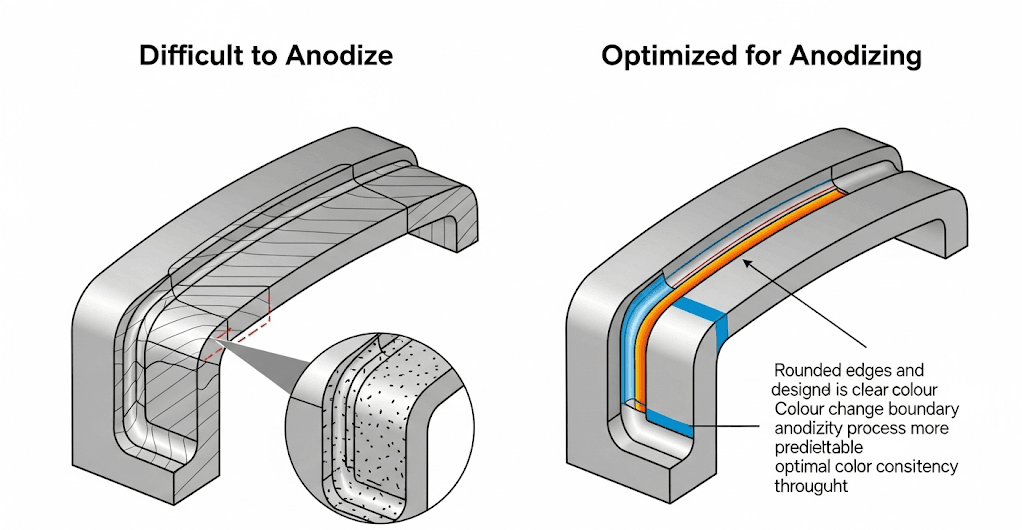

Design for Anodizing: Optimizing Your CNC Parts

To achieve the best results and control costs, it’s beneficial to design parts with the multi-color anodizing process in mind. Collaborating with your CNC machining partner during the design phase can prevent future manufacturing headaches and lead to a superior final product. This practice, known as Design for Manufacturing (DFM) or more specifically, Design for Anodizing (DFA), involves a few key considerations.

First, consider the edges and corners of your part. Very sharp external corners (90 degrees or less) can be problematic for anodizing. The anodic layer tends to build up thinner on these sharp edges, which can lead to a lighter color or reduced corrosion resistance in that area. Specifying a small radius or chamfer on these edges, even one as small as 0.5mm, allows for a more uniform coating thickness and better color consistency.

Second, think about the masking process. If your design requires a color boundary to fall on a complex, curving surface, it will be more challenging and costly to mask than a boundary that falls along a clear, defined edge or groove. Designing a shallow groove (e.g., 0.2mm deep) where two colors meet can provide a natural boundary for the mask, resulting in a cleaner line and a more efficient process.

Third, the alloy selection, a core part of the Aluminum CNC process, is paramount. As discussed, alloys like 6061 are excellent for bright, vibrant colors. Alloys from the 7000 series, while stronger, may yield slightly different or darker shades. It is crucial to discuss the desired color palette with your manufacturing partner to ensure the selected alloy can achieve it.

Lastly, be mindful of deep pockets and small, blind holes. It can be difficult for the acid and dye solutions to circulate properly in these areas, potentially leading to thinner coatings or inconsistent color. If possible, designing parts with through-holes instead of blind holes, and avoiding extremely deep and narrow cavities can improve the quality and consistency of the anodized finish. Thoughtful design, guided by the expertise of your CNC milling and finishing provider, is a cornerstone of success.

Applications Across Industries

The unique combination of durability, corrosion resistance, and aesthetic versatility makes multi-color anodized aluminum CNC parts a preferred choice across a wide range of demanding industries. The ability to color-code functions, enhance branding, and provide a premium feel while maintaining high performance is invaluable.

Consumer Electronics: Think about high-end laptops, smartphones, and audio equipment. Multi-color anodizing is used to create stunning visual effects, differentiate product lines (e.g., different colors for different storage capacities), and add premium branding elements. The durable finish withstands daily handling, and the precision of the CNC machining ensures a perfect fit and finish.

Automotive & Motorsport: In the automotive world, performance and appearance go hand-in-hand. Multi-color anodized parts are found in custom engine components, interior trim, and suspension parts. Red for high-performance, blue for a specific brand—the colors are both functional and aesthetic. The corrosion resistance is also vital for parts exposed to the elements.

Medical Devices: The medical industry requires materials that are biocompatible, sterilizable, and easily identifiable. Multi-color anodized aluminum is used for surgical tool handles, diagnostic equipment housings, and other components. Colors can be used to code different sizes or types of instruments, reducing the risk of error in a fast-paced medical environment. The sealed anodic layer provides a clean, non-leaching surface.

Aerospace and Defense: In this sector, every component’s performance is critical. While Type III hardcoat is often used for its wear resistance, Type II multi-color anodizing is used for cockpit panels, casings for avionics, and other components where identification is key. The process must meet stringent military specifications (e.g., MIL-A-8625F), a testament to its reliability. The lightweight nature of aluminum combined with the protective anodized finish makes it ideal for applications where every gram counts. This level of precision and reliability starts with expert Aluminum CNC machining.

Choosing the Right Partner: What to Look For

Selecting the right manufacturing partner is the single most important decision you will make in your project. A capable partner is more than just a supplier; they are an extension of your design and engineering team. When evaluating a potential CNC machining and anodizing vendor, especially for complex multi-color work, there are several key attributes to look for.

First and foremost is integrated capability. A facility like ly-machining that handles both the Aluminum CNC milling and the multi-color anodizing in-house offers a significant advantage. This eliminates the logistical challenges and potential for blame-shifting that can occur when work is subcontracted between a machine shop and a separate finishing house. An integrated process ensures seamless communication, unified quality control, and a single point of accountability.

Second, inquire deeply about their process control and quality assurance systems. Ask them how they monitor and document their bath chemistries, temperatures, and electrical parameters. Do they have colorimeters to ensure color matching? Can they provide certificates of conformity and inspection reports that verify coating thickness and adherence to standards like MIL-A-8625F? A confident and capable partner will be transparent about their quality systems.

Third, look for engineering expertise and a collaborative spirit. The best partners will review your design and provide DFM/DFA feedback. They will ask questions, suggest improvements, and work with you to find the most effective and cost-efficient way to achieve your desired result. They should be able to discuss the pros and cons of different aluminum alloys, masking techniques, and finishing options in the context of your specific application.

Finally, ask to see examples of their previous work. A portfolio of complex, multi-color anodized parts is the best evidence of their capability. Pay close attention to the sharpness of the color lines, the consistency of the finish, and the overall quality of the components. Choosing a partner with proven experience in high-quality Aluminum CNC and intricate finishing is your best guarantee of success.

Related Questions

1. Can you anodize a part that has been assembled from multiple CNC machined pieces?

Generally, it is not recommended to anodize an assembly. The anodizing process requires the part to be electrically conductive and for the solution to flow freely over all surfaces. The tiny gaps and seams in an assembly can trap chemicals, leading to corrosion (crevice corrosion) and an inconsistent finish. Furthermore, if the assembly contains different aluminum alloys or other metals (like steel screws), it can disrupt the electrochemical process entirely. The best practice is to perform the Aluminum CNC machining and anodizing on each component individually before assembly.

2. What is the difference in cost between single-color and multi-color anodizing?

Multi-color anodizing is significantly more expensive than single-color anodizing due to the extensive manual labor and additional process steps involved. The primary cost drivers are the masking and de-masking operations. Each additional color requires a full cycle of masking, color stripping/bleaching, re-dyeing, and de-masking. The complexity of the mask is also a major factor; a simple design using tape will be less costly than an intricate one requiring liquid masking or laser etching. As a rough estimate, a two-color part can be 2-4 times the cost of a single-color part, and the cost increases with each subsequent color. A detailed quote from your CNC machining partner is essential.

Frequently Asked Questions (FAQs)

1. What is the maximum number of colors you can apply to a single aluminum part? Theoretically, there is no hard limit to the number of colors. However, the practical limit is dictated by the part’s geometry, the available space for masking, and the escalating cost and complexity with each added color. Most multi-color projects involve 2 to 4 colors. Beyond that, the process becomes exponentially more difficult and expensive, and the risk of defects increases. It’s a balance between design intent and manufacturing feasibility that should be discussed with an expert from your CNC milling provider.

2. How durable are the colors in a multi-color anodized finish? The durability is excellent, especially when properly sealed. Because the dye is absorbed into the porous aluminum oxide layer, it is not a surface coating that can easily chip or peel like paint. The color is integral to the hard, ceramic-like anodic layer. However, the lightfastness can vary depending on the specific dye used and the environment. High-quality organic dyes offer good UV resistance for most applications, but for extreme outdoor or high-UV environments, you should discuss the most stable dye options with your anodizing specialist.

3. Can you achieve a metallic or glossy finish with multi-color anodizing? The standard anodized finish is typically matte or satin. However, the final appearance is heavily influenced by the initial surface preparation of the Aluminum CNC part. A highly polished part will have a brighter, more reflective anodized finish, while a bead-blasted part will have a more uniform, non-reflective matte finish. A “bright dip” chemical polishing step can be performed before anodizing to achieve a very glossy, almost mirror-like appearance, though this can add to the cost. Communicating your desired gloss level is a key part of the specification process.