Have you ever heard some wild stories about CNC machining aluminum enclosures? Maybe you’ve been told that it’s incredibly expensive or that it only works for high-end applications. I’ve talked to several people who have held back on using CNC machining for their projects simply because they were misled by these myths. Let’s set the record straight about the misconceptions surrounding CNC machining aluminum enclosures in China.

Common Misconceptions

One of the most significant myths is that CNC machining is far too costly for small-scale operations. In reality, CNC machining offers a balance of quality and affordability, especially for aluminum enclosures. I once worked with a startup that had tight budgets but needed precise components. We opted for CNC machining, and they managed to save nearly 30% on production costs compared to traditional methods. It’s essential to understand that while initial setup costs can be higher, the greater precision and reduced waste typically yield significant savings in the long run.

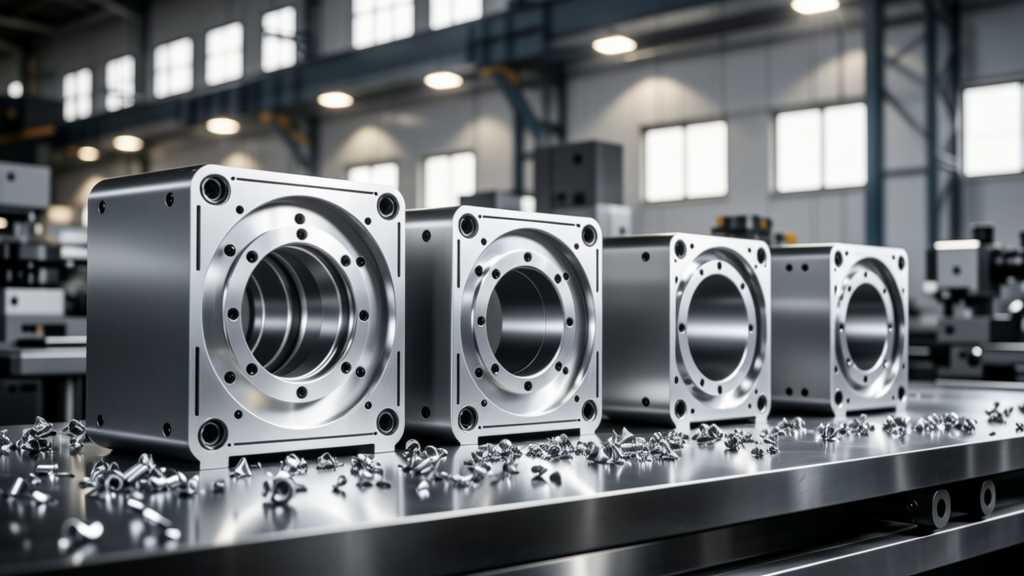

Another myth is the idea that CNC machines can only produce simple shapes. Many people I know think of wooden blocks and rectangles when they picture CNC machining, but they don’t realize that modern CNC machines can create highly intricate designs. For instance, advanced CNC tools can create complex geometries for aluminum enclosures that meet specific customer requirements. I’ve seen gorgeous designs come to life that would be nearly impossible with manual machining.

The Importance of Precision

A common concern among newcomers to CNC machining is the belief that aluminum enclosures can’t achieve the same level of quality as ones made from other materials. That’s outdated thinking! Aluminum is one of the best materials for achieving light weight while maintaining the required strength and durability. I remember a client who needed enclosures for a sensitive electronic device. We machined the enclosures using high-grade aluminum, and they met all quality standards while remaining lightweight and easy to transport.

Why is precision so vital? Because it directly affects the overall performance of the final product. Accurate machining minimizes fitting issues and improves the life cycle of the product. It’s worth noting that CNC machining of aluminum enclosures enables recycling and reuse, making it an eco-friendly option too.

Choosing the Right CNC Machining Services

When considering CNC machining for your aluminum enclosures, it’s crucial to choose the right manufacturer. You should look for a company like ly-machining that has a solid reputation and extensive experience. Be sure to ask about their previous projects and material handling capabilities. The right partner can make a significant difference in your project’s outcome.

Additionally, always clarify your requirements upfront—dimensions, tolerances, and finishes. One memorable project I handled had some initial miscommunications about size specifications, causing delays. We quickly resolved it with clear and open discussions, which reinforced the importance of good communication. Make sure your chosen service provider understands what you need.

Trustworthy Information Sources

If you’re still unsure about making the leap to CNC machining aluminum enclosures, check out resources like the National Institute of Standards and Technology (NIST) (nofollow) where they provide a wealth of knowledge about machining processes and their applications. Their standards can help you make informed decisions.

Another resource I recommend is the American Society of Mechanical Engineers (ASME) (nofollow). They offer various studies and industry standards that can shed light on current machining technologies and trends.

Choosing CNC machining doesn’t have to be shrouded in confusion. By uncovering these myths, you’re in a better position to make informed choices for your projects. Should you have any questions or considerations that come up, feel free to reach out! With a bit of investigation and discussion, you can navigate the world of CNC machining aluminum enclosures with confidence.

What are the common myths about CNC machining aluminum enclosures?

Many people think CNC machining is only suited for large-scale operations and can be too expensive for smaller projects. This isn’t true, as it often provides a cost-effective solution for both small and large operations.

Another misconception is that CNC machines can only produce simple shapes. In reality, modern CNC machines can create highly intricate designs from aluminum, suitable for various applications.

Why is precision important in CNC machining?

Precision in CNC machining directly impacts the performance of the final product. When the machining is accurate, it significantly reduces fitting issues, enhancing the overall quality and durability of aluminum enclosures.

Moreover, accurate machining also contributes to resource efficiency, minimizing waste and making the process more eco-friendly.

How do I choose the right CNC machining service?

When selecting a CNC machining service, consider their reputation and experience. It’s vital to ask about past projects to gauge their capabilities in handling specific requirements effectively.

Clear communication is crucial, so ensure they understand your project specifications, such as dimensions and tolerances, to avoid any avoidable delays down the line.

Where can I find reliable information on CNC machining?

One excellent resource is the National Institute of Standards and Technology (NIST), which provides comprehensive insights into machining processes and standards.

The American Society of Mechanical Engineers (ASME) is another great reference, offering studies and standard practices to help you make more informed decisions about CNC machining.