Night Vision Enclosure CNC machining demands precise surface finishes. Anodizing offers superior hardness and corrosion resistance, ideal for extreme conditions, while painting provides extensive aesthetic customization and environmental shielding for diverse Night Vision Surface Finish requirements.

In the demanding world of night vision, the difference between mission success and failure often hinges on a seemingly small detail: your device’s enclosure finish. When it comes to Night Vision Housing Machining, how do you decisively choose between anodizing and painting?

Making the wrong choice can compromise performance, durability, and ultimately, mission readiness. This guide from ly-machining will meticulously compare these two critical processes, empowering you to make an informed decision for your precision Night Vision Enclosure CNC projects.

CNC Machining for Night Vision: Precision

Critical Performance Demands of Night Vision Housings

Night vision housings are not merely protective shells; they are integral components that directly influence device performance and user experience. They must withstand extreme environmental conditions, from arid deserts to freezing arctic tundras.

Reliability in harsh operational settings is non-negotiable, requiring finishes that resist abrasion, impact, and chemical exposure. Thermal management, stealth characteristics, and precise optical alignment are also crucial factors.

Why CNC Machining is Essential for Complex Enclosures

Computer numerical control (CNC) machining offers unparalleled precision and repeatability, which is critical for Night Vision Enclosure CNC projects. The complex geometries and tight tolerances required for optics, sensor arrays, and ergonomic features demand this level of manufacturing.

Precision milling and turning ensure that critical dimensions are met, minimizing assembly issues and optimizing device functionality. This foundation of accuracy directly impacts the efficacy of any subsequent surface finish.

Material Selection for Optimal Enclosure Performance

The choice of material is fundamental to the overall performance of a night vision housing. Aluminum alloys, particularly 6061 and 7075, are frequently selected due to their excellent strength-to-weight ratio and machinability.

In our experience, these materials provide a robust base for various surface finishes, while meeting specific weight and structural integrity requirements. Selecting the right alloy is a critical early step in the DFM process.

| Material Type | Key Benefits | Common Applications |

|---|---|---|

| Aluminum Alloy 6061 | High strength, good corrosion resistance, excellent machinability | General purpose, cost-effective night vision enclosures |

| Aluminum Alloy 7075 | Superior strength, higher fatigue resistance | High-performance, military-grade night vision devices |

| Magnesium Alloys | Extremely lightweight, good EMI shielding | Ultralight, portable night vision systems |

Anodizing Night Vision Enclosures: Deep Dive

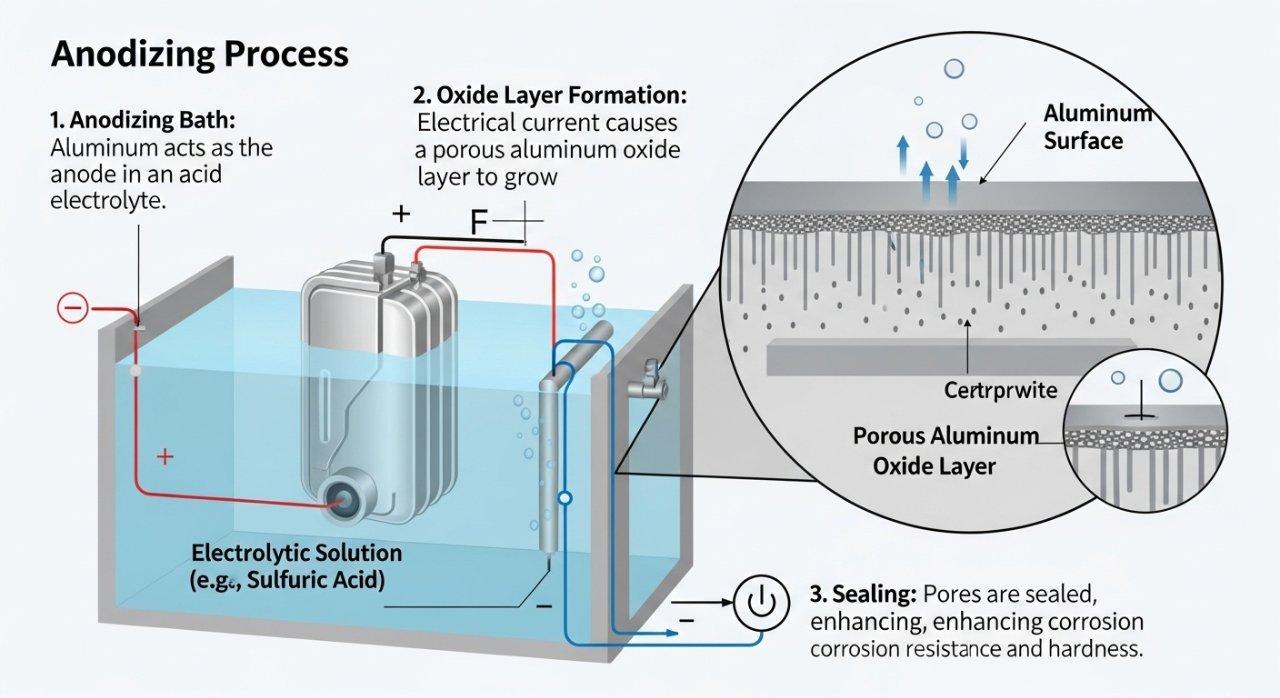

Understanding the Anodizing Process and Types

Anodizing is an electrochemical passivation process that thickens the natural oxide layer on metal surfaces, typically aluminum. It creates a durable, porous surface that can be dyed for various colors or left natural.

For night vision applications, Type II (sulfuric acid anodize) offers good corrosion and abrasion resistance, while Type III (hardcoat anodize) provides exceptional hardness and wear resistance, crucial for rugged use.

Key Benefits: Hardness, Corrosion, Thermal Properties

Hardcoat anodizing creates a surface that is significantly harder than the base aluminum, offering superior abrasion and scratch resistance. This is invaluable for night vision devices exposed to rough handling.

The anodized layer also provides excellent corrosion resistance, protecting the housing from salt spray, moisture, and chemical exposure. Furthermore, the porous structure of anodizing can enhance thermal emissivity, aiding in heat dissipation for internal components.

Limitations and Design Considerations for Anodizing

Anodizing adds a measurable layer to the part, which must be accounted for in critical tolerance areas. Parts with very tight fits might require masking or post-anodizing machining, impacting cost and lead time.

The color consistency can sometimes be challenging across large batches, and specific alloys may yield different color results. Sharp corners can also experience “burning” during the process, necessitating design adjustments.

Ideal Applications for Anodized Night Vision Parts

Anodizing, especially hardcoat, is the preferred Night Vision Surface Finish for devices subjected to extreme wear, high impact, or harsh environmental conditions. Think military-grade binoculars, weapon-mounted sights, and handheld thermal imagers.

It is highly suitable when durability, non-reflectivity (matte black), and a robust, integral surface are paramount. Anodizing provides a truly tough, long-lasting finish for critical outdoor equipment.

Painting Night Vision Enclosures: In-Depth

Different Paint Types and Application Methods

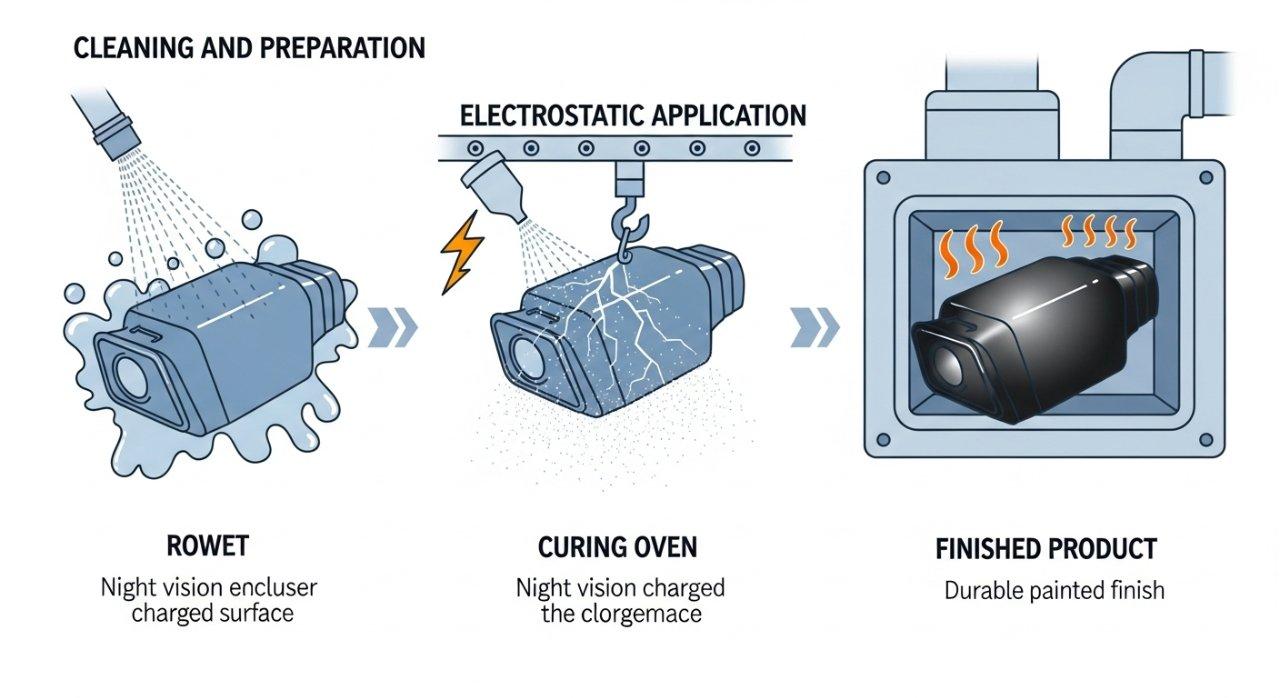

Painting for night vision enclosures encompasses a range of materials, including liquid paints (epoxies, polyurethanes) and powder coatings. Each type offers distinct properties and application methods, such as spraying or electrostatic deposition.

Specific paint formulations can provide stealth properties, such as low IR emissivity, or enhanced grip textures. The choice depends heavily on the operational environment and required aesthetics.

Advantages: Aesthetics, Customization, Environmental Shield

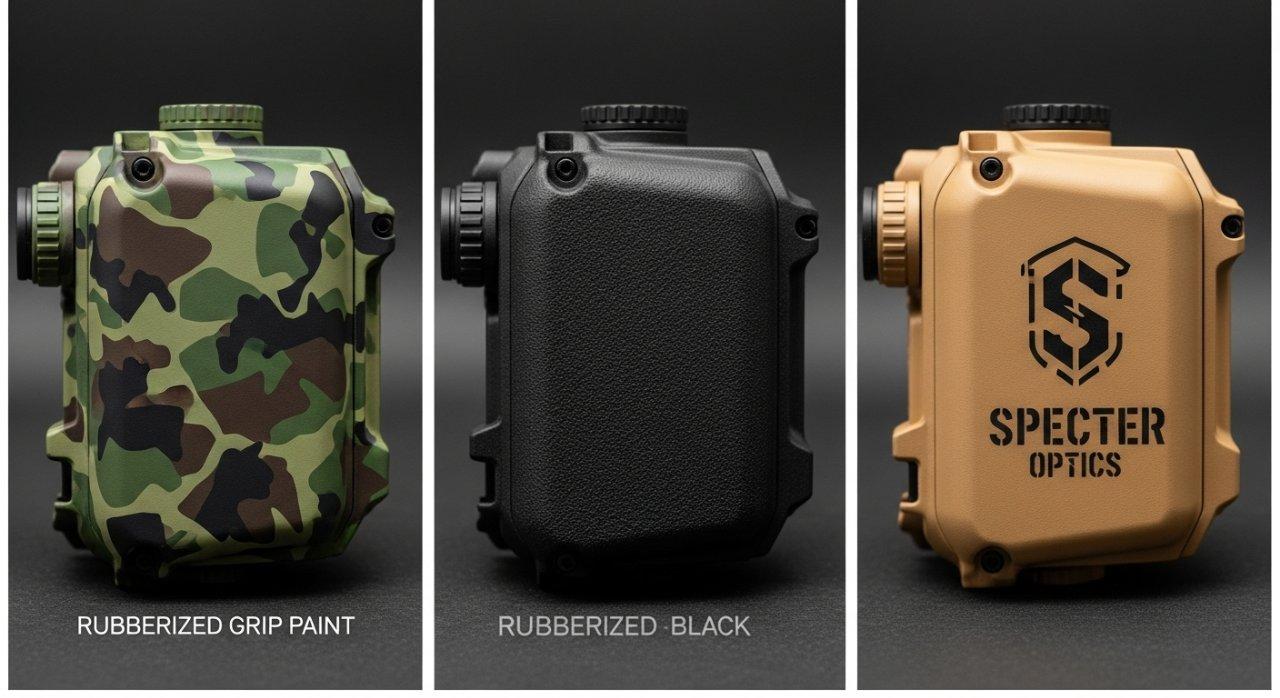

Painting offers unparalleled aesthetic flexibility, allowing for a vast spectrum of colors, textures, and finishes, including camouflage patterns or custom branding. It provides an excellent canvas for unique product designs.

Beyond aesthetics, certain paints can provide an effective barrier against chemicals, UV radiation, and moisture, enhancing environmental shielding. Specialized coatings can also offer non-slip surfaces for improved handling.

Potential Drawbacks and Long-Term Durability

Compared to hard anodizing, painted surfaces, especially thin liquid coats, can be more susceptible to chipping, scratching, and abrasion. The bond to the substrate is also typically mechanical, rather than integral.

This can lead to wear and tear in high-friction areas or extreme environments. Re-coating can be complex, and consistent adhesion requires meticulous surface preparation.

When to Choose Painted Night Vision Device Housings

Painting is often chosen when aesthetics, specialized tactical colors, or specific environmental barriers (like chemical resistance) are prioritized over extreme wear resistance. It’s a strong contender for commercial night vision devices or less ruggedized applications.

It allows for greater design freedom and can be a cost-effective solution for large production runs. When specific stealth properties or user-friendly textures are critical, painting offers tailored solutions.

Anodizing vs. Painting: Deciding Factors

Performance Comparison: Durability, Wear, Environment

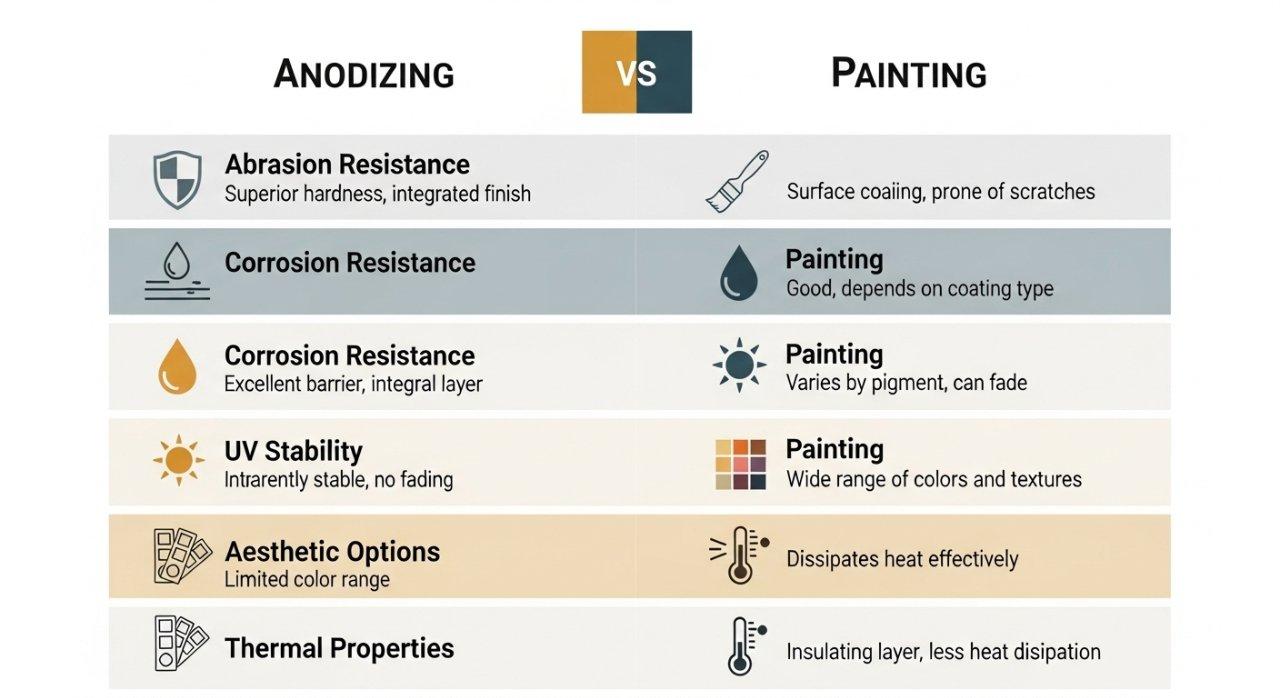

When evaluating Night Vision Surface Finish options, durability is often the top concern. Anodizing, particularly Type III, provides a ceramic-hard surface that resists abrasion and gouging.

Painting’s durability varies significantly by paint type; some robust powder coatings can be very tough, but typically don’t match hard anodize for integral hardness. Both offer corrosion resistance, but anodizing is inherently integral.

| Feature / Property | Anodizing (Type III Hardcoat) | Painting (e.g., Powder Coat) |

|---|---|---|

| **Abrasion Resistance** | Excellent (ceramic-hard layer) | Good to Very Good (depends on formulation) |

| **Corrosion Resistance** | Excellent (integral oxide layer) | Very Good (barrier coating) |

| **Impact Resistance** | Good (can crack on severe impact) | Good (can chip or scratch) |

| **Thermal Management** | Can enhance emissivity | Barrier, can trap heat (formulation dependent) |

| **Adhesion** | Integral bond, part of the substrate | Mechanical bond, dependent on prep |

| **UV Resistance** | Excellent (inorganic) | Good to Excellent (pigment dependent) |

Cost Implications: Initial vs. Lifetime Value

The initial cost of anodizing can sometimes be higher per piece than painting, especially for specialized hardcoat processes. This is due to the chemical treatment and precise process control required.

However, considering the long-term durability and reduced maintenance or replacement frequency, anodizing often offers a lower lifetime cost. Painting can be more economical for mass production and allows for simpler touch-ups.

Aesthetic and Tactile Considerations for Devices

Anodizing typically results in a matte, often non-reflective finish that is highly functional for tactical equipment. Color options are somewhat limited, usually to black, clear, or dark shades.

Painting offers limitless color customization, including specific camouflage patterns and a wide range of textures, from smooth to rubberized. This allows for branding and user-specific tactile feedback.

Impact on Production Lead Time and Process Flow

Both anodizing and painting processes require dedicated cycles and contribute to the overall lead time for Night Vision Enclosure CNC projects. Anodizing involves several chemical baths and precise timing.

Painting requires thorough surface preparation, application, and curing times. Our scheduling expertise allows us to optimize these processes, ensuring efficient production flows and meeting critical deadlines.

Regulatory Compliance and Industry Standards

For defense and aerospace applications, adherence to standards like AS9100 and ISO 9001 is paramount. Both finishing processes must comply with material specifications and performance requirements.

We ensure that our anodizing and painting processes meet or exceed these stringent standards, providing traceable documentation for all finished components. This commitment to quality is fundamental.

Expert Source Manufacturer Partnership

Our Deep Technical Expertise in CNC Machining

As a source manufacturer, ly-machining brings unparalleled technical expertise to every Night Vision Housing Machining project. Our engineers possess a profound understanding of material science, machining tolerances, and surface finishing.

We are not just a vendor; we are an extension of your R&D team, providing DFM insights from concept to production. This collaborative approach ensures optimal design and performance.

Ensuring High-Quality Parts and Consistent Performance

Our commitment to quality is unwavering. We utilize state-of-the-art CNC equipment and rigorous in-process inspection protocols, adhering to ISO standards. Each Night Vision Enclosure CNC part undergoes meticulous quality control.

This comprehensive approach guarantees consistent performance, part after part, and minimizes costly rework or field failures. Trust is built on every component we deliver.

Transparent Pricing and Optimized Solutions

We believe in transparent pricing structures, providing detailed quotes that clearly outline costs. Our goal is to offer optimized solutions that balance performance requirements with budget constraints.

Leveraging our deep understanding of both anodizing and painting, we help you achieve the best value without compromising on the critical demands of night vision devices.

Customized DFM Consultation for Your Project

Our engineering team provides customized Design for Manufacturability (DFM) consultations from the outset. We analyze your night vision enclosure designs to identify potential manufacturing efficiencies and cost savings.

This proactive approach ensures that your chosen Night Vision Surface Finish integrates seamlessly with the housing’s design, preventing costly delays and optimizing the entire production cycle.

Make the Right Night Vision Choice

Ultimately, the choice between anodizing and painting for your Night Vision Enclosure CNC project hinges on a thorough evaluation of environmental stressors, performance requirements, aesthetic goals, and cost-benefit analysis. With ly-machining, you gain a partner who provides the technical expertise and precision manufacturing necessary to navigate these critical decisions.

Our dedication to producing high-quality Night Vision Housing Machining, combined with our deep understanding of various Night Vision Surface Finish options, ensures your device performs flawlessly. We deliver solutions that stand up to the most demanding conditions.

Your Next Step: Expert Consultation and Quote

Stop guessing and start optimizing. For a truly durable, high-performance night vision enclosure, partner with the experts. Contact our engineering team today for a no-obligation technical consultation and transparent quote tailored to your project’s unique requirements. Let our deep technical expertise guide your next critical decision.

Case Study: Enhancing Arctic Reconnaissance Device Durability

Problem: A defense contractor approached ly-machining with a challenge: their existing night vision enclosures for arctic reconnaissance were failing due to severe abrasion and sub-zero corrosion. The painted finish chipped easily, exposing the aluminum to rapid degradation.

Our Solution: Our engineering team meticulously analyzed the extreme arctic environmental stressors. We recommended switching from a standard painted finish to a Type III hardcoat anodizing for their precision Night Vision Enclosure CNC parts. This involved optimizing the housing’s design for the anodizing process, ensuring critical tolerances were maintained.

Result: The hard anodized Night Vision Housing Machining demonstrated dramatically improved abrasion resistance and superior corrosion protection in rigorous field tests. The new Night Vision Surface Finish extended the device’s operational lifespan by over 75%, significantly reducing maintenance costs and ensuring unwavering reliability in critical missions.

FAQ Section

What is hardcoat anodizing for night vision?

Hardcoat anodizing, or Type III anodizing, is an electrochemical process that forms a very dense, abrasion-resistant aluminum oxide layer on the Night Vision Enclosure CNC. It significantly enhances surface hardness, making it ideal for rugged applications.

This integral layer provides exceptional durability and corrosion protection. It is a robust Night Vision Surface Finish choice.

Can painting provide stealth properties?

Yes, specialized paint formulations can be engineered to provide specific stealth properties for Night Vision Housing Machining. This includes low infrared (IR) reflectivity and non-glare finishes.

These coatings help the device remain inconspicuous in various operational environments. They are crucial for tactical applications.

How do I choose between anodizing and painting?

The choice depends on your primary performance priorities. If extreme durability, abrasion resistance, and inherent corrosion protection are paramount, anodizing is often superior.

If aesthetic customization, specific colors, or unique surface textures are critical, painting offers greater flexibility. Our team can help you evaluate these trade-offs for your Night Vision Enclosure CNC project.