The lens, everyone fixates on its glass, its coatings—but I tell you, the housing, *that’s* the uncelebrated titan of an optical system! Many overlook this fundamental truth. Are you genuinely confident your optical scope’s CNC-machined housing meets the exactitude required for flawless performance, or are you compromising on durability, weight, and critical tolerances from concept to finish? This is the essential question.

Our singular focus at ly-machining is on the uncompromising precision and long-term optical system reliability that a meticulously engineered housing provides. We see the housing not as a mere enclosure but as the unyielding backbone, the structural truth, that underpins all optical fidelity. This article delves into every facet, a definitive guide, truly.

Optical scope CNC machining demands a confluence of advanced materials, meticulous fabrication techniques, and stringent quality control. ly-machining, based in Shenzhen, China, specializes in delivering ultra-high precision CNC machined scope parts, ensuring every custom scope enclosure production project achieves peak performance and reliability. We are a premier source for aerospace-grade aluminum housing solutions.

Understanding Optical Scope Housing Requirements

To begin, what does an optical housing truly accomplish? It’s not simply a shell. It is, unequivocally, the structural integrity—the *raison d’être* for the optical train itself! Without it, your carefully ground lenses and prisms would wander freely, creating optical chaos.

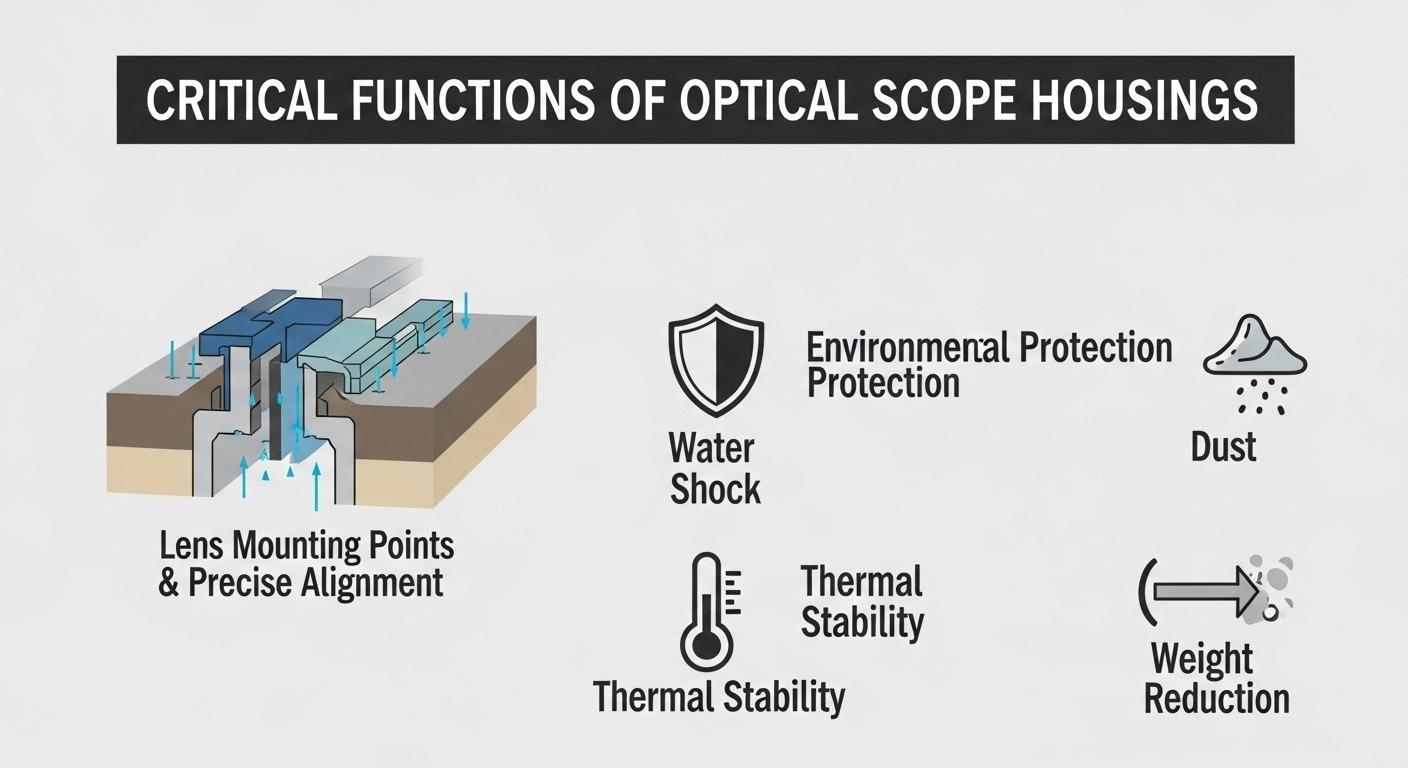

Critical Functions of an Optical Housing

A housing performs several absolutely vital functions. It securely mounts and aligns optical elements with sub-micron precision, protecting them from environmental ingress and mechanical shock. This structural component dictates the very performance envelope of the entire device. It cannot, must not, be an afterthought.

Demands for Precision and Durability

The relentless demands for precision—tolerances that can scarcely be measured without advanced metrology—are paramount. Then, there’s the durability. A scope housing must withstand truly brutal conditions: impacts, vibrations, extreme temperatures. It must not fail.

Why CNC Machining is Essential for Scopes

Only precision CNC machining can deliver such exacting requirements. Castings? Forget them. Additive manufacturing for high-stress optical components? Not yet, not for the core structure. CNC offers the repeatability, the accuracy, the sheer material control. It’s the only path forward.

Selecting Optimal Materials for Scope Housings

Material selection is where we begin to distinguish the exemplary from the merely adequate. It dictates weight, strength, and thermal response—each a non-negotiable factor in optical instrument machining. Choosing unwisely? A truly disastrous error.

Common Material Choices: Aluminum Alloys

Aluminum alloys are, for myriad reasons, the workhorses. Alloys like 6061 and 7075 offer exceptional strength-to-weight ratios and machinability. We routinely utilize aerospace-grade aluminum housing materials to achieve unparalleled performance. It’s a foundational decision, absolutely pivotal.

Advanced Materials: Titanium and Composites

But what about the truly extreme requirements? We consider titanium for its superior strength and corrosion resistance, though its machinability is a challenge we gladly conquer. Composites, too, have their place—especially when ultra-lightweight designs are mandated. Their application is a strategic choice, a thoughtful calculation.

Material Properties Influencing Scope Performance

Material properties influence everything; they truly do. Understanding these characteristics is not merely helpful; it’s absolutely crucial for optical scope CNC machining success. Poor thermal stability? Expect focus shifts, a true nightmare scenario!

Strength-to-Weight Ratio and Impact Resistance

The strength-to-weight ratio directly impacts usability and fatigue. No one wants a ponderous, fragile scope. Impact resistance ensures survival in rugged environments. It’s a core performance metric.

Thermal Stability and Environmental Corrosion

Thermal stability is paramount for consistent optical performance across temperature gradients. And then there’s corrosion! Protection against the elements, a critical consideration for maritime or battlefield applications, ensures longevity. We guarantee it.

The CNC Machining Process for Scope Housings

Our fabrication process is not a simple production line; it is a meticulously choreographed ballet of precision engineering. Every stage, every cut, is a testament to our deep technical expertise in custom scope enclosure production. We scrutinize every detail.

Design for Manufacturability (DFM) Principles

DFM is where the magic begins, honestly. Our engineers collaborate extensively with clients, optimizing designs for efficient, high-precision manufacturing *before* a single chip is cut. This proactive approach saves time and money, preventing costly redesigns. It’s incredibly powerful.

Table: Optical Housing Materials

| Material | Key Benefits |

|---|---|

| 6061 Aluminum | Excellent strength-to-weight, machinability |

| 7075 Aluminum | High strength, good fatigue resistance |

| Titanium (Gr.5) | Superior strength, corrosion resistance, rigid |

| Carbon Fiber | Extreme lightweight, high stiffness |]

Advanced CNC Machining Techniques Utilized

We deploy a formidable arsenal of advanced CNC machining techniques. This isn’t your grandfather’s machine shop. Our capabilities are truly state-of-the-art. We push the boundaries.

Multi-Axis Milling for Complex Geometries

Multi-axis milling, particularly 5-axis, is non-negotiable for the intricate, often organic geometries of scope housings. We achieve complex internal features and contours in a single setup, maintaining unparalleled datum integrity. This efficiency is critical, undoubtedly.

High-Precision Turning and Grinding

High-precision turning forms flawless cylindrical components, while grinding processes achieve mirror-like finishes and ultra-tight diameter tolerances. These steps are absolutely essential for optical interfaces, where the slightest deviation can cause a truly catastrophic failure. We meticulously execute them.

Tooling and Fixturing for Optical Scope Parts

The tooling and fixturing are not secondary; they are an extension of the machine’s precision. Custom-engineered fixtures securely hold delicate or thin-walled optical scope parts, preventing distortion. Specialized cutting tools maintain edge quality and surface integrity for these demanding applications. It’s an art, really, a science, undeniably.

Achieving Critical Tolerances & Surface Finish

Achieving critical tolerances—often down to a few microns—and exceptional surface finishes (Ra values approaching 0.4 µm) is our absolute standard, not an aspiration. These characteristics are indispensable for proper optical alignment and sealing. They are the very essence of optical instrument machining.

Post-Machining Processes for Optical Housings

The journey doesn’t conclude when the part leaves the machine; oh no! Post-machining processes are integral to the housing’s functional and aesthetic culmination. They are not merely supplementary steps.

Surface Treatment for Protection and Aesthetics

Surface treatments are incredibly important for both protection and visual appeal. This step enhances durability, corrosion resistance, and provides specific optical properties. It can transform a raw component.

Anodizing for Durability and Anti-Glare

Anodizing, especially hard anodizing, significantly increases surface hardness and wear resistance. For optical scope parts, a matte black anodized finish provides crucial anti-glare properties, preventing unwanted reflections that can impair optical performance. It’s a vital detail, a strategic finish.

Coatings for Environmental Resistance

Beyond anodizing, specialized coatings—such as cerakote or other proprietary polymer-ceramic blends—can impart superior environmental resistance against saltwater, abrasions, and chemicals. These are often application-specific, a customized defense.

Deburring and Edge Finishing Techniques

Deburring is not a trivial task! It’s an absolutely meticulous process. Any remnant burrs can compromise sealing surfaces, scratch delicate lenses during assembly, or create points of failure. We employ precise manual and automated deburring techniques. Flawless.

Assembly and Integration Considerations

We constantly consider assembly and integration during the machining phase. How will lenses be seated? What about sealing O-rings? Our designs and machining anticipate these challenges, ensuring seamless downstream processes. It saves our clients considerable headaches.

Quality Assurance for Optical Scope Housings

Quality assurance is not a checkpoint; it is a pervasive philosophy, integrated into every single stage of our Precision Housing Manufacturing. A defective housing is not merely an inconvenience; it can render an entire optical system useless! Unacceptable.

Rigorous In-Process Inspection Methods

From the moment raw material enters our facility, through every machining operation, rigorous in-process inspections are conducted. Our operators utilize calibrated gauges and visual checks, identifying deviations immediately. This prevents cascading errors.

Final Metrology for Critical Dimensions

The final metrology, however, is the ultimate arbiter of precision. This is where the rubber meets the road, where exactitude is proven. We leave no dimension unverified, no tolerance unmeasured.

CMM and Optical Measurement for Precision

Our advanced metrology lab deploys Coordinate Measuring Machines (CMMs) for three-dimensional accuracy down to single-micron levels. Optical comparators and non-contact profilometers analyze surface finishes and delicate features. We measure everything, leaving no ambiguity.

Functional Testing and Performance Verification

Beyond dimensional checks, functional testing can replicate real-world assembly scenarios, ensuring form, fit, and function are impeccable. Performance verification, too, guarantees the part meets its intended operational parameters. It’s a comprehensive validation, an absolute must.

Traceability and Material Certifications

Complete traceability, from the raw material billet to the finished part, is an absolute necessity. Material certifications, providing documented proof of alloy composition and properties, accompany every batch. This provides an audit trail, an irrefutable history.

Partnering with a Source for Scope Housings

Why partner with us, really? Because finding a true source manufacturer for high-precision CNC machined scope parts—one with transparent pricing and unwavering commitment to quality—is not a trivial pursuit. It’s a strategic alliance.

Benefits of Deep Technical Expertise

Our deep technical expertise is not merely a boast; it is a proven advantage. We don’t just machine parts; we solve engineering challenges, offering invaluable DFM insights that optimize your designs for superior performance and cost-efficiency. Our engineers become an extension of your team.

Transparent Pricing and Cost Efficiency

Opaque pricing is a common industry frustration, isn’t it? We believe in transparent pricing, providing detailed breakdowns so you understand exactly where your investment goes. This fosters trust and enables accurate budgeting. No hidden fees, ever.

Ensuring High-Quality Parts and Reliability

Ensuring high-quality parts and reliability is our solemn pledge. From material selection to final inspection, every step is geared towards delivering components that perform flawlessly under the most demanding conditions. Your reputation, frankly, depends on it!

Our Commitment from Material to Finished Product

Our commitment extends from the very first material selection—yes, even that!—all the way to the finished, meticulously inspected product. We are your dedicated partner for optical instrument machining, providing a robust foundation for your innovations. We never falter.

Case Study: Elevating a High-Performance Rifle Scope

A prominent client, specializing in high-performance rifle scopes, approached us with a truly vexing problem. Their existing supplier struggled with a complex internal geometry for a new, ultra-lightweight scope housing, resulting in excessive scrap rates and inconsistent lens seating. The project was teetering on the brink of disaster.

Our engineering team immediately engaged in an intensive DFM review. We identified that the thin-walled sections and deep internal pockets required specialized 5-axis tooling paths and a multi-stage stress-relieving process to prevent distortion. We also proposed a specific aerospace-grade aluminum housing alloy with enhanced machinability.

The result? ly-machining delivered prototypes that met all critical tolerances and surface finish requirements on the very first attempt! Our consistent production eliminated scrap, significantly reduced lead times, and ensured flawless assembly for the client. This collaboration, this engineering triumph, built a trust that continues to this day!

Article Summary

This article, a comprehensive analysis, has dissected the critical role of the CNC machined housing in optical scopes. We have traversed the entire journey, from the absolutely vital material selection—considering aerospace-grade aluminum housing and advanced alloys—through the intricate dance of advanced CNC machining techniques, including multi-axis milling and high-precision turning, all vital for precision housing manufacturing.

Post-machining treatments, like anodizing, contribute not only to aesthetics but also, crucially, to durability and performance. Quality assurance, a pervasive truth, ensures every custom scope enclosure production meets our rigorous standards, providing unwavering reliability. Partnering with a dedicated source for optical scope CNC machining, such as ly-machining, guarantees deep technical expertise, transparent pricing, and ultimately, high-quality parts.

Frequently Asked Questions

What materials are best for scope housings?

Aerospace-grade aluminum alloys, like 6061 and 7075, are often preferred for their excellent strength-to-weight ratios and machinability. They balance performance with cost-efficiency, undeniably.

For truly demanding applications, titanium offers superior strength and corrosion resistance, though it presents greater machining challenges. Composites are selected when extreme lightweighting is the absolute priority.

How does ly-machining ensure precision?

We integrate Design for Manufacturability (DFM) principles from project inception, optimizing designs for inherent accuracy. Our advanced multi-axis CNC machining, coupled with custom tooling and fixturing, executes these designs with unparalleled fidelity.

Crucially, our rigorous in-process and final metrology inspections—utilizing CMMs and optical measurement equipment—validate every critical dimension. Traceability and material certifications provide documented proof of our unwavering commitment.

Why choose a source manufacturer?

A source manufacturer, like ly-machining, offers direct access to deep technical expertise, allowing for collaborative DFM and optimal problem-solving. We control the entire production process, ensuring consistent quality, lead times, and rigorous IP protection.

Furthermore, transparent pricing structures provide clarity and predictability, avoiding the common pitfalls of intermediaries. This direct partnership cultivates trust, leading to superior results for your optical instrument machining needs.