Compelling Introduction

Has your coffee machine component manufacturing faced setbacks due to inconsistent quality, soaring costs, or extended lead times in CNC machining? These challenges can significantly impact product launch schedules and market competitiveness, often stemming from overlooked optimization opportunities in the production process.

The intricate nature of coffee machine parts demands unparalleled precision and reliability, making every machining detail critical. Without a systematic approach, achieving these standards while maintaining efficiency is exceptionally difficult.

This article, leveraging the extensive expertise of ly-machining, will unveil five data-backed strategies for optimizing coffee machine parts CNC machining. We aim to transform your production challenges into significant advantages, ensuring superior quality and enhanced cost-efficiency.

Featured Snippet

Implementing advanced CNC machining techniques and systematic optimization is crucial for achieving superior precision, consistency, and cost-efficiency in coffee machine component manufacturing.

Overcoming Coffee Machine Part Machining Challenges

Setting the Scene: Industry Pain Points

The global demand for high-performance coffee machines necessitates components of exceptional quality and durability. However, many manufacturers encounter significant hurdles in coffee machine parts CNC machining.

Common issues include micro-cracks, surface finish inconsistencies, and dimensional deviations that compromise both machine functionality and product longevity. These problems often lead to costly rework or, in severe cases, product recalls.

Common Challenges and Misconceptions

A prevalent misconception is that high precision inherently translates to exorbitant costs. While true precision parts machining requires investment, strategic optimization can actually reduce overall expenses by minimizing scrap rates and improving throughput.

Another challenge lies in managing complex geometries and ensuring material integrity, especially when working with specialized food-grade alloys required for coffee machine component manufacturing. Inadequate process control can easily undermine material properties.

Why Optimization is Crucial

For coffee machine brands, achieving manufacturing excellence is a direct path to market leadership and consumer trust. Optimized CNC machining techniques ensure every component meets the stringent demands of high-pressure, high-temperature environments.

Implementing robust optimization strategies not only elevates product quality but also provides a clear competitive edge, driven by improved efficiency and controlled production costs. This focus on optimization is paramount for sustained success.

Core Arguments and Content Preview

This guide presents a systematic framework for enhancing coffee machine parts CNC machining, drawing from extensive practical experience and data analysis. Our approach focuses on delivering repeatable, high-quality outcomes.

We will delve into five key areas, offering actionable strategies designed to improve precision, extend component lifespan, and streamline your production cycles. Each tip is supported by technical rationale and practical application insights.

Five Essential Machining Secrets

Mastering the intricacies of coffee machine component manufacturing involves more than just advanced machinery; it requires a meticulous optimization strategy. Our five secrets offer a proven pathway to excellence.

By understanding and implementing these precision CNC machining techniques, you will unlock new levels of quality, efficiency, and cost-effectiveness in your production lines. This systematic guidance equips you with critical insights.

In-Depth Optimization Strategies

The strategies presented are not theoretical but are derived from real-world application in precision parts machining. We emphasize a data-driven approach to identify bottlenecks and implement effective solutions.

From material selection to post-processing, each strategy is designed to contribute to a holistic improvement in your coffee machine parts CNC machining operations. Our goal is to provide a comprehensive, actionable blueprint.

Tip One: Material Selection and Pre-Processing

Fundamental Principles and Concepts

The foundation of exceptional coffee machine component manufacturing begins with the judicious selection of materials. Food-grade compliance and long-term durability are non-negotiable considerations.

Understanding the metallurgical properties of chosen alloys is critical for predicting their behavior during precision parts machining and ensuring they meet all regulatory standards for direct food contact.

Food-Grade Materials and Characteristics

Selecting materials that comply with food safety regulations, such as FDA or LFGB standards, is paramount for coffee machine parts. Stainless steel grades like 304 and 316L are common due to their corrosion resistance and inertness.

Other specialized polymers and ceramics may also be used for specific components, each requiring unique considerations for CNC machining techniques and surface finish requirements.

Table: Common Food-Grade Materials for Coffee Machine Parts

| Material Type | Key Characteristics | Typical Applications |

|---|---|---|

| Stainless Steel 304 | Corrosion resistance, machinable | Housings, fittings, pipes |

| Stainless Steel 316L | Enhanced corrosion resistance | Boiler components, valves |

| PEEK | High temperature, chemical resistant | Seals, internal structural |

| PTFE | Non-stick, low friction | Gaskets, bushings |

Pre-Processing Impact on Precision

Material pre-processing, such as annealing or stress relieving, plays a pivotal role in achieving high-precision results in coffee machine parts CNC machining. It mitigates internal stresses that can cause deformation during machining.

Proper pre-treatment ensures material stability, allowing for tighter tolerances and a more predictable outcome, which is vital for the functional reliability of coffee machine components.

Ensuring Durability and Safety

The correlation between selected materials and component lifespan is direct. High-quality, properly pre-processed materials significantly reduce wear and tear, extending the operational life of coffee machines.

Moreover, adherence to food-grade standards guarantees consumer safety, preventing contamination and preserving the integrity of beverage flavor. This is a critical factor in brand reputation.

Tip Two: Tooling and Cutting Parameter Optimization

Implementation Steps and Framework

Optimizing tooling and cutting parameters is central to efficient and high-quality coffee machine parts CNC machining. This involves a systematic approach to tool selection, geometry, and operational settings.

A robust framework includes initial material analysis, tool path simulation, and iterative parameter adjustments based on real-time feedback and measurement data. This data-driven approach minimizes trial-and-error.

Tool Selection for Coffee Machine Parts

Selecting the correct cutting tools is paramount for achieving the required surface finish and dimensional accuracy for precision parts machining. Factors such as material hardness, chip evacuation, and heat dissipation must be considered.

For stainless steel coffee machine components, specialized carbide tools with specific coatings are often chosen to enhance tool life and ensure smooth, burr-free cuts, preventing post-machining defects.

Cutting Parameter Optimization

Optimizing cutting parameters—feed rate, spindle speed, depth of cut, and coolant application—is a delicate balance. Incorrect settings can lead to premature tool wear, poor surface finish, or even part deformation.

For precision parts machining, advanced CAM software with simulation capabilities allows for fine-tuning these parameters to achieve optimal material removal rates and surface integrity, crucial for coffee machine component manufacturing.

Table: Cutting Parameter Optimization Guidelines (Stainless Steel 304)

| Parameter | Impact on Process | Optimized Range (Example) |

|---|---|---|

| Spindle Speed (RPM) | Surface finish, tool life | 800 – 1500 |

| Feed Rate (mm/min) | Material removal rate, chip control | 100 – 300 |

| Depth of Cut (mm) | Tool load, surface quality | 0.1 – 0.5 |

| Coolant Strategy | Heat dissipation, lubrication | Flood/MQL |

Case Study: Efficiency Enhancement

A client, a prominent coffee machine manufacturer, faced challenges with slow production and excessive tool wear when machining a complex flow-meter component. Their existing CNC machining techniques were inefficient.

By conducting a thorough analysis, ly-machining implemented new carbide end mills optimized for stainless steel, coupled with a customized cutting parameter matrix. This precision parts machining adjustment significantly improved material removal.

The result was a 35% reduction in cycle time and a 50% increase in tool life, demonstrating the direct impact of fine-tuned tooling and parameters on overall production efficiency and cost for coffee machine component manufacturing.

Tip Three: Fixture Design and Clamping Strategies

Addressing Pain Points and Obstacles

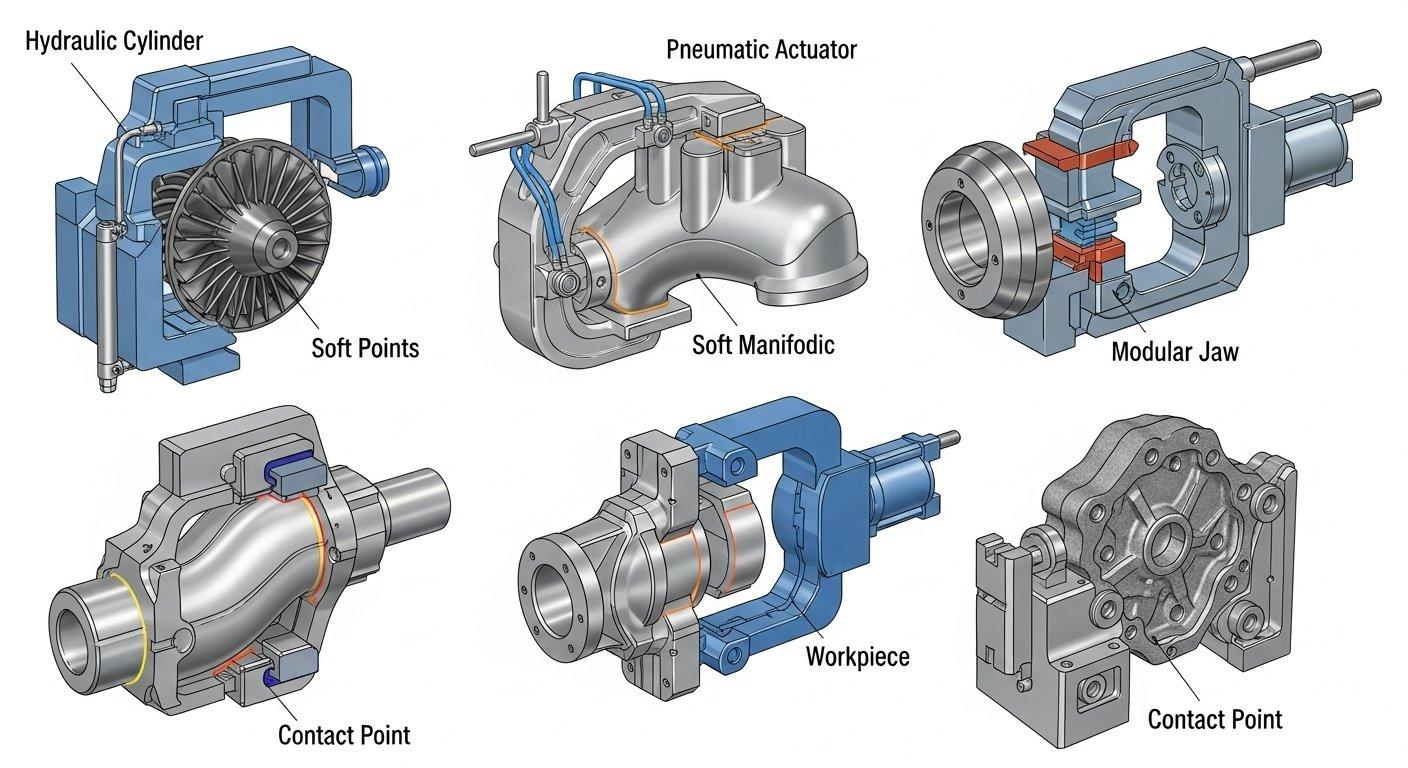

In precision parts machining, unstable clamping is a major source of dimensional inaccuracies and surface defects, especially for irregularly shaped coffee machine components. Traditional clamping methods often fall short.

The challenge lies in securely holding the workpiece without inducing stress or deformation, while also allowing optimal tool access. This is a critical aspect of effective coffee machine parts CNC machining.

Stable Clamping for Complex Structures

For intricate coffee machine parts, custom-designed fixtures are indispensable. These fixtures must provide rigid support, absorb machining forces, and minimize vibration, ensuring consistent precision throughout the machining process.

Vacuum fixtures or hydraulic clamping systems are particularly effective for delicate or thin-walled components, preventing distortion while maintaining robust stability during high-speed precision parts machining.

Advanced Techniques and Industry Trends

The trend in coffee machine component manufacturing leans towards modular and reconfigurable fixturing systems. These allow for quick changeovers and adaptation to diverse part geometries, enhancing production flexibility.

Automated clamping systems, integrated with robotic loading and unloading, represent the pinnacle of efficiency. They significantly reduce setup times and human error, optimizing throughput in coffee machine parts CNC machining.

Automation and Rapid Changeover

The integration of automated fixtures with quick-change pallet systems revolutionizes the efficiency of precision parts machining. It minimizes downtime between batches and maximizes spindle utilization.

Rapid changeover technologies are especially beneficial for manufacturers producing a variety of coffee machine components in varying batch sizes, providing agility and significant cost savings.

Tip Four: Multi-Axis Machining Efficacy

Implementation Steps and Application Framework

Multi-axis CNC machining is a transformative technology for manufacturing complex coffee machine parts, enabling the production of intricate geometries in a single setup. This minimizes accumulated errors and improves overall precision.

An effective framework involves advanced CAD/CAM programming, tool path simulation to prevent collisions, and skilled operators who understand the nuances of 3-axis, 4-axis, and 5-axis operations.

Advantages of Multi-Axis for Coffee Machine Parts

The primary advantage of multi-axis CNC machining in coffee machine component manufacturing is its ability to create highly complex, organic shapes and deep cavities that are impossible with traditional 3-axis methods.

This capability translates to superior surface finishes, reduced need for secondary operations, and significantly tighter tolerances, directly impacting the performance and aesthetics of precision coffee machine components.

Table: Benefits of Multi-Axis Machining for Coffee Machine Parts

| Benefit | Description | Impact on Coffee Machine Production |

|---|---|---|

| Enhanced Geometry | Complex curves, undercuts, intricate internal features | Innovative designs, improved flow |

| Superior Surface Finish | Reduced tool marks, smoother surfaces | Better hygiene, enhanced aesthetics |

| Tighter Tolerances | Greater accuracy in all dimensions | Optimized performance, less leakage |

| Reduced Setups | Machining from multiple angles in one go | Lower cumulative error, faster cycles |

Surface Quality and Cycle Time Improvement

By allowing the cutting tool to approach the workpiece from virtually any angle, multi-axis machining ensures optimal chip evacuation and maintains a constant cutting load. This leads to exceptional surface quality.

Furthermore, integrating multiple operations into a single setup drastically reduces overall cycle times, offering significant efficiency gains in coffee machine parts CNC machining and lowering per-part costs.

Case Study: Integrated Valve Body

A client specializing in high-end espresso machines required a precision valve body with complex internal channels and critical sealing surfaces. Traditional 3-axis machining struggled with the intricate geometry and surface finish requirements.

Ly-machining deployed its 5-axis CNC machining capabilities, allowing for the complete integration of the valve body’s features in a single setup. This significantly streamlined the coffee machine component manufacturing process.

The result was a perfectly integrated valve body with exceptional flow characteristics and zero leakage, achieved with unparalleled accuracy and a reduced lead time, proving the efficacy of advanced CNC machining techniques.

Tip Five: Post-Processing and Quality Control

Addressing Pain Points and Obstacles

Even with the most precise coffee machine parts CNC machining, post-processing and rigorous quality control are essential to ensure the final product meets exacting standards. Surface imperfections or residual stresses can compromise performance.

The challenge lies in applying appropriate post-treatment without altering critical dimensions and implementing a comprehensive inspection protocol to catch any deviations before assembly.

Surface Treatments and Performance Impact

Surface finishing processes, such as polishing, passivation, or specialized coatings, are crucial for coffee machine components. Polishing improves aesthetics and hygiene, reducing bacterial adhesion on food-contact surfaces.

Passivation enhances corrosion resistance, especially vital for stainless steel parts exposed to water and heat, directly impacting the longevity and reliability of the coffee machine.

Table: Post-Processing Methods and Their Benefits

| Method | Primary Benefit | Application for Coffee Machine Parts |

|---|---|---|

| Polishing/Buffing | Enhanced aesthetics, hygiene | External housings, brew heads |

| Passivation | Improved corrosion resistance | Stainless steel internal components |

| Electropolishing | Smoother surface, reduced burrs | Fluid pathways, intricate valves |

| Anodizing (Aluminum) | Hardness, corrosion resistance | Structural frames, aesthetic covers |

Advanced Techniques and Industry Trends

Modern quality control in precision parts machining increasingly relies on intelligent detection systems. These include automated optical inspection (AOI) and sophisticated CMMs (Coordinate Measuring Machines) that provide sub-micron accuracy.

Full-process quality traceability, leveraging QR codes or RFID tags, allows for detailed tracking of each coffee machine component from raw material to final inspection. This ensures accountability and rapid issue resolution.

Smart Detection and Traceability

Implementing smart detection systems for coffee machine component manufacturing drastically reduces human error and speeds up inspection times. Real-time data collection enables immediate adjustments to CNC machining techniques.

Comprehensive traceability systems provide a complete historical record for every precision part, a critical asset for regulatory compliance and proactive quality management in the event of any field issues.

Conclusion: Achieving Coffee Machine Part Excellence

Key Takeaways and Emphasis

Optimizing coffee machine parts CNC machining is an imperative, not just an option, for achieving market leadership. The five strategies—meticulous material selection, precise tooling, advanced fixturing, multi-axis capabilities, and rigorous quality control—form a comprehensive framework.

By systematically applying these precision parts machining techniques, manufacturers can overcome common production hurdles, ensuring consistent quality, improved efficiency, and reduced costs in coffee machine component manufacturing.

Our Expertise, Your Competitive Edge

At ly-machining, our deep technical expertise and commitment to data-driven optimization empower our clients to surpass their manufacturing goals. As a source factory, we combine advanced machinery with unparalleled engineering insight.

We pride ourselves on delivering not just parts, but optimized solutions that elevate product performance and streamline supply chains, positioning your coffee machine brand at the forefront of innovation and reliability.

Call to Action

Invite readers to get a free quote or technical consultation. Contact ly-machining today to discuss how our expert CNC machining techniques and optimization strategies can elevate your coffee machine component manufacturing. Let us help you achieve superior quality and efficiency.

FAQ Section

Why precision parts matter?

Precision parts are critical for coffee machines because they directly impact performance, reliability, and the quality of the brewed coffee. Exact tolerances ensure proper sealing, consistent flow rates, and long-term durability under high pressure and temperature. Inaccurate components can lead to leaks, breakdowns, and inconsistent beverage quality, undermining user experience and brand reputation.

What materials are food-grade?

Food-grade materials for coffee machine component manufacturing typically include specific grades of stainless steel, such as 304 and 316L, which offer excellent corrosion resistance and are non-reactive. Other approved materials can include high-performance polymers like PEEK and PTFE, selected for their temperature stability, chemical resistance, and inertness when in contact with food and beverages.

How to lower CNC costs?

Reducing CNC machining costs involves several optimization strategies, including precise material selection to minimize waste, optimizing cutting parameters for faster cycle times and extended tool life, and investing in advanced fixturing to reduce setup times and improve stability. Multi-axis machining can also consolidate operations, while stringent quality control prevents costly reworks, ultimately enhancing overall production efficiency and ROI.