Optimizing Massage Gun Casing CNC

Massage gun casing CNC machining requires strategic material selection and precision processing to achieve superior performance and aesthetics. In our experience, careful consideration of alloys and finishes optimizes durability, heat dissipation, and user experience, positioning us as a reliable CNC machining source manufacturer.

Is your massage gun’s true potential trapped by its casing? Discover how strategic material selection and precision CNC machining aren’t just about aesthetics, but about unlocking superior performance, durability, and user experience that elevates your brand above the competition. We see too many designs compromise on these critical factors.

As a leading CNC machining source manufacturer, we understand that the external shell is more than just a cover; it’s integral to the product’s function, longevity, and perceived value. This guide will delve into the critical role of advanced CNC manufacturing and material selection for robust massage gun casings.

Why Casing CNC Machining Matters

CNC machining is fundamental to producing high-quality massage gun casings, ensuring both aesthetic appeal and critical functional performance. This process allows for unmatched precision and repeatability, which are vital for components under constant stress and handling. In our experience, this level of control translates directly into superior end products.

Beyond Aesthetics: Functionality & Durability?

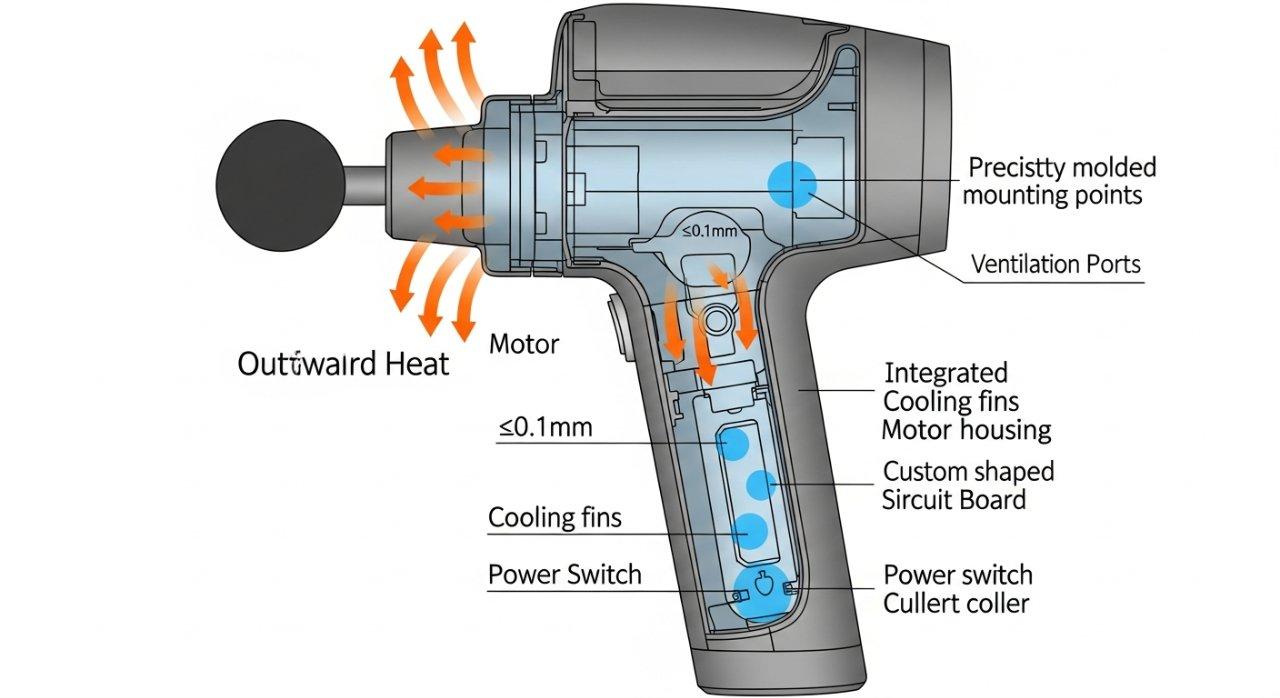

The casing of a massage gun plays a crucial role in its overall functionality and long-term durability, extending far beyond visual appeal. Precision CNC machining ensures exact fitments for internal components, preventing vibration-induced wear and tear. A robust casing protects the sensitive internal motor and electronics, directly impacting the device’s lifespan.

It also significantly influences the ergonomics and user experience, contributing to a comfortable and secure grip during use. A well-designed and precisely manufactured casing ensures that the device feels solid and reliable, enhancing user confidence and satisfaction.

What are common casing manufacturing challenges?

A common issue we see in massage gun casing manufacturing includes maintaining tight dimensional tolerances across complex geometries, which is essential for seamless assembly and component integration. Achieving consistent surface finishes, especially on curved or intricate designs, also presents significant challenges.

Another critical pain point is balancing material properties such as strength, weight, and thermal conductivity with cost-effectiveness. Furthermore, effective heat dissipation from the motor through the casing is paramount to prevent overheating and ensure prolonged device operation.

Material Selection for Casings

The choice of material for a massage gun casing is a foundational decision that impacts everything from performance and durability to manufacturing cost and aesthetics. As a CNC machining source manufacturer, we guide our clients through this critical process.

Which materials balance strength and weight?

Selecting the right material involves a careful trade-off between structural integrity and overall device weight, crucial for user comfort and portability. Aluminum alloys, such as 6061 and 7075, are frequently chosen for their excellent strength-to-weight ratios. High-performance plastics like ABS+PC blends also offer a good balance for lighter applications.

Our expertise allows us to recommend specific grades that meet both structural demands and weight targets, ensuring the device feels robust yet manageable. For instance, aerospace-grade aluminum can provide superior impact resistance without adding excessive bulk.

How does thermal conductivity impact performance?

Thermal conductivity is a critical property for massage gun casings, directly affecting the device’s ability to dissipate heat generated by the motor during operation. Materials with high thermal conductivity, like aluminum alloys, efficiently draw heat away from internal components. This prevents overheating, extends motor life, and ensures consistent performance, especially during prolonged use.

In our experience, neglecting thermal considerations can lead to premature device failure and a poor user experience. We meticulously analyze thermal requirements to recommend materials that maintain optimal operating temperatures.

What about aesthetics and tactile feel?

Beyond functional properties, the aesthetic appeal and tactile feel of the casing significantly influence the perceived quality and brand identity of the massage gun. CNC machining offers unparalleled control over surface finishes, allowing for diverse textures from smooth polished to finely sandblasted or anodized matte. These finishes not only enhance visual appeal but also contribute to an improved grip and overall user experience.

Different materials also naturally offer distinct tactile qualities; metals provide a premium, cool-to-touch feel, while plastics can offer warmth and specific textural possibilities.

Cost-Benefit Analysis of casing materials?

Conducting a thorough cost-benefit analysis is essential when selecting casing materials for massage guns. While some materials, like high-grade aluminum alloys, may have a higher initial material cost, their superior thermal properties, durability, and premium feel can lead to long-term benefits. These benefits include reduced warranty claims, enhanced brand perception, and increased customer satisfaction.

Conversely, while certain plastics may offer lower upfront costs, potential compromises in heat dissipation or perceived quality could incur hidden costs in the product’s lifecycle. We help clients weigh these factors to find the optimal solution.

Performance Optimization via CNC

Precision CNC machining is not merely about shaping materials; it’s a powerful tool for performance optimization across multiple dimensions of a massage gun casing. Our advanced capabilities as a CNC machining source manufacturer enable us to refine designs for peak functionality.

How does CNC precision enhance durability?

The inherent precision of CNC machining allows for the creation of components with extremely tight tolerances and consistent wall thicknesses. This eliminates weak spots and stress concentrations that could lead to premature failure under vibration or impact, directly enhancing the casing’s durability.

By precisely controlling material removal, we can optimize the internal structure of the casing to withstand operational stresses, ensuring a long product lifespan. This level of accuracy is critical for a product like a massage gun that undergoes constant mechanical strain.

What surface finishes improve grip and feel?

CNC machining offers a wide array of surface finishing options that dramatically improve both the grip and tactile feel of a massage gun casing. Techniques such as fine bead blasting create a matte, non-slip texture ideal for secure handling during intense use. Anodizing, beyond providing color, can seal the surface, offering a smoother yet firm touch.

Our team works closely with clients to select finishes that complement their brand’s aesthetic while prioritizing ergonomic comfort and safety. From subtle brushing to specialized texturing, each option is carefully considered.

How does design impact heat dissipation?

Effective thermal management is paramount for massage gun performance, and CNC precision machining enables optimal design for heat dissipation. By integrating cooling fins or channels directly into the casing’s internal or external structure, we maximize the surface area available for heat transfer. This keeps the motor running efficiently and prolongs battery life.

Material selection for thermal conductivity, combined with precise geometry, ensures that heat generated by the motor is efficiently drawn out and dissipated into the ambient air. Our design for manufacturability (DFM) approach focuses on these critical thermal aspects early in the development cycle.

Can CNC reduce assembly complexity?

Absolutely. One of the significant advantages of precision CNC manufacturing is its ability to create parts with highly accurate dimensions and features, which inherently reduces assembly complexity. By holding tight tolerances, components fit together seamlessly, minimizing the need for manual adjustments or rework.

This precision also allows for the integration of multiple features into a single part, reducing the total number of components required. In our experience, this not only speeds up the assembly process but also leads to more robust and reliable final products.

CNC Machining Expertise & Quality

As a dedicated CNC machining source manufacturer, our expertise is built upon years of hands-on experience and a commitment to precision engineering. We understand the nuances of producing high-performance components, and this knowledge is embedded in every project we undertake.

What makes us a reliable source manufacturer?

Our reliability stems from a combination of deep technical knowledge, advanced manufacturing facilities, and a rigorous quality control system. Being a source manufacturer means we control the entire production process from raw material to finished part, ensuring consistent quality and predictable lead times.

We invest in state-of-the-art CNC machinery and continuous staff training, positioning us at the forefront of precision machining technology. This allows us to handle complex projects and deliver exceptional results consistently.

Our technical approach to complex geometries?

Tackling complex geometries in massage gun casings requires a sophisticated technical approach. We utilize advanced CAD/CAM software for precise design translation and toolpath generation, optimizing machining strategies for intricate curves, deep pockets, and internal features. Our multi-axis CNC machines allow for simultaneous machining from various angles, reducing setups and enhancing accuracy.

This methodical approach minimizes material waste and machining time while ensuring that every detail of the design is faithfully reproduced with exceptional precision. We thrive on challenges that other manufacturers might deem too difficult.

Ensuring consistent high-quality parts?

Consistency in quality is paramount for mass production of massage gun casings. Our robust Quality Management System (QMS) adheres to international standards like ISO 9001 and AS9100. We implement in-process inspections using CMM (Coordinate Measuring Machine) and other precision metrology tools to verify critical dimensions at every stage.

Furthermore, statistical process control (SPC) monitors manufacturing parameters, proactively identifying and correcting deviations. This multi-layered approach guarantees that every single part meets the exact specifications and quality expectations.

The value of transparent pricing?

Transparent pricing is a cornerstone of our service as a CNC machining source manufacturer. We provide detailed breakdowns of material costs, machining time, tooling, and finishing processes, ensuring clients understand every aspect of their investment. This eliminates hidden fees and fosters trust.

Our commitment to transparent pricing allows clients to budget accurately and make informed decisions, knowing they are receiving fair value for premium-quality CNC machining services. We believe that clarity in pricing is essential for long-term partnerships.

Your Casing Project, Our Solution

Partnering with ‘ly-machining’ for your massage gun casing CNC machining project means gaining a dedicated manufacturing ally. We are committed to transforming your design concepts into high-performance, aesthetically superior products.

How to start your CNC machining project?

Starting your CNC machining project with us is straightforward and efficient. Simply provide your 3D CAD models (e.g., STEP, IGES, SolidWorks files) along with any relevant 2D drawings that specify tolerances, material requirements, and desired surface finishes. Our engineering team will review your specifications.

We then offer expert feedback on design for manufacturability (DFM) to optimize your design for efficient and cost-effective production. This initial consultation ensures a smooth transition from design to manufacturing.

What to expect from our consultation?

During our technical consultation, you can expect an in-depth discussion with our experienced engineers. We will analyze your design, recommend optimal material choices based on performance and cost objectives, and suggest CNC machining strategies to achieve your desired outcomes.

We aim to identify potential challenges early and provide innovative solutions, ensuring your massage gun casing meets all functional, aesthetic, and budgetary requirements. Our goal is to empower your product’s success.

Ready to elevate your massage gun’s performance and aesthetics? Contact our engineering experts today for a free, no-obligation consultation and a transparent quote tailored to your specific CNC machining project needs.

How is CNC different from injection molding?

CNC machining removes material from a solid block, offering extreme precision for complex geometries and prototypes without tooling costs. Injection molding forces molten material into a mold, ideal for high-volume production once tooling is made.

In our experience, CNC is superior for small to medium runs, rapid prototyping, and parts requiring tight tolerances or specialized material properties. It offers greater design flexibility early in the product lifecycle.

What is the typical lead time for casing prototypes?

Typical lead times for CNC machined massage gun casing prototypes range from 5 to 10 business days, depending on design complexity, material availability, and required post-processing. Rush services are often available for urgent projects.

We work closely with clients to meet their deadlines, understanding the critical importance of time-to-market. Our efficient internal processes are designed to expedite rapid prototyping without compromising precision.

Can you help with DFM for massage gun casings?

Yes, Design for Manufacturability (DFM) is a core service we offer for massage gun casings. Our engineers will review your design to identify potential manufacturing challenges, suggest material alternatives, and propose design modifications.

This ensures your design is optimized for cost-effective, high-quality CNC machining, reducing production time and improving overall part integrity. Our DFM expertise helps avoid costly rework down the line.