Mastering CNC Surface Roughness Ra

Is your project’s performance being compromised, or costs inflated, by overlooked surface roughness specifications? Designers often specify Ra values without fully understanding their profound implications on part functionality, manufacturability, and budget. Suboptimal surface finishes can lead to critical component failure or unnecessary expenditure.

Navigating the complexities of CNC machining surface roughness Ra is crucial for engineers and procurement professionals alike. Achieving the precise Ra value can be the difference between a product that performs flawlessly and one that falls short, impacting both reliability and cost.

This guide delves into the technical definition, grades, and practical application of Ra. It aims to equip you with the knowledge to optimize your designs, enhance product performance, and streamline your manufacturing processes, ensuring both quality and cost-effectiveness.

Precision CNC machining achieves superior part performance and cost-efficiency through meticulously controlled surface roughness Ra, underpinned by deep technical expertise and transparent manufacturing.

Unlocking CNC Precision

Setting the Scene: Machining Pain Points

Are your Ra specs costing you?

Many engineering projects encounter unexpected budget overruns or production delays due to misjudged surface finish requirements. Specifying an overly fine Ra value can dramatically increase machining time and tooling costs. This often leads to unnecessary expenses without a tangible improvement in part performance.

Conversely, an Ra value that is too coarse can compromise critical functionalities. It might reduce a component’s lifespan, impair its sealing capabilities, or negatively impact its aesthetic appeal, leading to costly reworks or product failures in the field.

Why Ra is Critical for Your Success

Surface roughness, particularly the Ra value, is a fundamental characteristic influencing mechanical performance. It directly affects friction, wear resistance, lubrication film retention, and even the adhesion of coatings. For optical or medical devices, it also dictates aesthetic quality and biocompatibility.

Precise control over Ra is not merely a preference but a necessity for optimal functionality. It ensures components integrate seamlessly and perform reliably within their intended assemblies. Mastery of Ra is key to achieving consistent, high-quality output and customer satisfaction.

Your Path to Ra Mastery

What this guide will reveal

This comprehensive guide will demystify the intricacies of surface roughness Ra. We will explore its definition, standard classification systems, and the profound impact it has on the functional integrity of your machined parts. Our goal is to empower you with actionable knowledge.

You will gain insights into how different Ra grades translate into practical applications. Understanding these principles will enable more informed decision-making during the design phase, leading to more efficient and effective manufacturing.

Preview of Ra insights ahead

We will delve into the critical factors that influence Ra during the CNC machining process. This includes an examination of cutting tools, machining parameters, and advanced techniques employed to achieve specific surface finishes. You’ll see how our expertise translates to tangible results.

Expect to learn about the common challenges in controlling Ra and effective troubleshooting strategies. This knowledge will enhance your ability to specify and verify surface finish requirements, ensuring your projects meet the highest standards of precision machining quality.

Ra: Definition & Core Principles

Defining Ra: The Basics

Understanding Ra Values

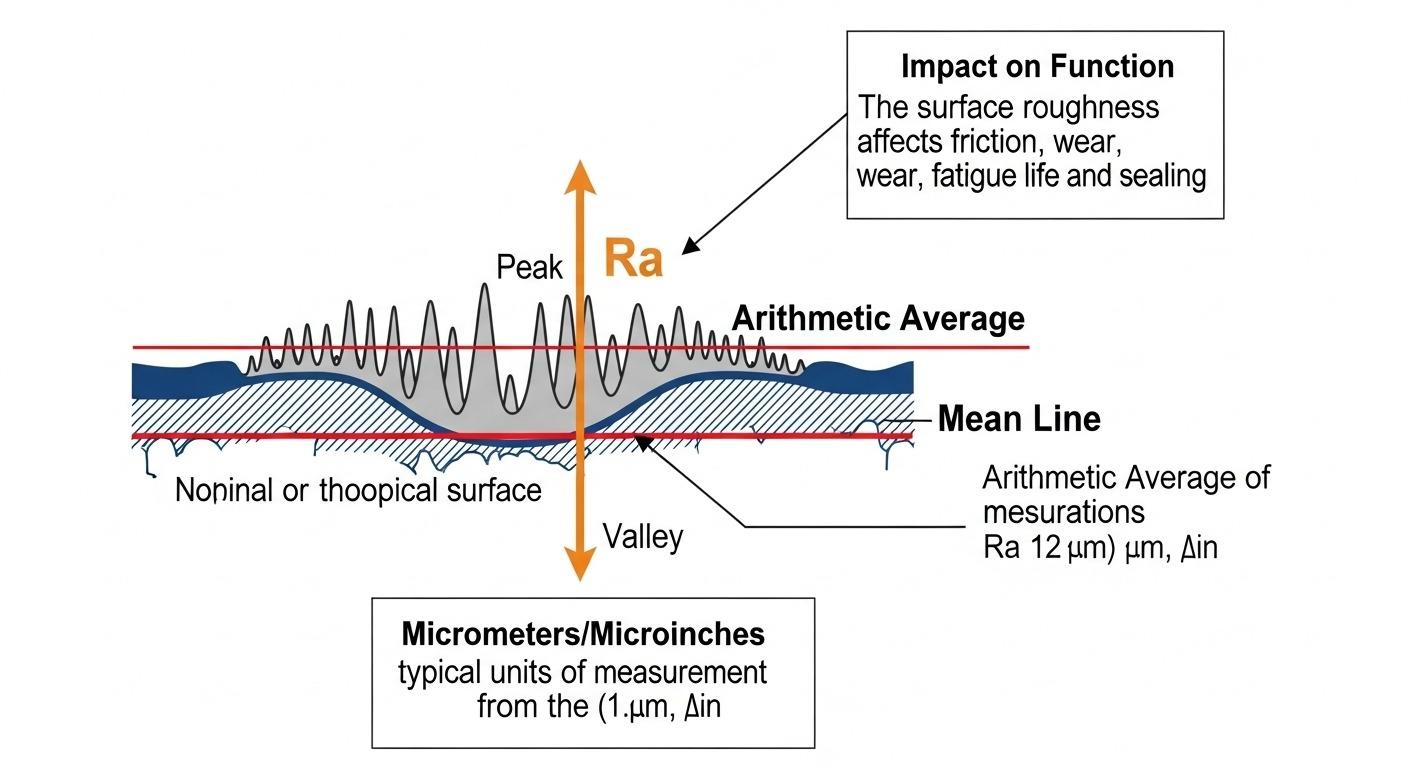

Ra, or Roughness average, is the arithmetic mean of the absolute values of the profile deviations from the mean line. It is the most universally recognized and specified parameter for quantifying surface texture. This value provides a straightforward measure of overall surface smoothness.

Expressed typically in micrometers (µm) or microinches (µin), a lower Ra value indicates a smoother surface. Conversely, a higher Ra value signifies a rougher surface finish. It offers a single, quantifiable metric for comparing surface textures across various components and processes.

Beyond the Numbers: Ra’s True Meaning

While Ra provides a critical numerical representation, its true meaning extends to the functional behavior of a part. A specified Ra value is not merely a number; it dictates how a component will interact with mating parts, fluids, and environmental elements. The choice of Ra is a critical engineering decision.

For instance, a finer Ra can reduce friction in sliding applications, improving efficiency and prolonging part life. In contrast, a slightly rougher Ra might be essential for adhesive bonding or for retaining lubricants. Understanding these functional implications is paramount for precision machining quality.

Ra’s Impact on Part Performance

Function, Wear, & Aesthetics

The selected CNC Machining Surface Roughness Ra directly influences a part’s functional integrity. A precision bearing surface, for example, demands a very low Ra to minimize friction and wear, ensuring smooth operation and extended service life. The microscopic peaks and valleys affect how two surfaces interact.

For sealing applications, an optimal Ra provides sufficient contact points for a gasket while allowing for minor fluid retention, crucial for effective sealing. Too smooth, and it might leak; too rough, and it could damage the seal. Each application requires careful consideration of the Ra value meaning.

Furthermore, Ra significantly contributes to the aesthetic quality of visible components. A finely finished surface not only looks professional but also impacts how light reflects, enhancing perceived quality. The specific Ra also determines how well coatings or paints adhere, affecting durability and appearance.

Ra Grades & Practical Application

Decoding Ra Classification Systems

Standard Ra Grades Explained

Surface roughness grades are systematically categorized to provide universal standards for engineers and manufacturers. These grades typically follow a geometric progression, with each subsequent grade representing a significant change in surface texture. This allows for precise specification across various applications.

Commonly encountered Surface Roughness Grades include Ra 0.8, Ra 1.6, Ra 3.2, and Ra 6.3 µm. These are often correlated with specific machining processes and finishing techniques. For example, grinding can achieve very fine Ra values, while rough milling results in coarser finishes.

Here is a summary of typical Ra Grades and associated processes:

| Ra Grade (µm) | Ra Grade (µin) | Typical Process & Finish |

|---|---|---|

| 0.1 – 0.2 | 4 – 8 | Lapping, Polishing, Superfinishing (Mirror-like) |

| 0.2 – 0.4 | 8 – 16 | Precision Grinding, Honing, Fine Lapping (Very Smooth) |

| 0.4 – 0.8 | 16 – 32 | Fine Grinding, Reaming, Fine Turning (Smooth) |

| 0.8 – 1.6 | 32 – 63 | General Turning, Milling, Boring (Standard Machined Finish) |

| 1.6 – 3.2 | 63 – 125 | Rough Turning, Coarse Milling, Planing (Visible Machine Marks) |

| 3.2 – 6.3 | 125 – 250 | Rough Machining, Sawing (Very Coarse Finish) |

Selecting the Right Ra: Avoid Errors

Mistakes in selecting the appropriate Ra can be costly, affecting both product performance and manufacturing efficiency. Over-specifying a very fine Ra value when it’s not functionally necessary can significantly inflate production costs and extend lead times. This happens without yielding a proportional benefit.

Conversely, under-specifying can lead to premature wear, increased friction, or sealing failures, ultimately resulting in product recalls or warranty claims. A precise understanding of the Ra value meaning and its application is therefore critical. Engineers must balance functional requirements with manufacturing realities.

Real-World Ra Selection: Case Studies

Optimal Ra for High-Performance Parts

For aerospace components, where reliability is paramount, a low Ra is crucial for fatigue resistance and aerodynamic efficiency. Engine parts, for instance, demand finely controlled surfaces to ensure optimal fuel efficiency and prevent micro-cracks that could propagate under stress. This ensures long-term performance.

In medical device manufacturing, biocompatibility often hinges on surface texture. Implants require extremely smooth surfaces to minimize tissue irritation and bacterial adhesion. The Ra specification directly influences patient safety and the device’s success, highlighting the importance of precision machining quality.

For optical applications, such as lens mounts or sensor housings, Ra values must be exceptionally low. This prevents scattering and ensures precise light transmission and sensor accuracy. These examples underscore how specific functional demands drive the selection of appropriate Surface Roughness Grades.

Achieving & Verifying Desired Ra

Controlling Ra: Common Challenges

Process Variables Affecting Roughness

Achieving consistent CNC Machining Surface Roughness Ra is a complex task influenced by numerous process variables. Cutting tool geometry, including nose radius and edge sharpness, directly impacts the formation of the surface profile. Worn tools invariably lead to a rougher finish and require frequent replacement.

Feed rate and spindle speed are critical parameters that must be meticulously controlled. A higher feed rate generally results in a coarser finish, while optimized speeds can stabilize the cutting process. Material properties such as hardness and ductility also play a significant role.

Here are key process variables impacting Ra:

| Variable | Impact on Ra | Mitigation Strategy |

|---|---|---|

| Cutting Tool Geometry | Tool nose radius, edge sharpness, chip-breaker | Select appropriate tools, maintain sharpness, specific coatings |

| Feed Rate | Higher feed = coarser Ra; Lower feed = finer Ra | Optimize feed for material and desired Ra, multi-pass strategy |

| Spindle Speed | Affects cutting stability, heat generation | Adjust RPM for material, tool, and desired chip load |

| Depth of Cut | Influences cutting forces and material removal | Gradual cuts, multiple shallow passes for fine finishes |

| Coolant/Lubrication | Reduces friction, clears chips, cools workpiece | Use appropriate coolant type and flow rate |

| Workpiece Material | Hardness, ductility, microstructure | Adjust cutting parameters, use specific tooling for material |

| Machine Rigidity | Vibrations, chatter | Ensure machine stability, use rigid fixturing |

Troubleshooting Ra Deviations

When the measured Ra deviates from the specified Surface Roughness Grades, a systematic troubleshooting approach is essential. The first step involves inspecting the cutting tool for wear, chipping, or improper indexing. A dull tool is a primary cause of poor surface finish.

Next, verify machining parameters against established process sheets. Incorrect feed rates, speeds, or depths of cut can significantly alter the Ra value. Machine vibrations, often caused by loose fixturing or worn bearings, must also be investigated. Environmental factors like temperature fluctuations can also play a role.

Advanced Ra & Our Expertise

Our Technical Depth in Ra Control

At ly-machining, our engineering team possesses profound technical depth in controlling CNC Machining Surface Roughness Ra. We leverage advanced machining strategies, including high-speed machining, precision grinding, and specialized polishing techniques, to achieve exceptionally tight Ra tolerances. Our expertise extends to a comprehensive understanding of various Ra value meaning implications.

We employ state-of-the-art surface profilometers for meticulous measurement and verification, ensuring every part meets stringent Ra specifications. Our commitment to precision machining quality means we analyze material behavior and tool interactions at a microscopic level. This allows us to optimize processes for superior outcomes.

**Case Study: Optimizing Ra for Medical Device Performance**

Problem: A client manufacturing a new surgical instrument faced challenges with inconsistent performance and high production costs. Their initial design specified an overly fine Ra 0.2 µm on internal fluid channels, believing it was essential for sterility and flow. This ultra-fine specification led to extremely long machining cycles and frequent tool wear, significantly increasing unit cost and lead times, yet they still experienced occasional flow issues.

Our Solution: Our engineering team initiated a comprehensive DFM (Design for Manufacturability) review. Through detailed analysis of fluid dynamics and material interaction, we proposed optimizing the Ra specification to Ra 0.4 µm, combined with a specific post-machining passivation process. We demonstrated that Ra 0.4 µm provided the optimal balance for laminar flow and sterilization, while being significantly more achievable and cost-effective. We adjusted tool paths, cutting parameters, and utilized a specialized micro-finishing technique within our CNC machining process.

Result: The client achieved a 30% reduction in per-part manufacturing cost and a 20% improvement in lead time. The optimized Ra 0.4 µm surface finish eliminated the previous flow inconsistencies, enhancing the instrument’s functional reliability and improving its overall performance in clinical trials. This collaborative approach, rooted in our deep technical expertise, provided a superior product at a significantly lower cost.

Ready to optimize your CNC parts for peak performance and cost-efficiency? Contact our expert engineering team for a free consultation on your next project’s surface roughness requirements, and experience the difference of a true source manufacturer.

Your Ra Mastery Journey

Key Takeaways for Optimal Ra

Recap: Quality, Cost, & Confidence

Mastering CNC Machining Surface Roughness Ra is paramount for achieving both superior product quality and cost-efficiency. It demands a holistic approach, integrating design intent with manufacturing capabilities and a clear understanding of Ra value meaning. This strategic precision ensures every component performs exactly as specified.

By carefully selecting appropriate Surface Roughness Grades, designers can mitigate risks associated with both over-specification and under-specification. This balance leads to optimized material usage, reduced rework, and ultimately, a more reliable and competitive product. It builds trust in the manufacturing process.

Empowering Your Next CNC Project

Equipped with this deepened understanding of Ra, you are now better positioned to make informed decisions for your next CNC project. Specifying the correct Ra from the outset can save significant time and resources, enhancing your project’s overall success and accelerating time-to-market. Our commitment is to ensure precision machining quality.

This knowledge empowers you to engage more effectively with manufacturers, articulating your requirements with clarity and confidence. It transforms potential pain points into opportunities for optimized performance and transparent, cost-effective production. We aim to be your trusted technical partner.

Ready for Precision?

Consult Our Ra Experts Today

For complex projects or specific applications requiring stringent CNC Machining Surface Roughness Ra control, our expert engineering team is ready to assist. We offer unparalleled technical consultation, guiding you through every step from design optimization to final inspection. Our goal is to provide unmatched precision machining quality.

Leverage our deep expertise in achieving precise Surface Roughness Grades for diverse industries. Partner with ly-machining to ensure your components not only meet but exceed performance expectations, delivered with efficiency and confidence. We guarantee accurate Ra value meaning implementation for all your parts.

FAQ Section

What is CNC Ra surface finish?

CNC Ra surface finish refers to the arithmetic average of the absolute values of the microscopic peaks and valleys on a machined surface. It is a widely used metric to quantify the texture or roughness of a component. A lower Ra value indicates a smoother surface.

This value is critical for determining how a part will interact with its environment and mating components. It directly influences factors like friction, wear, sealing, and aesthetic appeal in precision machining quality.

How are Ra values measured?

Ra values are typically measured using a surface profilometer. This instrument traces a stylus across the surface, detecting minute changes in height. The profilometer then calculates the average deviation from a mean line, providing the Ra value.

Advanced optical methods can also be employed for non-contact measurement. These tools ensure accurate and repeatable surface roughness analysis, crucial for maintaining stringent quality control in manufacturing.

What is a good Ra for CNC parts?

A “good” Ra for CNC parts is entirely application-dependent, as there is no universal optimal value. For high-friction bearing surfaces or medical implants, a very low Ra (e.g., Ra 0.2-0.4 µm) is considered good for durability and biocompatibility.

Conversely, for parts requiring paint adhesion or specific tactile feedback, a slightly higher Ra (e.g., Ra 1.6-3.2 µm) might be more suitable. The ideal Ra value meaning always aligns with the part’s intended function and performance requirements.