Finding a reliable supplier for CNC machining of nylon components...

Read More →High-precision plastic parts processing and customization manufacturer | Free proofing

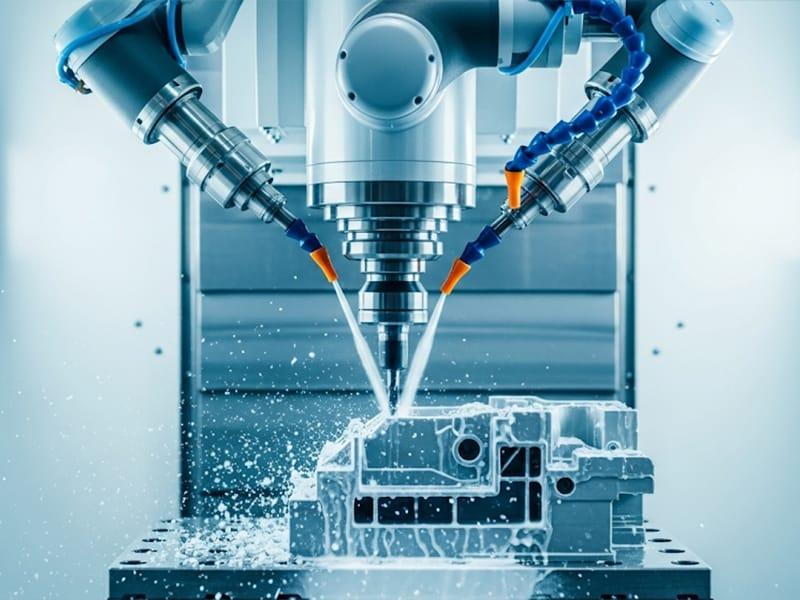

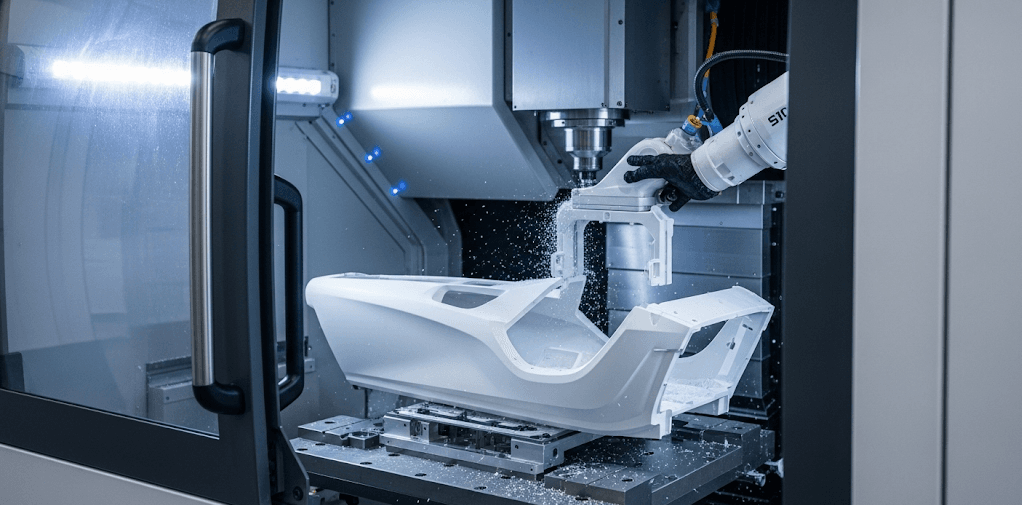

Plastic CNC Machining

We provide one-stop plastic CNC machining services, focusing on ABS, PC, acrylic and other plastic parts processing and small batch production. We are your reliable CNC machining supplier, guaranteeing delivery and accuracy, get online quotes now.

Rapid prototyping to volume CNC machining services

Machining Services

Why choose CNC machining to manufacture your plastic parts?

CNC machining is a high-precision, high-flexibility subtractive manufacturing technology. Compared with 3D printing, it can provide better surface finish, mechanical strength and material selection; compared with injection molding, it does not require expensive mold investment and is an ideal choice for functional prototype verification, small batch production and customized parts manufacturing.

Are your projects facing these plastic parts processing challenges?

Precision not up to standard? The supplier’s processing accuracy cannot meet your drawing tolerance requirements.

Delivery delay? The promised delivery time is delayed again and again, seriously affecting your project progress.

High communication cost? Poor communication with the processing plant, engineers and purchases repeatedly confirm, wasting precious time.

Minimum order quantity limit? Only need a small batch of plastic parts processing, but can’t find a manufacturer willing to accept the order.

CNC machining advantages

No molds required, cost-effective: especially suitable for production needs of dozens to thousands of pieces, saving you high mold opening costs and time costs.

Excellent part strength and performance: the machined parts maintain the original physical properties of the material, with a dense structure and better performance than most 3D printing technologies.

Unparalleled machining accuracy: Our multi-axis CNC equipment can manufacture complex geometries, deep cavities, threads and precision holes that are difficult to achieve with traditional processes.

Quick response to market changes: It only takes a few days from design updates to obtaining physical parts, allowing your products to iterate faster and go to market faster.

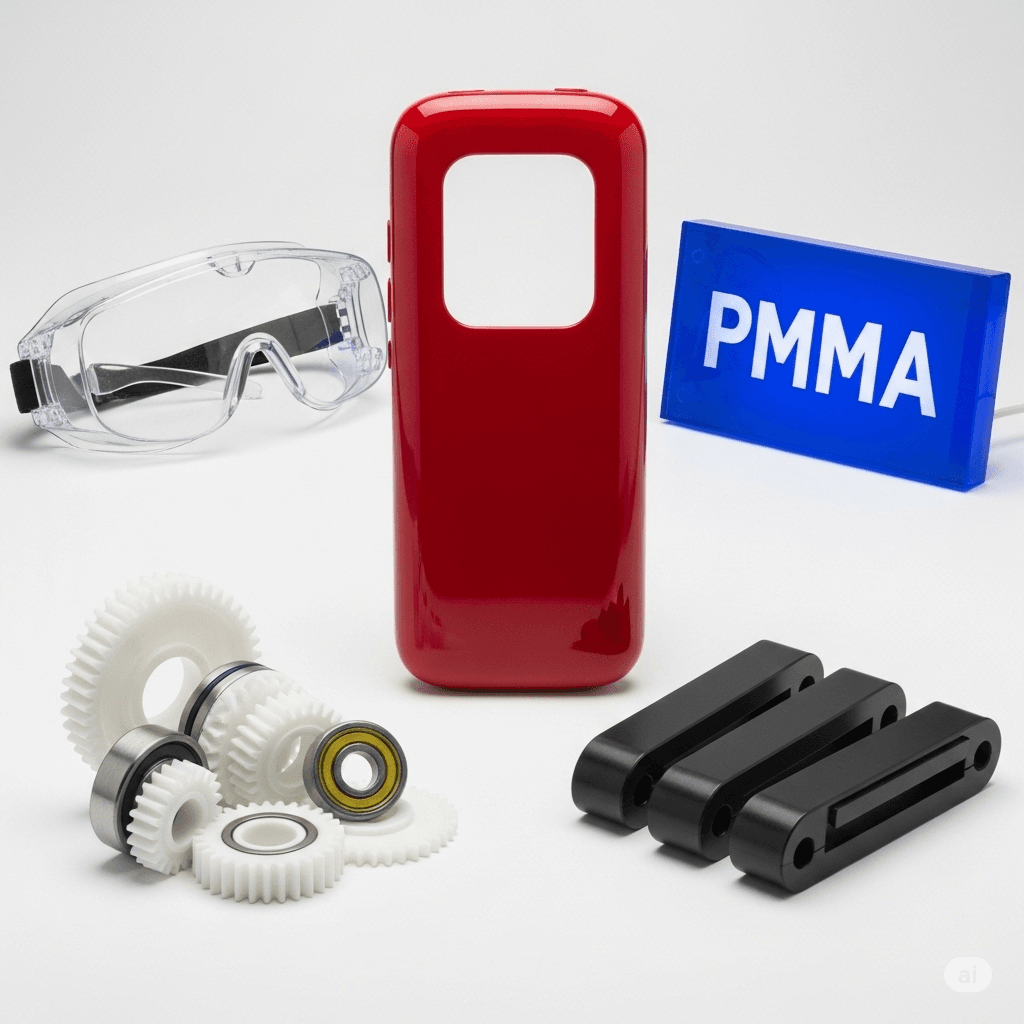

General engineering plastics

ABS: Good comprehensive performance, easy to process, suitable for making shells and prototypes.

PC (polycarbonate): High impact strength, transparent, heat resistant, suitable for optical lenses and protective covers.

PMMA (acrylic): Excellent transparency and optical properties, often used in light guide plates and crafts.

Nylon (nylon PA6, PA66): Excellent wear resistance and toughness, suitable for manufacturing gears and bearings.

POM (polyoxymethylene/saigang): Low friction coefficient, high rigidity, dimensional stability, used for precision transmission parts.

High-performance special plastics

PEEK (polyetheretherketone): High temperature resistance, chemical corrosion resistance, high strength, used in medical and aerospace fields.

PTFE (Teflon): Excellent corrosion resistance and non-stickiness, used for seals and pipes.

PEI (Ultem): High strength, high rigidity, high temperature resistance, often used in electronics and medical devices.

Industries We Serve

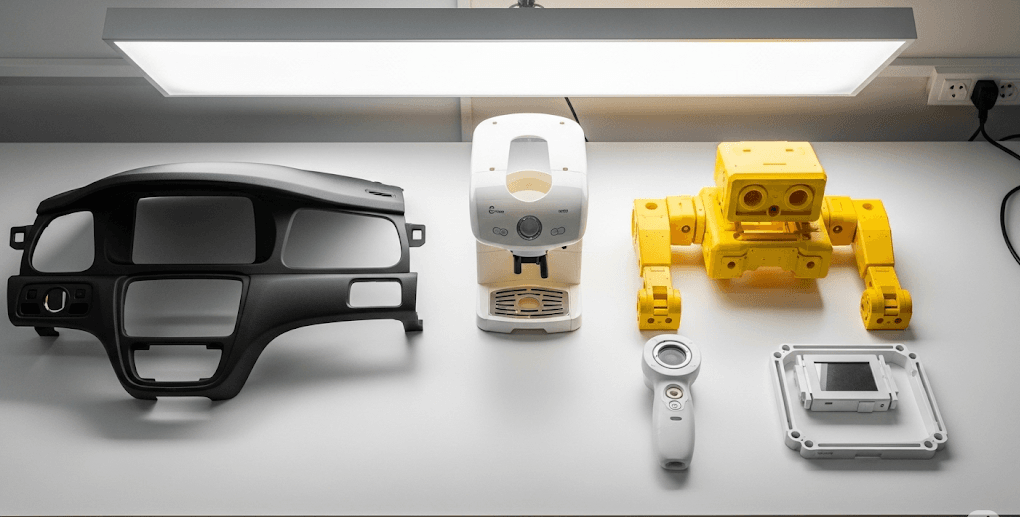

Medical equipment: surgical instrument handles, equipment housings, diagnostic instrument components (using PEEK, PC).

Automotive industry: concept car models, lighting prototypes, interior and exterior functional parts (using ABS, PMMA, POM).

Consumer electronics: drone fuselages, smart home housings, robot structural parts (using PC+ABS, Nylon).

Automation and robotics: custom fixtures, sensor brackets, precision transmission parts (using POM, Aluminum).

Aerospace: lightweight structural parts, interior dashboard components, connectors (using PEEK, PEI).

Not sure which material is best for your project? Our material experts are here to advise you.

- ABS

- PC

- POM

- PMMA

- PA

- PP

- PEEK

In the realm of precision manufacturing, the choice of material is as critical as the machining process itself. Acrylonitrile Butadiene Styrene, commonly known as ABS, stands out as a versatile and reliable thermoplastic polymer that is exceptionally well-suited for CNC (Computer Numerical Control) machining. Its unique combination of properties makes it a go-to material for a vast array of applications, from rapid prototyping to the production of durable end-use parts.

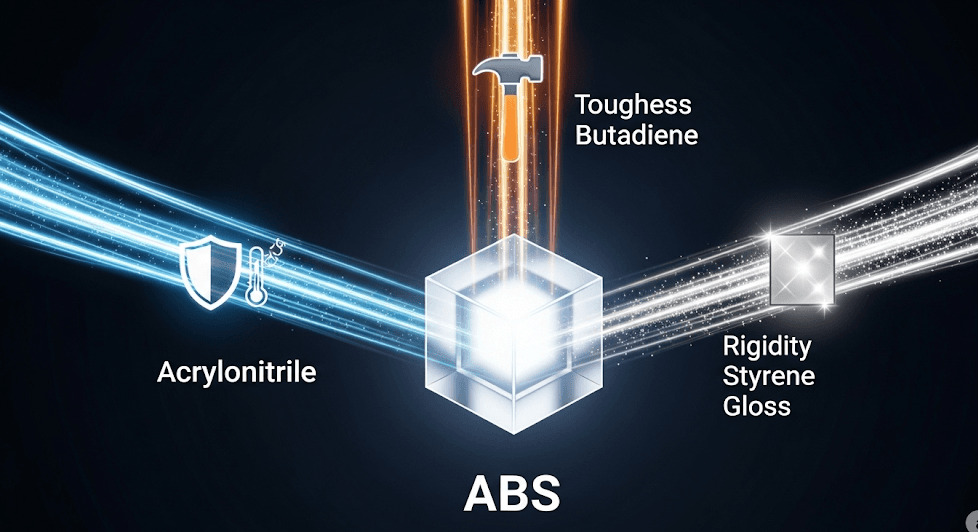

A Trifecta of Elements: The Composition of ABS

ABS is a terpolymer, meaning it is derived from three different monomers: acrylonitrile, butadiene, and styrene. This elemental makeup is the key to its balanced mechanical characteristics.

Acrylonitrile contributes to the material’s chemical resistance and thermal stability, allowing it to withstand exposure to a variety of chemicals and maintain its integrity at elevated temperatures.

Butadiene, a synthetic rubber, imparts toughness and impact strength, enabling ABS parts to absorb shock and resist fracturing.

Styrene provides the polymer with its rigidity and a glossy, easily processed surface finish.

The ratio of these three components can be tailored during production to create different grades of ABS with specific properties optimized for particular applications.

A Comparative Look: ABS Properties in the Spotlight

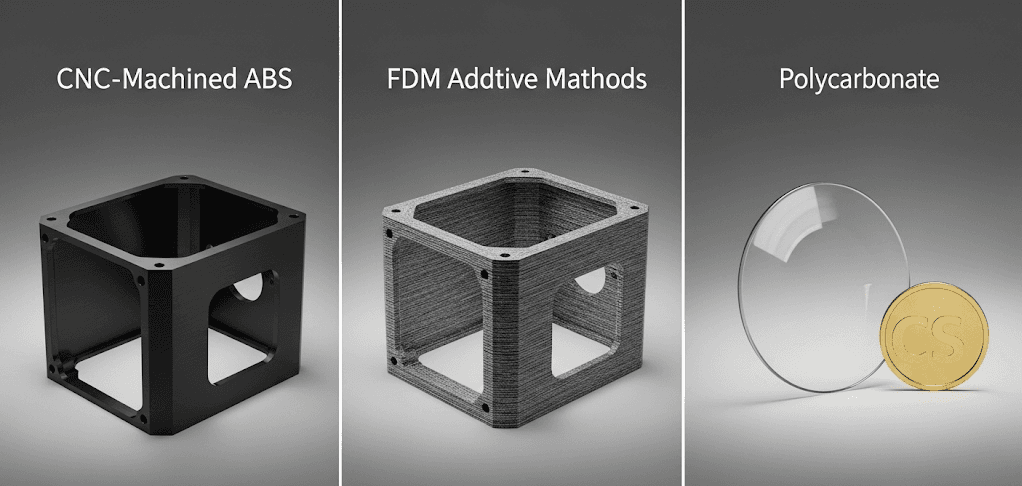

When compared to other common engineering plastics, ABS offers a compelling balance of properties. While materials like polycarbonate may offer higher impact strength, they often come at a greater cost. Similarly, while nylon may have superior wear resistance, ABS is generally easier to machine and has better dimensional stability. Its favorable strength-to-weight ratio, coupled with good electrical insulation properties, further solidifies its position as a versatile and cost-effective choice for many CNC machining projects.

The CNC Advantage: Why Machine ABS?

While ABS can be processed through various methods, including injection molding and 3D printing, CNC machining offers distinct advantages, particularly for low to medium volume production runs and for parts with intricate geometries and tight tolerances.

Advantages of CNC Machining ABS:

High Precision and Tight Tolerances: CNC machines can produce parts with exceptional accuracy, ensuring that components fit and function as intended.

No High Tooling Costs: Unlike injection molding, which requires the expensive and time-consuming creation of a mold, CNC machining works directly from a digital design, making it highly cost-effective for prototyping and smaller production quantities.

Superior Surface Finish: CNC machining can achieve a smooth and clean surface finish, often superior to that of FDM 3D printing, which can require significant post-processing.

Retention of Material Properties: As a subtractive manufacturing process, CNC machining does not alter the inherent mechanical properties of the ABS material, ensuring that the final part exhibits the full strength and durability of the raw stock.

Considerations:

While highly advantageous, CNC machining ABS does require careful consideration of tool selection, cutting speeds, and feed rates to prevent melting or warping due to heat generation.

From Prototypes to Production: Applications of CNC-Machined ABS

The versatility of CNC-machined ABS parts is evident in their widespread use across numerous industries. In the automotive sector, they are used for creating durable and lightweight interior and exterior components such as dashboards, trim, and grilles. The electronics industry relies on ABS for its excellent electrical insulation properties in housings, enclosures, and keyboard components. For consumer goods, its impact resistance and aesthetic qualities make it ideal for everything from appliance casings to toys. Furthermore, in the field of product development, CNC machining of ABS is invaluable for creating high-fidelity functional prototypes that closely mimic the look and feel of final production parts.

In conclusion, the unique elemental composition of ABS, its well-balanced properties, and the distinct advantages offered by CNC machining make it a cornerstone material in modern manufacturing. Its ability to be transformed into precise, durable, and aesthetically pleasing parts ensures its continued relevance in an ever-evolving technological landscape.

In the world of high-performance plastics, Polycarbonate (PC) stands as a titan of toughness and transparency. Renowned for its incredible impact resistance and optical clarity, PC is a premier material for CNC (Computer Numerical Control) machining, enabling the creation of robust, precise components for demanding applications. Its unique chemical makeup and balanced properties make it an indispensable resource in modern manufacturing.

Elemental Composition: The Core of Strength

Polycarbonate is a thermoplastic polymer whose name reveals its core chemical structure: its polymer chains are linked by carbonate groups (-O-(C=O)-O-). The most common type of PC is derived from the reaction of bisphenol A (BPA) and a carbonyl source. It is this unique molecular arrangement that endows PC with its exceptional combination of properties. The large, complex polymer structure resists deformation from impact, while the arrangement of these chains allows light to pass through with minimal distortion, resulting in its signature transparency.

A Material in Contrast: PC’s Competitive Edge

When benchmarked against other common engineering plastics, Polycarbonate’s advantages become clear:

vs. ABS: While ABS offers good toughness, PC provides significantly higher impact strength and superior temperature resistance. PC also boasts optical clarity, a property absent in the typically opaque ABS.

vs. Acrylic (PMMA): PC is approximately 250 times more impact-resistant than standard glass and significantly tougher than acrylic. While acrylic may have slightly better optical clarity and is easier to polish, it is far more brittle and prone to cracking under stress.

vs. Nylon: PC offers better dimensional stability, especially in moist environments, as Nylon tends to absorb water. PC also maintains its strength and rigidity at higher temperatures compared to many grades of Nylon.

CNC Machining vs. Other Methods: Precision in Practice

While Polycarbonate can be injection molded or 3D printed, CNC machining offers distinct benefits, particularly for prototyping, low-to-mid volume production, and parts requiring the highest levels of precision.

Advantages of CNC Machining PC:

Exceptional Impact Resistance: CNC machined PC parts retain the full, monolithic strength of the raw material, making them significantly more durable than layered 3D printed counterparts.

Optical Clarity: Machining can produce optically clear components, which is difficult to achieve with FDM 3D printing.

High Precision and Tight Tolerances: CNC machining excels at creating intricate features and holding tight dimensional tolerances that are critical for complex assemblies.

No Mold Costs: Unlike the high upfront investment for injection molding tooling, CNC machining is a direct digital manufacturing process, making it ideal for creating prototypes and small-batch production runs cost-effectively.

However, machinists must employ specific techniques, such as sharp tooling and appropriate coolants, to prevent melting and achieve a clean surface finish, as PC can be sensitive to heat buildup and stress.

Demanding Applications: Where PC Excels

The unparalleled strength and clarity of CNC-machined Polycarbonate make it indispensable across a wide range of industries. It is a favored material for:

Safety and Security: Bullet-resistant glass, machine guards, and safety visors.

Electronics: Clear housings, light pipes, and lenses for LEDs.

Automotive: Headlight covers, interior components, and durable transparent panels.

Medical and Lab Equipment: Housings for medical devices, clear manifolds, and durable, sterilizable components.

Prototyping: Creating functional, high-strength prototypes that can withstand rigorous testing.

In essence, CNC-machined Polycarbonate delivers a powerful combination of durability, precision, and optical properties, solidifying its role as a critical material for engineering challenges where failure is not an option.

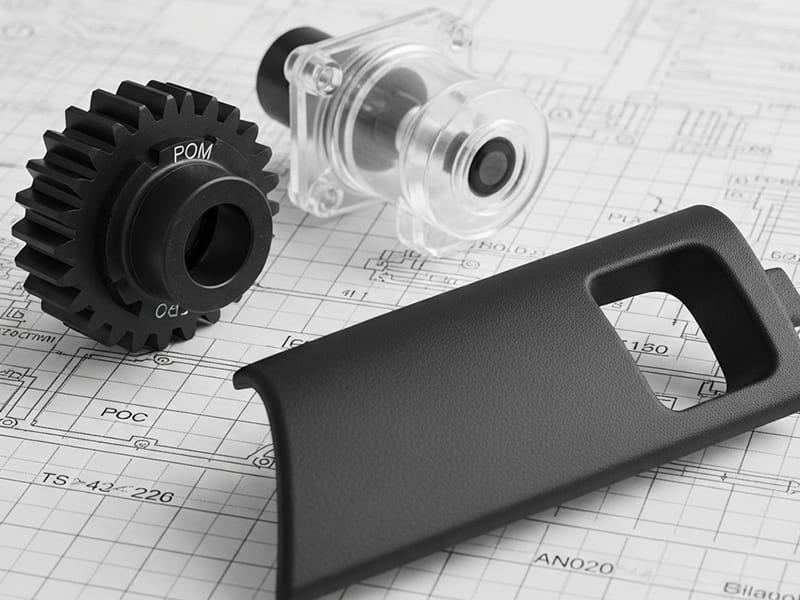

In the landscape of engineering thermoplastics, Polyoxymethylene (POM), widely known as acetal or by brand names like Delrin®, stands out as a material prized for its exceptional mechanical properties. Its unique combination of high stiffness, low friction, and excellent dimensional stability makes it a first-choice material for CNC (Computer Numerical Control) machining, enabling the production of high-performance, precision-engineered components.

Elemental Composition: The Foundation of Function

At its core, Polyoxymethylene is a semi-crystalline thermoplastic. Its chemical name reveals its simple yet robust elemental makeup: it is a polymer consisting of repeating -CH₂O- units. This straightforward chain of formaldehyde (carbon, hydrogen, and oxygen) creates a highly ordered molecular structure. This crystallinity is the key to POM’s most valued attributes, providing a strong and stable backbone that results in high strength and rigidity without the need for reinforcement.

A Comparative Analysis: POM’s Distinct Properties

When compared to other engineering plastics, POM carves out a unique niche defined by its mechanical prowess:

vs. Nylon (PA): POM’s primary advantage over Nylon is its significantly lower moisture absorption. While Nylon swells and can lose dimensional stability in humid environments, POM remains stable, making it superior for applications requiring tight tolerances in varying conditions.

vs. ABS: POM is substantially stronger, stiffer, and more resistant to wear and chemical solvents than ABS. Its natural lubricity also gives it a much lower coefficient of friction.

vs. Polycarbonate (PC): While PC offers superior impact strength and transparency, POM excels in wear resistance, creep resistance, and performance in applications involving friction and moving parts.

CNC Machining: The Path to Precision

While POM is readily injection moldable for high-volume production, CNC machining is the preferred method for creating high-precision parts, prototypes, and low-to-mid-volume production runs.

Advantages of CNC Machining POM:

Exceptional Machinability: POM is renowned for being one of the easiest engineering plastics to machine. It cuts cleanly, holds tight tolerances effortlessly, and can produce an excellent, smooth surface finish directly off the machine.

Dimensional Stability: The low internal stress and stable crystalline structure of POM mean it does not warp or deform easily during or after the machining process, ensuring the final part matches the digital design with high fidelity.

Cost-Effective for Precision: For components like gears, bearings, or jigs where precision is non-negotiable, CNC machining bypasses the high upfront cost of injection molds, offering an economical route to superior quality parts.

The main alternative, 3D printing, cannot match the surface finish, tight tolerances, or isotropic strength of a solid, CNC-machined POM component. The process of machining from a solid block of POM ensures the part retains its full mechanical integrity.

Real-World Applications: Where POM Excels

The unique profile of CNC-machined POM makes it indispensable for components that must endure friction, maintain their shape, and operate with precision. Its use is widespread across numerous industries:

Automotive: Gears for window lifters, fuel system components, and seatbelt mechanisms.

Industrial: High-performance gears, bearings, bushings, rollers, and conveyor-belt parts.

Electronics: Insulators, connectors, and fine-mechanics components within printers and other devices.

Consumer Goods: Zippers, ski bindings, and high-performance parts in kitchen appliances.

In conclusion, CNC-machined Polyoxymethylene is the go-to solution for engineering challenges that demand low friction, high stiffness, and unwavering reliability. Its superb machinability and stable nature ensure that complex and critical components can be manufactured with the utmost precision, solidifying its status as a cornerstone material for engineers worldwide.

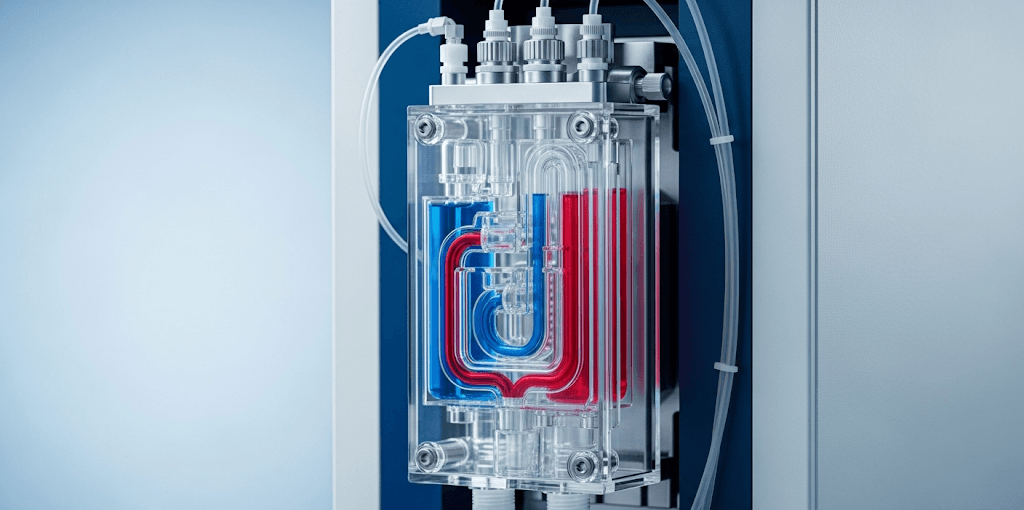

In the diverse world of plastic CNC machining, few materials offer the blend of beauty and functionality found in Polymethyl methacrylate (PMMA). Commonly known as acrylic or by brand names like Plexiglas®, PMMA is a premier choice when optical clarity and a pristine finish are non-negotiable. Its unique properties make it a standout material for CNC (Computer Numerical Control) machining, enabling the creation of components that demand exceptional transparency and precision, from intricate light pipes to high-end retail displays.

Elemental Composition: A Vision in Polymer Form

At its core, PMMA is a synthetic polymer of methyl methacrylate. Its chemical formula, (C₅O₂H₈)ₙ, reveals its composition of carbon, hydrogen, and oxygen. The key to its signature transparency lies in its molecular structure. As an amorphous thermoplastic, PMMA lacks the ordered, crystalline structure of materials like POM or Nylon. This random arrangement of polymer chains allows light to pass through with minimal scattering, giving PMMA a remarkable light transmittance of up to 92%—often clearer than glass itself.

A Comparative Look: PMMA’s Unique Properties

Within the realm of plastic CNC materials, PMMA holds a distinct position, especially when compared to other transparent or high-finish plastics:

vs. Polycarbonate (PC): While PC is superior in impact strength, PMMA excels in optical clarity, UV resistance (it is less prone to yellowing), and scratch resistance. It can also be polished to a more brilliant, glass-like finish.

vs. ABS: PMMA is significantly more transparent and offers a more aesthetic, high-gloss appearance than the typically opaque ABS. Although more brittle, PMMA is more rigid and weather-resistant.

vs. Glass: PMMA provides the clarity of glass at about half the weight and with far greater shatter resistance. Critically for manufacturing, it is much easier to shape and machine into complex designs.

The CNC Advantage: Beyond Simple Fabrication

While PMMA can be laser cut or cast, CNC machining unlocks a superior level of detail and quality.

Advantages of Plastic CNC Machining PMMA:

Geometric Complexity: CNC machining allows for the creation of 3D features like threaded holes, countersinks, pockets, and chamfers that are impossible to achieve with 2D methods like laser cutting.

Flawless Finishes: With specialized tooling and techniques, CNC machining can produce optically clear surfaces. Post-machining processes like vapor or flame polishing can then create a perfectly transparent, high-gloss finish.

Unmatched Precision: For components requiring tight tolerances, such as lenses, scientific instruments, or light guides, plastic CNC machining is the only method that guarantees the necessary dimensional accuracy.

The primary challenge when machining PMMA is managing its brittleness and low melting point. This requires experienced operators using sharp tools, high spindle speeds, and correct feed rates to prevent chipping or melting.

Applications: Where Clarity and Precision Meet

The outstanding optical qualities and excellent machinability of CNC-machined PMMA make it indispensable across many industries:

Electronics & Lighting: Manufacturing custom light pipes, lenses for LEDs, and light guides for backlighting.

Medical & Scientific: Creating microfluidic devices, transparent manifolds, cuvettes, and housings for diagnostic equipment.

Retail & Display: Producing luxury product displays, museum-quality vitrines, high-end signage, and architectural models.

Automotive: Crafting light covers, transparent instrument panels, and interior decorative elements.

In conclusion, for any plastic CNC project where pristine clarity, intricate design, and a flawless aesthetic are required, PMMA remains the undisputed, clear choice.

In the demanding field of plastic CNC machining, few materials offer the blend of toughness, wear resistance, and versatility found in Polyamide (PA), universally known as Nylon. As one of the most widely used engineering thermoplastics, Nylon is a true workhorse, relied upon for its exceptional mechanical performance. When precision-machined, it yields durable, high-performance parts capable of withstanding rigorous industrial and mechanical applications.

Elemental Composition: The Strength of the Amide Bond

Polyamide’s name reveals its fundamental chemical structure. It is a polymer composed of repeating units linked by amide bonds (-CO-NH-). These core elements—carbon, oxygen, nitrogen, and hydrogen—form long, strong molecular chains. This powerful amide linkage is the source of Nylon’s most celebrated characteristics, including its high strength, elasticity, and incredible resistance to abrasion and chemical exposure. Different types of Nylon (e.g., PA6, PA66) are defined by the specific number of carbon atoms in their polymer chains, allowing for a range of tailored properties.

A Comparative Look: Nylon’s Distinctive Attributes

When evaluated against other key materials in the plastic CNC portfolio, Nylon’s specific advantages become clear:

vs. POM (Acetal/Delrin): While POM offers superior dimensional stability due to lower moisture absorption, Nylon provides greater toughness, higher fatigue resistance, and better performance at elevated temperatures.

vs. ABS: Nylon is significantly tougher and more durable than ABS, boasting superior wear and chemical resistance, making it suitable for more demanding functional applications.

vs. PC (Polycarbonate): While PC is stiffer and has better impact strength, Nylon excels in applications requiring low friction and high wear resistance, such as for sliding or rotating parts.

A critical design consideration for Nylon is its tendency to absorb moisture, which can cause dimensional changes and a slight reduction in stiffness. However, this absorption also contributes to its toughness and impact resistance.

The CNC Advantage: Precision for Performance Parts

While Nylon is a cornerstone of injection molding for mass production and is popular in 3D printing (especially SLS), CNC machining remains the superior choice for high-precision, low-volume, and robust functional parts.

Advantages of Plastic CNC Machining Nylon:

Superior Mechanical Properties: A part machined from a solid block of Nylon possesses the material’s full, isotropic strength, unlike layered 3D printed parts which can have weaknesses between layers.

Exceptional Surface Finish and Tolerances: CNC machining produces a smooth surface finish and can hold extremely tight tolerances, which is critical for components like gears, bearings, and precision fittings.

No High Tooling Costs: For prototyping and small-batch production, CNC machining is far more cost-effective than injection molding, which requires a significant upfront investment in a mold.

Excellent Machinability: Despite its toughness, Nylon machines well, producing clean cuts and predictable results, although heat management is important to prevent melting.

Applications: Where Toughness Meets Precision

The unique profile of CNC-machined Nylon makes it the ideal material for components that must endure friction, impact, and repeated mechanical stress. Its use is widespread across numerous industries:

Industrial & Manufacturing: High-load gears, bearings, bushings, sprockets, wear pads, and rollers.

Automotive: Engine components, cable ties, fluid reservoirs, and thrust washers.

Electronics: Insulators, connectors, and structural components requiring durability and electrical resistance.

Aerospace: High-strength, low-weight components like seals, gaskets, and clips.

In conclusion, for any plastic CNC project that demands exceptional toughness and wear resistance, PA (Nylon) is an unparalleled choice. Its ability to be machined into precise, durable, and reliable parts ensures its continued role as a fundamental material in modern engineering.

In the vast world of polymer manufacturing, Polypropylene (PP) stands out as a material prized for its extraordinary chemical resistance, versatility, and cost-effectiveness. While often associated with high-volume production methods, PP is also an excellent candidate for CNC (Computer Numerical Control) machining. This process transforms the humble polymer into highly specific and durable plastic parts that serve critical functions where other materials would fail.

Elemental Composition: Simple, Stable, and Strong

Polypropylene is a thermoplastic polymer belonging to the polyolefin family. Its elemental makeup is one of the simplest among all plastics, consisting solely of carbon and hydrogen atoms. Its chemical formula is (C₃H₆)ₙ. This straightforward hydrocarbon structure results in a semi-crystalline polymer that is non-polar. This non-polar nature is the key to its most valuable property: an exceptional resistance to a wide array of chemicals, including acids, bases, and organic solvents, which would degrade many other types of plastic parts.

A Comparative Look: PP’s Unique Advantages

When compared to other common plastics, Polypropylene’s distinct property profile makes it uniquely suitable for specific applications:

vs. PVC (Polyvinyl Chloride): PP is much lighter, contains no chlorine, and possesses superior fatigue resistance. It is also generally considered safer for food-contact applications.

vs. PE (Polyethylene): While both are chemically resistant polyolefins, PP is stiffer, has a higher melting point, and offers better tensile strength, making it more suitable for structural plastic parts.

vs. ABS: While ABS is harder and more rigid, PP provides far superior chemical resistance and is more resistant to fatigue. PP’s integral hinge property—the ability to be flexed repeatedly without breaking—is a unique advantage.

The CNC Machining Edge: Precision for Specialized Needs

Although injection molding is the most common method for producing PP plastic parts in large quantities, CNC machining offers critical advantages for prototyping, customization, and low-volume production.

Advantages of CNC Machining PP:

Prototyping and Testing: CNC machining allows for the rapid creation of functional prototypes from solid PP stock. This is invaluable for testing designs, especially for fluidic systems or chemical containers, before committing to expensive molding tools.

High Precision: For applications requiring tight tolerances, such as manifolds, valves, or medical components, CNC machining can achieve a level of accuracy that is difficult to match with other methods.

No Mold Costs: The direct-from-digital process of CNC machining eliminates the significant time and financial investment required for injection molds, making it highly economical for small production runs.

The primary challenge in machining PP is its low melting point and high thermal expansion rate, which requires sharp tooling, appropriate cutting speeds, and often the use of coolant to prevent melting and ensure dimensional accuracy.

Applications: Where Chemical and Fatigue Resistance are Paramount

The unique characteristics of CNC-machined PP plastic parts make them indispensable in a variety of demanding environments:

Medical and Laboratory: Components for diagnostic instruments, chemically resistant trays, and custom fluidic manifolds.

Chemical Processing: Flanges, valves, nozzles, and tanks used to handle corrosive substances.

Automotive: Prototypes for fluid reservoirs, battery housings, and components requiring resistance to automotive chemicals.

Food & Beverage: Cutting boards, custom fixtures, and components for processing equipment, thanks to its FDA-compliant grades.

In conclusion, CNC machining elevates Polypropylene from a commodity plastic to a high-performance material capable of producing precise, durable, and chemically inert plastic parts for critical applications where reliability is essential.

In the hierarchy of polymers, Polyetheretherketone (PEEK) occupies the summit. As an ultra-high-performance thermoplastic, PEEK is reserved for the most demanding applications where other materials fail. For creating mission-critical plastic parts, CNC (Computer Numerical Control) machining of PEEK is the definitive process, transforming this elite polymer into components with unparalleled strength, stability, and resistance for extreme environments.

Elemental Composition: The Architecture of Extreme Performance

PEEK is a semi-crystalline thermoplastic belonging to the polyaryletherketone (PAEK) family. Its name describes its molecular architecture: a repeating chain of ether (-O-) and ketone (C=O) functional groups linked by aryl (aromatic) rings. This robust structure, composed of carbon, hydrogen, and oxygen, is incredibly stable. The aromatic rings provide immense rigidity and thermal stability, while the ether linkages offer a degree of flexibility and toughness. It is this powerful, stable molecular backbone that endows PEEK with its extraordinary performance characteristics.

A Comparative Look: PEEK vs. Other High-Performance Materials

When evaluating PEEK, it is often benchmarked not just against other plastics, but against metals, showcasing its unique position.

vs. Other High-Performance Plastics (e.g., PEI/Ultem, PPS): While materials like Ultem also offer high-temperature resistance, PEEK generally provides superior chemical inertness, better fatigue and wear resistance, and higher tensile strength, placing it in a higher performance tier.

vs. Metals (e.g., Aluminum, Stainless Steel): The most significant advantage of PEEK is its high strength-to-weight ratio. PEEK plastic parts can offer strength comparable to some aluminum alloys at a fraction of the weight. Furthermore, it boasts exceptional corrosion resistance, biocompatibility, and electrical insulation properties that metals cannot match.

vs. Standard Engineering Plastics (e.g., Nylon, PC): PEEK operates on a completely different level, with a continuous service temperature often exceeding 250°C (482°F), a point where standard plastics would have completely melted or degraded.

CNC Machining: The Only Choice for Ultimate Precision

While PEEK can be injection molded for high-volume production, CNC machining is essential for creating the most precise and structurally sound plastic parts.

Advantages of CNC Machining PEEK:

Maximum Material Integrity: CNC machining from a solid PEEK billet ensures the final part possesses the material’s full, isotropic strength and crystalline structure. This is critical for components under extreme mechanical or thermal stress, avoiding potential weaknesses found in molded or 3D-printed parts.

Unmatched Precision and Complexity: CNC machining can achieve extremely tight tolerances and complex geometries that are vital for aerospace, medical, and semiconductor applications.

Prototyping and Low-Volume Production: It provides a cost-effective method for producing high-quality, functional prototypes and small batches of PEEK parts without the astronomical cost of specialized injection molds.

Machining PEEK presents challenges due to its toughness and abrasion resistance, requiring specialized carbide tooling, rigid machine setups, and precise control over cutting parameters to manage heat and prevent stress.

Applications: Thriving in the Most Extreme Environments

CNC-machined PEEK plastic parts are found where failure is not an option:

Aerospace: Structural components, electrical insulators, and high-temperature engine parts, valued for weight reduction and reliability.

Medical: Spinal fusion cages, orthopedic implants, and dental healing caps due to its biocompatibility, radiolucency (transparent to X-rays), and ability to be repeatedly sterilized.

Oil & Gas: Seals, compressor rings, and downhole electrical connectors that must withstand high pressures, corrosive chemicals, and extreme temperatures.

Semiconductor: Wafer handling components, test sockets, and CMP rings that require chemical inertness and dimensional stability.

In essence, CNC machining of PEEK is the process of choice for creating the most robust and reliable plastic parts known to engineering, pushing the boundaries of what is possible in technology and innovation.

Frequently Asked Questions

We accept orders for plastic CNC parts with no minimum order quantity—we can start with just a single piece.

This flexibility is ideal for creating prototypes, testing new designs, or fulfilling custom small-batch production runs. By ordering only what you need, you can significantly reduce upfront development costs and minimize inventory risk.

We are committed to supporting your project at every stage. Please feel free to send us your CAD files and material specifications, and our team will promptly provide you with an accurate quote.

Our standard CNC machining tolerance is typically within ±0.1 mm (or ±0.004 inches), which adheres to the ISO 2768-m standard for general applications.

Absolutely, higher precision can be achieved. We can hold tolerances as tight as ±0.01 mm (±0.0004 inches) or better, depending on the part’s geometry, material, and specific feature requirements.

For high-precision needs, please indicate the critical dimensions and required tolerances directly on your technical drawings. Our engineering team will review them to ensure full compliance and optimize the machining process accordingly.

Our process is designed for efficiency. Quotations are provided promptly after we review your design files and requirements.

Once the order is confirmed, production for standard plastic CNC parts generally takes several business days to complete. The final timeline for receiving your parts will then depend on the shipping duration.

This entire process can be influenced by factors such as the complexity of the part, the quantity ordered, and any required finishing services. For a more specific schedule tailored to your project, we encourage you to send us your detailed requirements.

We accept a wide range of 3D drawing formats to ensure a smooth workflow. For the best results, we recommend universal and robust formats such as:

STEP (.stp, .step)

IGES (.igs, .iges)

These are preferred as they are compatible with virtually all CAD/CAM systems. We also accept native CAD files from software like:

SolidWorks (.sldprt)

AutoCAD (.dwg, .dxf)

For a complete manufacturing picture, we highly recommend providing a 2D PDF drawing alongside your 3D model to specify tolerances, materials, finishes, and other critical information.

We understand that the confidentiality of your intellectual property is paramount. We take rigorous steps to protect your design files and ensure their security throughout the entire process.

Our key measures include:

Non-Disclosure Agreements (NDA): We are always prepared to sign a formal NDA to provide a legal framework for confidentiality before you share any sensitive information.

Secure Data Handling: Your files are stored on secure, encrypted servers, and all data transfers are protected.

Strict Access Control: Access to your designs is strictly limited to the essential personnel directly involved in the quotation and production of your parts.

Our commitment is to provide a secure and trustworthy environment for your projects.

Yes, absolutely. In addition to our expertise in plastics, we provide comprehensive CNC machining services for a wide range of metal materials.

Our capabilities include precision machining of:

Aluminum (e.g., 6061, 7075)

Stainless Steel (e.g., 303, 304, 316L)

Carbon Steel

Brass and Copper

Titanium

Whether you require a single prototype or full production runs, our team is equipped to handle your metal machining needs with the same commitment to quality and precision. Please send us your project requirements for a detailed quotation.

Blog Post

Explore expert tips, industry trends, and productivity hacks

Plastic CNC Machining: A Guide to Acrylic, Delrin, PC & PEEK

Finding a reliable supplier for plastic CNC machining can be...

Read More →PA vs. PVC in CNC Machining for Medical Devices

In the precision-driven world of medical device manufacturing, material selection...

Read More →