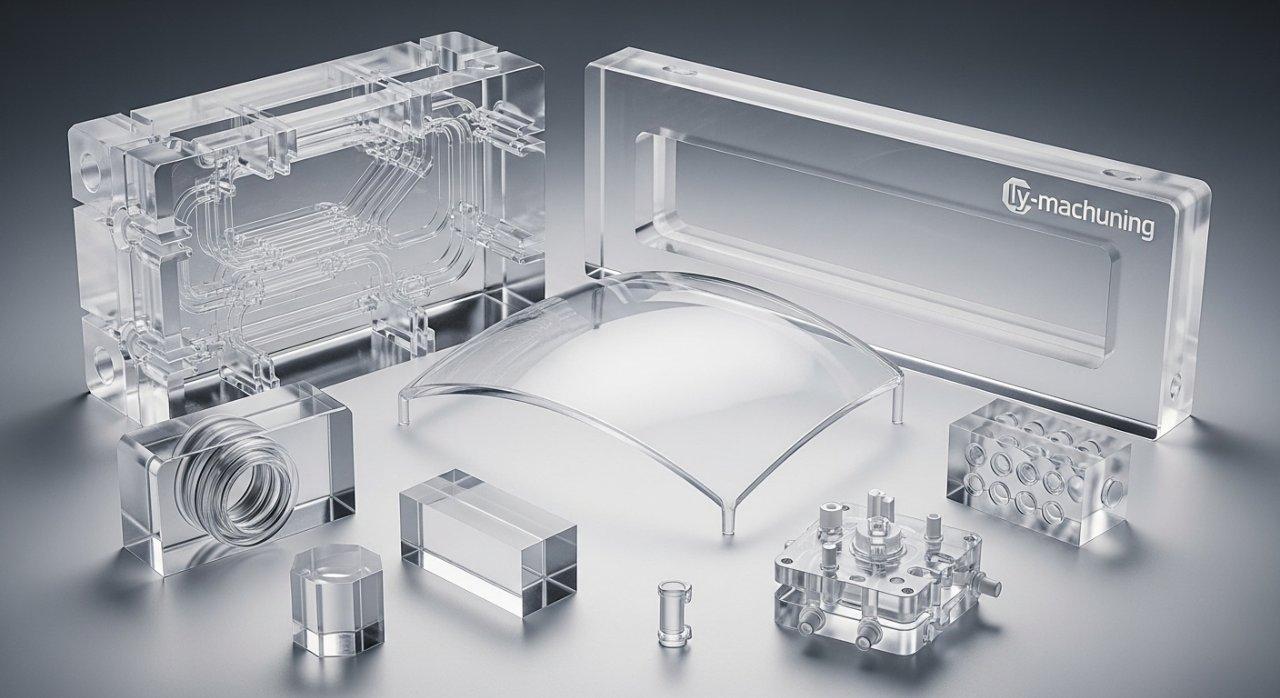

PMMA CNC Cracking: Expert Solutions

PMMA CNC cracking solution lies in meticulous process control, precise tool selection, and critical PMMA stress relief annealing. These integrated PMMA machining techniques are essential for acrylic cracking prevention and achieving flawless results.

Is your PMMA CNC machining project plagued by frustrating cracks, leading to costly scrap and missed deadlines? Many manufacturers face this persistent challenge, often underestimating PMMA’s unique material characteristics.

The frustration of high scrap rates and compromised part integrity can significantly impact project timelines and budgets. Without precise control over every stage, PMMA parts are susceptible to various forms of cracking.

This comprehensive guide, informed by our deep experience as a leading source manufacturer, will dismantle the root causes of PMMA cracking. We will reveal the definitive strategies and advanced PMMA machining techniques to eliminate these issues, ensuring your components are flawless.

Understanding PMMA Cracking in CNC Machining

Common Causes of PMMA Cracks

In our experience, PMMA cracking often stems from a combination of mechanical, thermal, and chemical stresses. Improper machining parameters are a primary culprit, generating excessive heat and inducing stress.

Insufficient cooling during cutting is another significant factor we observe. This leads to localized overheating, which can compromise the material’s structural integrity. Poor tool geometry also contributes directly to crack formation.

Chemical exposure, even to seemingly mild coolants or cleaning agents, can cause environmental stress cracking. This is particularly prevalent when the PMMA is already under residual stress from machining.

Table: Common Causes of PMMA Cracking

| Cause | Description |

|---|---|

| Excessive Heat | Generated by high RPMs, inadequate cooling, or dull tools. |

| Mechanical Stress | Incorrect clamping, aggressive feed rates, or improper tool engagement. |

| Residual Stress | Inherent material stress or stress induced during machining and cooling. |

| Chemical Exposure | Incompatible coolants, cleaners, or adhesives causing environmental attack. |

| Poor Tool Geometry | Tools that scrape or push rather than cut cleanly, leading to material tear. |

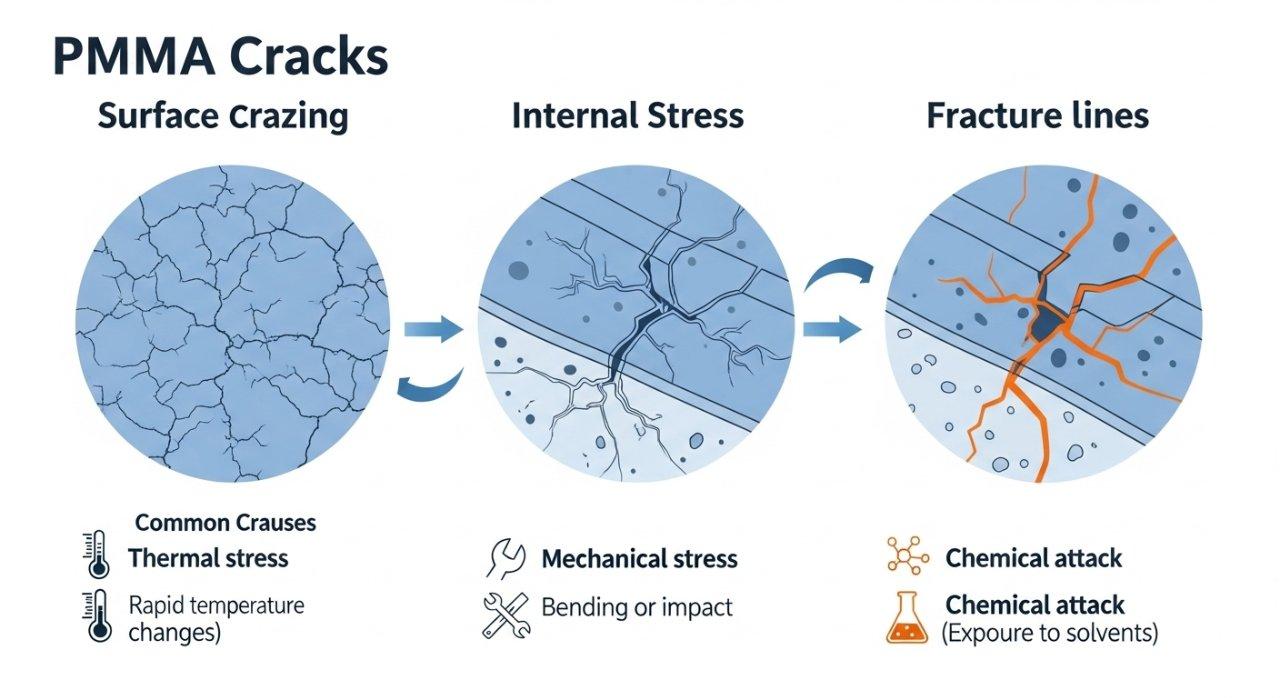

Types of Cracks and Their Origins

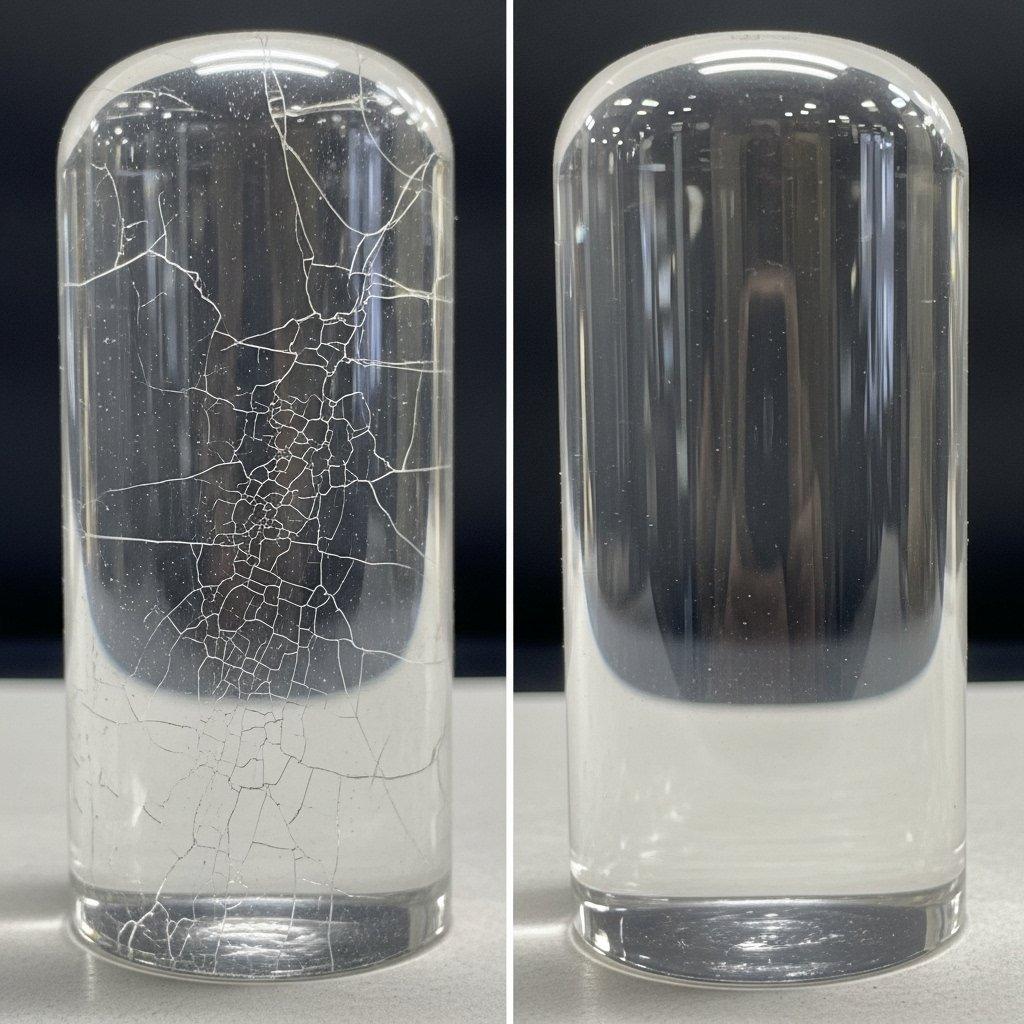

PMMA can exhibit several distinct types of cracks, each with its own specific origin. Surface crazing, characterized by a network of fine, hair-like cracks, typically results from residual tensile stress combined with solvent exposure or minor surface damage.

Internal stress cracks are often deeper and less visible on the surface, originating from thermal gradients during cooling or internal stresses built up during manufacturing. These can propagate over time, leading to sudden failure.

Fracture lines, on the other hand, are usually a result of acute stress beyond the material’s yield strength. This can be caused by impact, incorrect clamping pressure, or catastrophic failure during machining due to extreme stress. Understanding these types is crucial for effective acrylic cracking prevention.

Why PMMA is Prone to Cracking

PMMA, while offering excellent optical clarity and rigidity, possesses inherent characteristics that make it susceptible to cracking. Its relatively low impact strength means it doesn’t absorb sudden mechanical shock well.

The material’s viscoelastic nature implies that it responds to stress over time, often manifesting delayed cracking. This can be challenging for those unfamiliar with proper PMMA machining techniques.

Furthermore, PMMA has a high coefficient of thermal expansion. Rapid temperature changes or localized heat generation during machining induce significant internal stresses, making it highly prone to thermal cracking.

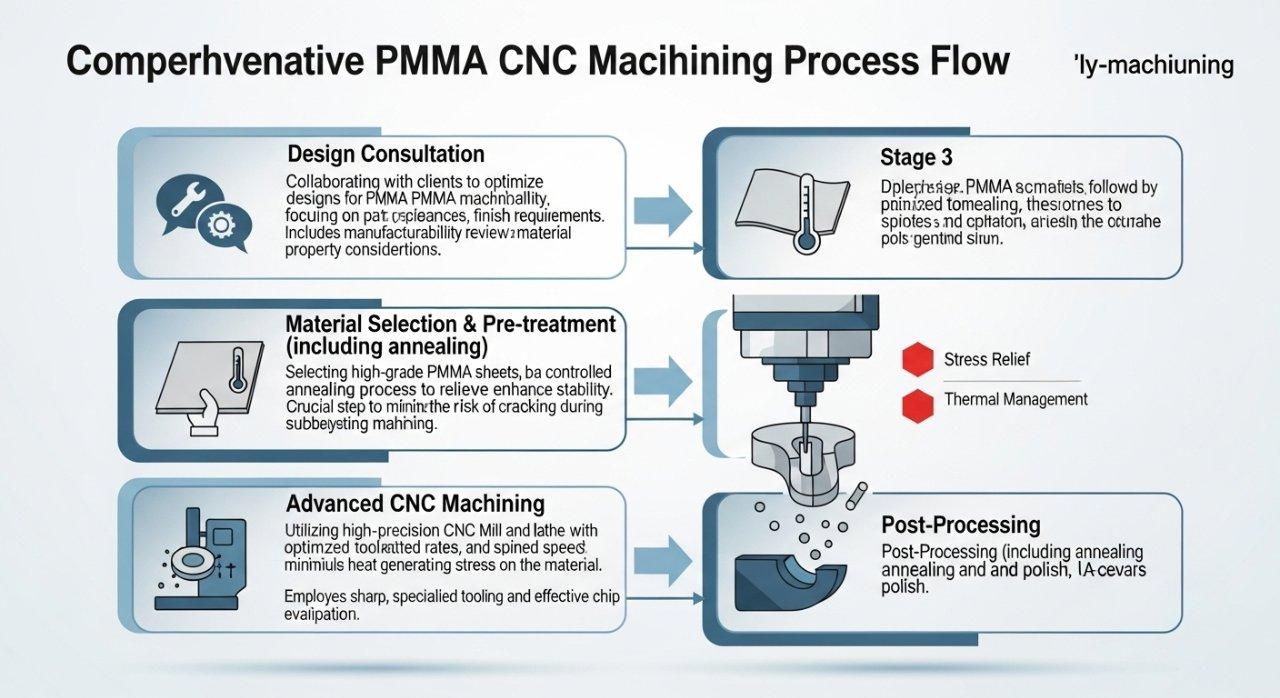

Preventing PMMA Cracking: Material & Design

Selecting the Right PMMA Grade

The choice of PMMA grade is foundational to preventing cracking. Cast PMMA generally offers better machinability and lower internal stress compared to extruded PMMA. Its higher molecular weight contributes to better resistance.

Extruded PMMA, while more economical, can have higher residual stress due due to its manufacturing process. This makes it more challenging to machine without inducing cracks. Understanding the application helps in selecting the optimal type.

In our experience, specifying cast PMMA for precision parts significantly reduces the risk of cracking. We always advise clients on the most suitable grade for their specific application, considering both performance and cost.

Table: Cast vs. Extruded PMMA Properties

| Feature | Cast PMMA | Extruded PMMA |

|---|---|---|

| Internal Stress | Lower, due to slower polymerization. | Higher, due to rapid cooling and stretching during extrusion. |

| Machinability | Better, less prone to chipping and cracking during cutting. | More challenging, higher risk of stress cracking. |

| Molecular Weight | Higher, resulting in better chemical resistance and thermal stability. | Lower, leading to slightly reduced performance in some areas. |

| Optical Clarity | Excellent, often preferred for high-end optical applications. | Good, but may exhibit more flow lines or imperfections. |

Optimizing Part Design for PMMA

Thoughtful design is a critical aspect of acrylic cracking prevention. Avoid sharp internal corners and tight radii, as these create stress concentration points where cracks are most likely to initiate.

We recommend incorporating generous radii, typically at least 0.8mm (0.030 inches) or larger, at all internal corners. This helps distribute stress more evenly across the material.

Maintain consistent wall thicknesses where possible to prevent differential cooling and internal stress build-up. Abrupt changes in thickness can lead to warpage and cracking during post-processing.

Importance of Material Pre-treatment

Proper pre-treatment prepares the PMMA for machining and minimizes the risk of cracking. Material should be acclimated to the workshop temperature and humidity for at least 24-48 hours before machining.

This allows the material to stabilize, reducing internal stresses caused by thermal shock when machining cold material. Ensuring the material is clean and free of surface contaminants also aids in consistent machining.

Any surface imperfections can act as nucleation sites for cracks under stress. A clean, stable starting material is key to successful PMMA machining techniques.

Stress Relief Before PMMA Machining

Pre-machining stress relief annealing is a highly effective method for *PMMA stress relief annealing*. This process involves heating the PMMA slowly to a specific temperature, holding it, and then cooling it gradually.

This controlled thermal cycle reduces any inherent residual stresses present in the material from its manufacturing process. It makes the material more stable and less prone to cracking during subsequent CNC operations.

In our facility, we often recommend and perform this critical step, especially for complex or high-tolerance PMMA parts. It’s a proactive measure that significantly enhances the material’s machinability.

Table: Pre-Machining PMMA Stress Relief Annealing Parameters

| Parameter | Typical Value | Purpose |

|---|---|---|

| Heating Rate | 10-20°C per hour (0.18-0.36°F per minute) | Prevents thermal shock; allows gradual relaxation of internal stress. |

| Soak Temperature | 70-80°C (158-176°F), depending on PMMA grade and thickness. | Allows molecular chains to rearrange, releasing residual stress. |

| Soak Time | 1-4 hours per 25mm (1 inch) of thickness. | Ensures uniform stress relief throughout the material. |

| Cooling Rate | 5-10°C per hour (0.09-0.18°F per minute) to room temperature, in the oven. | Prevents reintroduction of new thermal stresses during cooling. |

Advanced CNC Machining Techniques for PMMA

Tool Selection & Geometry for PMMA

The right tool is paramount for successful PMMA machining techniques. We exclusively use razor-sharp, highly polished tools, typically single-flute end mills or router bits specifically designed for plastics.

These tools must have a high positive rake angle (10-20 degrees) to provide a shearing action rather than pushing or scraping the material. A high helix angle (around 40-55 degrees) is also crucial for efficient chip evacuation.

This specialized geometry minimizes heat generation and reduces the mechanical stress on the material. Dull or improperly ground tools are a leading cause of localized heating and subsequent cracking in PMMA.

Table: Ideal Tool Geometries for PMMA Machining

| Parameter | Recommended Range | Benefit |

|---|---|---|

| Rake Angle | 10-20 degrees (Positive) | Promotes clean shearing action, reduces cutting forces and heat. |

| Helix Angle | 40-55 degrees (High) | Facilitates efficient chip evacuation, prevents re-cutting. |

| Flute Count | 1-2 Flutes | Larger chip loads, less heat build-up per tooth, better chip removal. |

| Tool Material | Polished Carbide or HSS | Sharp edge retention, smooth surface finish, reduced friction. |

| Cutting Edge | Razor Sharp, Polished | Prevents tearing and stress induction, ensures superior surface quality. |

Optimized Feed Rates & Spindle Speeds

Achieving the optimal balance between feed rate and spindle speed is critical for acrylic cracking prevention. Too slow a feed rate can lead to excessive rubbing, generating heat and melting the PMMA.

Too fast a feed rate, conversely, can cause aggressive chip loads, increasing cutting forces and risking fracturing. Our engineers meticulously calculate these parameters to ensure a clean, efficient cut.

We aim for a chip load that creates a distinct, continuous chip without melting or tearing. This prevents heat build-up and reduces internal stresses. In our experience, slower RPMs with appropriately higher feed rates often yield better results than high RPMs with low feed rates.

Effective Cooling Strategies for PMMA

Effective cooling is non-negotiable for PMMA CNC cracking solution. We primarily employ compressed air blasts directed precisely at the cutting zone. This rapidly removes heat and clears chips simultaneously.

Mist coolants can also be effective, providing both cooling and lubrication. However, careful selection of the coolant type is essential, as some chemical coolants can react with PMMA, causing environmental stress cracking.

We generally advise against flood cooling unless absolutely necessary, as it can induce thermal shock if not carefully managed. The goal is to keep the cutting zone cool without introducing sudden temperature changes.

Managing Chip Evacuation in PMMA CNC

Efficient chip evacuation is often overlooked but crucial for PMMA machining techniques. PMMA chips can be sticky and stringy, easily re-welding to the workpiece or tool if not promptly removed.

Re-cutting chips causes friction, generates heat, and can mar the surface finish. Our machining centers utilize high-volume air blasts and often vacuum systems to ensure chips are cleared instantly from the cutting path.

Proper tool geometry, as mentioned, also significantly aids in chip formation and expulsion. Well-formed, cleanly detached chips are a sign of optimized machining conditions and help prevent acrylic cracking prevention.

Multi-Axis Machining Benefits for PMMA

Multi-axis CNC machining offers significant advantages for complex PMMA parts. By allowing the tool to approach the workpiece from multiple angles, it reduces the need for multiple setups and re-clamping.

Each re-clamping introduces potential for misalignment and new clamping stresses. Multi-axis machining enables smoother, continuous tool paths, minimizing entry and exit points that are prone to stress concentration.

This results in a superior surface finish, tighter tolerances, and most importantly, significantly reduced internal stresses within the part. It’s a key strategy in achieving high-quality PMMA CNC cracking solution.

Post-Processing & Quality Control for PMMA

Essential PMMA Annealing Processes

Post-machining *PMMA stress relief annealing* is as critical as pre-treatment. This process is designed to relieve any residual stresses induced during the CNC machining process itself.

The parameters for post-machining annealing are similar to pre-machining but must be carefully controlled to avoid deforming the finished part. This step is a cornerstone of our PMMA CNC cracking solution.

Our controlled annealing cycles prevent delayed cracking and ensure dimensional stability. It significantly enhances the long-term reliability and optical clarity of the machined PMMA components.

Table: Post-Machining PMMA Stress Relief Annealing Profile

| Step | Temperature Range | Duration | Purpose |

|---|---|---|---|

| Heating Rate | 5-10°C per hour | Gradual | Prevents thermal shock, allows uniform heating. |

| Soak Temperature | 60-75°C | 2-6 hours (depending on part geometry and thickness) | Relieves machining-induced internal stresses without deforming the part. |

| Cooling Rate | 2-5°C per hour | Gradual, back to room temperature within the oven. | Prevents reintroduction of new stresses; maintains dimensional stability. |

| Final Inspection | Visual, Polarized Light | Post-cooling | Confirms absence of new cracks or residual stress after annealing. |

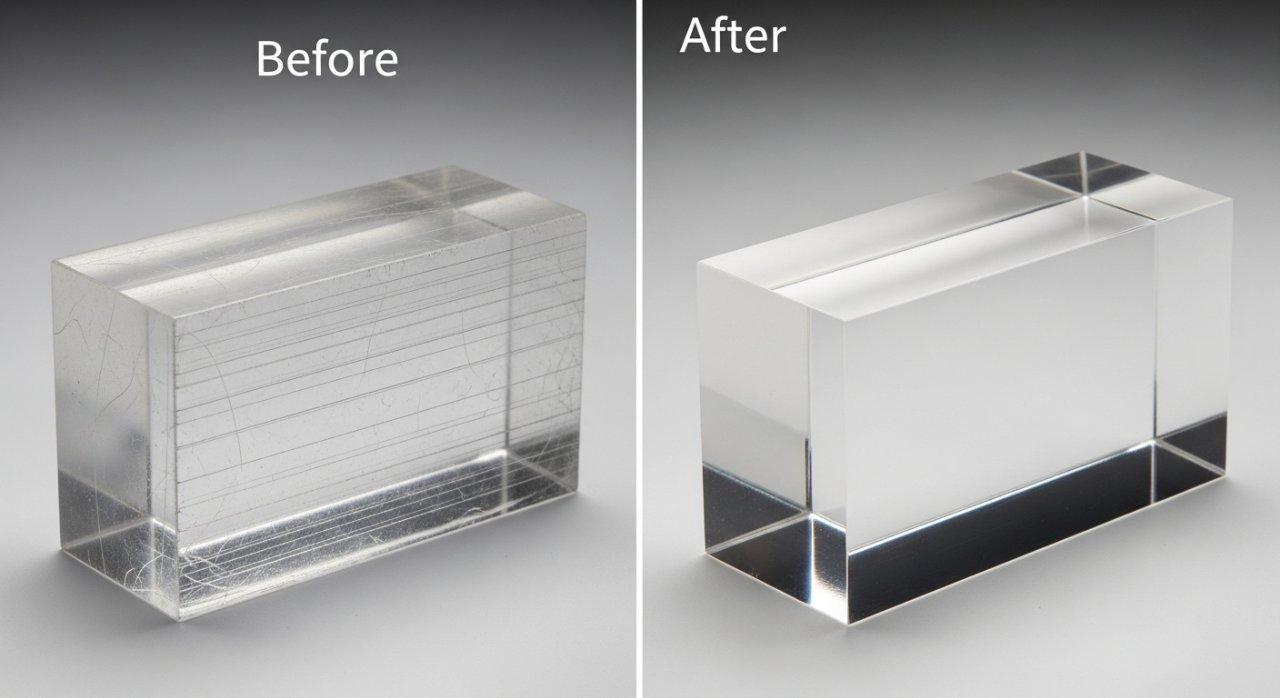

Surface Finishing to Prevent Micro-Cracks

Even after meticulous machining and annealing, the surface finish plays a role in acrylic cracking prevention. Machining can leave microscopic tool marks or sub-surface damage that act as stress risers.

Techniques like vapor polishing, flame polishing, or mechanical polishing can remove these imperfections. This creates a smoother, more uniform surface that is less prone to initiating micro-cracks under stress.

Our advanced polishing techniques are crucial for removing sub-surface damage that might otherwise propagate into visible cracks over time. This ensures both aesthetic appeal and structural integrity.

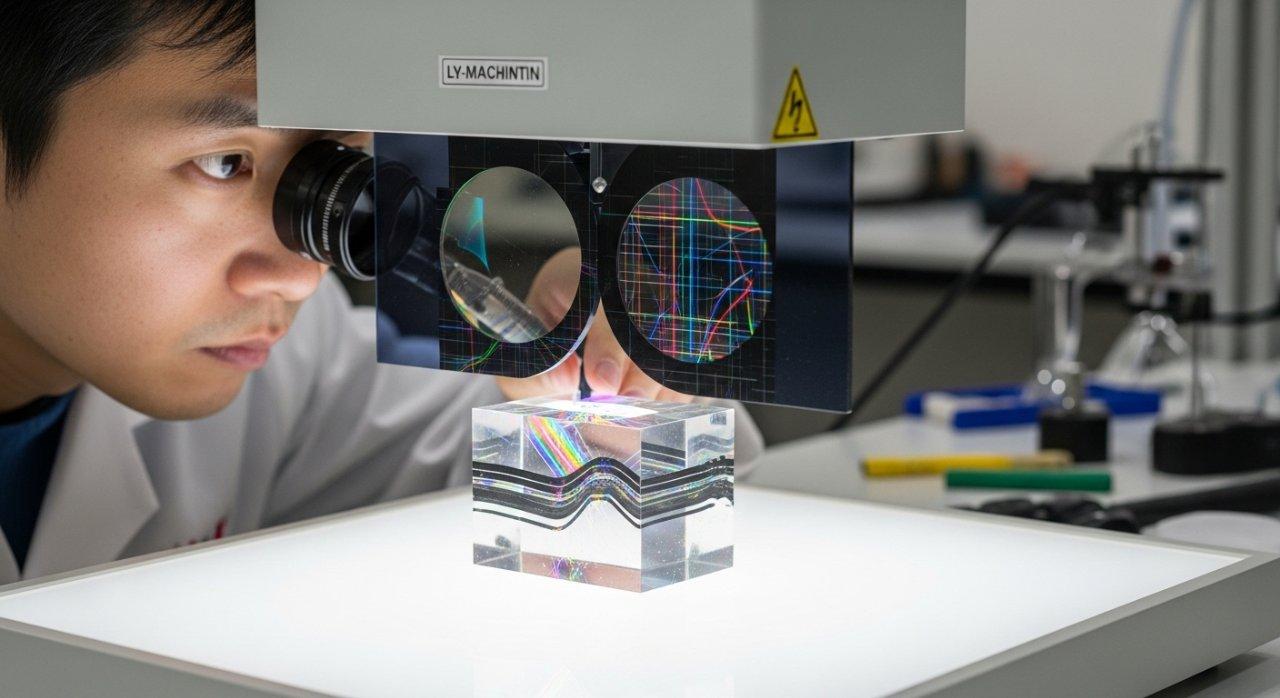

Rigorous PMMA Quality Inspection

Quality inspection is a continuous process at ‘ly-machining’, not just a final check. After machining and post-processing, every PMMA part undergoes rigorous inspection.

This includes visual inspection under magnification for surface defects and optical clarity. We also utilize polarized light inspection to detect internal stresses that are invisible to the naked eye.

Dimensional checks ensure the part meets tight tolerances. Our comprehensive inspection protocols guarantee that only flawless, crack-free PMMA components are delivered to our clients.

Packaging & Handling of PMMA Parts

The final step in ensuring crack-free PMMA parts is proper packaging and handling. PMMA parts must be protected from impact, scratches, and extreme temperature fluctuations during transport.

We use custom-fit, non-abrasive packaging materials that cushion the parts and prevent movement. Each component is individually wrapped to prevent surface damage.

Careful handling prevents accidental stress or damage that could compromise the integrity of the meticulously machined parts. This attention to detail reflects our commitment to quality from start to finish.

Case Study: Eliminating Cracking in Medical Device Housings

A client developing a new diagnostic device approached us after experiencing persistent cracking issues with their PMMA housings from previous manufacturers. The complex geometry, thin walls, and tight tolerances made it particularly challenging. Traditional PMMA machining techniques were failing consistently.

Our solution began with a thorough material analysis, confirming the need for specific cast PMMA. We then implemented a two-stage *PMMA stress relief annealing* process: once before machining and again after. During machining, our engineers developed a custom tool path with specialized single-flute tooling, optimized feed rates, and a continuous air blast cooling strategy. This ensured precise material removal without inducing thermal or mechanical stress.

The result was a batch of perfectly clear, crack-free PMMA medical device housings that met all aesthetic and functional requirements. The client was able to accelerate their product launch, avoiding costly reworks and gaining confidence in their supply chain. Our deep technical expertise provided a definitive PMMA CNC cracking solution.

Partnering for Flawless PMMA CNC Parts

Our Deep Technical Expertise in PMMA

At ‘ly-machining’, our expertise in PMMA CNC machining is unparalleled. Our engineers and machinists possess a deep understanding of PMMA’s unique properties, from its molecular structure to its thermal and mechanical responses.

This specialized knowledge allows us to anticipate challenges and implement proactive PMMA CNC cracking solution strategies. We don’t just machine parts; we engineer solutions to complex material challenges.

We continuously invest in research and development to refine our PMMA machining techniques, ensuring we remain at the forefront of precision manufacturing.

High-Quality PMMA Machining Guaranteed

Our commitment to quality is unwavering. We adhere to stringent quality control standards throughout every stage of the PMMA machining process, from material selection to final inspection.

Every PMMA component we produce undergoes rigorous testing and verification to ensure it meets the highest standards for dimensional accuracy, surface finish, and freedom from internal stresses or cracks. This is our promise for acrylic cracking prevention.

Our ISO-certified processes and dedicated quality assurance team guarantee consistent, high-quality results for every project. We stand by the integrity and performance of our PMMA parts.

Transparent Pricing for Your PMMA Project

We believe in complete transparency in all our dealings, including pricing. Our quotes for PMMA CNC machining are detailed, competitive, and free from hidden costs.

We provide a clear breakdown of expenses, from material procurement to machining time and post-processing. Our goal is to offer exceptional value without compromising on quality or expertise.

You’ll receive a straightforward assessment of what it takes to deliver your flawless PMMA components, ensuring you can budget effectively for your project.

Why Choose a Source PMMA Manufacturer

Partnering with a source PMMA manufacturer like ‘ly-machining’ offers distinct advantages. We have direct control over every aspect of the manufacturing process, eliminating middlemen and potential communication gaps.

This vertical integration ensures consistent quality, faster turnaround times, and greater flexibility to adapt to your specific needs. Our direct oversight allows for immediate adjustments and optimizations.

Working with us means leveraging our deep expertise, state-of-the-art facilities, and unwavering commitment to producing high-quality, crack-free PMMA parts. We are your dedicated partner for success.

Call to Action:

Tired of PMMA cracking disrupting your projects? Contact our PMMA CNC machining experts today for a personalized consultation and a transparent quote. Let our deep technical expertise ensure your next project is flawless.

Conclusion: Master PMMA CNC Cracking

Take Action: Eliminate PMMA Cracking Now

Mastering PMMA CNC machining and preventing cracking requires a holistic approach, from material selection and design to advanced machining techniques and meticulous post-processing. Our comprehensive strategies, including expert *PMMA stress relief annealing*, are proven to deliver superior results.

By understanding PMMA’s unique properties and applying specialized knowledge, ‘ly-machining’ provides definitive *PMMA CNC cracking solution* and *acrylic cracking prevention*. We leverage our deep technical expertise to ensure every component is manufactured to the highest standards.

Don’t let PMMA cracking compromise your projects. Partner with a trusted source manufacturer who understands the intricacies of *PMMA machining techniques*. We are here to transform your challenges into flawlessly executed parts.

FAQ:

How to prevent PMMA cracking?

Preventing PMMA cracking involves careful material selection, optimizing part design with generous radii, and critical pre- and post-machining *PMMA stress relief annealing*. Using sharp, specialized tools with optimized feed rates and effective cooling is also crucial.

Why does acrylic crack during CNC?

Acrylic cracks during CNC machining primarily due to induced thermal and mechanical stresses. Excessive heat from friction, improper tool geometry, aggressive feed rates, and inherent residual stresses in the material all contribute to crack formation.

Is annealing essential for PMMA?

Yes, annealing is often essential for PMMA, both before and after CNC machining. Pre-machining annealing relieves residual stresses from manufacturing, while post-machining annealing addresses stresses induced during the cutting process, significantly improving part stability and preventing delayed cracking.